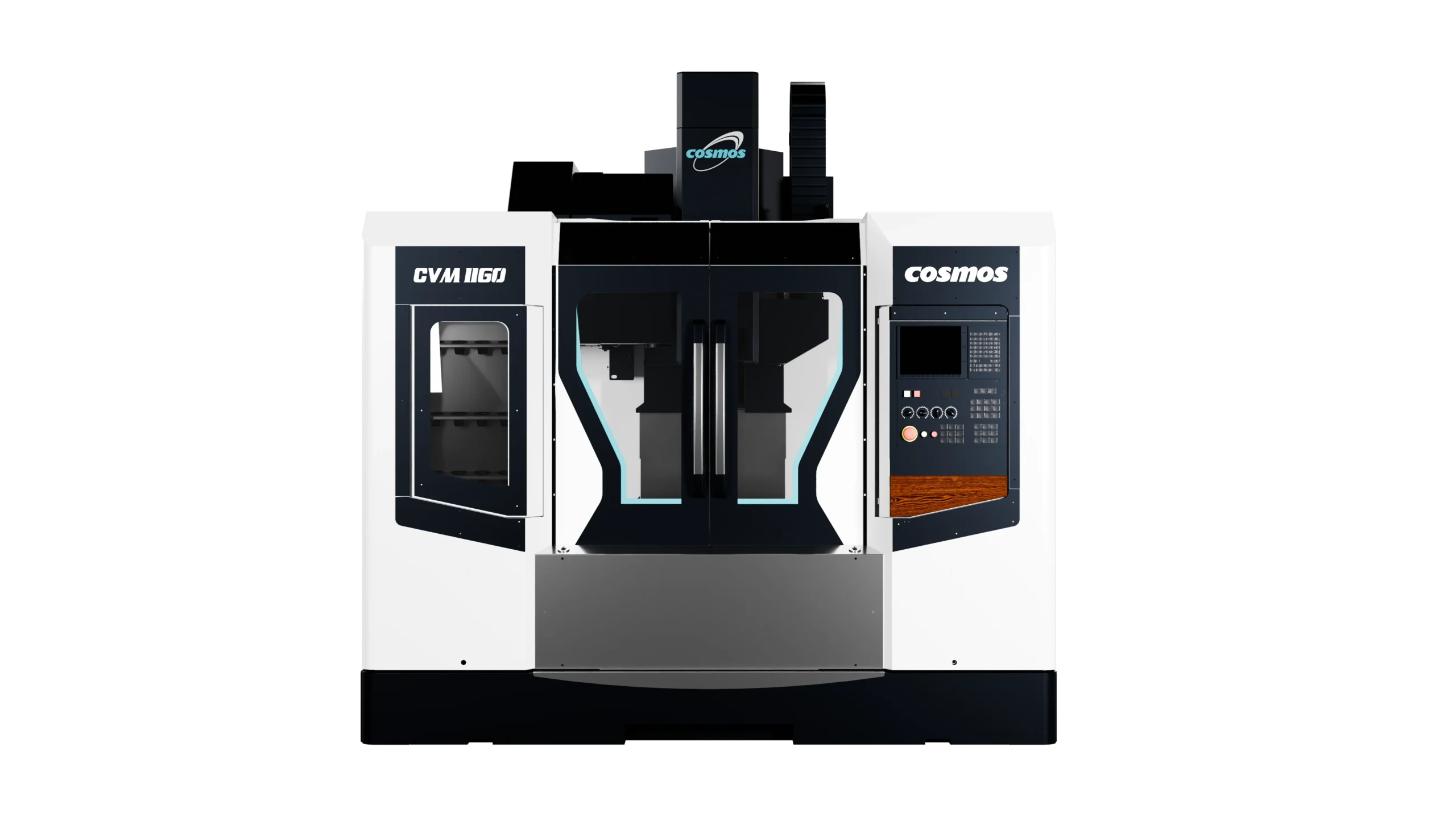

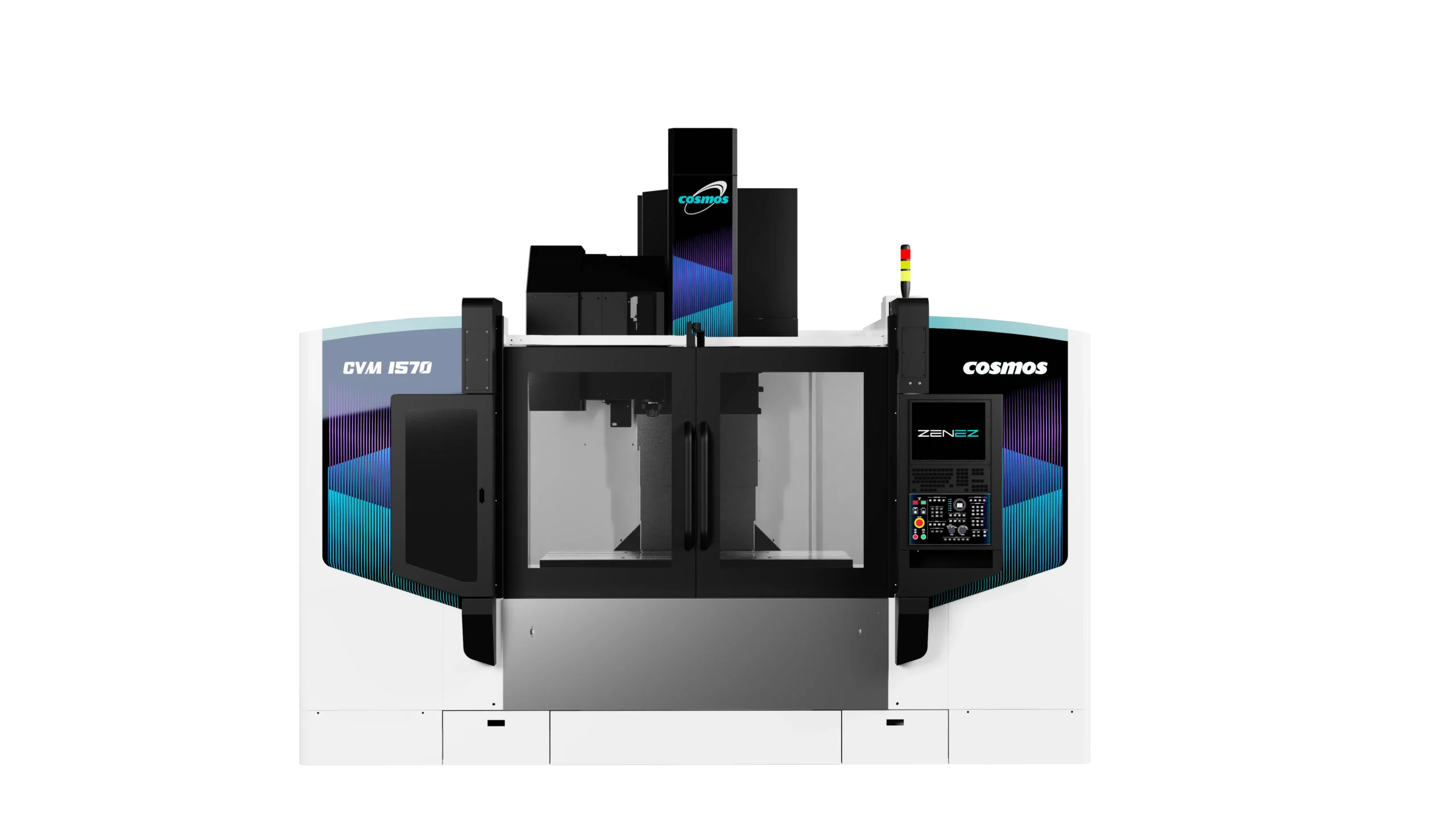

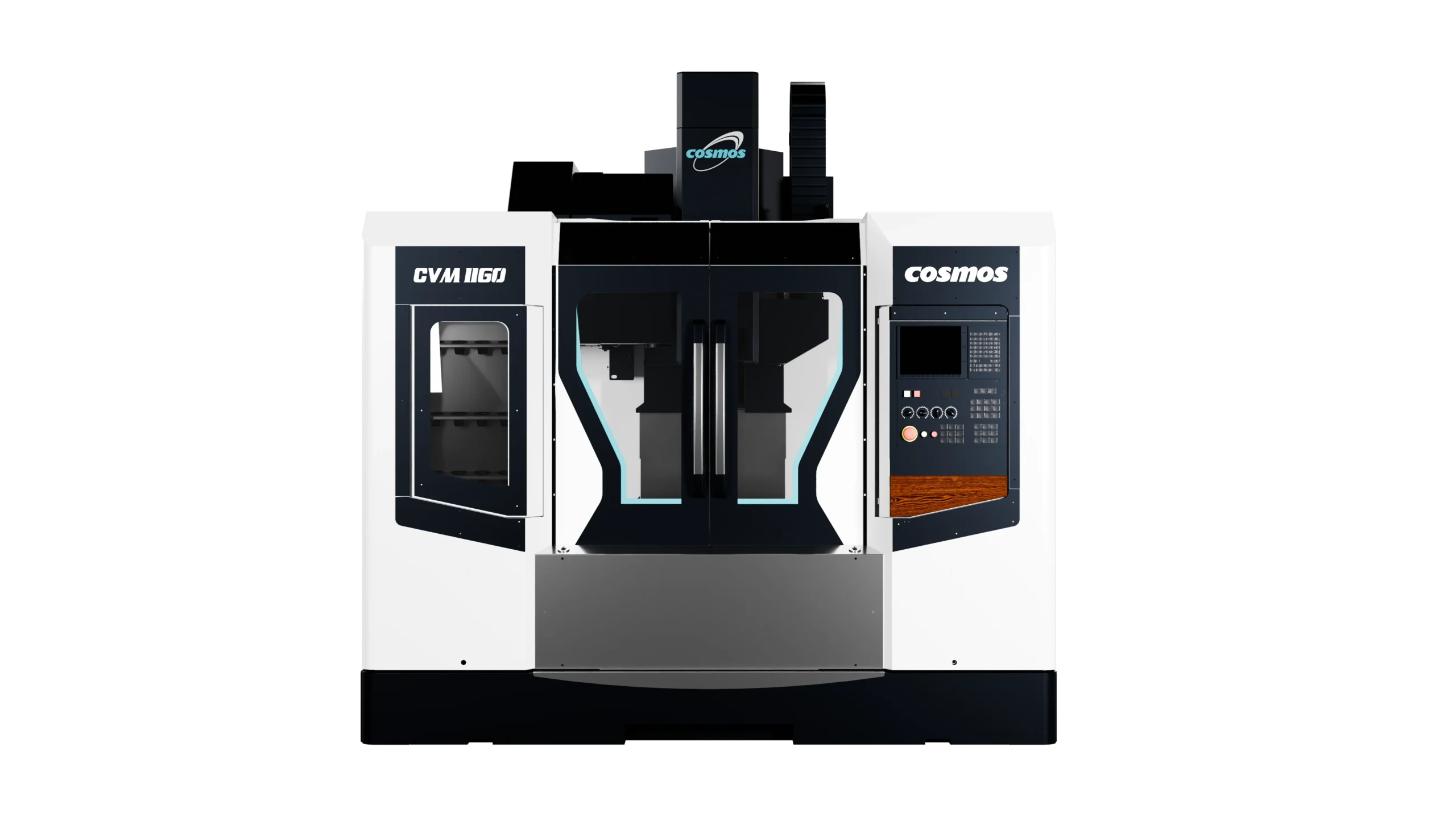

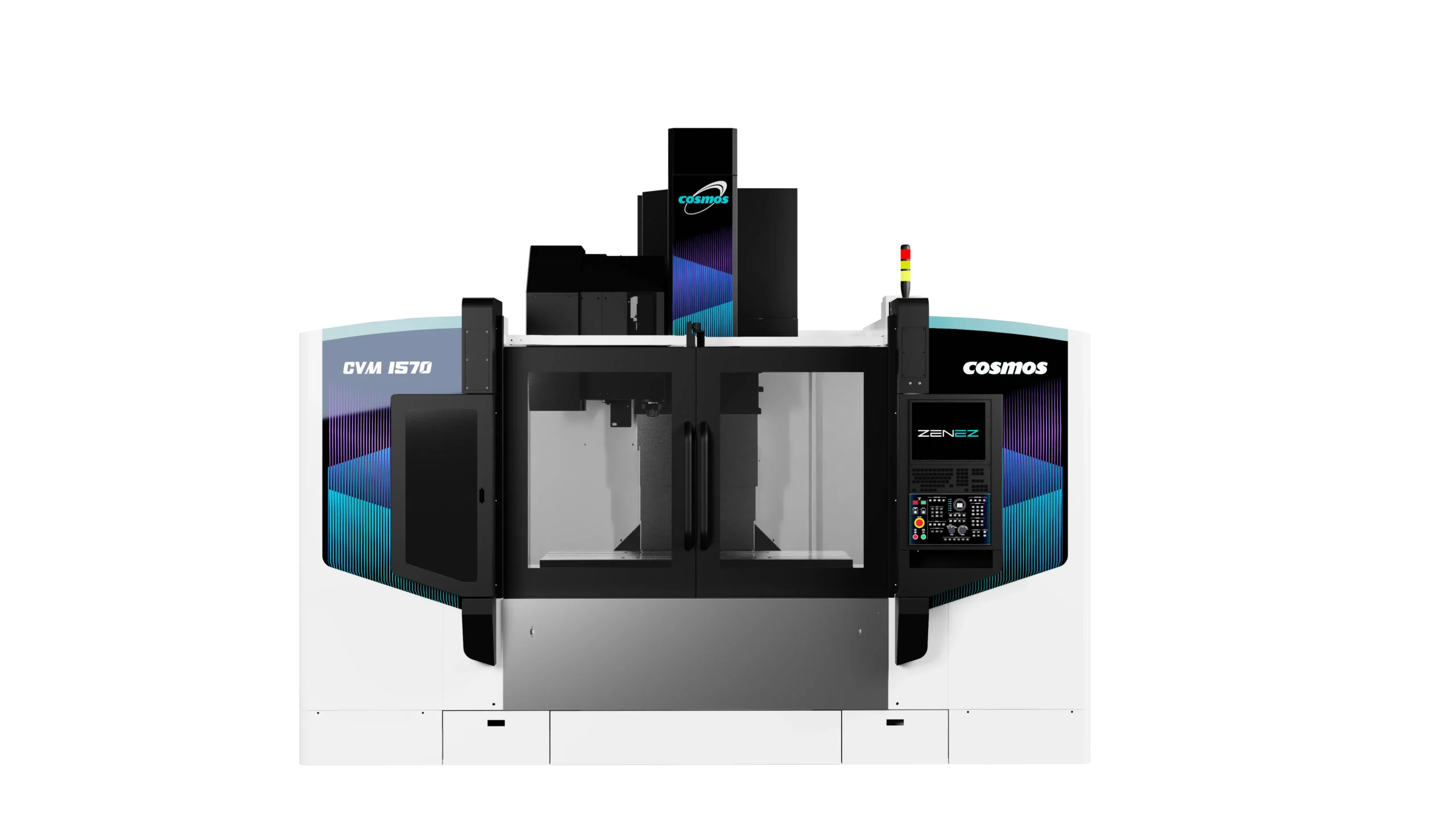

| Specifications | Unit | CVM-700 | CVM-700/G | CVM-800 | CVM-1050 | CVM-1160 | CVM-1365 | CVM-1370 | CVM-1570 | CVM-1680 |

|---|---|---|---|---|---|---|---|---|---|---|

| X-axis Travel | mm | 700 | 700 | 800 | 1050 | 1100 | 1300 | 1300 | 1500 | 1600 |

| Y-axis Travel | mm | 450 | 450 | 500 | 520 | 650 | 650 | 700 | 700 | 800 |

| Z-axis Travel | mm | 500 | 500 | 500 | 520 | 600 | 600 | 700 | 700 | 800 |

| Spindle Nose to Table Surface | mm | 100-600 | 100-600 | 100-600 | 125-645 | 150-750 | 100-700 | 140-740 | 90-690 | 150-850 | 100-800 | 150 -850 | 100-800 | 150-950 | 100-900 |

| Spindle Centre to Sliding Cover Face | mm | 500 | 500 | 520 | 520 | 652 | 652 | 716 | 716 | 830 |

| Table Size | mm | 800×450 | 800×450 | 1000×500 | 1150×500 | 1250×600 | 1450×650 | 1450×650 | 1650×650 | 1750×800 |

| Maximum Table Load | kg | 400 | 400 | 600 | 800 | 1000 | 1000 | 1500 | 1500 | 2000 |

| Table T-slot | mm | 18x4x100 | 18x4x100 | 18x5x100 | 18x5x100 | 18x5x100 | 18x5x125 | 18x5x125 | 18x5x125 | 18x5x150 |

| Spindle Speed | rpm | 8000 | 12000 | 8000 | 8000 | 8000/6000 | 8000/6000 | 8000/6000 | 8000/6000 | 8000 | 6000 |

| Mitsubishi Motor Power (OPT) | kW | 7.5/11/15 | 7.5/11/15 | 11/15/18.5 | 11/15/18.5 | 11/15/18.5 | 11/15/18.5 | 11/15/18.5 | 11/15/18.5 | 15/18.5 |

| Fanuc Motor Power (OPT) | kW | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 | 11/15/18.5 | 11/15/18.5 | 15/18.5 |

| Siemens Motor Power (OPT) | kW | 9/17 | 9/17 | 9/17 | 9/17 | 9/17 | 9/17 | 12/18 | 12/18 | – |

| Spindle Taper | – | BBT 40 | BBT 40 | BBT 40 | BBT 40 | BBT 40 | BT 50 | BBT 40 | BT 50 | BBT 40 | BT 50 | BBT 40 | BT 50 | BBT 40 | BT 50 |

| Rapid Traverse Rate (OPT) | m/min | 36 | 36 | 36 (48) | 36 | 30 | 30 | 24 | 24 | 24 | 24 | 20 |

| Cutting Feed Rate | m/min | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Tool Nos. Capacity (OPT) | nos | 24 | 24 | 30 | 30 | 30 | 24 | 30 | 24 | 30 | 24 | 30 | 24 | 24| 24 |

| Max. Tool Length | mm | 250 | 250 | 250 | 250 | 250 | 350 | 250 | 350 | 250 | 350 | 250 | 350 | 250 | 350 |

| Max. Tool Weight | kg | 8 | 8 | 8 | 8 | 8 | 18 | 8 | 18 | 8 | 18 | 8 | 18 | 8 | 18 |

| Tool Dia. (with adjacent tool) | mm | 80 | 80 | 80 | 80 | 80 | 110 | 80 | 110 | 80 | 110 | 80 | 110 | 80 | 110 |

| Tool Dia. (without adjacent tool) | mm | 150 | 150 | 150 | 150 | 150 | 220 | 150 | 220 | 150 | 220 | 150 | 220 | 150 | 220 |

| Tool Changing Time (Tool to Tool) (OPT) | sec | 2 | 2 | 2 | 2 | 2 | 4.5 | 2 | 4.5 | 2 | 4.5 | 2 | 4.5 | 2 | 4.5 |

| Positioning Accuracy | mm | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.015 |

| Positioning Repeatability | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.004 |

| Machine Weight with ATC (STD M/C) | kg | ~3950 | ~3950 | ~4450 | ~4900 | ~6400 | ~6975 | ~8075 | ~8875 | ~12300 |

| Power Requirement | Kva | 25 | 25 | 30 | 30 | 30 | 30 | 35 | 35 | 35/ 40 |