Civil Aviation

The Makers Behind Machines That Reach the Sky

How we help Civil Aviation Industry

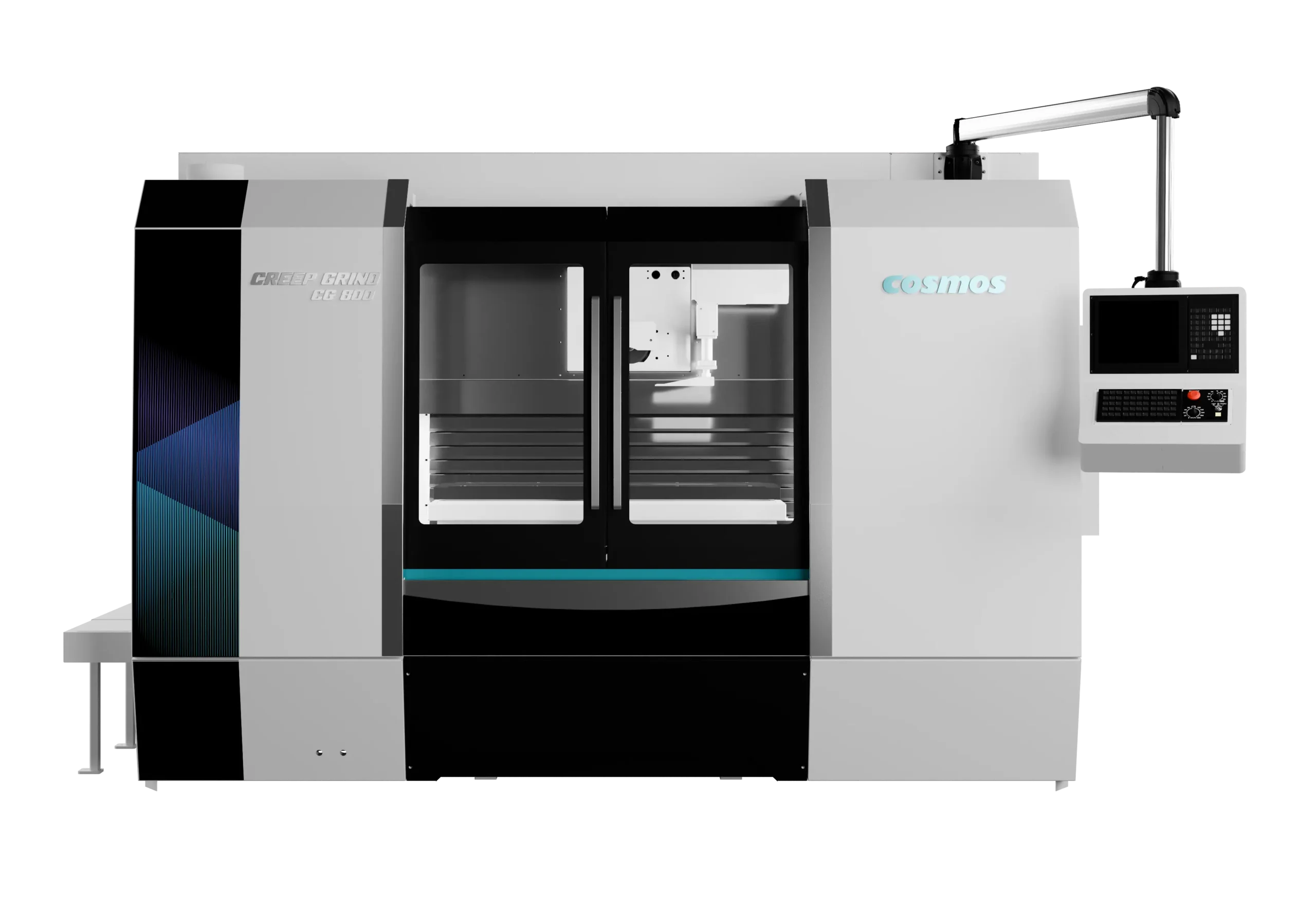

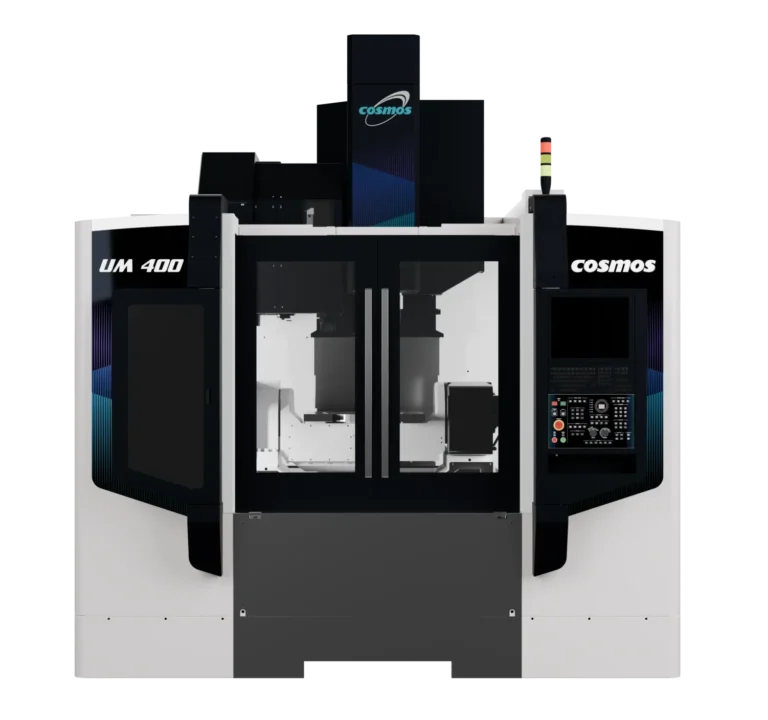

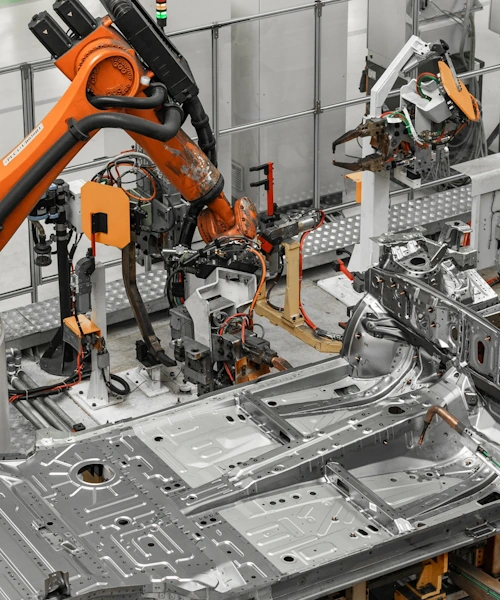

At Cosmos, we are the architects behind the machines that redefine flight. Our state-of-the-art CNC solutions deliver unmatched precision and durability, enabling Civil Aviation manufacturers to push technological boundaries. From aerostructures to propulsion systems, we engineer components that are lighter, stronger, and tailored to meet the rigorous demands of the industry. By driving advancements in efficiency and performance, we don’t just support Civil Aviation innovation—we help shape the future of the skies.

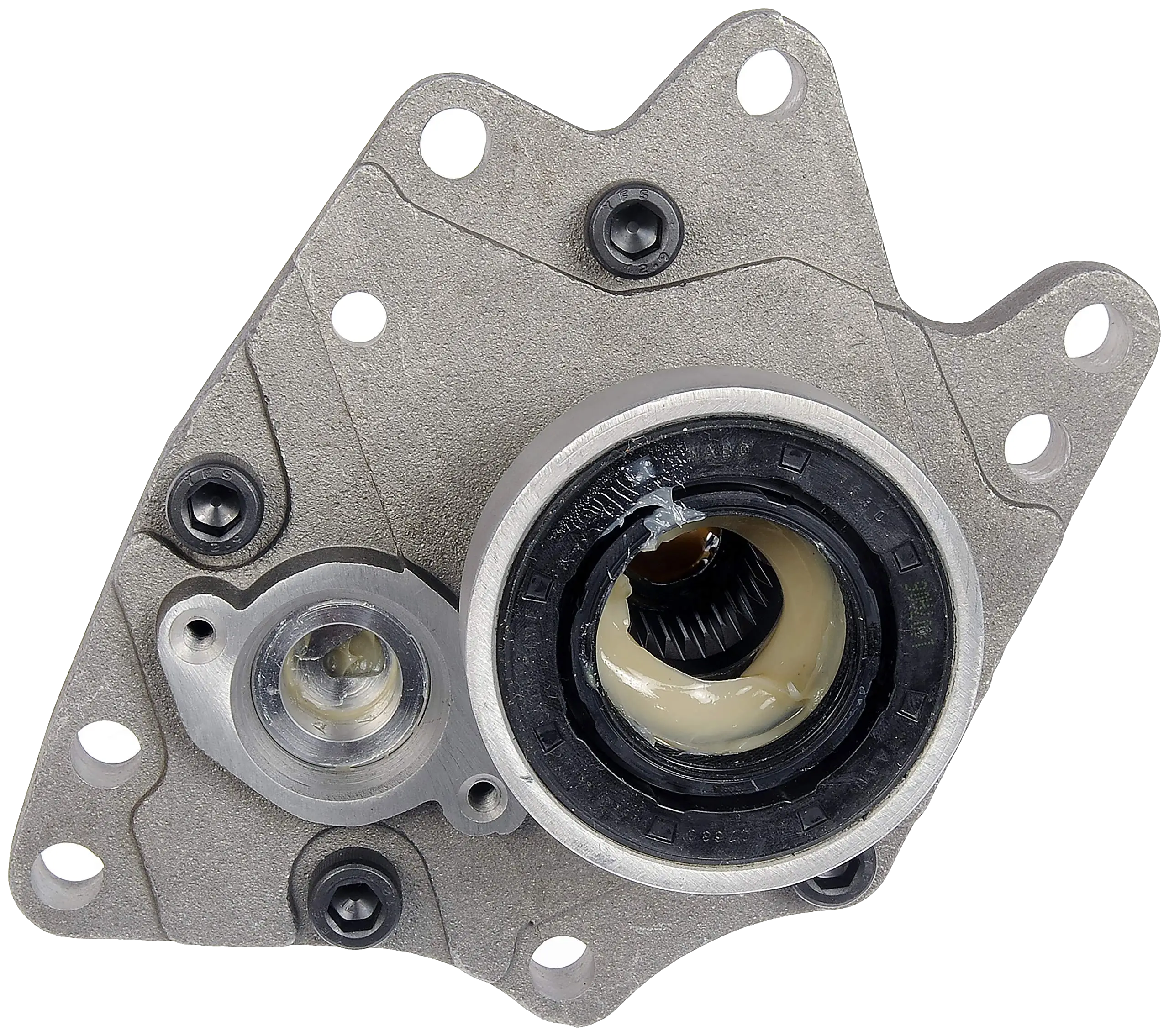

Actuator Housing

More Precision Components

Hydraulic Manifold

Steam

Turbine Blade

Applications Solutions for Civil Aviation Industry

Engine Components

In Civil Aviation, the complexity and precision required for engine components are unmatched. Turbine blades, compressor discs, and engine casings must withstand extreme stress and temperatures. Crafted from advanced materials, these components are engineered to deliver superior performance and fuel efficiency. With the precision of CNC machining, every part meets the stringent safety and performance standards, making these technologies crucial for the future of Civil Aviation engineering.

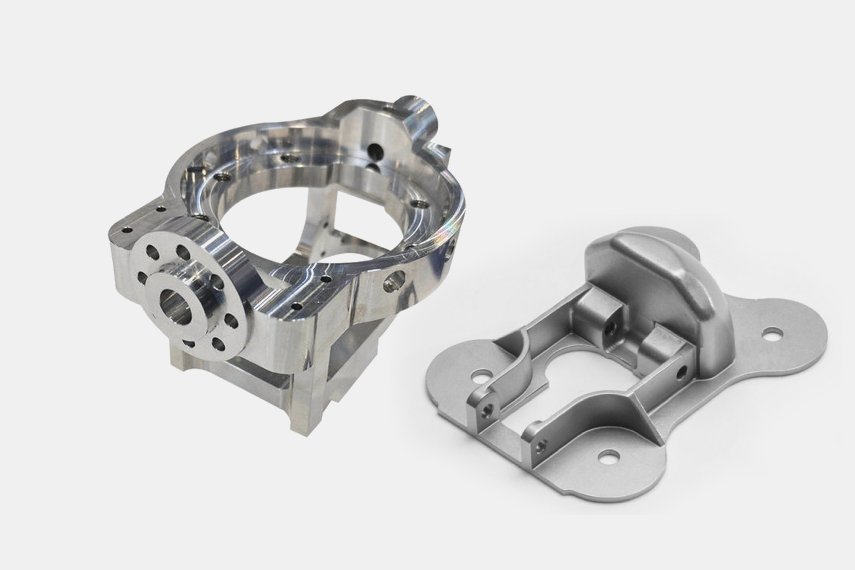

Structural Components

When it comes to the backbone of an aircraft, precision and strength are non-negotiable. Wing spars, fuselage frames, and bulkheads are meticulously crafted to ensure optimal performance in the sky. Using high-performance materials, these structural components undergo CNC machining for unmatched accuracy, enhancing both safety and longevity. Each part plays a key role in maintaining the structural integrity of aircraft, contributing to their overall efficiency and performance.

Avionics and Electronics Housings

Protecting the delicate electronics onboard an aircraft requires both strength and precision. Radar enclosures, instrument panels, and electrical system housings are designed to shield sensitive components from interference while withstanding extreme conditions. CNC machining ensures these intricate parts are flawlessly crafted, providing more than just protection. These housings are integral to ensuring avionics systems operate seamlessly, even in the most demanding Civil Aviation environments.

Interior and Cabin Components

Inside an aircraft, every detail matters—from the strength of the seat frames to the smooth operation of overhead bins and door hinges. These interior and cabin components are where engineering precision meets passenger comfort. Crafted with CNC machining, each part is designed for durability, safety, and lightweight efficiency, ensuring reliability at 35,000 feet. But it’s not just about functionality—these components shape the cabin experience, combining sleek design with uncompromising performance to create a space that’s both functional and invitin.

Miscellaneous Precision Parts

In the Civil Aviation industry, it’s the small, often overlooked components that make a world of difference. Miscellaneous precision parts like fasteners, connectors, bearings, and bushings are essential to the flawless operation of larger systems. CNC machining ensures these parts are made with the utmost accuracy, guaranteeing they fit perfectly and perform reliably under extreme conditions. Though small in size, these components are integral to the overall function and safety of Civil Aviation vehicles, proving that precision in every detail matters in keeping the skies safe.

Control helps connecting your operator & machine in a mutually beneficial bond. Now operators can utilize on board dashboards and tools to maximize your Profits.

Dashboard Monitoring

Program Transfer

Alarm Analysis

Tool Cutting Time Information

All-in-one-Dashboard

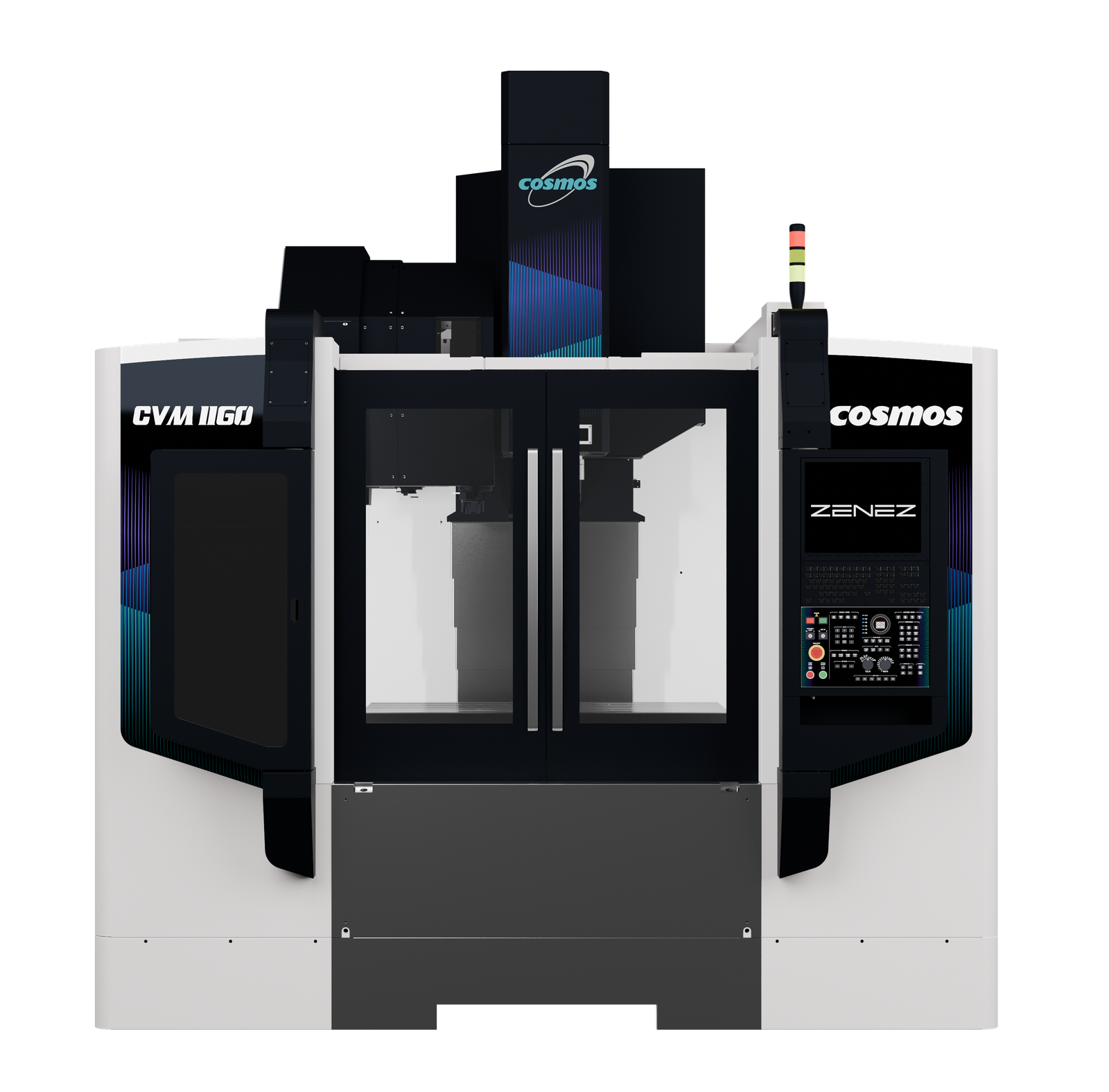

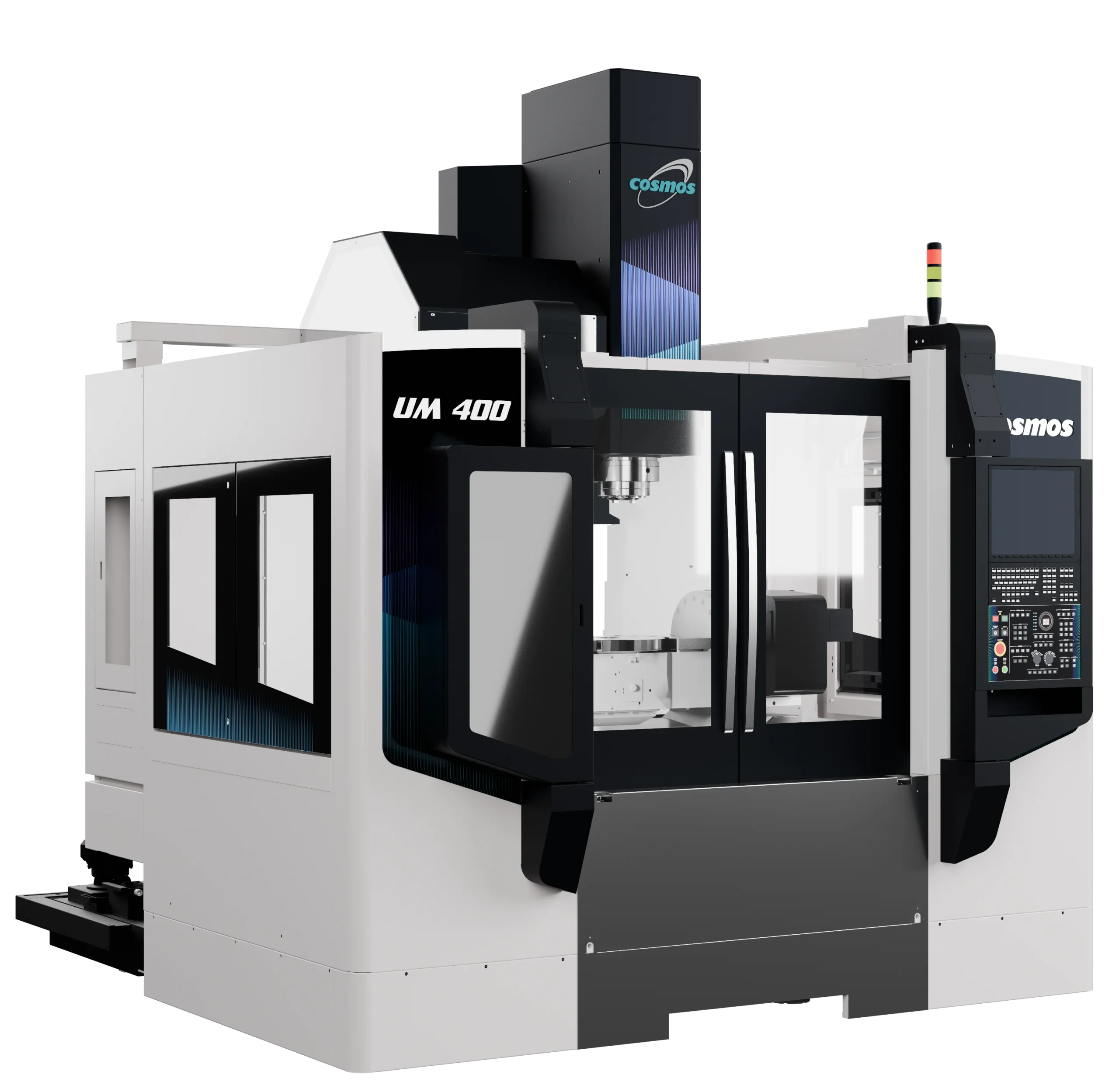

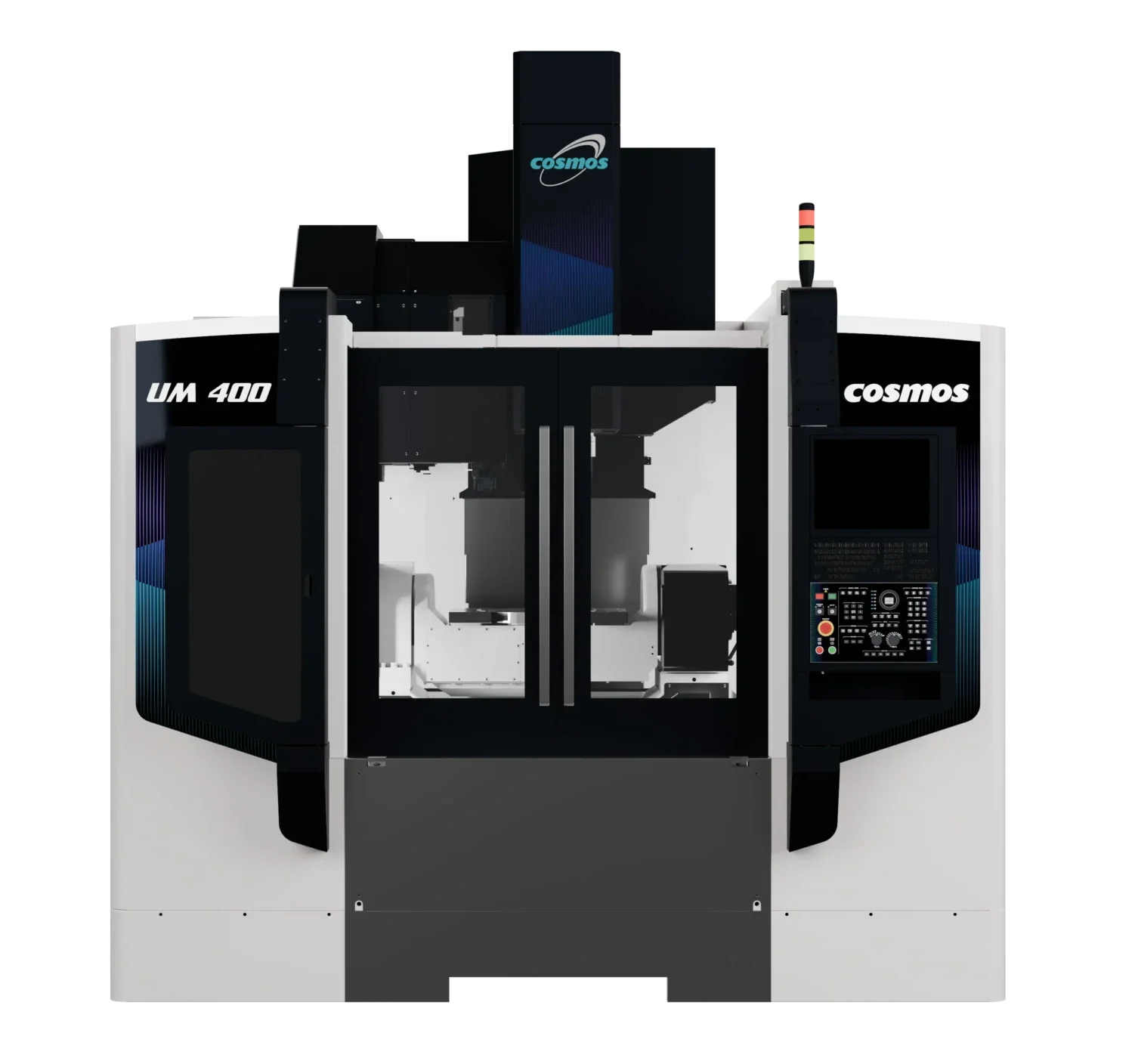

Product Information

Downtime Analysis

Email Alerts

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

FAQs

What role do CNC machines play in Civil Aviation manufacturing?

CNC machines are essential in the Civil Aviation industry for precision machining of critical components such as turbine blades, engine parts, and structural components, ensuring stringent tolerances and high-performance standards.

What is the typical lead time for Civil Aviation parts using CNC machines?

Lead times can vary depending on the complexity of the parts and batch size, but Cosmos delivers efficient production timelines while maintaining the highest standards of precision and quality.

How does Cosmos ensure the quality of CNC machines used in Civil Aviation applications?

Cosmos adheres to rigorous quality control standards, implementing advanced testing protocols, and using Civil Aviation-grade materials to deliver precision, durability, and reliability for demanding Civil Aviation applications.

Can Cosmos CNC machines handle both large and small batch production?

Yes, Cosmos CNC machines are versatile, capable of both high-volume and small-batch production, offering scalability to meet the unique needs of various industries.

Are Cosmos CNC machines customisable for specific requirements?

Cosmos offers customisation options to cater to specific production needs, ensuring that our machines meet the unique demands of our clients, whether in Civil Aviation or other industries.

Have a question about our products or services?

Submit Your Enquiry

Our team of experts is here to assist you. Fill out our quick enquiry form and let

us know how we can help you achieve progress.

For more information, write us at hrd3@cosmos.in

Navigate through other range of Industries

We serve many! Choose an option from below…

Die and Mould Industry

Read in detail about 'Your Partner in Progress' and its history

Medical Implants and Equipment Industry

Finding location or contact numbers to reach out?

Steel and Energy Industry

Engineering Strength and Sustainability in Steel and Energy

Electronics and Semiconductors Industry

Innovating the Next Generation of Electronics and Semiconductors