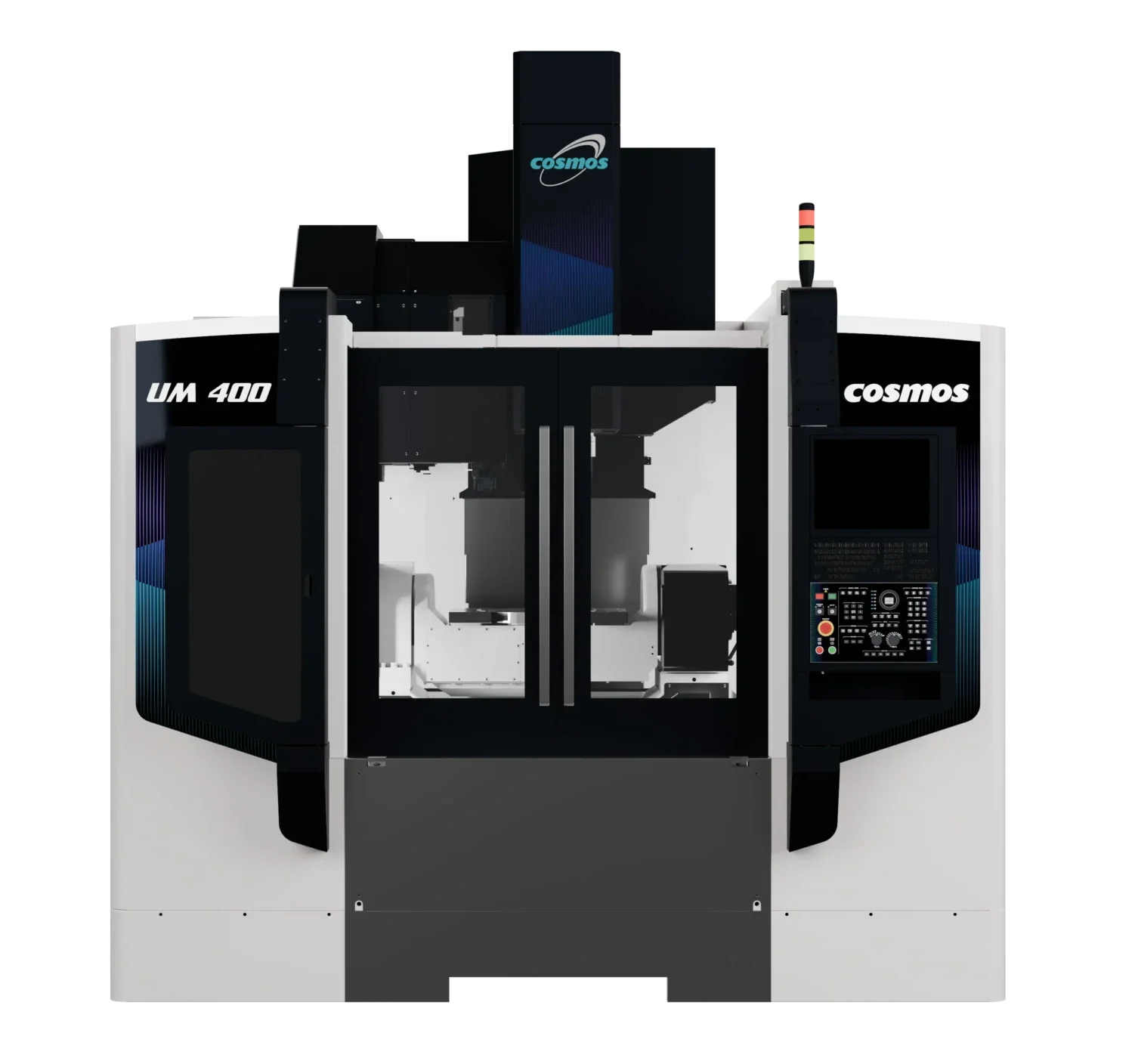

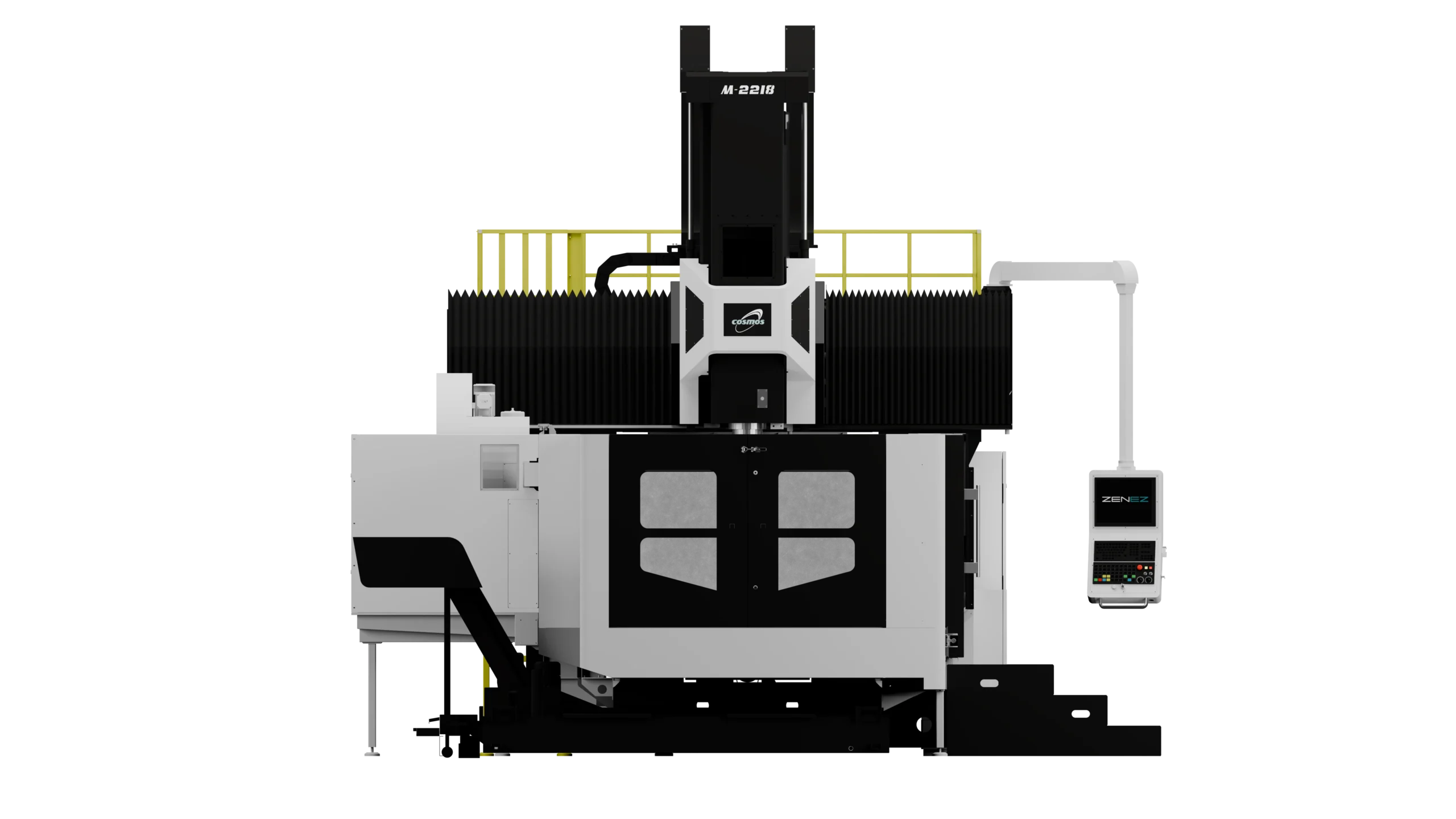

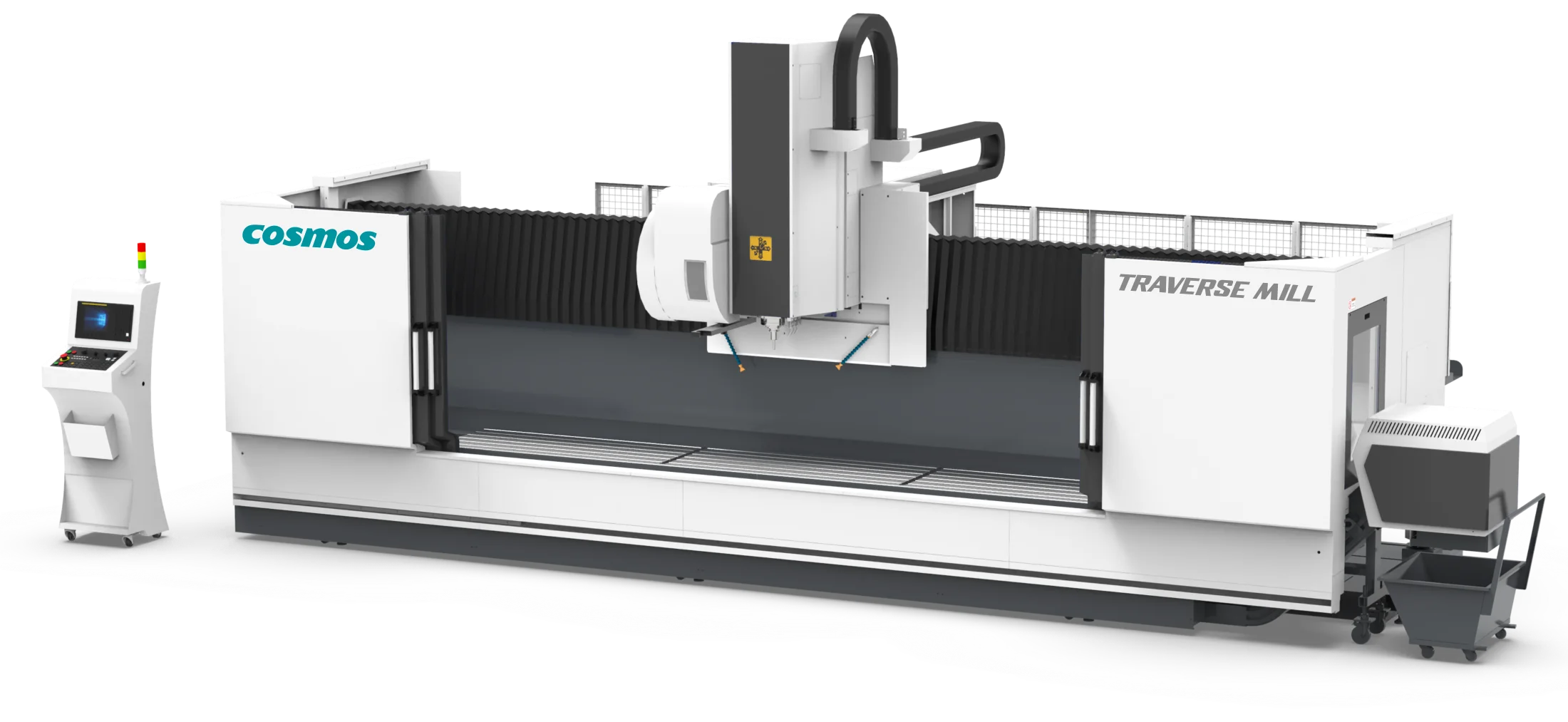

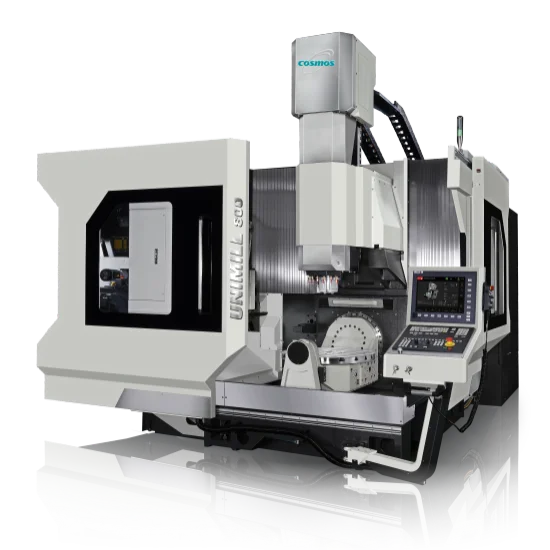

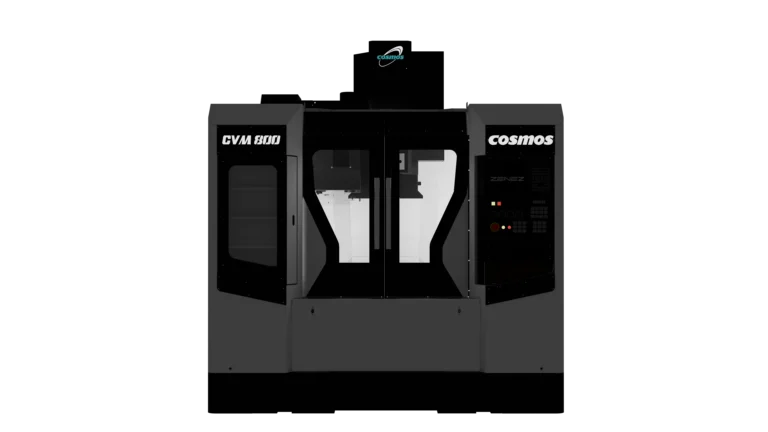

Machine Overview

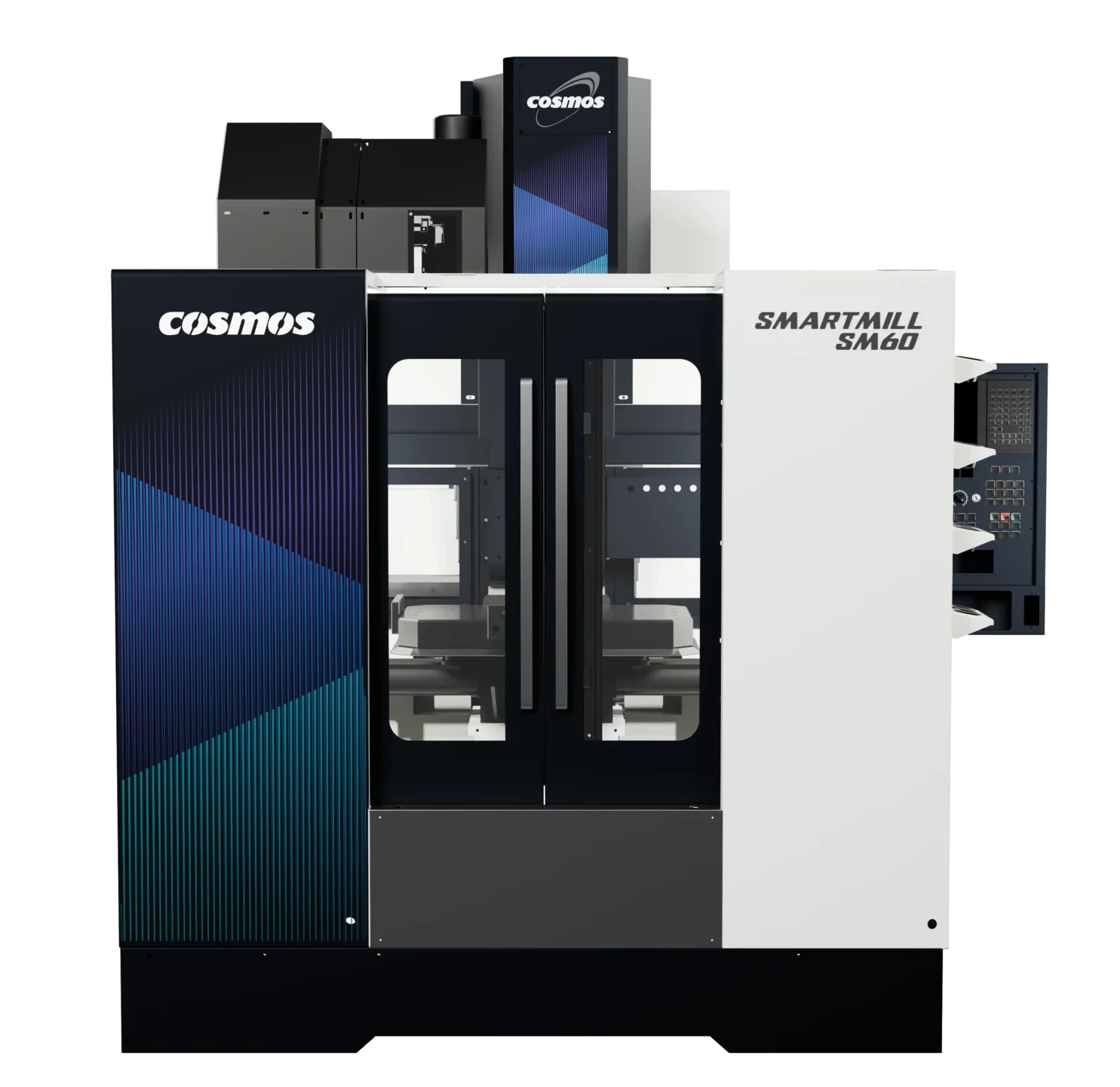

Simultaneous Five Axis Machining Centres

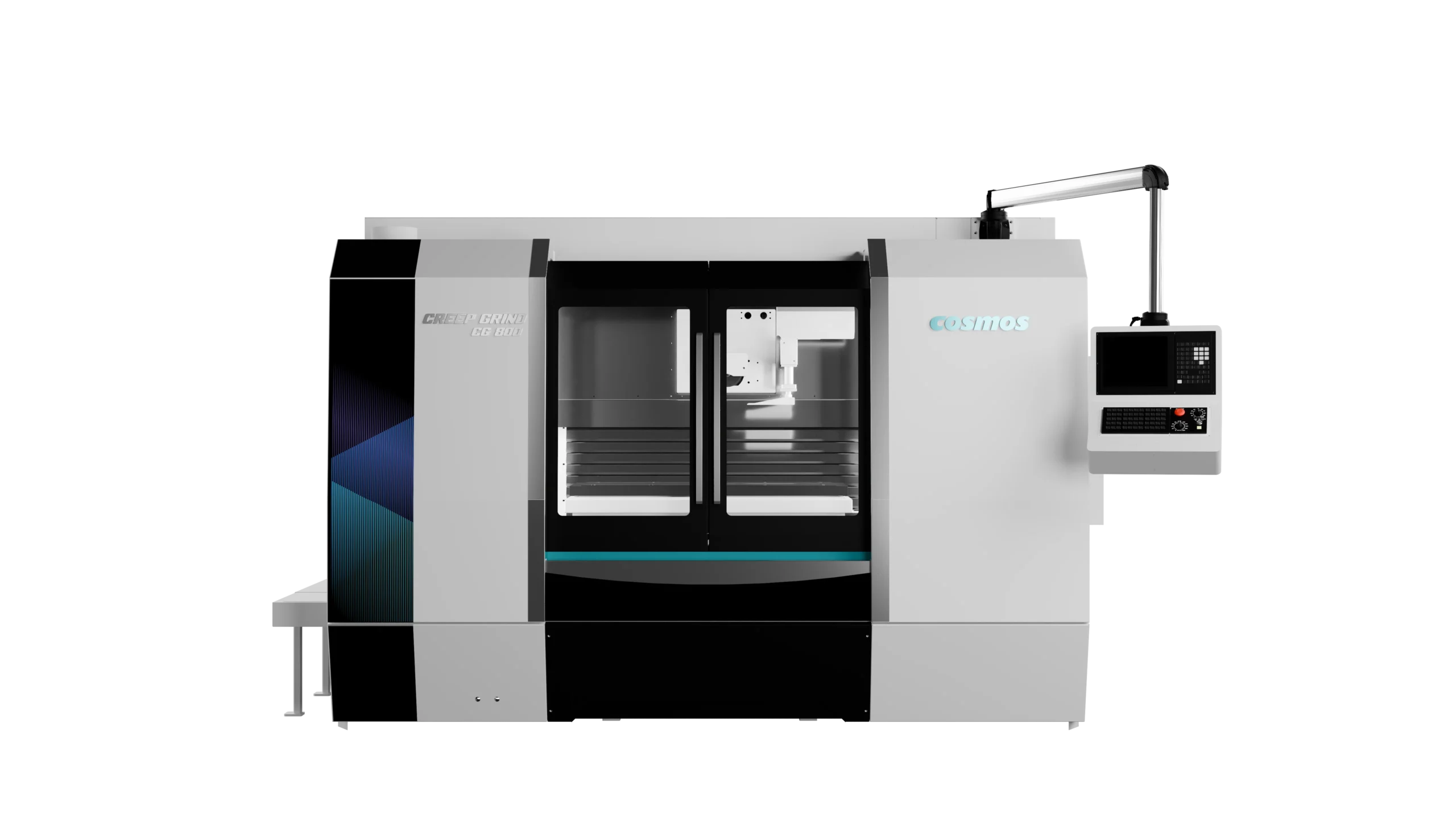

Bed-mounted - 5-axis Table

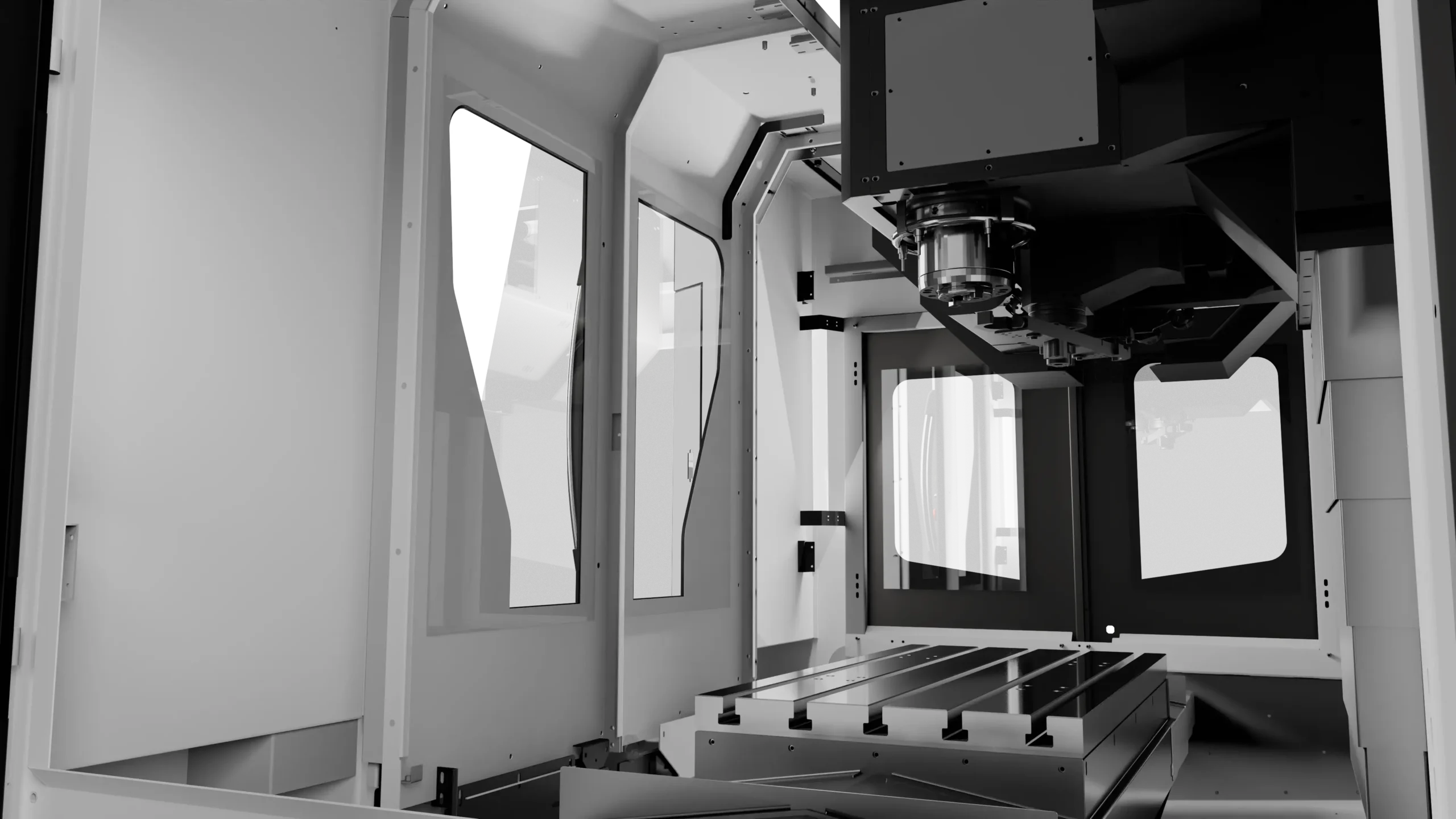

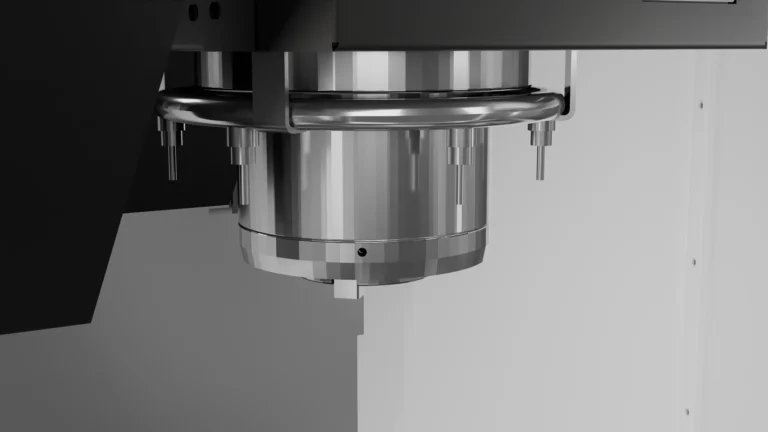

Fully Supported Table, is Bed-mounted at both ends by the base ensuring astable foundation for the rotary axes.

Both rotary axes are roller-cam driven to ensure high speed, zero backlash, and low friction, allowing efficient and smooth transmission with minimal heat generation for precise operation.

User-friendly Operation Space

The operation space design ensures a minimum distance of 200mm for manual tool changes.

Swivel Operation Panel

Can be adjusted to any position and angle, providing flexibility for the operator.

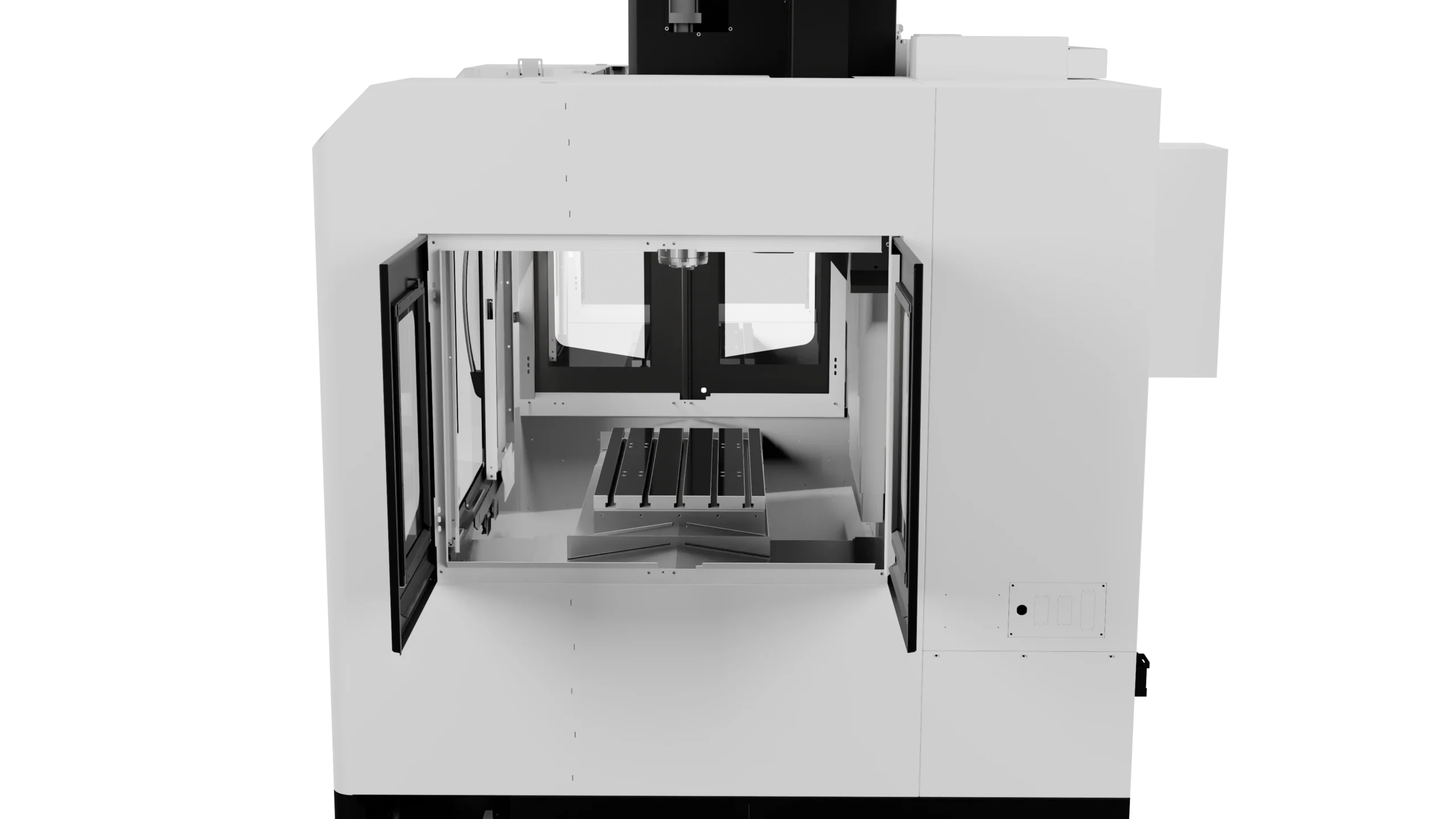

Double-door Opening

The wider space of double-door opening makes workpiece easier to be loaded and unloaded.

Indication Light Bar

The indication light bar shows the machines status, allowing constant monitoring of its operation.

Additional Features

Stainless Steel Sill

Protector

Big Dual

Side Windows

Fully Enclosed

Guarding

Inbuilt Tool

Stronge Cabinet

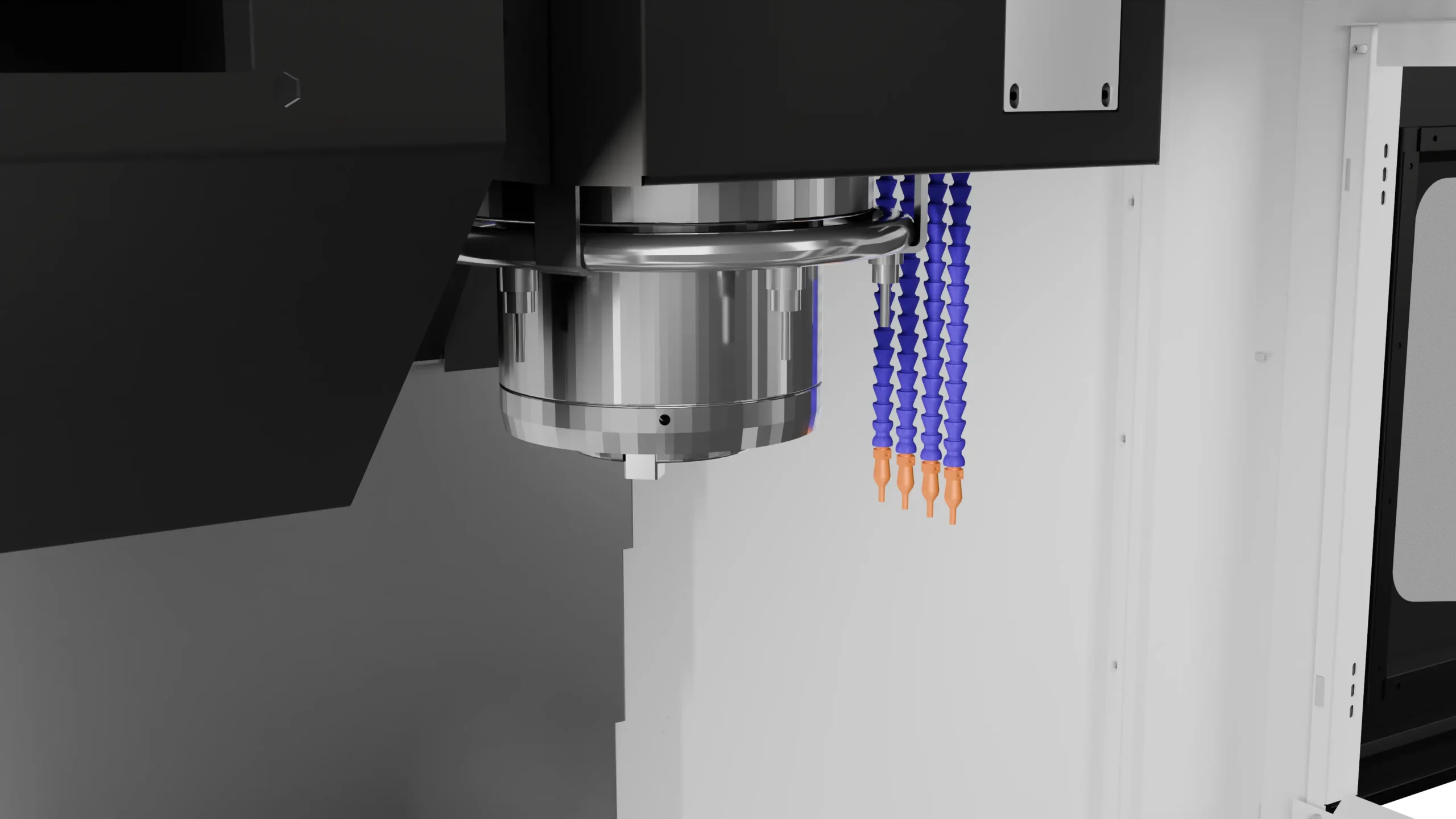

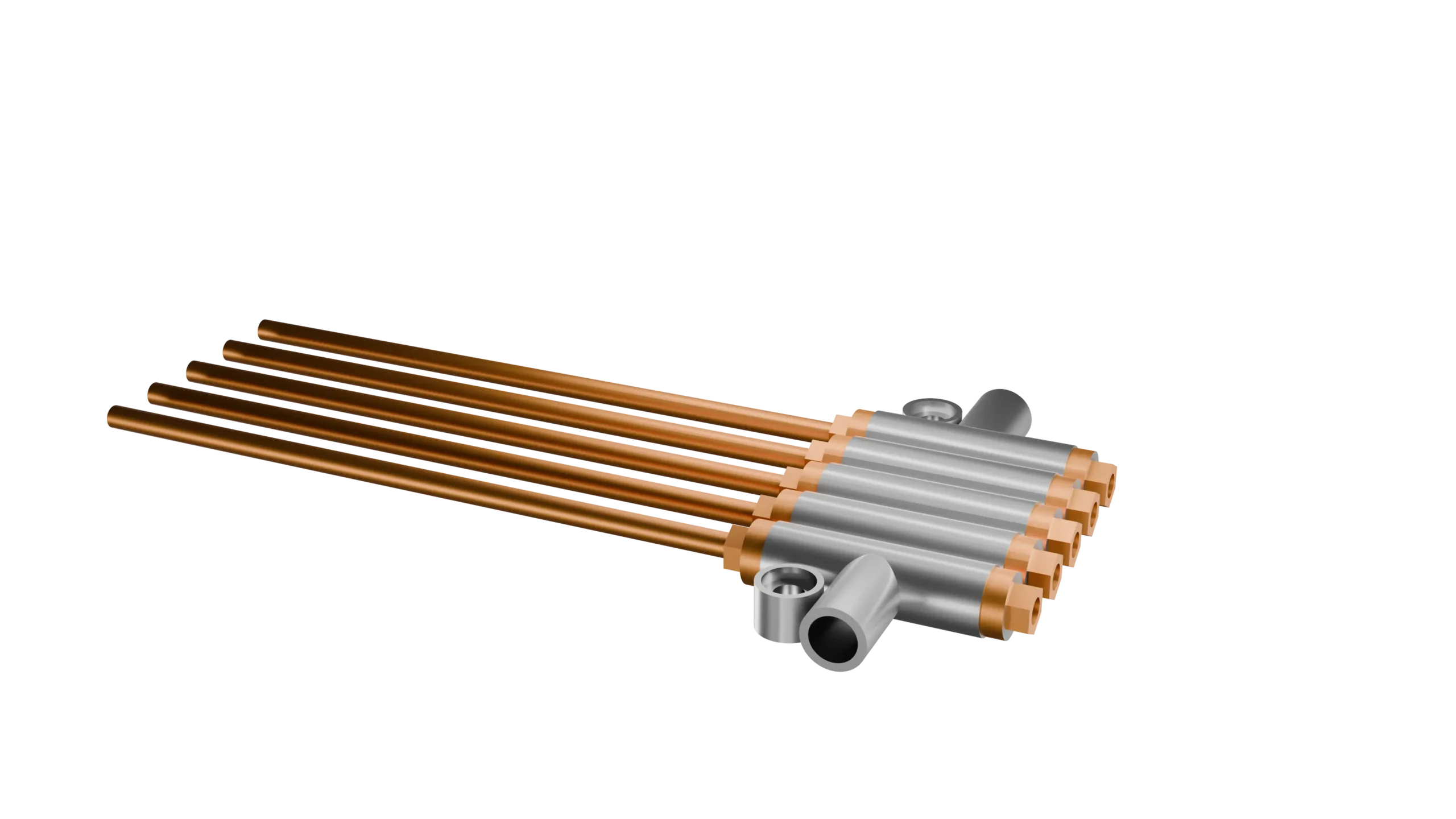

1 Air and 3 Coolant

Nozzles

Copper Pipe

for Lubrication

High Visibility Front Doors

The front doors are constructed using heavy-duty, shatterproof polycarbonate material. The generously sized window provides operators with clear and unobstructed visibility, making it effortless to monitor machining processes.

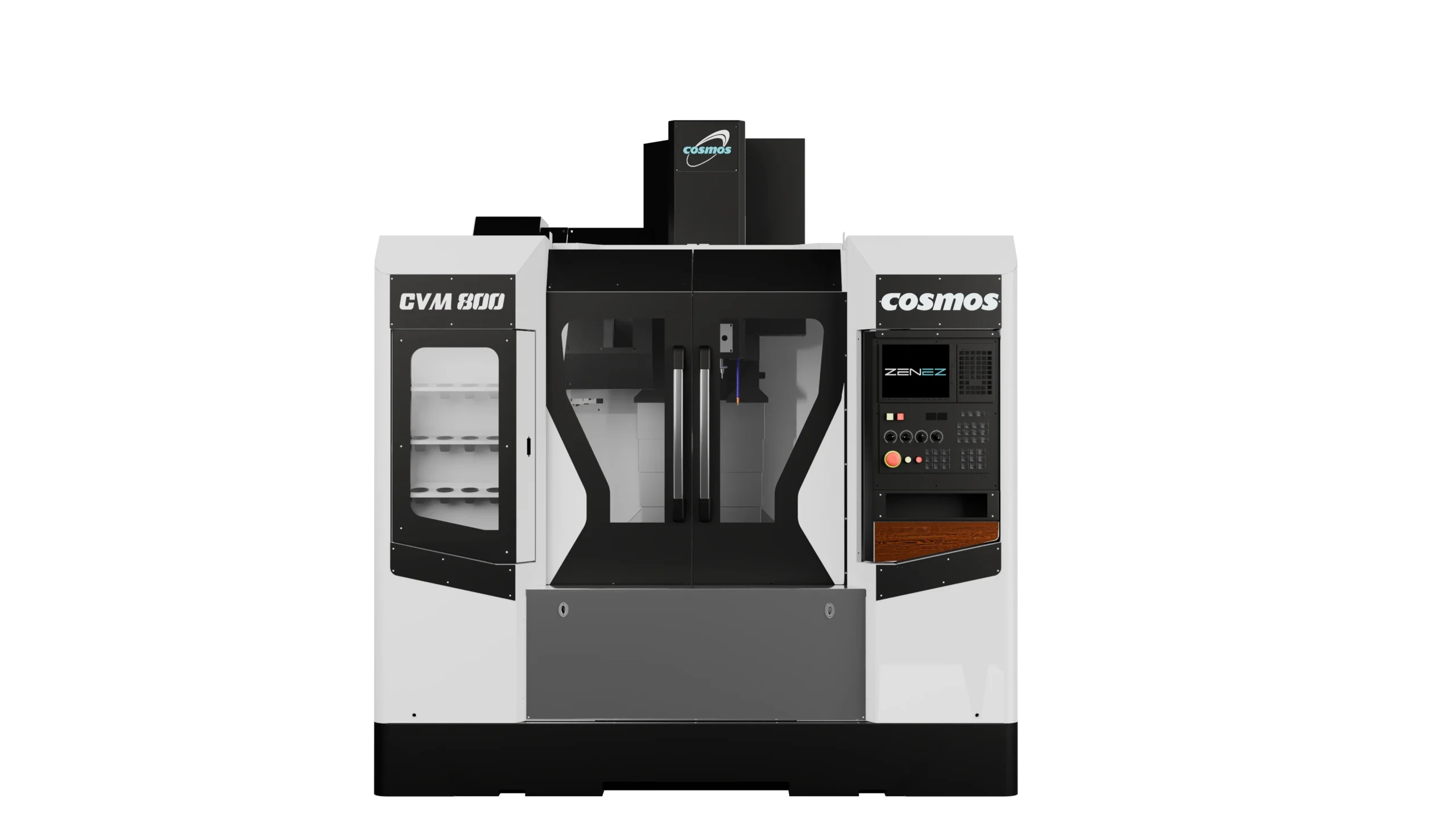

Secure Tool Storage: Enclosed Cabinet With Adjustable Rack

All CVM machines come equipped with endorsed cabinets featuring racks, providing a safe and organised space to store your valuable tools. The adjustable design ensures flexibility to accommodate tools of various sizes with ease.

Holster For Your Guns

The machines feature scuffless steel panels equipped with holsters for the coolant and air guns. This thoughtful design ensures your guns are securely stored, preventing paint scratches, accidental drops, and messy coolant drips, enhancing both efficiency and workplace safety.

Stainless Steel Protector

Front panels often bear the brunt of scratches and rust from operator handling of tools, tackle, and components. Our solution? Stainless steel protection to eliminate these issues, ensuring lasting durability and a pristine appearance. Say goodbye to scratches and rust concerns.

Brilliantly Illuminated for Optimal Visibility

Designed for optimal visibility in low light, CVM machines include a dual work lamp with white LEDs, a three-colour tower lamp, ambient tool cabinet lighting, and an illuminated machine name, ensuring a well-lit workspace for operator ease.

Seamless Access: Spacious Side Doors

Generously sized side doors are designed for easy access to the machine. These doors are strategically positioned below the table height, ensuring convenience during extended use. Work comfortably and efficiently with hassle-free access to your machine. (Except 640)

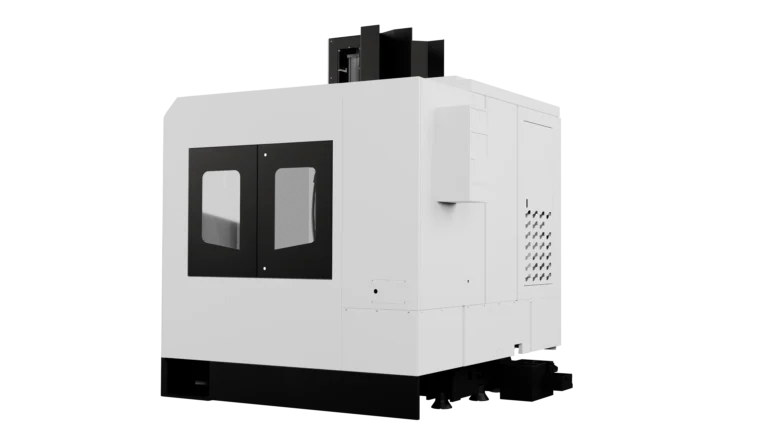

Versatile 360° Machine Design

Our machines feature a smooth, flush design on all four faces, offering you the freedom to position the machine in any orientation within your factory. Enjoy a sleek appearance from every angle.

Machine Specs

X-Axis: 700 mm

Y-Axis: 510 mm

Z-Axis: 600 mm

A-Axis: +30° / -120°

C-Axis: 360°

Spindle Speed: 10,000 (12,000) rpm

Spindle Taper: BBT 40 | HSKA63

Rapid Traverse Rate: 30 m/min

Cutting Feed Rate: 10 m/min

Controller: Mitsubish,Fanuc

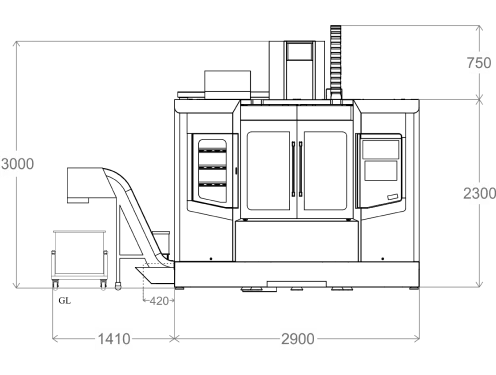

Dimensions

| X Axis Travel 700 mm |

Y Axis Travel 510 mm |

Z Axis Travel 600 mm |

Table Size Rectangle 620 x 410, Table with 410 Dia rotating |

| Spindle Nose to Table Surface 71-671 mm |

Maximum Loading Capacity 200/150 mm |

| Machine Weight 7200 kg |

Power Requirement (Controller) 35 KVA |

Capacity

| Spindle Taper BBT 40 |

Spindle Speed 10,000 |

Spindle Type Belt Drive |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Controller Mitsubishi, Fanuc |

|

| Rapid Traverse Rate (Opt) 30 m/min |

Cutting Feed Rate 10 m/min |

Tool Nos. Capacity 30 |

X-Axis: 700 mm

Y-Axis: 510 mm

Z-Axis: 600 mm

A-Axis: +30° / -120°

C-Axis: 360°

Spindle Speed: 12,000 rpm

Spindle Taper: BBT 40 | HSKA63

Rapid Traverse Rate: 30 m/min

Cutting Feed Rate: 10 m/min

Controller: Fagor

Dimensions

| X Axis Travel 700 mm |

Y Axis Travel 510 mm |

Z Axis Travel 600 mm |

Table Size Rectangle 620 x 410, Table with 410 Dia rotating |

| Spindle Nose to Table Surface 71-671 mm |

Maximum Loading Capacity 200/150 mm |

| Machine Weight 7200 kg |

Power Requirement (Controller) 35 KVA |

Capacity

| Spindle Taper BBT 40 |

Spindle Speed 10,000 |

Spindle Type Direct Drive |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw |

Controller Fagor |

|

| Rapid Traverse Rate (Opt) 30 m/min |

Cutting Feed Rate 10 m/min |

Tool Nos. Capacity 30 |

X-Axis: 700 mm

Y-Axis: 700 mm

Z-Axis: 500 mm

A-Axis: +120° / -120°

C-Axis: 360°

Spindle Speed: 15,000 rpm

Spindle Taper: BBT 40 | HSKA63

Rapid Traverse Rate: 48 m/min

Cutting Feed Rate: 20 m/min

Controller: Fagor

Dimensions

| X Axis Travel 700 mm |

Y Axis Travel 700 mm |

Z Axis Travel 500 mm |

Table Size Dia. 680 |

| Spindle Nose to Table Surface 150-650 mm |

Maximum Loading Capacity 500 / 300 mm |

| Machine Weight 8750 kg |

Power Requirement (Controller) 50 KVA |

Capacity

| Spindle Taper - |

Spindle Speed 15,000 |

Spindle Type Direct Drive |

| Mitsubishi Motor power(OPT) 11 / 42 kw |

Controller Fagor |

|

| Rapid Traverse Rate (Opt) 48 m/min |

Cutting Feed Rate 20 m/min |

Tool Nos. Capacity 32 |

X-Axis: 800 mm

Y-Axis: 700 mm

Z-Axis: 500 mm

A-Axis: +120° / -120°

C-Axis: 360°

Spindle Speed: 18,000 rpm

Spindle Taper: BBT 40 | HSKA63

Rapid Traverse Rate: 48 m/min

Cutting Feed Rate: 20 m/min

Controller: Fagor

Dimensions

| X Axis Travel 700 mm |

Y Axis Travel 700 mm |

Z Axis Travel 500 mm |

Table Size Dia. 680 |

| Spindle Nose to Table Surface 150-650 mm |

Maximum Loading Capacity 500 / 300 mm |

| Machine Weight 9200 kg |

Power Requirement (Controller) 50 KVA |

Capacity

| Spindle Taper - |

Spindle Speed 15,000 |

Spindle Type Direct Drive |

| Mitsubishi Motor power(OPT) 11 / 42 kw |

Controller Fagor |

|

| Rapid Traverse Rate (Opt) 48 m/min |

Cutting Feed Rate 20 m/min |

Tool Nos. Capacity 32 |

Tools

| Maximum Tool Length 250 mm |

Tool Charging Timer 2.5 sec |

Maximum Tool Weight 7 Kg |

| Tool Diameter (with Adjacent Tool) 080 |

Tool Diameter (without Adjacent Tool) 0150 |

Accuracy

| Positioning Accuracy 0.01 mm |

Positioning Repeatability + 0.003 |

Angular Repeatability ( Rotary/Tilting) 6″ / 8″ |

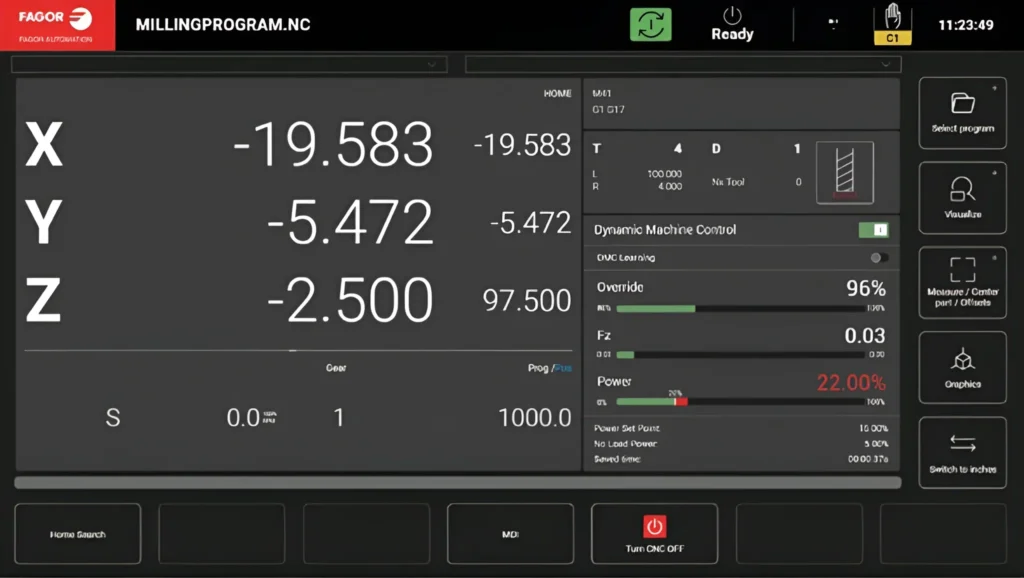

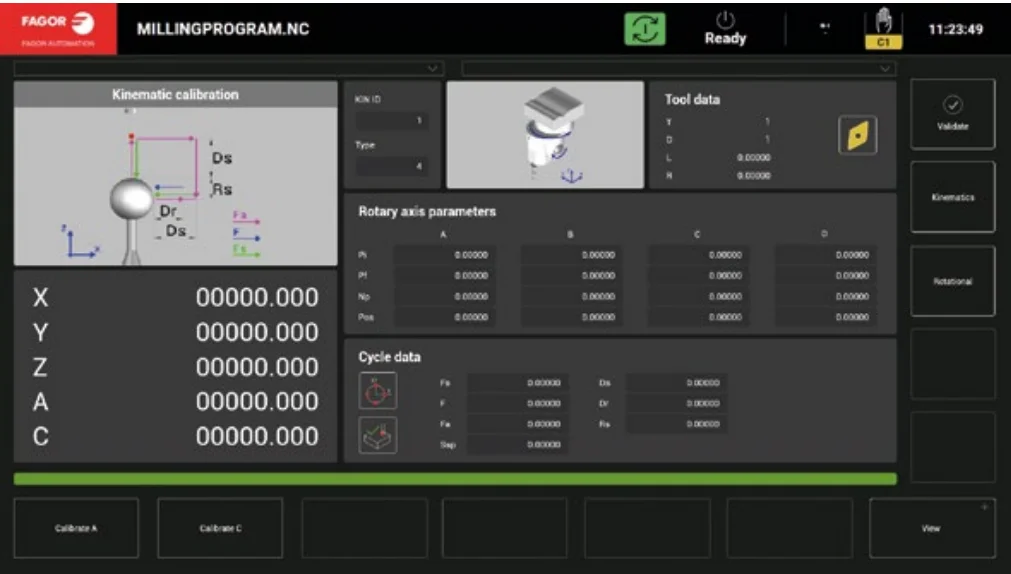

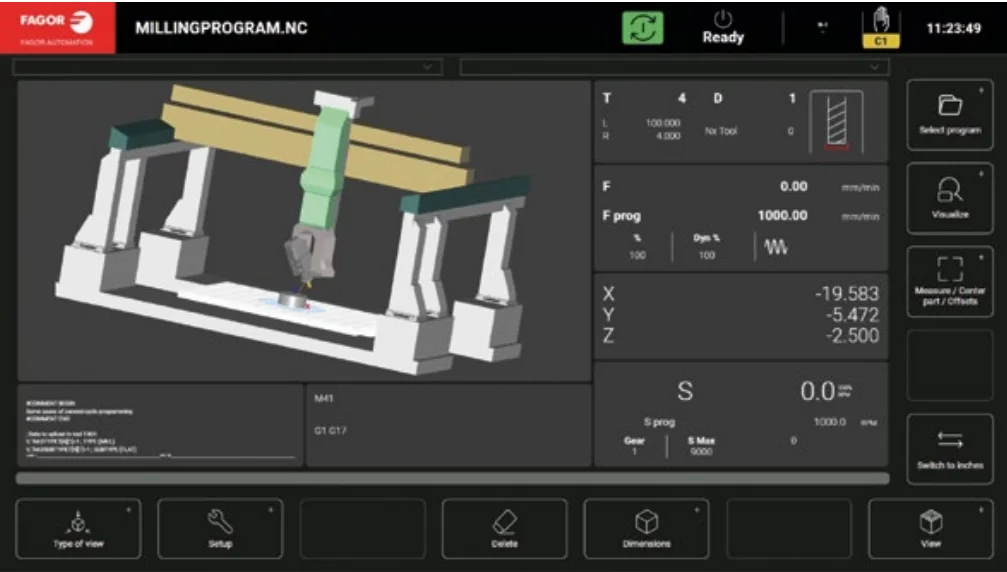

Automatic Kinematic Calibration

During the start-up of the machine or due to its continuous use or due to some incident, if recalibration is required, this controller can automatically do it.

HSSA (High Speed Surface Accuracy)

You can easily select the type of machining you want to obtain:

- As fast as possible (roughing)

- As accurate as possible

- The best surface quality

DMC (Dynamic Machining Control)

With this feature, the CNC automatically adapts the machining feed rate according to the tool force (load).

3+2 and 5-axis Machining

Library of kinematics. Work in inclined planes, 3+2,4+1 and continuous 5-axis RTCP machining.

Our Other Range of Excellence

High-tech Products For Unmatched Performance