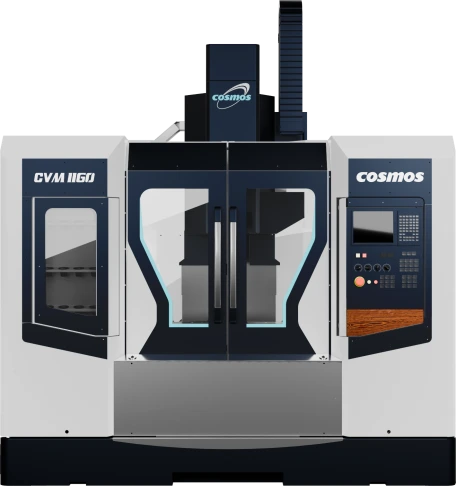

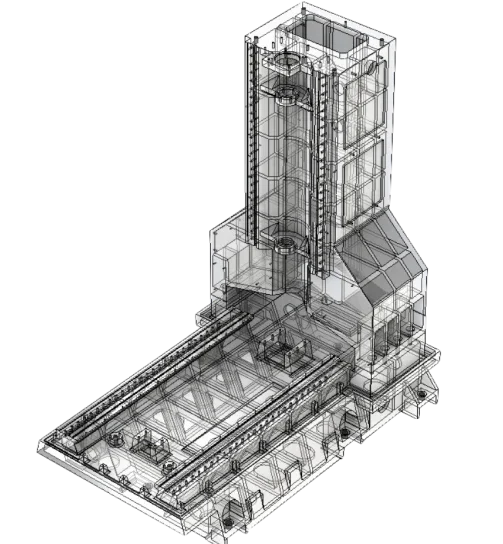

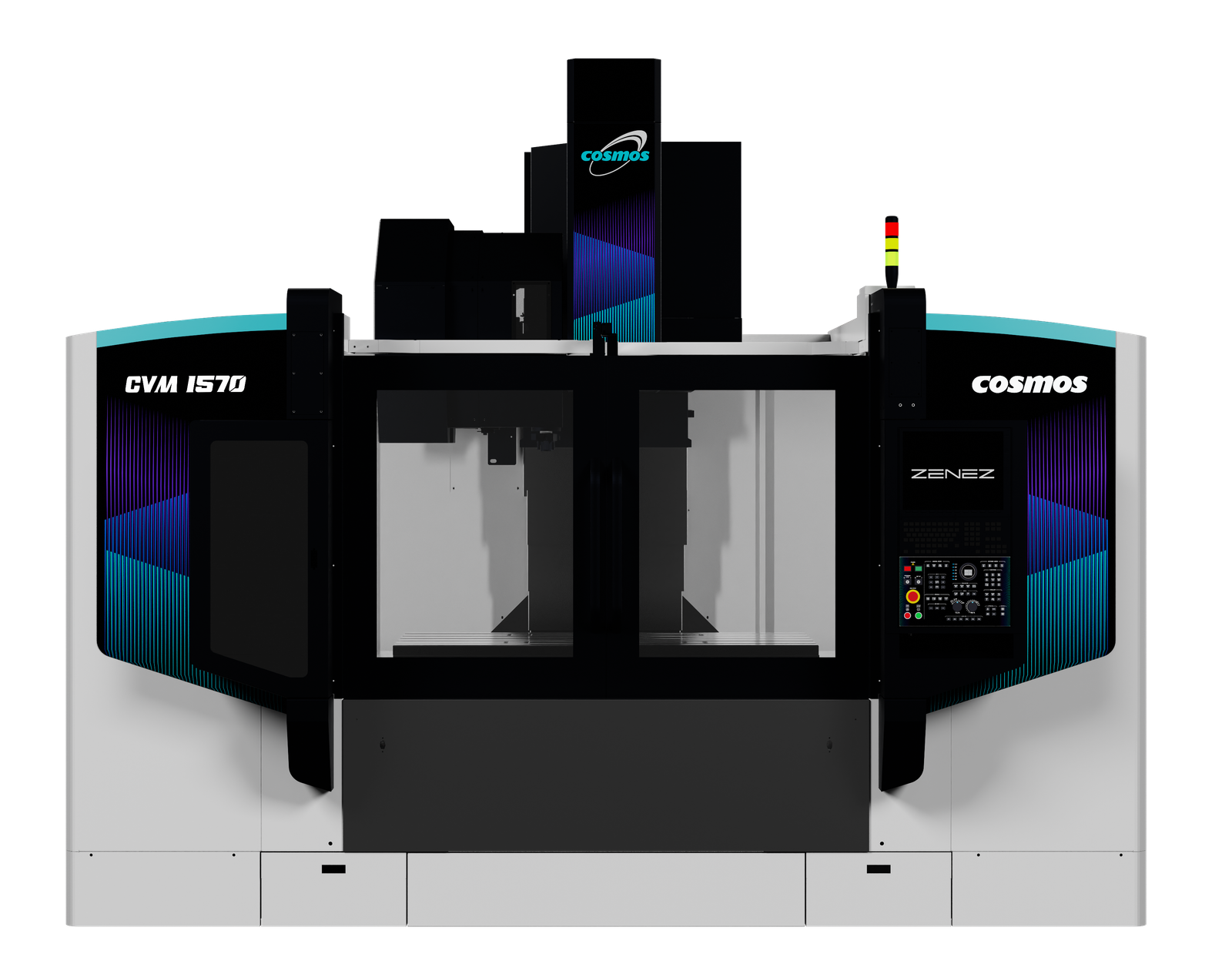

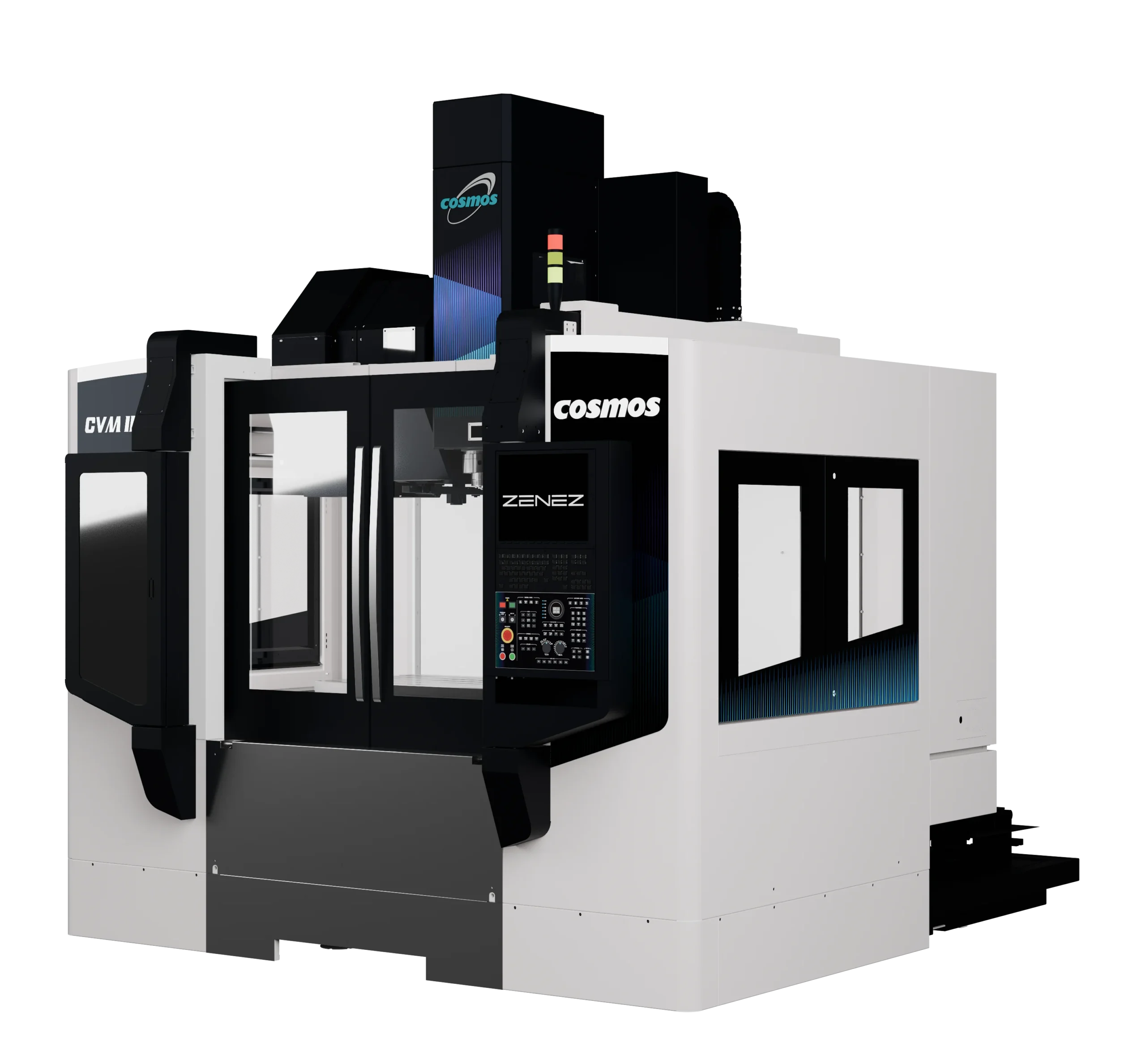

Machine Overview

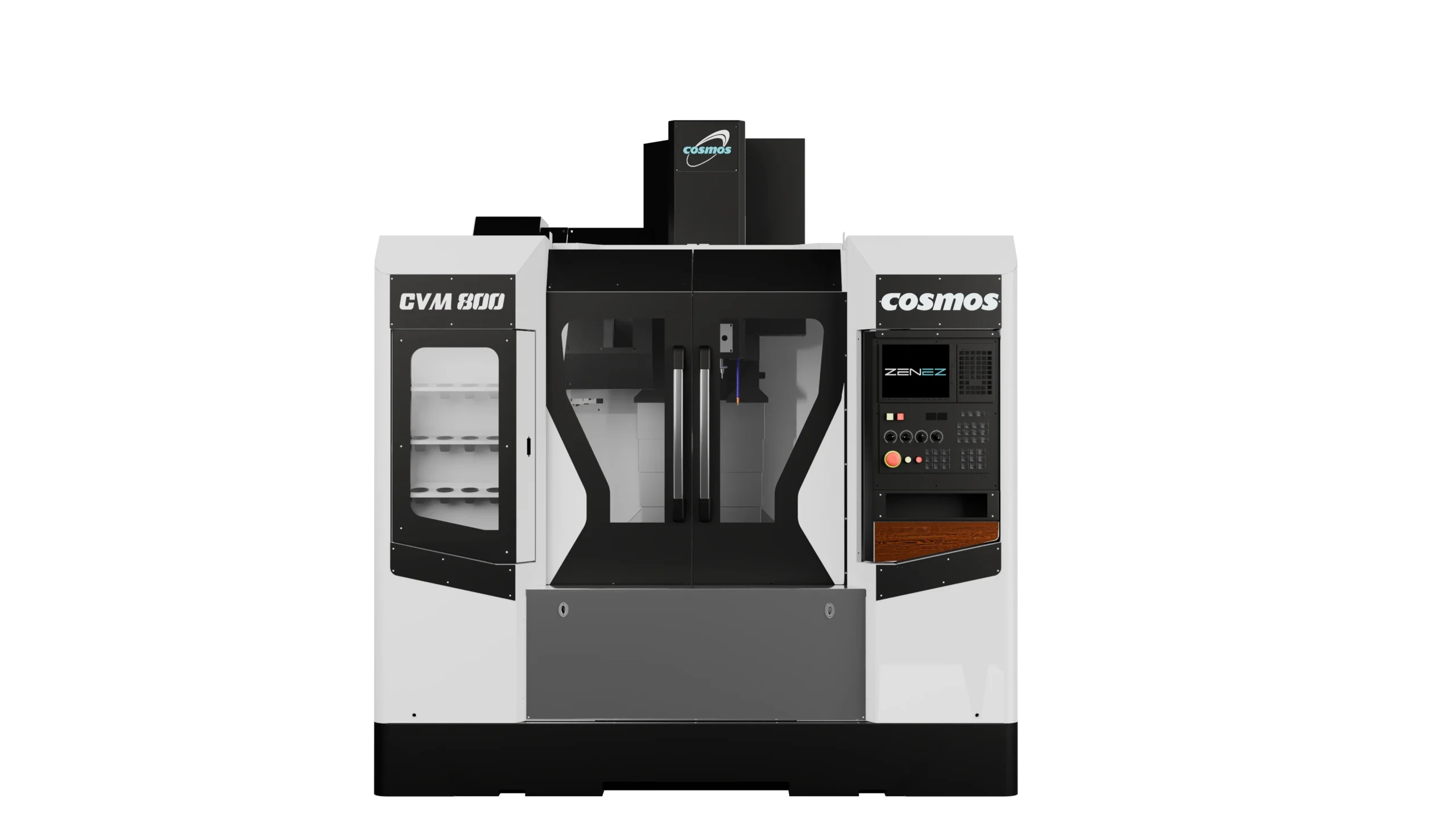

The CVM series reflects our unwavering commitment to excellence, combining durability with optimised functionality. It's a sincere effort to surpass global quality standards while ensuring affordability.

In the world of machining, the CVM series embodies our core principle: enhancing Productivity. These machines are designed with heartfelt consideration for the end-users, putting their needs and satisfaction at the forefront.

Step into a world of precision and innovation with the CVM Series vertical machining centre. Our cutting-edge machine offers a range of exceptional features that not only elevate your machining capabilities but also enhance your entire experience

Illuminated Design

All our machines are with LED lamps to create a well-lit working environment, ensuring optimal visibility and ease of operation. Built for durability and minimal maintenance.

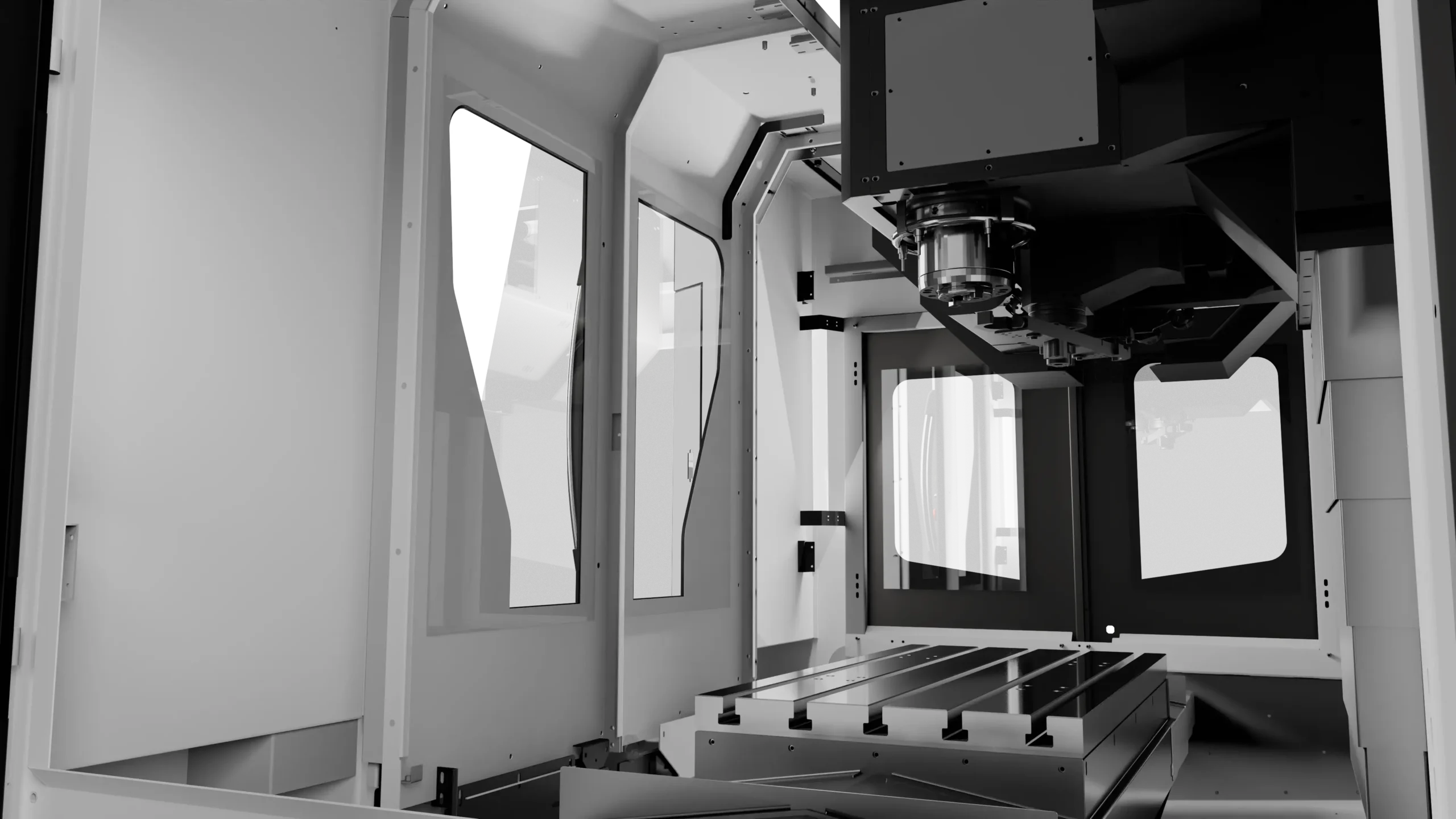

Easy Access Maintenance

We’ve improved machine manageability with easy access windows to essential peripherals, streamlining maintenance and ensuring efficient operation.

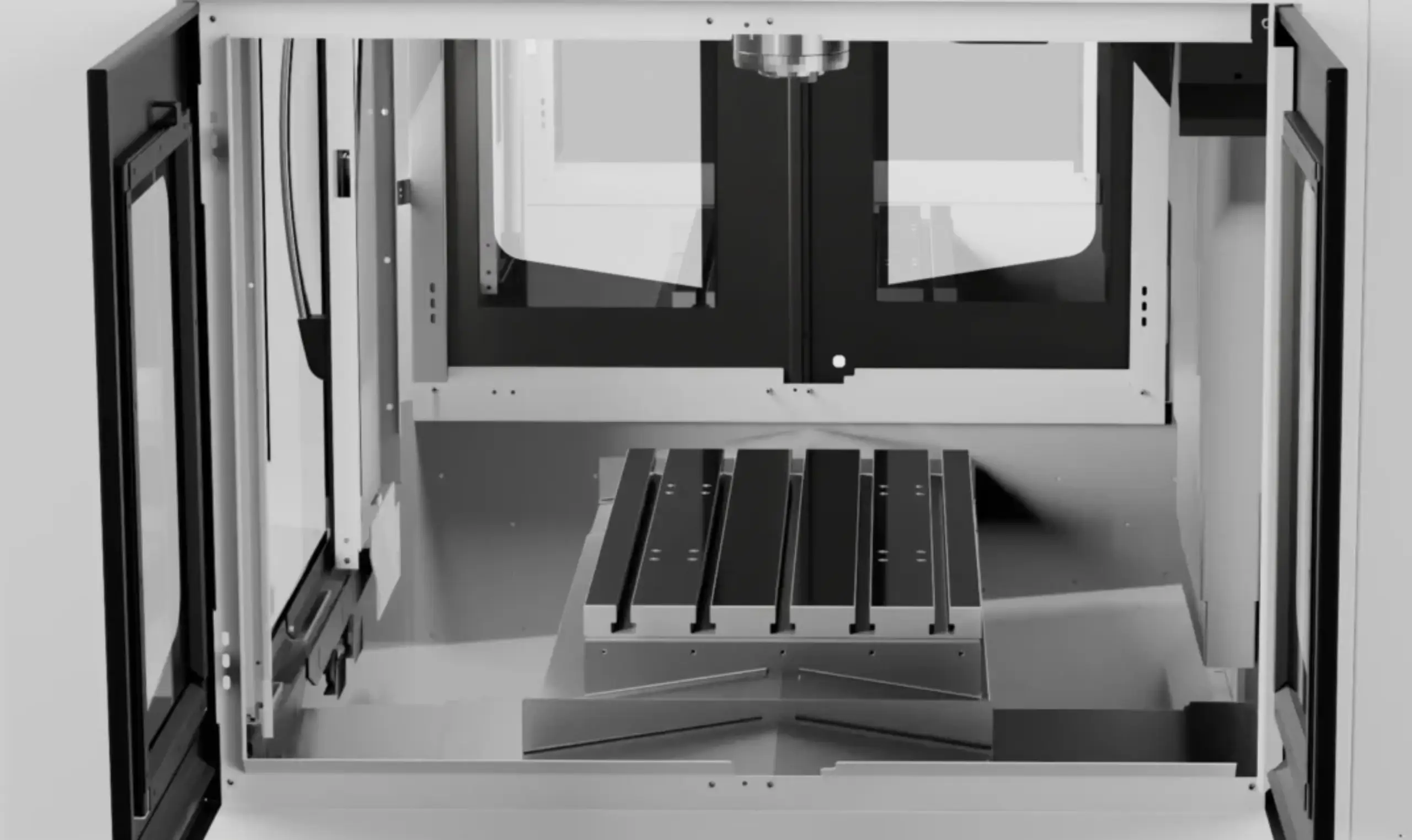

Excellent Chip Disposal

The machines feature steeply slanted telescopic sliding covers that excel in chip disposal performance, keeping your workspace clean and ensuring uninterrupted machining.

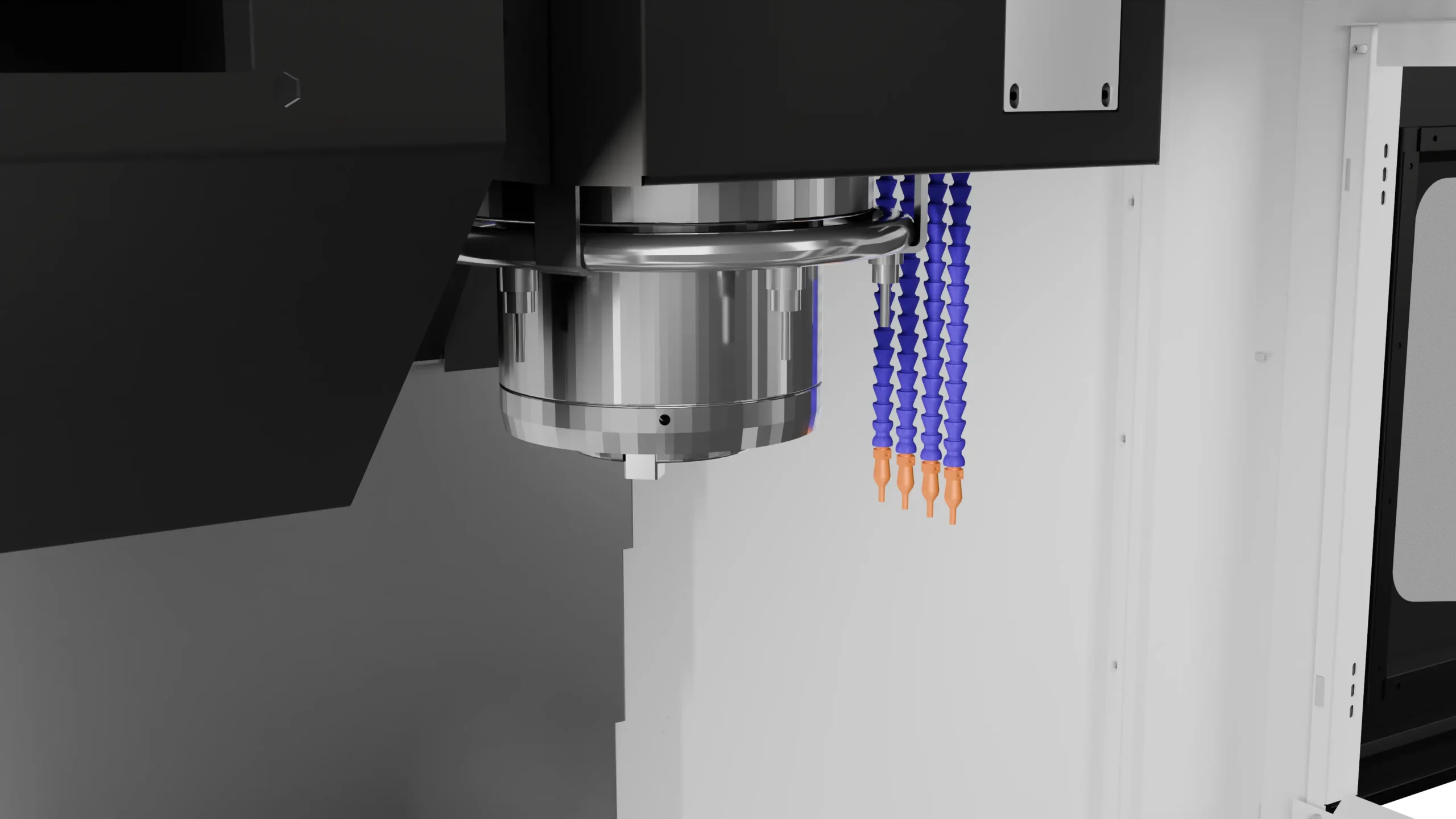

Ring Coolant

Our ring coolant nozzles, strategically positioned around the spindle, deliver coolant to the cutting area, ensuring performance, efficient heat dissipation, and an optimal machining experience.

Additional Features

Stainless Steel Sill

Protector

Big Dual

Side Windows

Fully Enclosed

Guarding

Inbuilt Tool

Stronge Cabinet

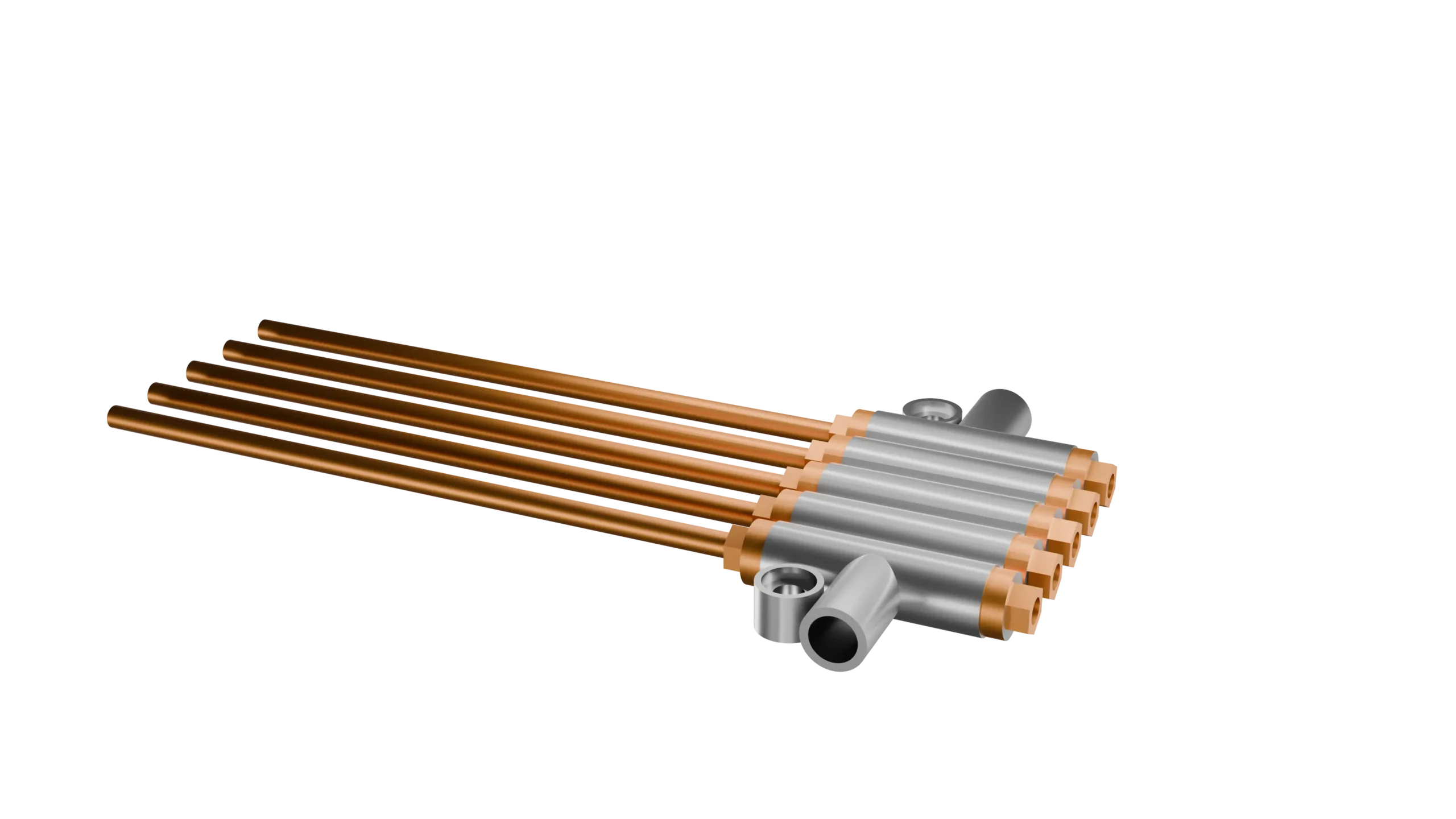

1 Air and 3 Coolant

Nozzles

Copper Pipe

for Lubrication

Machine Specs

X-axis Travel: 1370 mm

Y-axis Travel: 700 mm

Z-axis Travel: 700 mm

Table Size: 1450×650 mm

Maximum Loading Capacity: 1500 kg

Spindle Speed: 8,000 rpm

Mitsubishi Motor Power: 11/15/18.5 KW

Spindle Taper: BBT 40 | 50

Rapid Traverse Rate: 24 m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30 | 24

Dimensions

| X Axis Travel 700 mm |

Y Axis Travel 450 mm |

Z Axis Travel 500 mm |

Table Size 800x450 mm |

Maximum Table Load 400 mm |

| Spindle Nose to Table Surface 100-600 mm |

Spindle Center to Sliding Cover Face 500 mm |

Table T-Slot 4X18X100 mm |

| Spindle Speed 8000 rpm |

Machine Weight (with ATC) 4300 kg |

Power Requirement (Controller) 20 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

LM Guideways Ball |

| Mitsubishi Motor power(OPT) 7.5/11/15 kw |

Fanuc Motor power(OPT) 7.5/11/15 kw |

Siemens Motor power(OPT) 9/17 kw |

| Rapid Traverse Rate (Opt) 36 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 24 |

Tools

| Maximum Tool Length 250 mm |

Maximum Tool Weight 8 Kg |

Tool Charging Timer 2 sec |

| Tool Diameter (with Adjacent Tool) 80 mm |

Tool Diameter (without Adjacent Tool) 150 mm |

Accuracy

| Positioning Accuracy 0.01 mm |

Positioning Repeatability + 0.003 mm |

X-axis Travel: 800 mm

Y-axis Travel: 500 mm

Z-axis Travel: 500 mm

Table Size: 1000×500 mm

Maximum Loading Capacity: 600 kg

Spindle Speed: 8,000 rpm

Mitsubishi Motor Power: 11/15/18.5 kW

Spindle Taper: BBT 40

Rapid Traverse Rate: 36(48) m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30

Dimensions

| X Axis Travel 800 mm |

Y Axis Travel 500 mm |

Z Axis Travel 500 mm |

Table Size 1000X500 mm |

Maximum Table Load 600 mm |

| Spindle Nose to Table Surface 100-600 mm |

Spindle Center to Sliding Cover Face 520 mm |

Table T-Slot 18X5X100 mm |

| Machine Weight (with ATC) 4500 kg |

Power Requirement (Controller) 30 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

LM Guideways Ball |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Fanuc Motor power(OPT) 7.5/11/15 kw |

Siemens Motor power(OPT) 9/17 kw |

| Rapid Traverse Rate (Opt) 36(48) m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 30 |

Tools

| Maximum Tool Length 250 mm |

Maximum Tool Weight 8 Kg |

Tool Charging Timer 2 sec |

| Tool Diameter (with Adjacent Tool) 80 mm |

Tool Diameter (without Adjacent Tool) 150 mm |

X-axis Travel: 1050 mm

Y-axis Travel: 520 mm

Z-axis Travel: 520 mm

Table Size: 1150×500 mm

Maximum Loading Capacity: 800 kg

Spindle Speed: 8,000 rpm

Mitsubishi Motor Power: 11/15/18.5 kW

Spindle Taper: BBT 40

Rapid Traverse Rate: 36 m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30

Dimensions

| X Axis Travel 1050 mm |

Y Axis Travel 520 mm |

Z Axis Travel 520 mm |

Table Size 1150X500 mm |

| Spindle Nose to Table Surface 125-645 mm |

Spindle Center to Sliding Cover Face 520 mm |

Table T-Slot 18X5X100 mm |

| Machine Weight (with ATC) 5000 kg |

Power Requirement (Controller) 30 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Fanuc Motor power(OPT) 7.5/11/15 kw |

Siemens Motor power(OPT) 9/17 kw |

| Rapid Traverse Rate (Opt) 36 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 30 |

X-axis Travel: 1100 mm

Y-axis Travel: 650 mm

Z-axis Travel: 650 mm

Table Size: 1250×600 mm

Maximum Loading Capacity: 1000 kg

Spindle Speed: 8,000 rpm

Mitsubishi Motor Power: 11/15/18.5 KW

Spindle Taper: BBT 40 | 50

Rapid Traverse Rate: 30 (36) m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30 | 24

Dimensions

| X Axis Travel 1100 mm |

Y Axis Travel 650 mm |

Z Axis Travel 600 mm |

Table Size 1250X600 mm |

| Spindle Nose to Table Surface 150-750 mm |

Spindle Center to Sliding Cover Face 652 mm |

Table T-Slot 18X5X100 mm |

| Machine Weight (with ATC) 6600 kg |

Power Requirement (Controller) 30 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Fanuc Motor power(OPT) 7.5/11/15 kw |

Siemens Motor power(OPT) 9/17 kw |

| Rapid Traverse Rate (Opt) 36 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 30 |

X-axis Travel: 1300 mm

Y-axis Travel: 650 mm

Z-axis Travel: 600 mm

Table Size: 1450×650 mm

Maximum Loading Capacity: 1000 kg

Spindle Speed: 8,000 rpm

Mitsubishi Motor Power: 11/15/18.5 KW

Spindle Taper: BBT 40 | 50

Rapid Traverse Rate: 30 m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30 | 24

Dimensions

| X Axis Travel 1300 mm |

Y Axis Travel 650 mm |

Z Axis Travel 600 mm |

Table Size 1450X650 mm |

| Spindle Nose to Table Surface 150-850 mm |

Spindle Center to Sliding Cover Face 652 mm |

Table T-Slot 18X5X125 mm |

| Machine Weight (with ATC) 7000 kg |

Power Requirement (Controller) 30 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Fanuc Motor power(OPT) 7.5/11/15 kw |

Siemens Motor power(OPT) 9/17 kw |

| Rapid Traverse Rate (Opt) 30 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 30 |

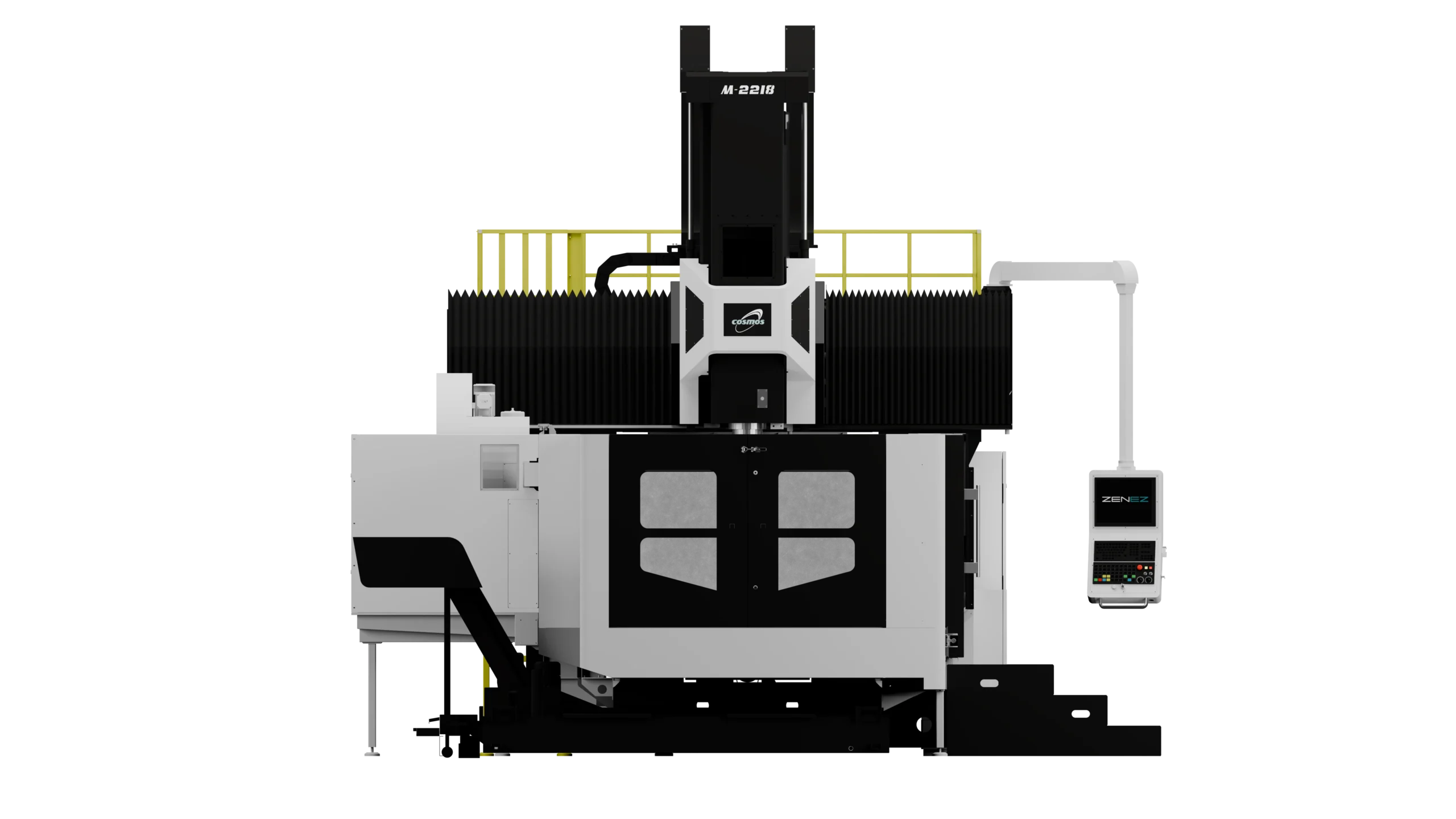

X-axis Travel: 1370 mm

Y-axis Travel: 700 mm

Z-axis Travel: 700 mm

Table Size: 1450×650 mm

Maximum Loading Capacity: 1500 kg

Spindle Speed: 8,000 rpm

Mitsubishi Motor Power: 11/15/18.5 KW

Spindle Taper: BBT 40 | 50

Rapid Traverse Rate: 24 m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30 | 24

Dimensions

| X Axis Travel 1300 mm |

Y Axis Travel 700 mm |

Z Axis Travel 700 mm |

Table Size 1450X650 mm |

| Spindle Nose to Table Surface 150-850 mm |

Spindle Center to Sliding Cover Face 716 mm |

Table T-Slot 18X5X125 mm |

| Machine Weight (with ATC) 8300 kg |

Power Requirement (Controller) 35 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Fanuc Motor power(OPT) 11/15/18.5 kw |

Siemens Motor power(OPT) 12/18 kw |

| Rapid Traverse Rate (Opt) 30 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 30 |

X-axis Travel: 1500 mm

Y-axis Travel: 700 mm

Z-axis Travel: 700 mm

Table Size: 1650×650 mm

Maximum Loading Capacity: 1500 kg

Spindle Speed: 15,000 rpm

Mitsubishi Motor Power: 11/15/18.5 KW

Spindle Taper: BBT 40 | 50

Rapid Traverse Rate: 24 m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 30 | 24

Dimensions

| X Axis Travel 1500 mm |

Y Axis Travel 700 mm |

Z Axis Travel 700 mm |

Table Size 1450X650 mm |

| Spindle Nose to Table Surface 150-850 mm |

Spindle Center to Sliding Cover Face 706 mm |

Table T-Slot 18X5X125 mm |

| Machine Weight (with ATC) 9000 kg |

Power Requirement (Controller) 35 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Fanuc Motor power(OPT) 11/15/18.5 kw |

Siemens Motor power(OPT) 12/18 kw |

| Rapid Traverse Rate (Opt) 30 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 30 |

X-axis Travel: 1600 mm

Y-axis Travel: 800 mm

Z-axis Travel: 800 mm

Table Size: 1750×800 mm

Maximum Loading Capacity: 2000 kg

Spindle Speed: 16,000 rpm

Mitsubishi Motor Power: 15/18.5 KW

Spindle Taper: BBT 50

Rapid Traverse Rate: 24 | 24 | 20 m/min

Cutting Feed Rate: 10 m/min

Tool Nos. Capacity: 24

Dimensions

| X Axis Travel 1600 mm |

Y Axis Travel 800 mm |

Z Axis Travel 800 mm |

Table Size 1750X800 mm |

| Spindle Nose to Table Surface 100-900 mm |

Spindle Center to Sliding Cover Face 830 mm |

Table T-Slot 18X5X150 mm |

| Machine Weight (with ATC) 12300 kg |

Power Requirement (Controller) 40 KVA |

Capacity

| Spindle Taper BBT 40 |

Guideway Type Ball LM Type |

Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 15/18.5 kw |

Fanuc Motor power(OPT) 15/18.5 kw |

Siemens Motor power(OPT) - |

| Rapid Traverse Rate (Opt) 24/24/20 m/min |

Cutting Feed Rate 10 m/min |

Tool Capacity 24 |

| W1 | W2 | W3 | H1 | H2 | H3 | Depth | |

|---|---|---|---|---|---|---|---|

| CVM-700 | 2150 | 1410 | 420 | 2600 | 2050 | 800 | 2050 |

| CVM-800 | 2450 | 1410 | 420 | 2650 | 2100 | 700 | 2200 |

| CVM-1050 | 2770 | 1410 | 420 | 2780 | 2155 | 750 | 2200 |

| CVM-1160 | 2900 | 1410 | 420 | 3000 | 2300 | 750 | 2250 |

| CVM-1365 | 3450 | 1410 | 420 | 3100 | 2325 | 750 | 2350 |

| CVM-1370 | 3500 | 1410 | 420 | 3100 | 2400 | 800 | 2430 |

| CVM-1570 | 3900 | 1410 | 420 | 3170 | 2200 | 800 | 2410 |

| CVM-1680 | 4350 | 1410 | 420 | 3365 | 2430 | 800 | 4300 |

WIDE A-SHAPED COLUMN

The extra-wide base of the column provides superior stability and effectively absorbs cutting forces, preventing any deflection and leading to improved cutting dynamics.

GOLDEN TRIANGULAR FRAME DESIGN

By ensuring maximum bed width, we optimize kinematics for superior performance. This design also lowers the center of gravity, enhancing stability during cutting, resulting in a chatter-free surface finish and prolonged tool life.

EXTENDED HEADSTOCK GUIDES

The extended A:B ratio not only allows for larger components on the machine table but also enhances headstock rigidity during rapid high-feed cutting. This rigidity safeguards spindle accuracy by preventing headstock sag, ensuring precision in machining operations.

HIGH QUALITY IMPORTED SPINDLE

Our Cartridge Type Spindle delivers exceptional performance, minimizing run-out while providing impressive cutting torque. Every spindle in our lineup undergoes rigorous dynamic balancing and thermal deformation testing, ensuring optimal precision and reliability in every machining operation.

MACHINING STABILITY ENSURED

Our machines are distinguished by the extraordinary power of our signature ribs, the cornerstone of strength and quality in our construction. These ribs are strategically positioned to fortify our machines, elevating their structural integrity and amplifying overall robustness.

For heavy-duty cutting tasks, our ribs are the secret to success. They stand out in enhancing torsional rigidity, expertly reducing vibrations, and virtually eliminating deformation. The outcome is a level of machining precision and reliability that’s second to none – a testament to the enduring quality and unwavering strength of our ribs. Place your trust in the bedrock of excellence; rely on our ribs to deliver.

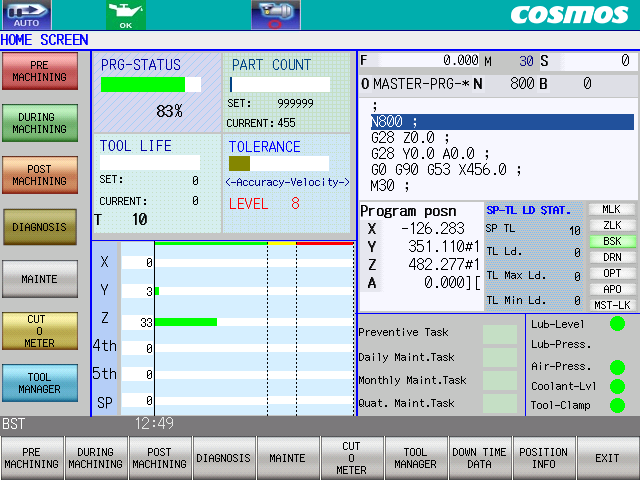

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

It focuses on customised dashboards and tools that help the operator to simplify his daily activity. The overall feature and package can reduce the time lost due to the complexity of the controller GUI; as a result, Zenez can significantly increase the machine output and profitability. • 10.4-inch display or large 15-inch display.

- 10.4-inch display or large 15-inch display

- Multi-touch User Interface

- Fully functional vertical and horizontal soft-keys for non-touch usage

- Crystal Type

- Enhanced hardware to ensure reliability

The Home Screen

Status View

Program Status

Show Tool Life Status

Active Machining Condition

Port Count vs Total Required

ZENEZ Menu

Menu Pre-Machining APP

During Machining APP

Post Machining APP

Diagnosis APP

Maintenance APP

Tool Manager APP

Axis Load Meter

CNC View

Axis Feed Rote

Spindle rpm Program Name

Sequence Number (N)

Block Number (B)

Progrom Buffer

Program Position

Spindle Load Stat

Maintenance Alert

An alert shows up if maintenance tasks are pending or one of the following is not normal:

Lubrication Level

Air Pressure Coolant Level

Tool Clamp

Scroll

Scroll in lists - Tool and Work offset list, Program, Gcode List Parameter.

Tap

Tap to move the cursor or navigate through the menus.

Pinch

Zoom in and out of graphic content during simulation mode.

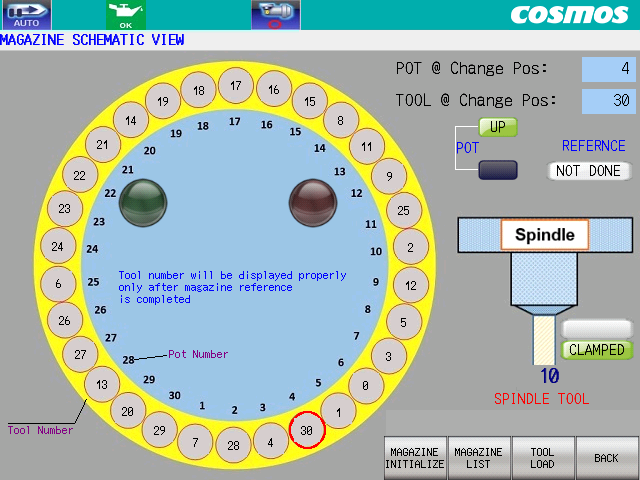

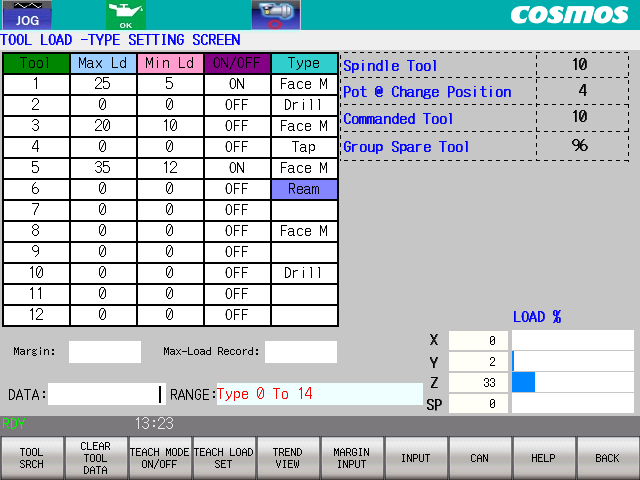

QUICK SETUP

Magazine View

Users can assign large tools, fixed tools. locked tools, and maximum and minimum loads with tool type. Load Teaching is a value-added feature.

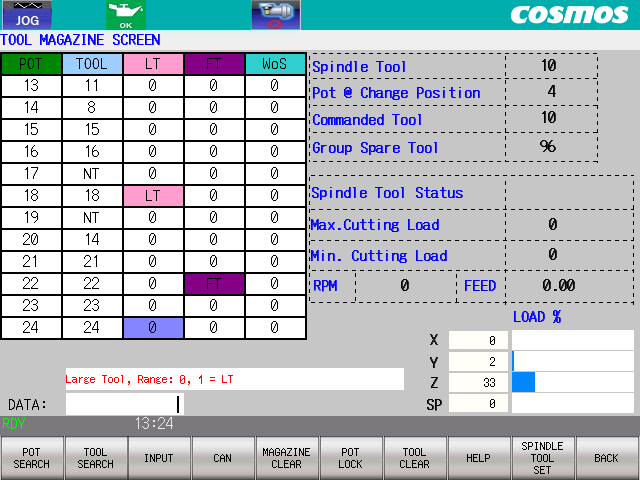

QUICK SETUP

Tool Manager

User Can assign Large Tools, Fixed Tools. Locked Tools. Maximum and Minimum Load with Tool Type. Load Teaching is a value added feature. *LT-Lorge Tool | FT - Fixed Tool | Wo5-Tool without Spindle Rotation

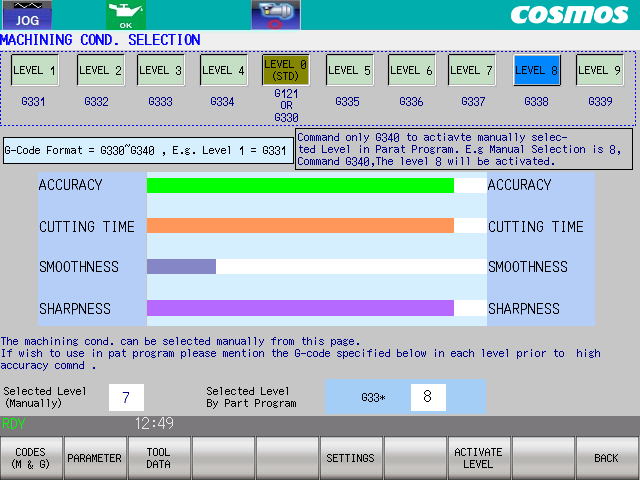

ADVANCE CONTROL

Machining Condition Selection

Machining

Condition Selection -

Settings Level 1-9 offers the user

control over the servo tuning. 1-9 represents tuning presets calibrated by the Cosmos and Mitsubishi Japan tech team to offer users the servo tuning control in a more understandable manner to maximise their profits by gaining customised control over roughing, semi-roughing, and finishing parameters.

"Can be activated by G-Code G331-339-or Manually. This option can be password

protected for restricted access.

ADVANCE CONTROL

Downtime Analysis

Downtime (DTE) Entry

Popup Whenever machine stops, the DTE pops up for classification for

interruption in machining

Downtime Analysis Report

Complete report on why machine was idle. Now you know where the issue is.

CVM Next - Gen

A radiant new hue with enhanced performance.

features and user experience launching soon for a global market.

Coming Soon...

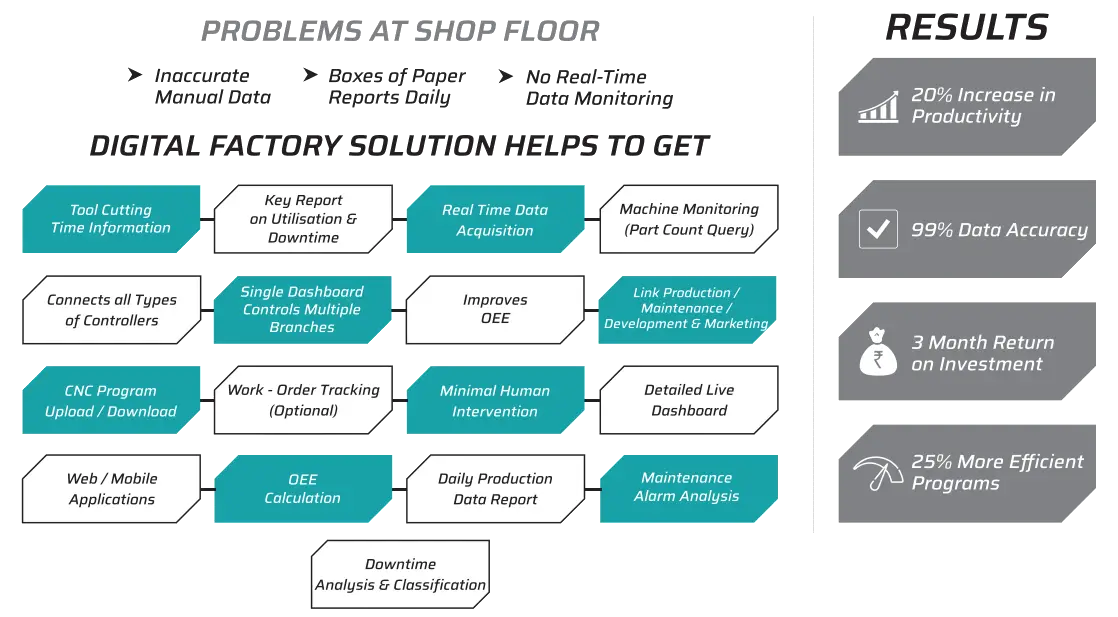

All-in-One Digital Data Monitoring Solution for Manufacturing Industries

digiFAC Features

Dashboard Monitoring

- Live information of the entire factory.

- Categorize machines (Unit-wise).

- View regular utilisation of the machine.

Program Transfer

- Upload programs from computer to machine remotely.

- Download programs and edit them from anywhere around the globe.

Alarm Analysis

- Alarm history by code/machine.

- Time and duration of all alarms generated by a separate machine.

Tool Cutting Time Informationt

- No more unidentified dry-runs.

- Program path optimization in-sight.

- Tool usage clarity.

- Shorter cycle-times (if modified).

- Eliminate NVA air time and improve your process.

All-in-One Dashboard

- Overview of all data of one machine on one screen.

- Find out the machine's status right away.

- One machine's information is displayed on a single screen.

Production Information (Utilisation)

- Detailed production information report: An automated daily production report.

- All reports are available in Excel format.

Downtime Analysis

- See total machine downtime.

- Monitor downtime and the reasons for it (Macro Downtime Feature).

- Focus and easily get the classified major losses/downtimes and work on optimization.

Email Alerts

- Set a time for machines' idle condition and receive or get alarm notifications via email.

- Management Reporting: Receive daily production reports and downtime analysis reports by email on a daily basis.

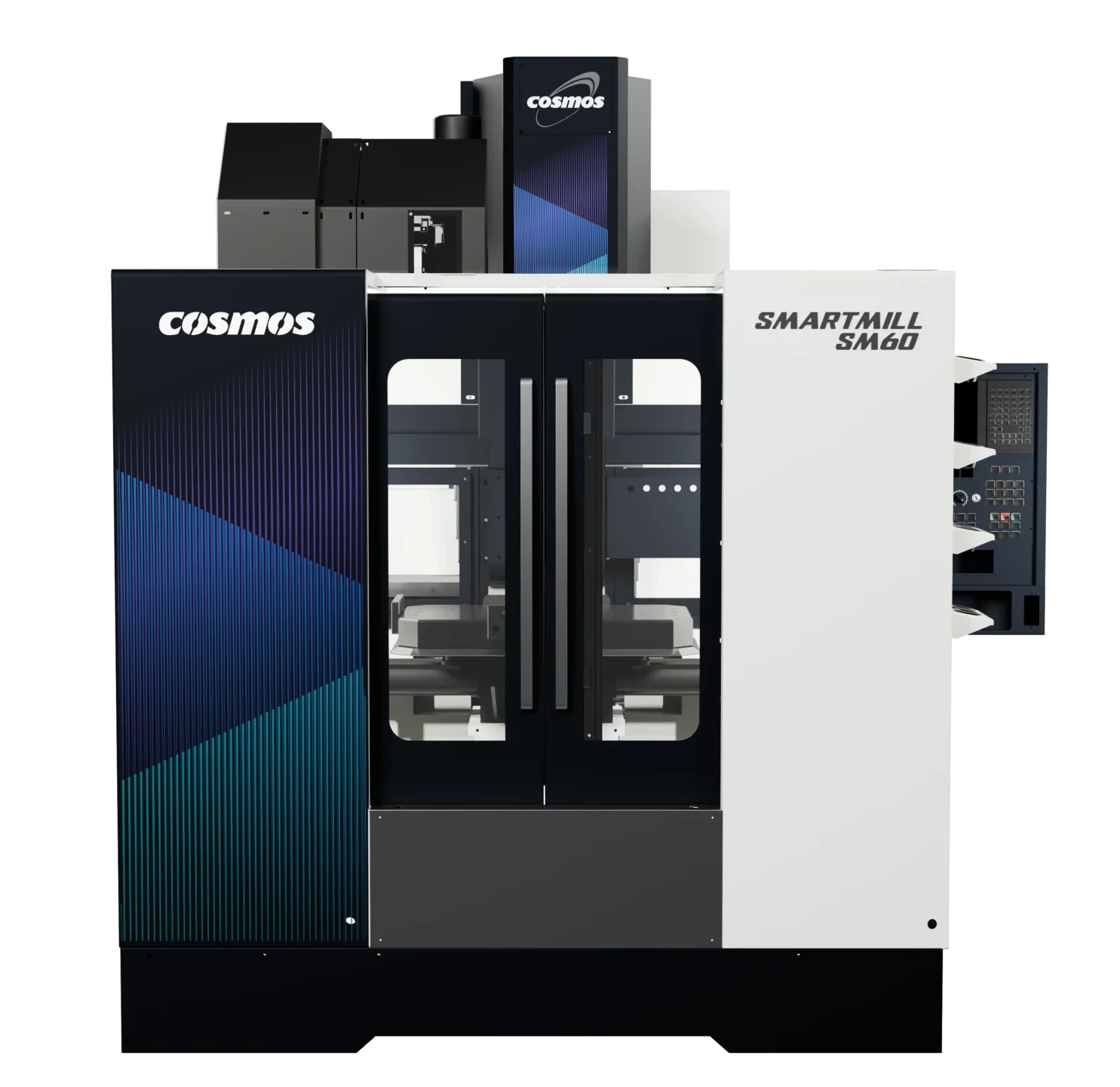

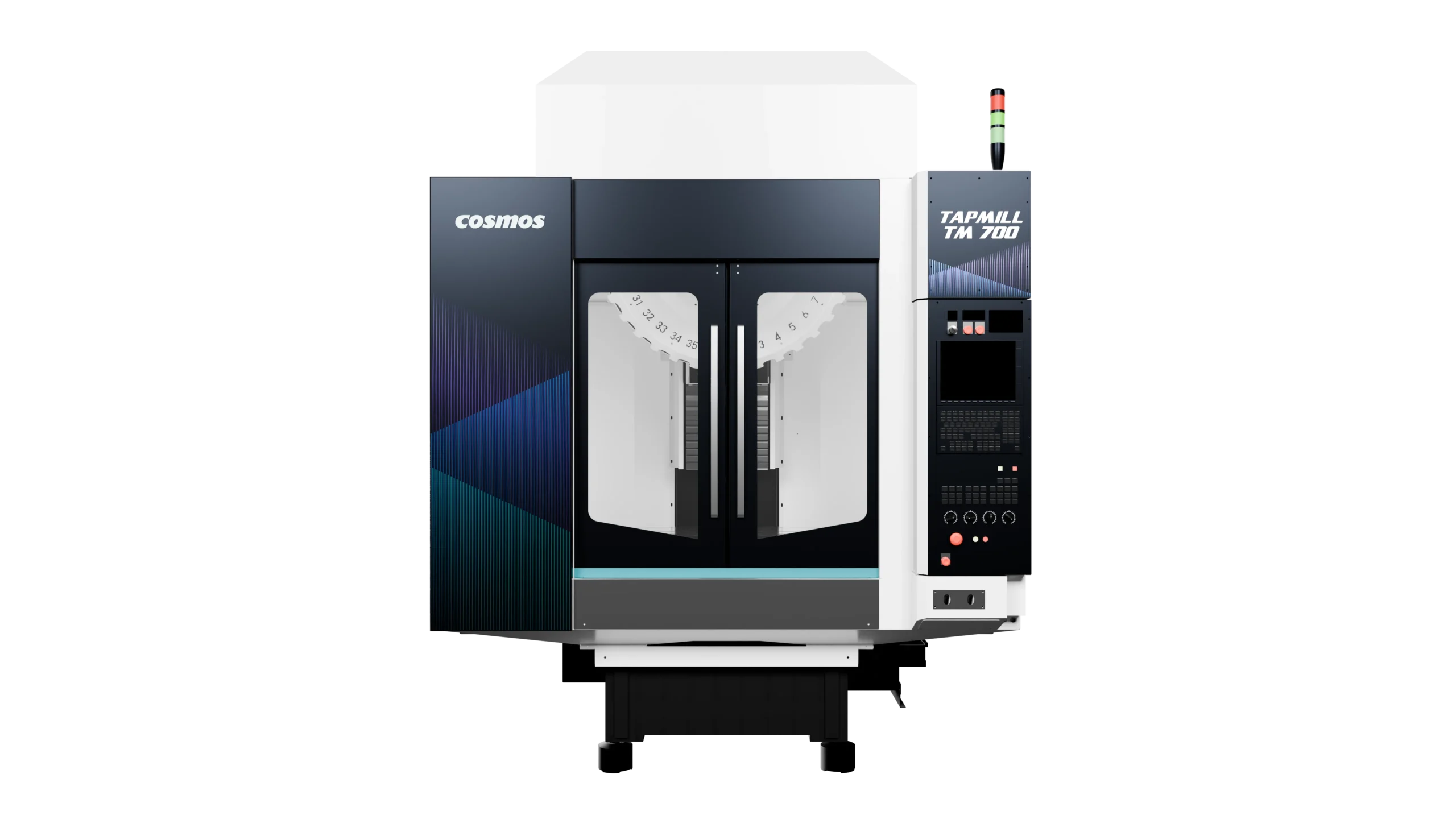

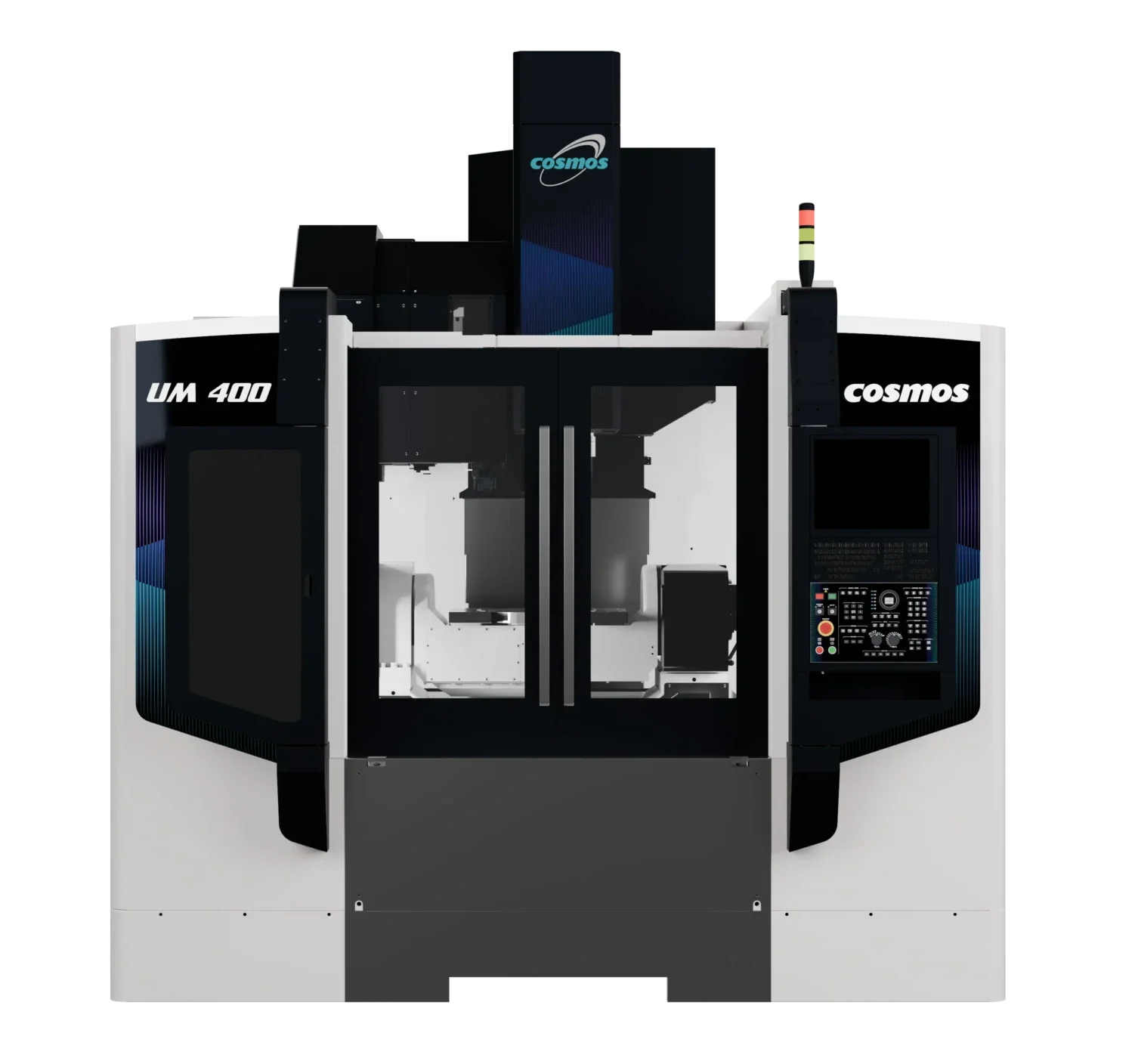

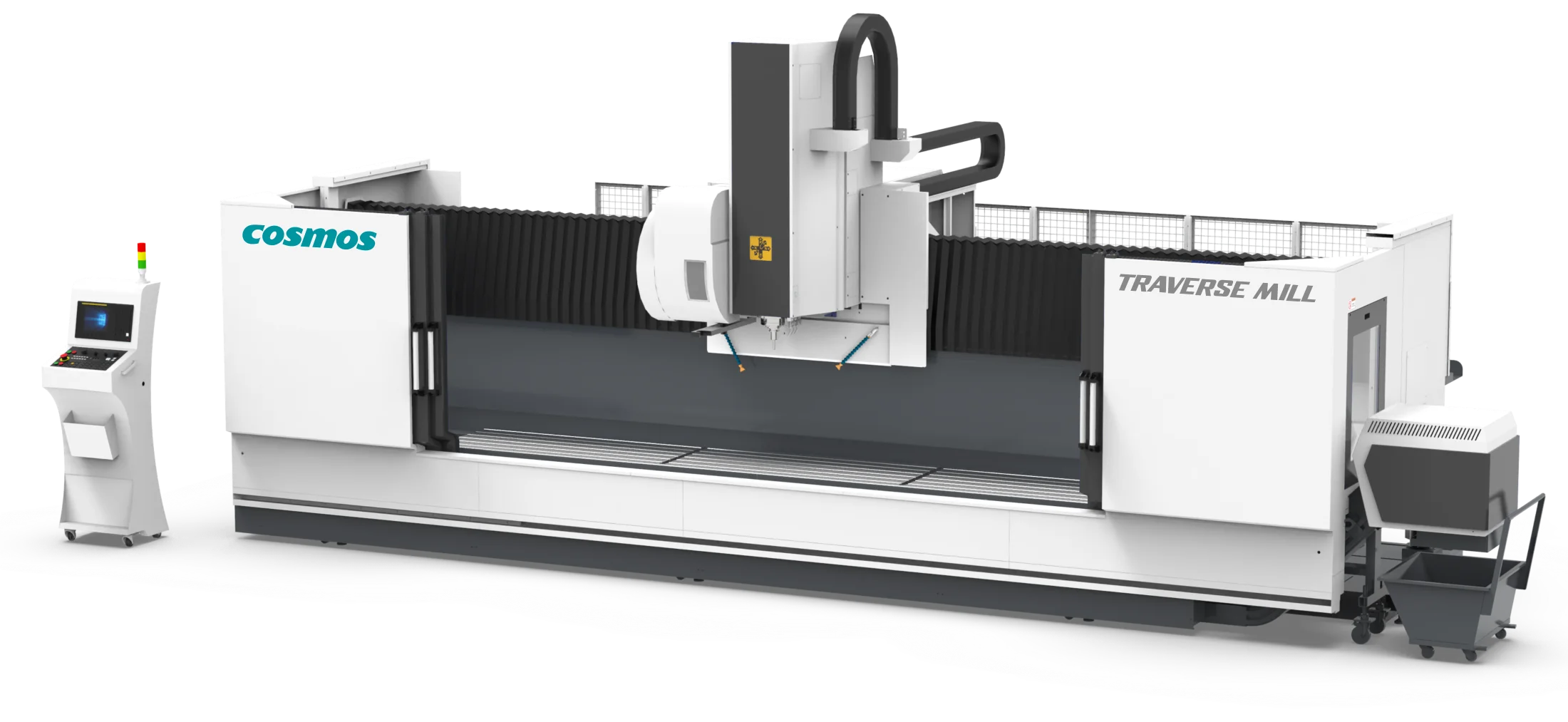

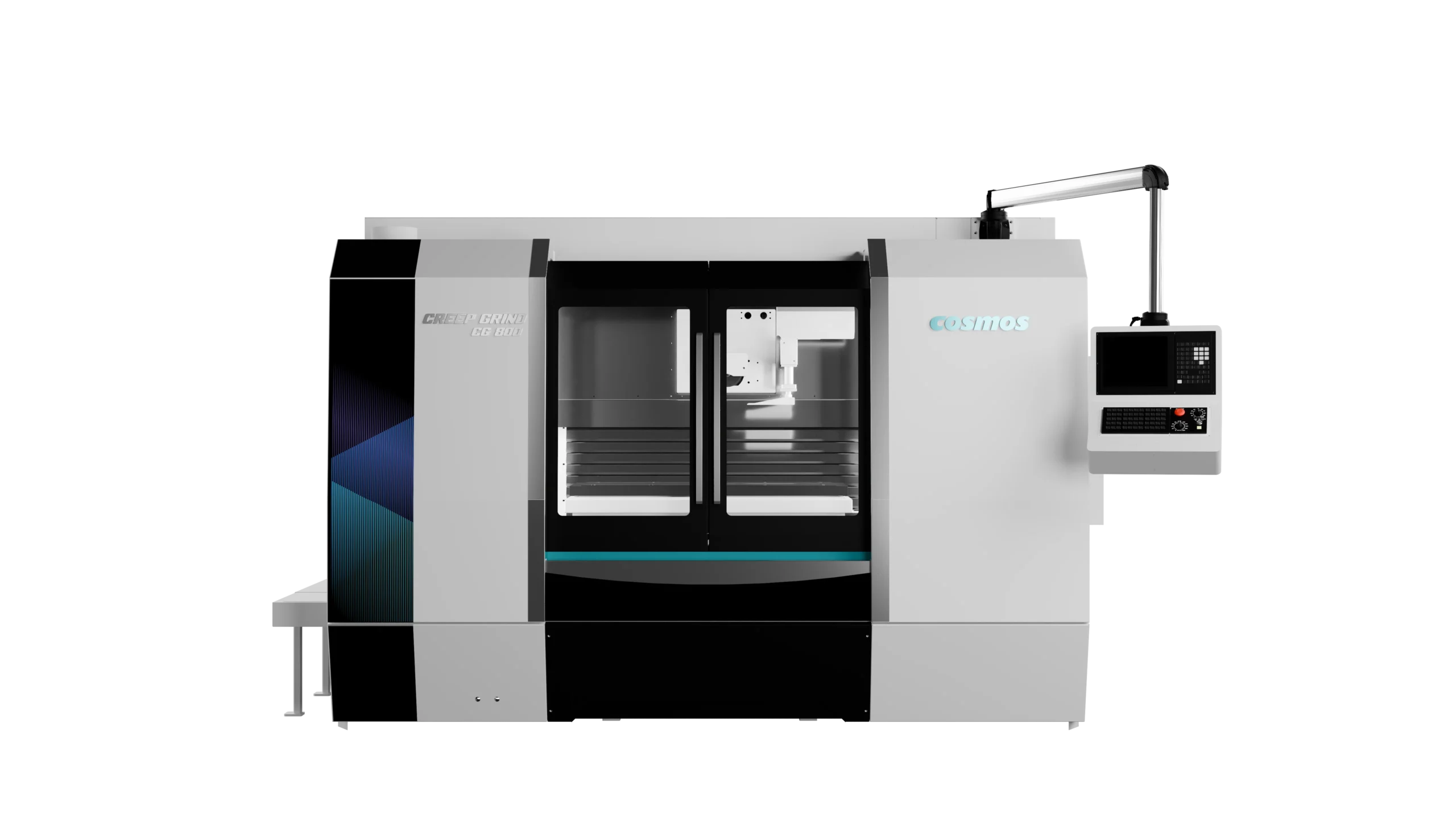

Our Other Range of Excellence

High-tech Products For Unmatched Performance