Die and Mould

Innovating Die and Mould for Superior Performance

How we help the Die and Mould Industry

At Cosmos, we’re fuelling the automotive industry's drive for innovation with cutting-edge CNC solutions that deliver precision and performance at every turn. Our advanced machines craft everything from high-performance engine parts to intricate transmission systems, ensuring every component meets the highest standards of safety, efficiency, and durability. Whether it’s reducing vehicle weight for better fuel efficiency or pushing the boundaries of design for electric and hybrid vehicles, we’re helping shape the future of mobility. With Cosmos, automotive manufacturers can turn bold ideas into reality, powered by precision and reliability.

EDM Electrodes

Forging Dies

Jigs and Fixtures

PET Moulds

Application Solutions for the Die and Mould Industry

Die Inserts and Components

Die inserts are the cornerstone of precision moulding and stamping processes. These intricate components are crafted to create highly detailed shapes and designs in metal and plastic. CNC machining ensures that every contour, groove, and surface finish is flawless, enabling die inserts to deliver consistent, high-quality results across large production runs.

Mould Cores and Cavities

The heart of any mould lies in its core and cavity, responsible for shaping the final product with absolute accuracy. CNC machining delivers unparalleled precision, ensuring perfect dimensions and a seamless fit. Whether for injection moulding, blow moulding, or compression moulding, these components are designed to handle the pressures of mass production while maintaining impeccable surface quality.

Mould Bases

Mould bases provide the structural foundation for the entire mould assembly. Precision-crafted using CNC technology, these components ensure proper alignment, stability, and durability during high-stress operations. With exceptional accuracy and material versatility, CNC-machined mould bases are built to endure the rigours of industrial use while enabling hassle-free setup and maintenance.

Electrodes for EDM

Electrodes are critical tools for Electric Discharge Machining (EDM), especially in crafting intricate details and hard-to-reach areas in dies and moulds. CNC machining enables the creation of electrodes with precise shapes and smooth finishes, ensuring optimal performance in EDM processes. This accuracy translates to improved efficiency and reduced lead times in die and mould production.

Jigs, Fixtures, and Tooling

Supporting components like jigs and fixtures play an essential role in maintaining precision and repeatability during die and mould operations. CNC machining delivers highly accurate and robust tooling solutions that streamline production, reduce downtime, and enhance overall efficiency. These tools are indispensable for achieving consistent quality in complex manufacturing environments.

Precision Components for Custom Applications

Every die and mould project has unique demands, requiring custom solutions. CNC machining excels at producing highly specialised components, from ejector pins to guide bushes and runner systems. These precision parts are tailored to meet specific operational requirements, delivering reliability and superior performance in the most demanding conditions.

Control helps connecting your operator & machine in a mutually beneficial bond. Now operators can utilize on board dashboards and tools to maximize your Profits.

Dashboard Monitoring

Program Transfer

Alarm Analysis

Tool Cutting Time Information

All-in-one-Dashboard

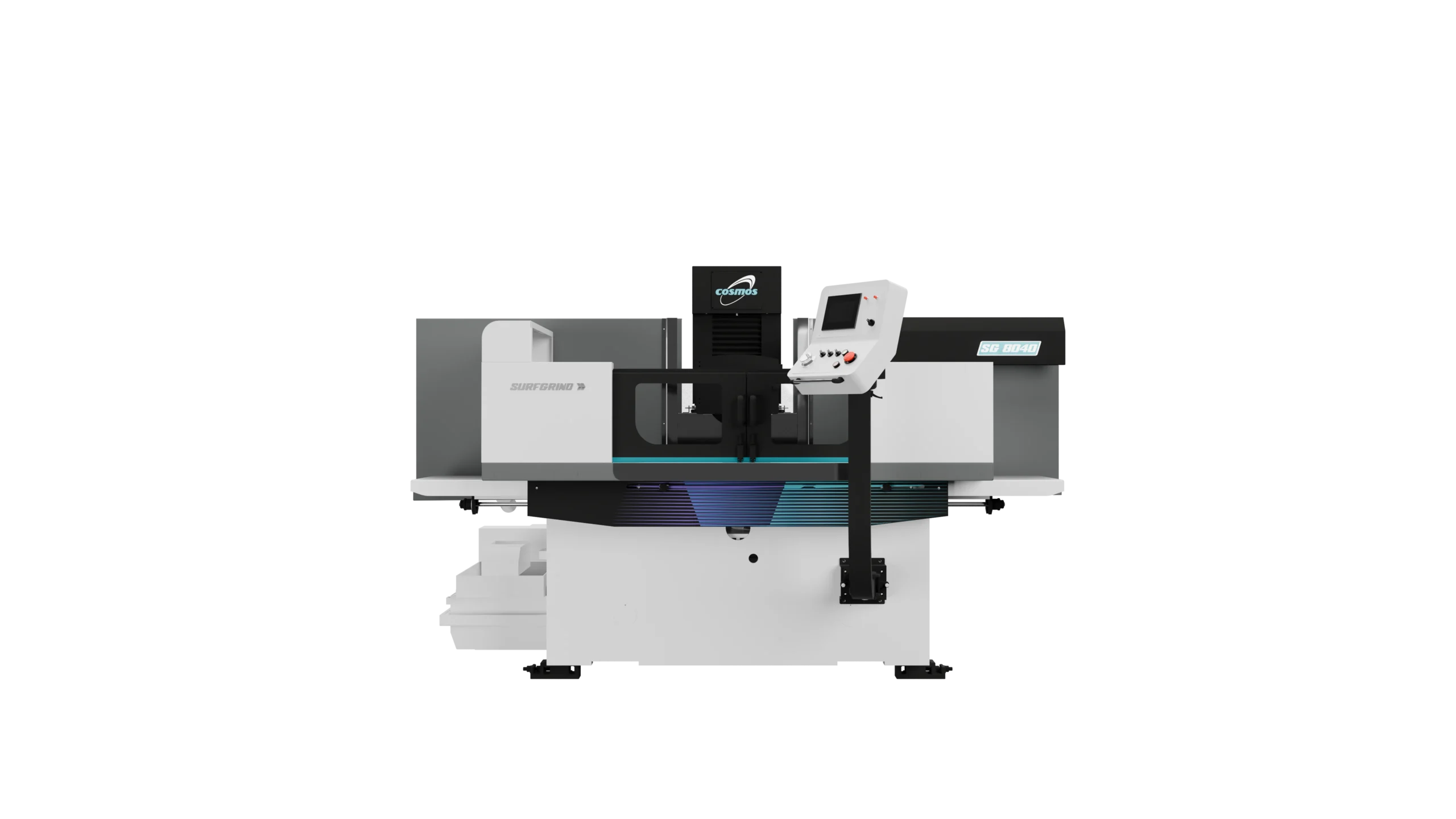

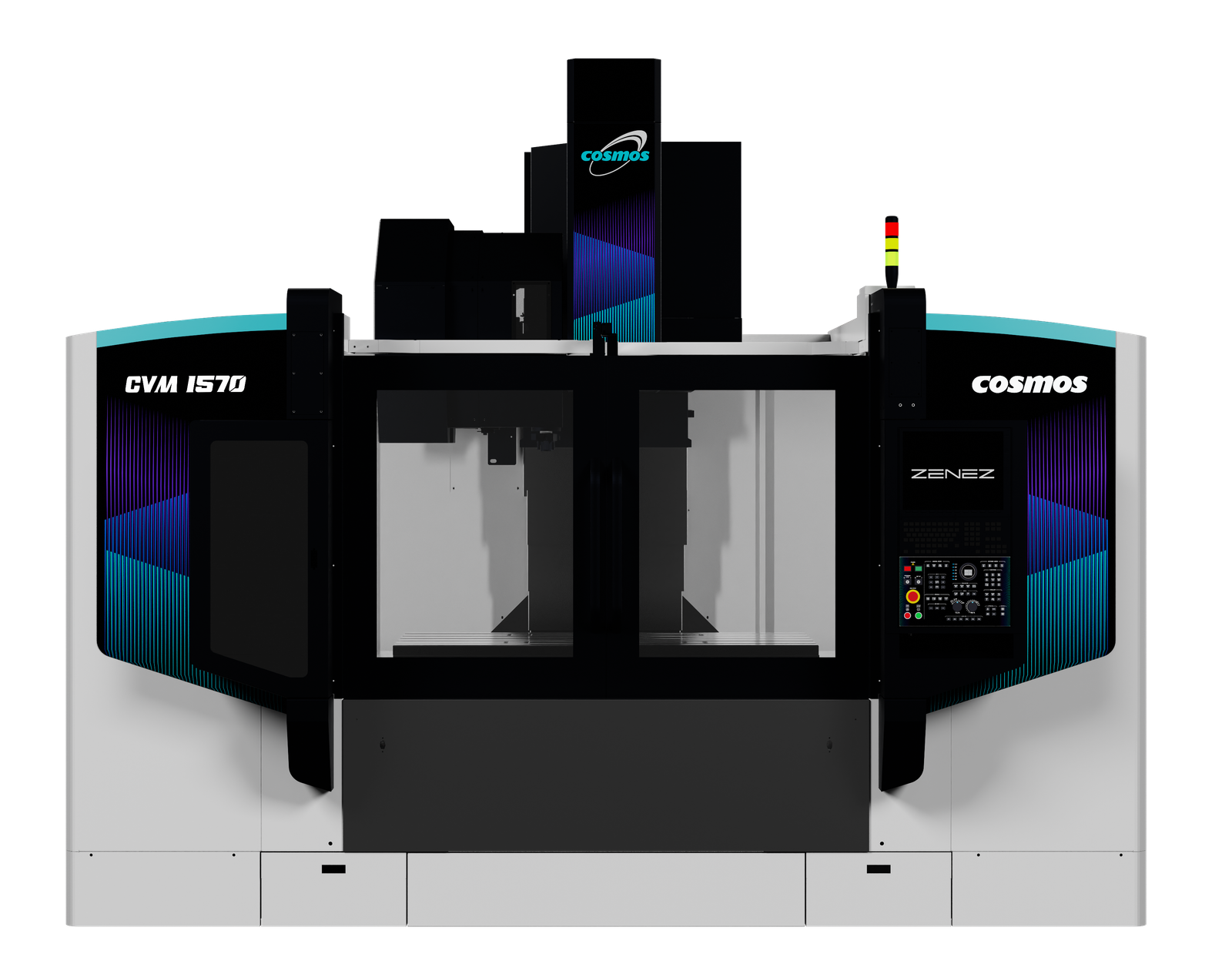

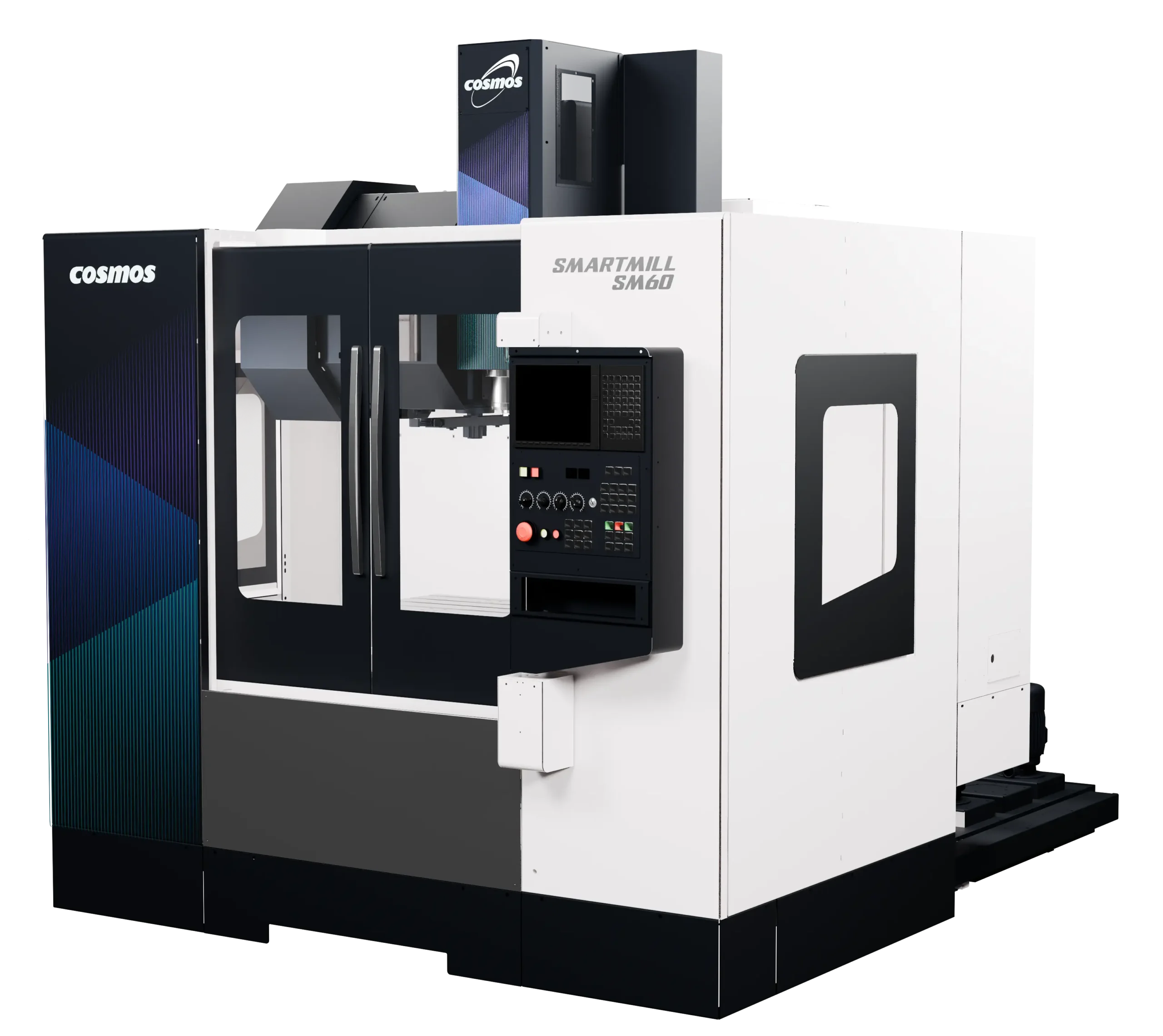

Product Information

Downtime Analysis

Email Alerts

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

FAQs

How are CNC machines used in the die and mould industry?

CNC machines are integral to the die and mould industry for creating precise mould cavities, punches, and complex die components with exceptional accuracy and repeatability.

Are Cosmos CNC machines customisable for die and mould applications?

Yes, Cosmos offers customisable solutions to meet the specific requirements of die and mould manufacturing, such as unique toolpaths, automation, and specialised fixturing.

What are the benefits of using Cosmos CNC machines in die and mould production?

Our CNC machines provide high precision, faster cycle times, reduced material wastage, and the ability to create complex designs, ensuring cost-effective and reliable manufacturing for the die and mould industry.

How does Cosmos ensure the durability of its CNC machines?

Cosmos uses robust engineering, premium-grade materials, and rigorous testing to ensure long-lasting performance and reliability in demanding manufacturing environments.

What industries benefit from Cosmos CNC machines?

Cosmos CNC machines cater to various industries, including die and mould, automotive, Civil Aviation, medical, electronics, and more, delivering precision solutions for each sector’s unique needs.

Have a question about our products or services?

Submit Your Enquiry

Our team of experts is here to assist you. Fill out our quick enquiry form and let

us know how we can help you achieve progress.

For more information, write us at hrd3@cosmos.in