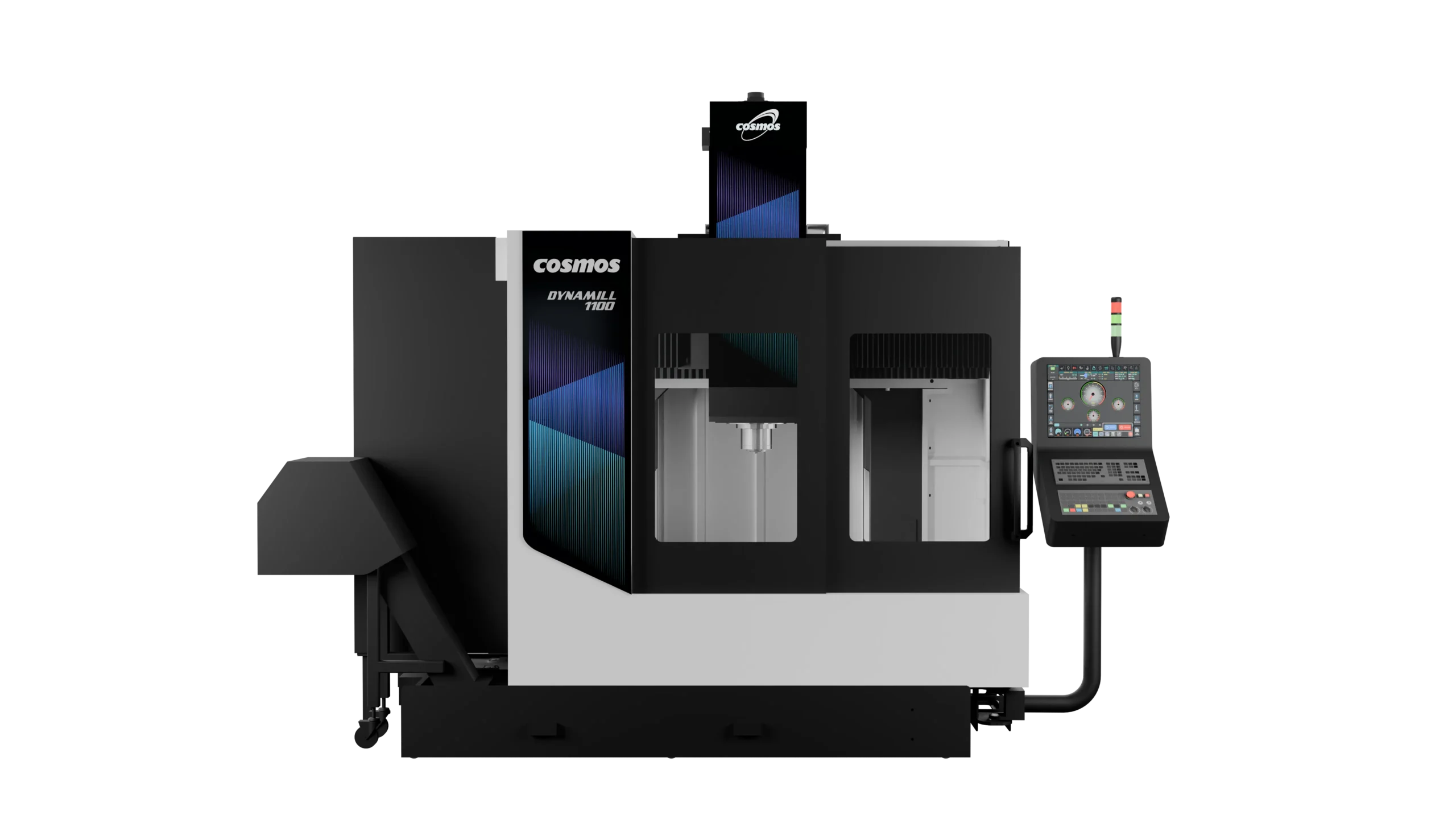

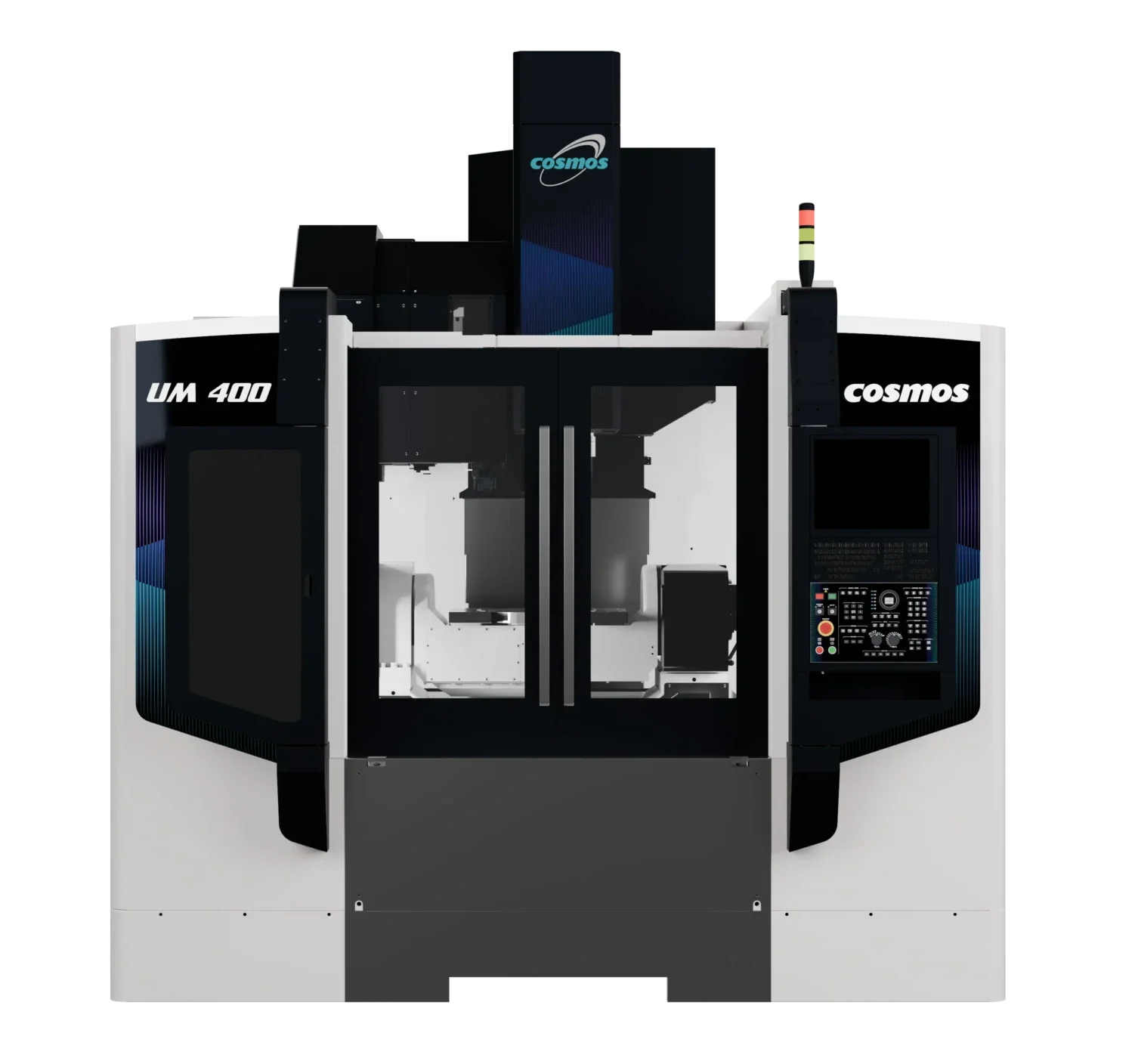

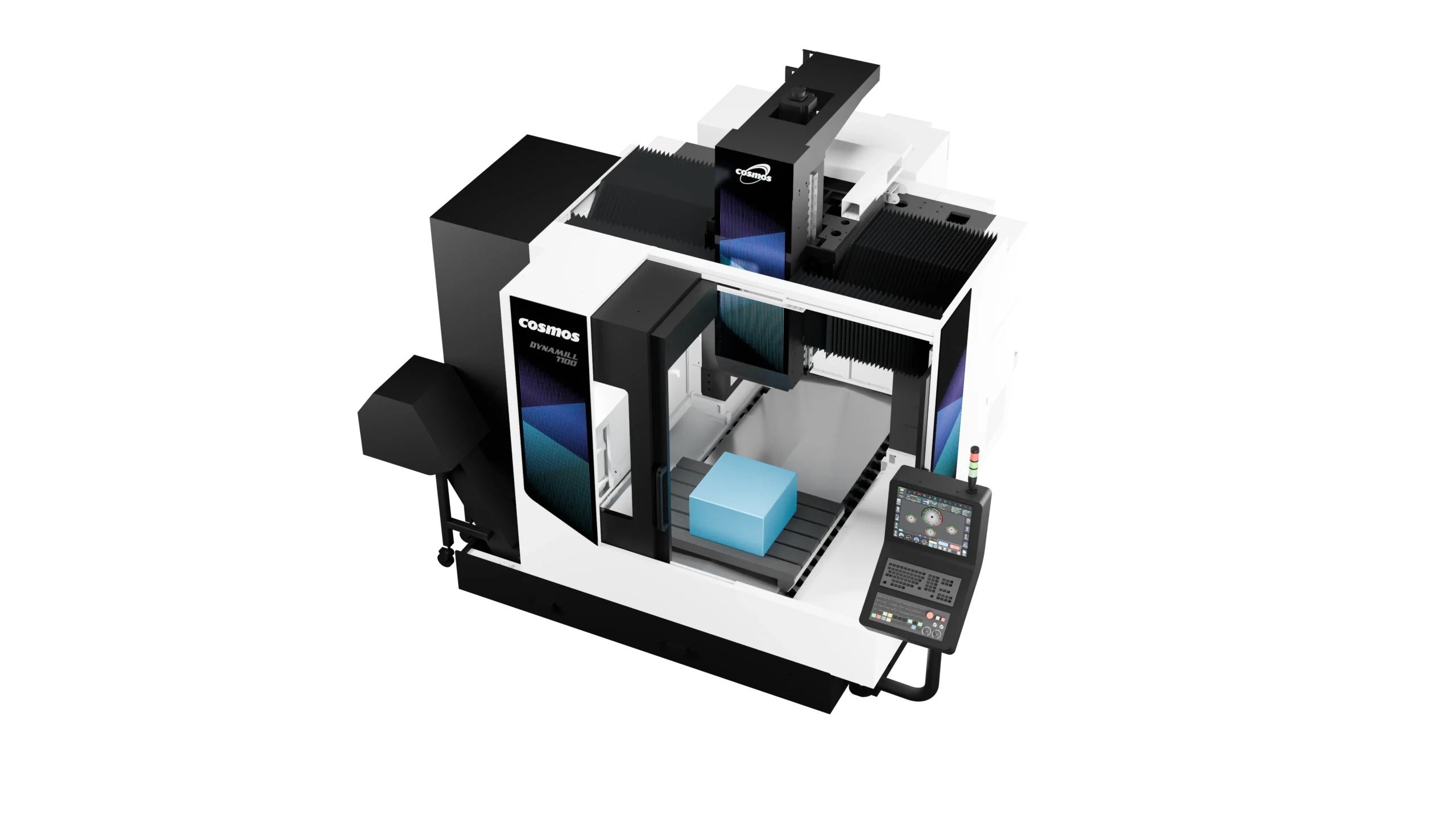

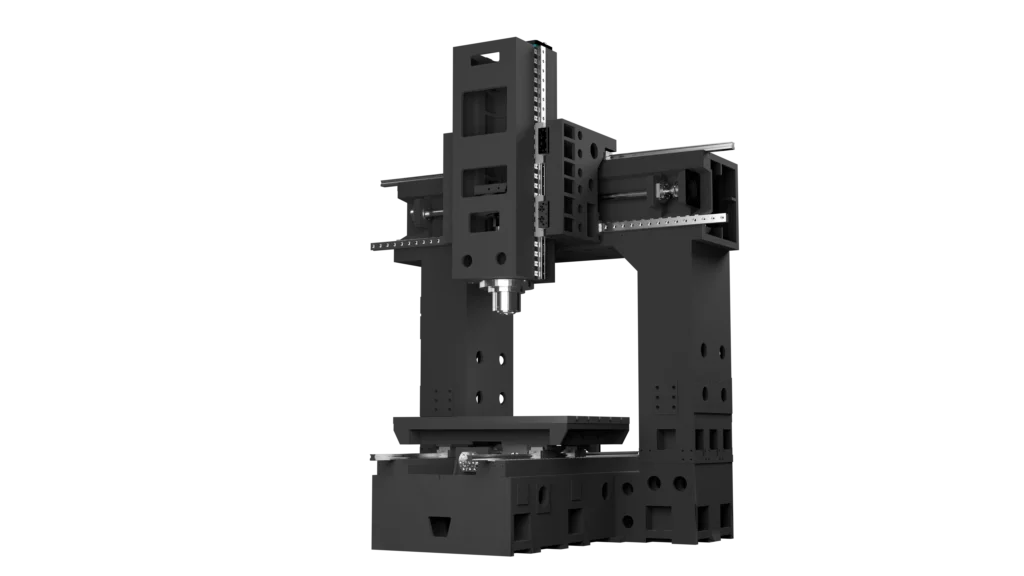

Machine Overview

The DYNAMILL Series Machining Centres are designed for high Dynamics and accuracy as demonstrated in both surface finish quality and consistent precision.

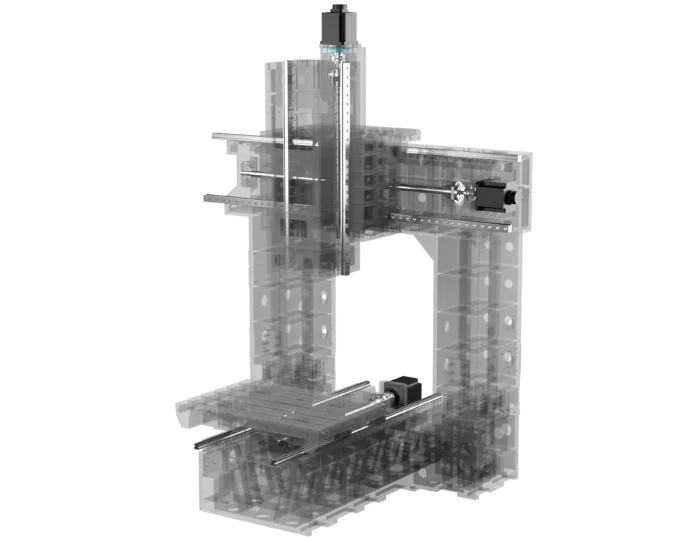

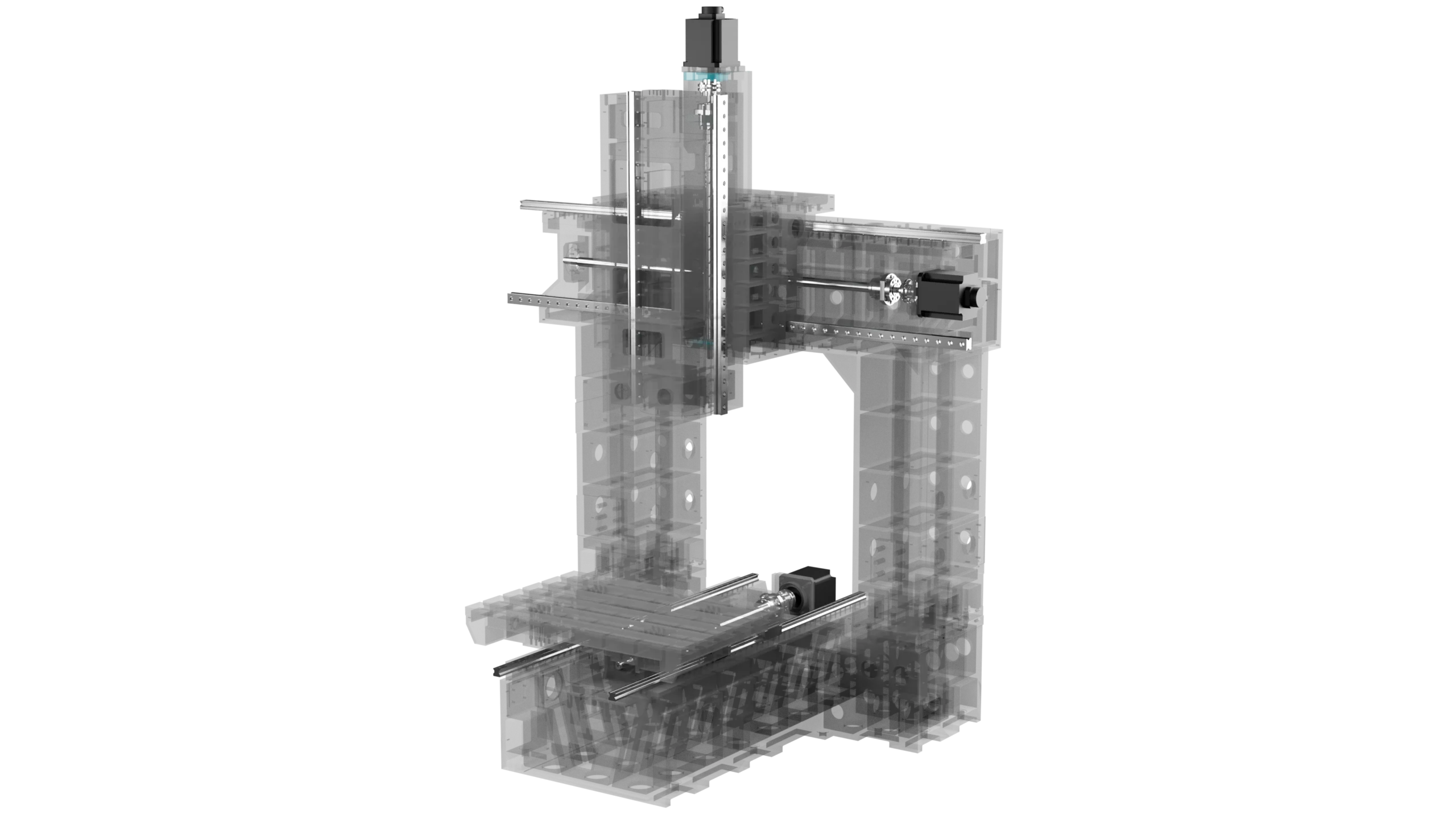

Centro-Aligned Z-axis with Spindle: The Heart of High-Performance Cutting

• The new DYNAMILL Series redefines machining precision with its Centro-aligned Z-axis and Spindle. By aligning the spindle and LM guideway with the centre of gravity of moving parts, it delivers unmatched balance and stability.

• This advanced design minimises deflection and vibrations, ensuring superior Z-axis responsiveness for high-speed, high-feed operations.

• A rigid nested framework further enhances this setup, offering robust support for fine, swift tool movements. The result? Optimal performance, even for the most complex profiles.

Machine Features

Ergonomics Design

- The full enclosure (without the top cover) provides a safe and clean operating environment. The top cover is optional and can be added to meet CE safety directives or specific machining needs.

- The swivel operation panel allows users to operate from any angle or position.

- A wide door width makes loading and unloading of the workpiece easier.

- Large windows on the door provide excellent visibility.

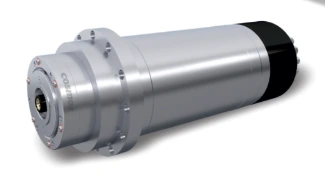

Spindle Cooling

The DYNAMILL series machine is the only one in its class with a heat-dissipating spindle chiller, maintaining tight control over the spindle, bearings, and motor. This reduces thermal growth, ensuring better spindle preload, stiffness, rigidity, tool life, surface finish, and part accuracy.

- Stiffness and rigidity for roughing and hard milling operations

- High-speed for small tools, finishing operations and graphite

- Thermal control for precision

Machine Specs

| Sr. No. | Machine Model | H1 | H2 | L | D |

|---|---|---|---|---|---|

| 1 | DM 1100 | 2285 | 3660 | 2990 | 2818 |

| 2 | DM 1400 | 2400 | 3800 | 3100 | 4200 |

X axis Travel: 1100 mm

Y axis Travel: 700 mm

Z axis Travel: 600 mm

Distance Between Columns: 1100 mm

Table Dimension: 1050 x 700 mm

Table Max. load: 1000 kg

Spindle Speed: 12,000 rpm

Mitsubishi Motor Power : 11/15/18.5 kW

Spindle Taper: BBT 40

Rapid Traverse (X/Y/Z): 32 m/min

Cutting Feed Rate: 20 m/min

Dimensions

| X Axis Travel 1100 mm |

Y Axis Travel 700 mm |

Z Axis Travel 600 mm |

Table Size 1050 x 700 mm |

| Max. load 1000 kg |

Table T-Slot 18*100*5 mm |

|

| Machine Weight (with ATC) 7500 kg |

Power Supply 415V/ 3phase, 50~60Hz |

Total Connected Load 30 KVA |

Capacity

| Spindle taper BBT40 |

Spindle type (Standard) Direct-drive |

Spindle speed 12000 RPM |

| Rapid Traverse Rate (Opt) 32 m/min |

Cutting Feed Rate 20 m/min |

Motor power (X / Y / Z)(Mitsubishi M80V/M830V control) 3/3/4.5 KW |

X axis Travel: 1400 mm

Y axis Travel: 1000 mm

Z axis Travel: 600 mm

Distance between columns: 1100 mm

Table Dimension: 1600 x 1000 mm

Table Max. load: 3000 kg

Spindle speed: 12,000 rpm

Motor power – Mitsubishi: 11/15/18.5 kW

Spindle taper: BBT 40

Rapid traverse (X/Y/Z): 32 m/min

Cutting feed rate: 20 m/min

Dimensions

| X Axis Travel 1400 mm |

Y Axis Travel 1000 mm |

Z Axis Travel 600 mm |

Table Size 1600×1000 mm |

| Max. load 3000 kg |

Table T-Slot 18*100*5 mm |

|

| Machine Weight (with ATC) 10000 kg |

Power Supply 415V/ 3phase, 50~60Hz |

Total Connected Load 30 KVA |

Capacity

| Spindle taper BBT40 |

Spindle type (Standard) Direct-drive |

Spindle speed 12000 RPM |

| Rapid Traverse Rate (Opt) 32 m/min |

Cutting Feed Rate 20 m/min |

Motor power (X / Y / Z)(Mitsubishi M80V/M830V control) 4.5/3/4.5 KW |

Tools

| Maximum Tool Length 300 mm |

Tool Charging Timer 2.4 sec |

Maximum Tool Weight 7 Kg |

Tool Capacity 24 |

Max. tool diameter 150 |

Next pocket empty 150 |

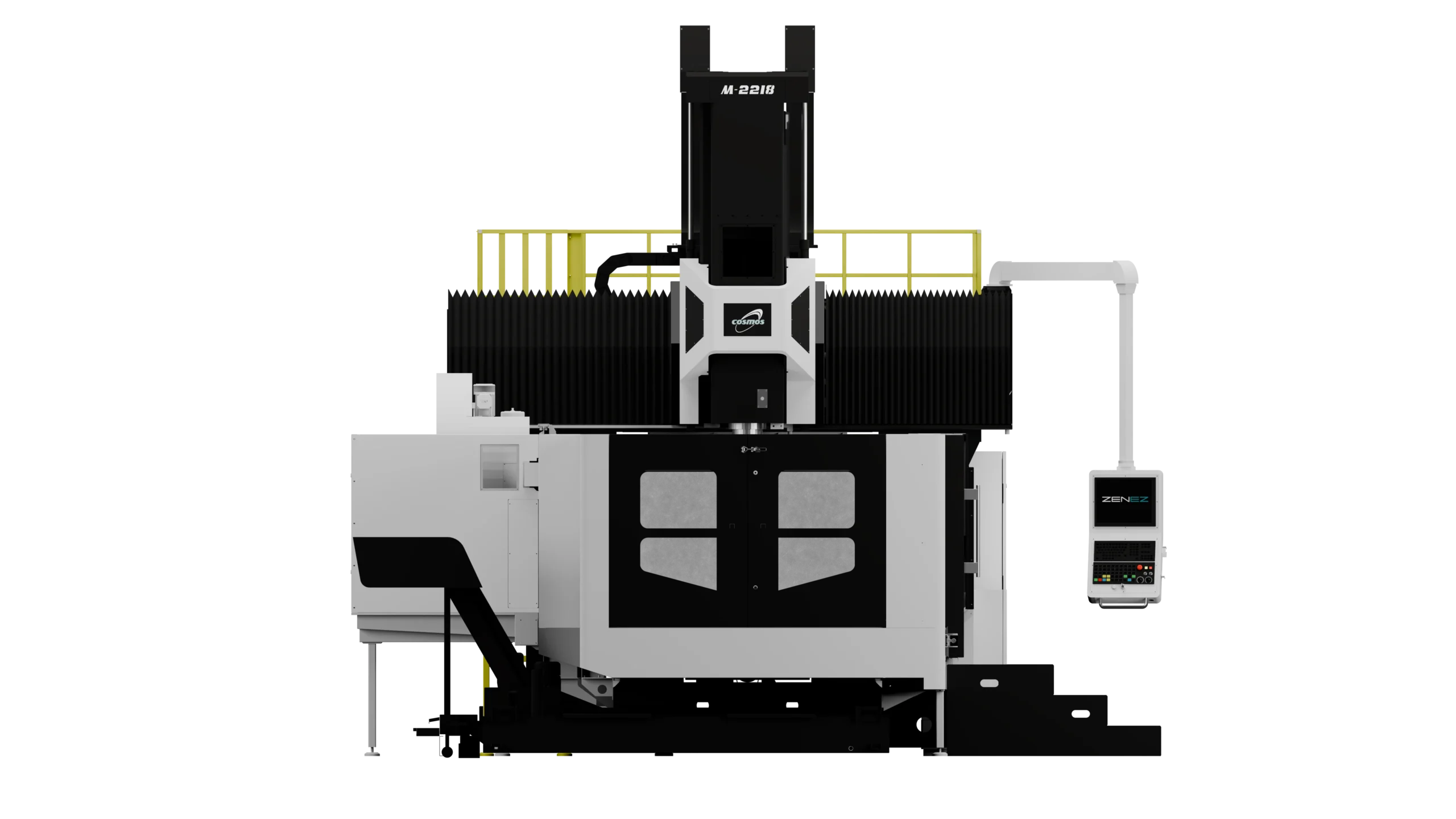

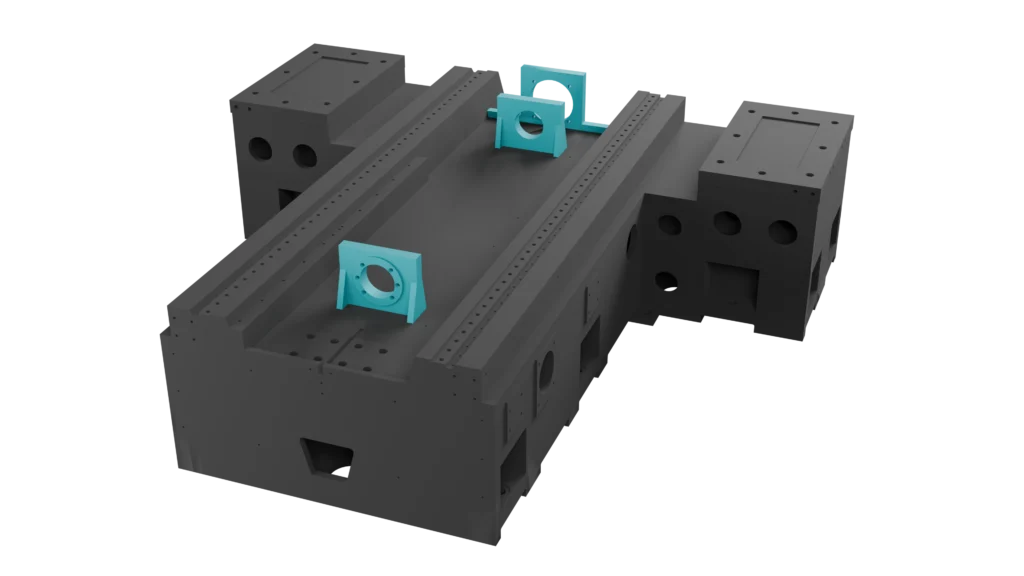

Robust single casting bed

The integrated bed frame ensures high rigidity, excellent vibration absorption, and outstanding surface finishes, especially when compared to separate structures. The base width provides stability for heavy table loads even when operating at high speed.

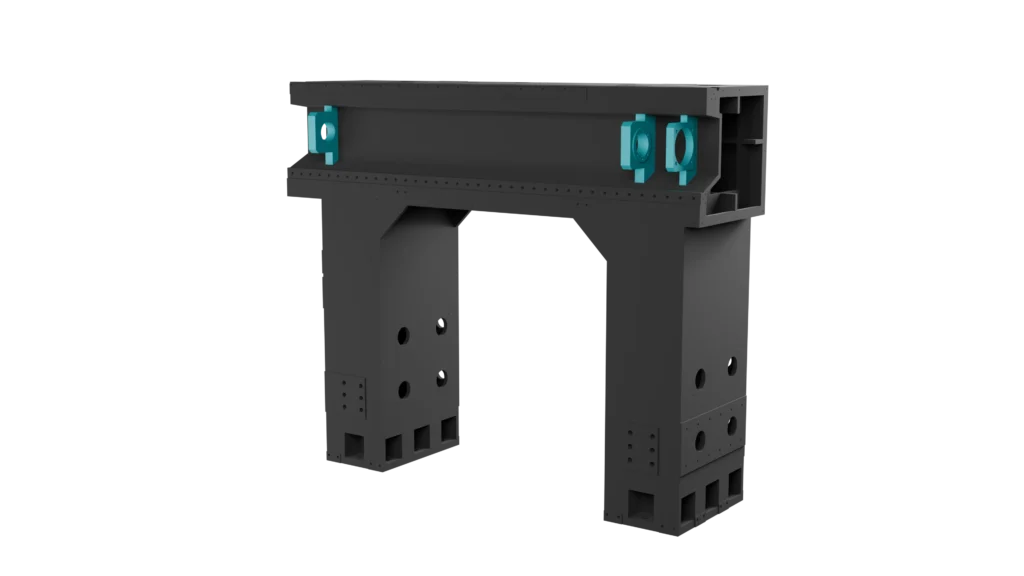

Mono bridge Type Column Design

The one-piece design provides increased weight to absorb cutting vibration, and increased rigidity. The dual contact areas with the base eliminate pitch in the Y-axis and reduce the effect of machine levelling changes over time.

Step Type Beam for Improved Cutting Stability

The oversized beam is a step-type construction that allows for better stability of cutting.

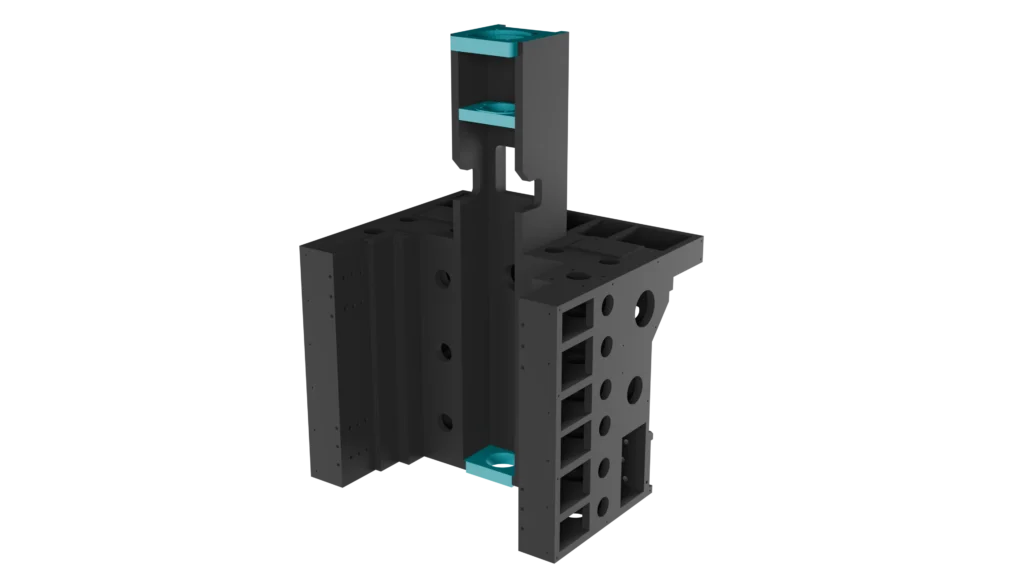

Unity Structure

We’ve significantly enhanced the lifespan of our machines by reducing the number of subassemblies, making them more efficient and durable. By integrating essential components, such as the bearing housing, motor brackets, and nut housing, directly into the main casting, we not only improve the overall durability but also streamline maintenance processes. This thoughtful design reduces the need for frequent replacements and adjustments, ensuring a more reliable, hassle-free experience for operators while increasing the machine’s longevity and overall performance.

MACHINING STABILITY ENSURED

Our machines are distinguished by the extraordinary power of our signature ribs, the cornerstone of strength and quality in our construction. These ribs are strategically positioned to fortify our machines, elevating their structural integrity and amplifying overall robustness.

For heavy-duty cutting tasks, our ribs are the secret to success. They stand out in enhancing torsional rigidity, expertly reducing vibrations, and virtually eliminating deformation. The outcome is a level of machining precision and reliability that’s second to none – a testament to the enduring quality and unwavering strength of our ribs. Place your trust in the bedrock of excellence; rely on our ribs to deliver.

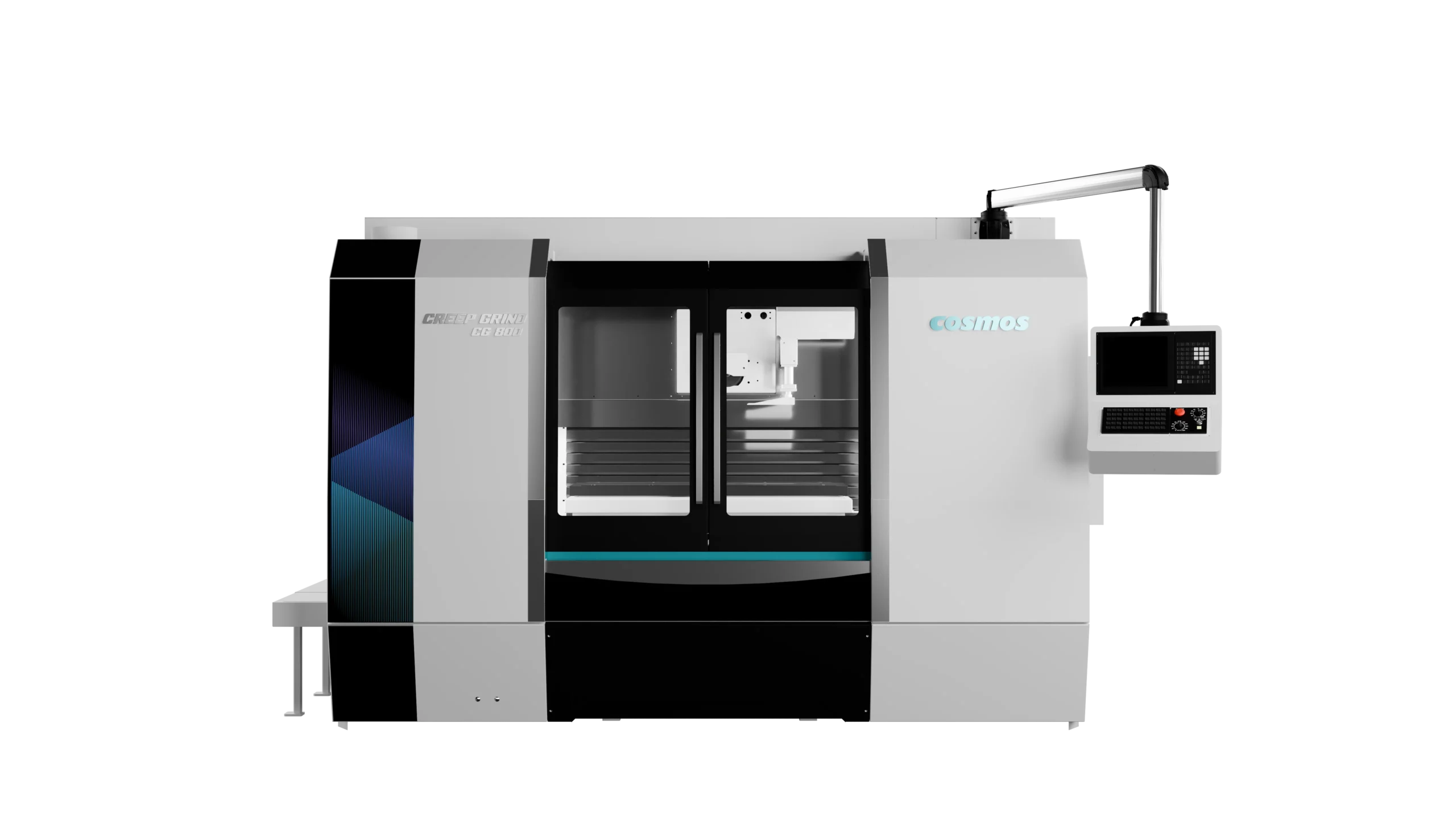

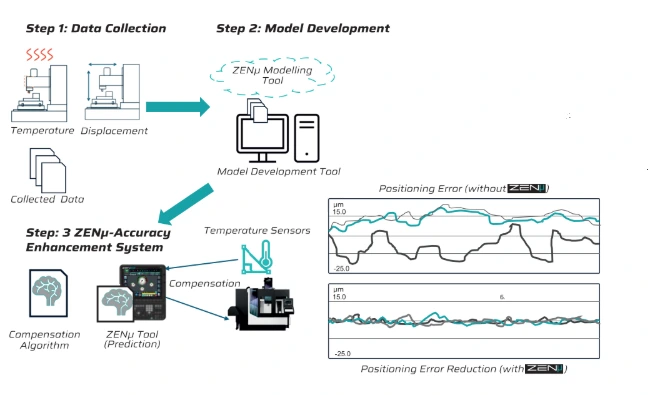

ZENµ

- Zenµ is “AI based” accuracy enhancement system which focuses on maintaining the tool centre point using ai algorithms.

- Using algorithms written in the module, the external zero point of X,Y and Z axis are shifted in multiple degrees of freedom to maintain the tool centre point at a constant position in the real time.

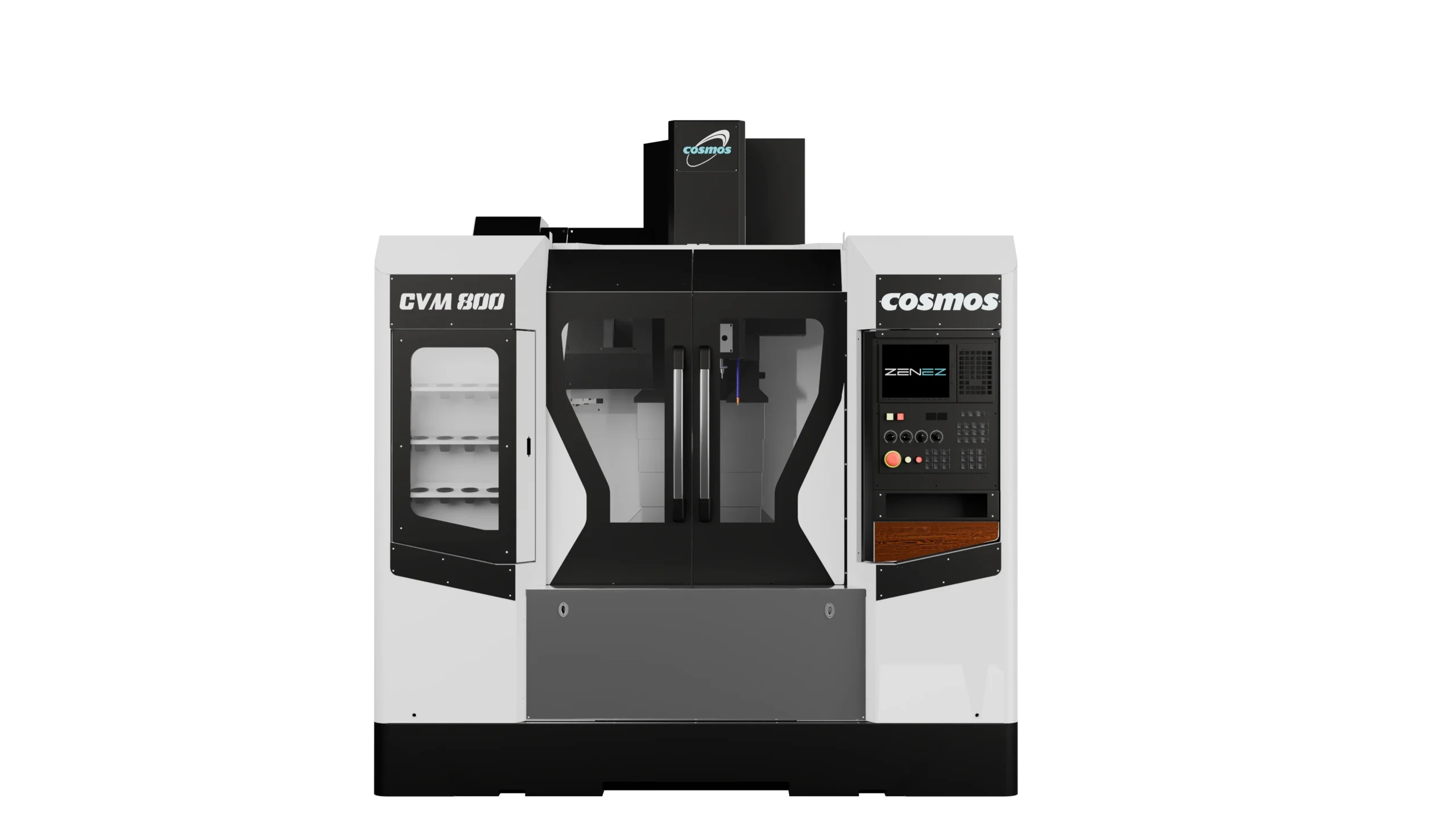

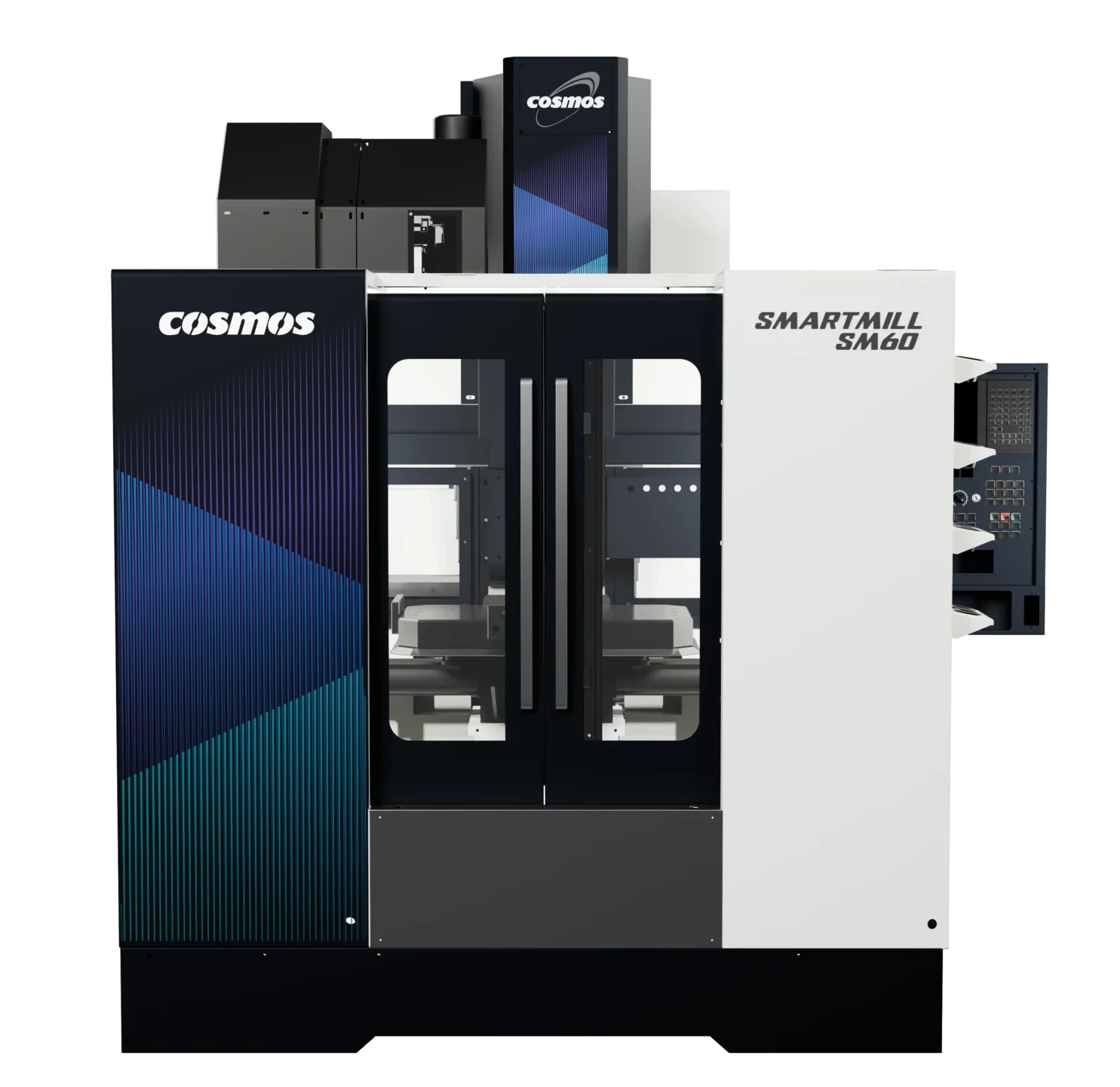

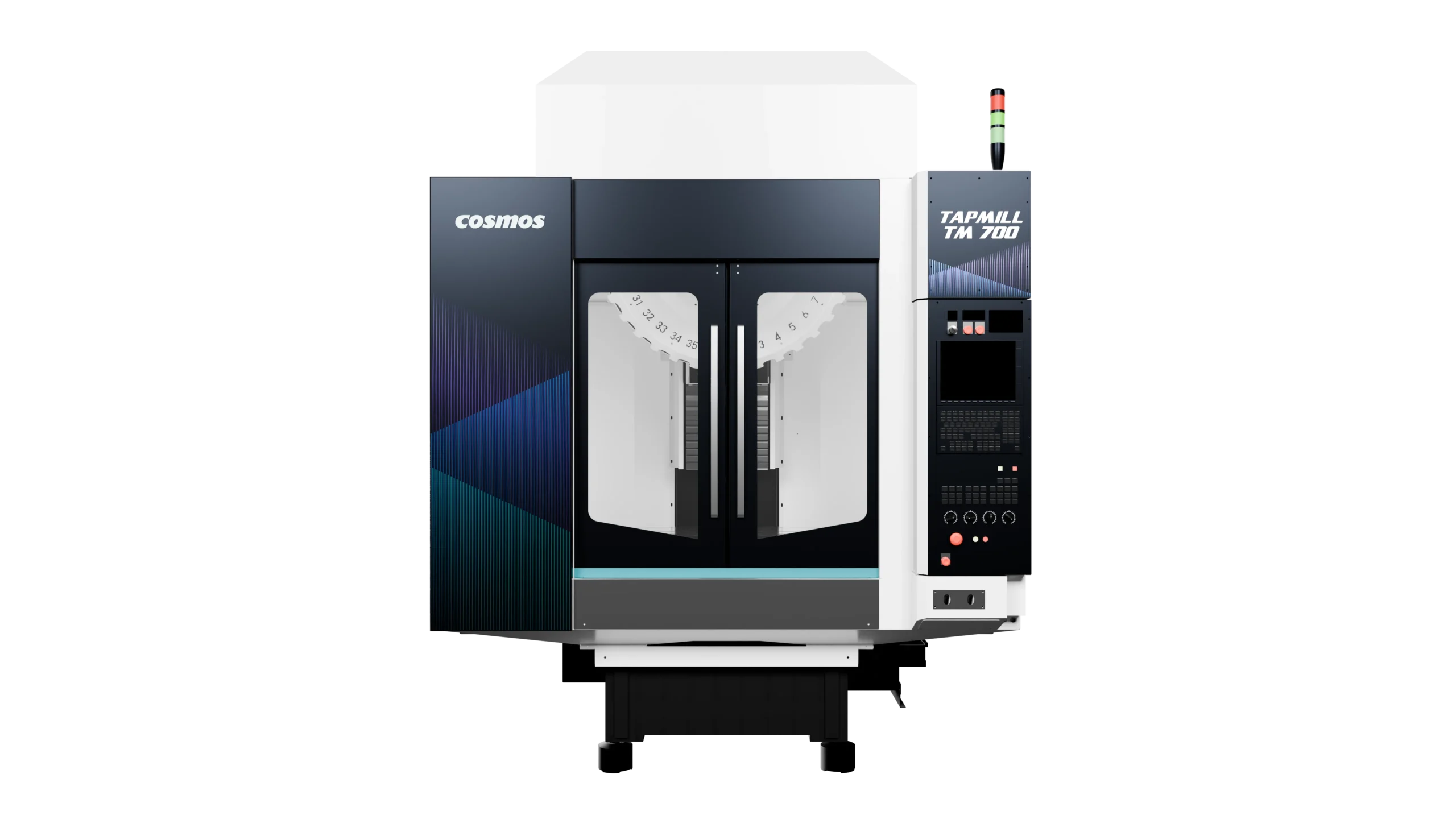

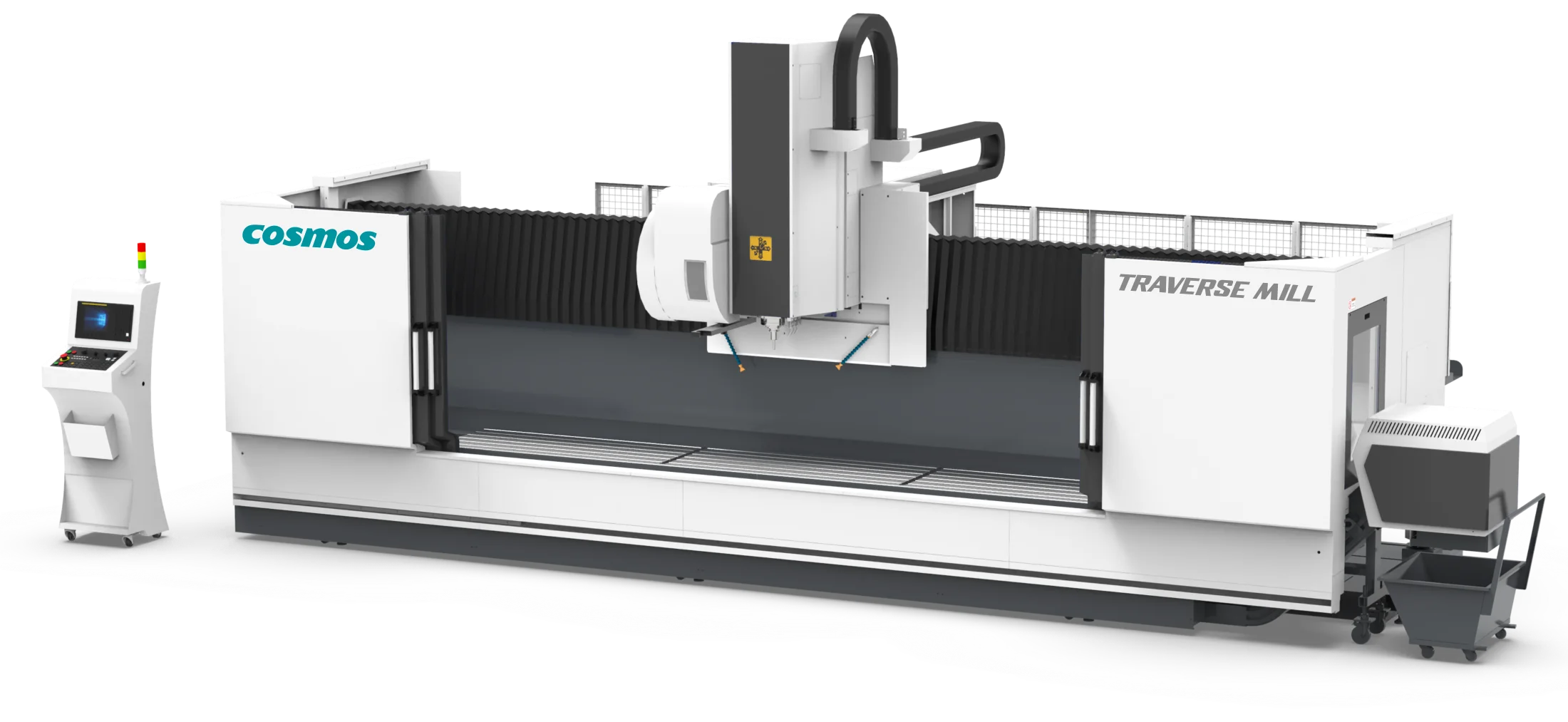

Our Other Range of Excellence

High-tech Products For Unmatched Performance