Steel and Energy

Engineering Strength and Sustainability in Steel and Energy

How we help the Steel and Energy Industry

At Cosmos, we’re shaping the future of steel and energy with precision CNC solutions that fuel innovation and efficiency. Our advanced machines craft durable, high-performance components that power everything from steel production to renewable energy systems. Whether it’s enhancing the strength of steel or driving the next wave of energy solutions, Cosmos is helping businesses stay ahead of the curve. With cutting-edge technology at the heart of everything we do, we’re energising industries and paving the way for a sustainable tomorrow.

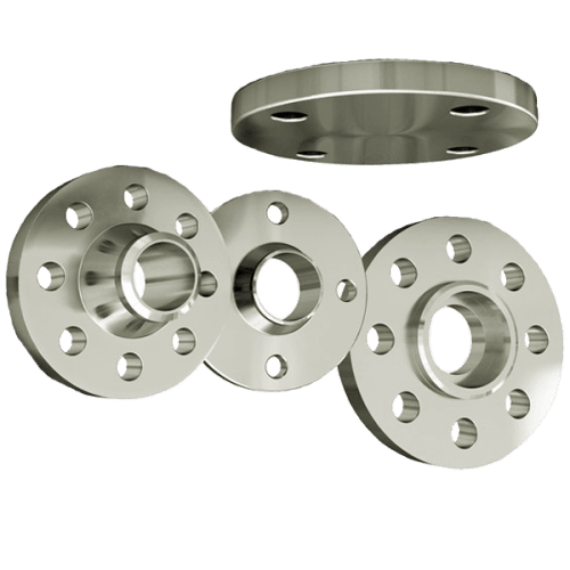

Flanges

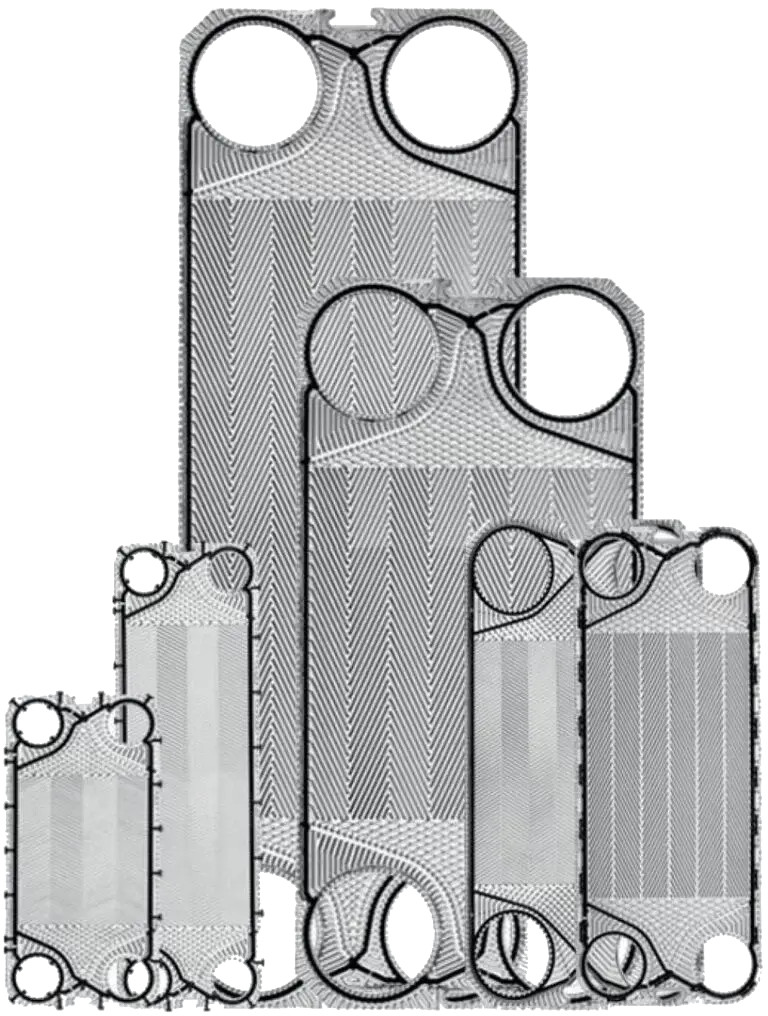

Heat

Exchanger Plates

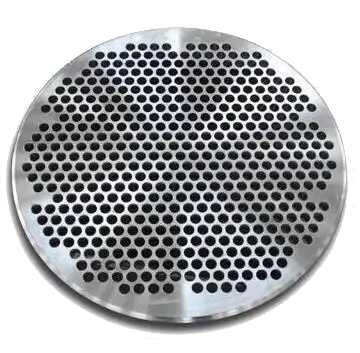

Tube Sheet.avif

Manifold

Application Solutions for the Steel and Energy Industry

Steel Plant Equipment

In the steel industry, durability and precision are paramount. From rolling mill rolls to continuous casting components, CNC machining ensures each part meets the rigorous demands of high-temperature and high-pressure operations. By delivering perfect dimensions and superior surface finishes, CNC-crafted components enhance production efficiency, reduce downtime, and extend the lifespan of equipment used in steel manufacturing.

Boiler and Heat Exchanger Components

Boilers and heat exchangers are integral to energy production, requiring components that can withstand extreme temperatures and pressures. CNC machining enables the creation of precisely engineered parts like tubesheets, headers, and baffles, ensuring optimal heat transfer and system reliability. With tight tolerances and robust materials, these components meet the demanding requirements of power plants and industrial heating systems.

Turbine Components

Turbines are the heartbeat of power generation, whether in gas, steam, or wind energy systems. CNC machining delivers precision-engineered blades, rotors, and casings that ensure maximum efficiency and long-term performance. By achieving perfect aerodynamic shapes and flawless finishes, CNC technology enhances turbine reliability, reducing energy loss and maintenance costs.

Flanges and Pipe Fittings

Flanges and pipe fittings are critical in transporting fluids and gases in steel and energy applications. CNC machining ensures these components are manufactured to exact specifications, providing leak-proof connections and exceptional durability. Whether it’s for pipelines, refineries, or power plants, precision-engineered flanges and fittings ensure system integrity and safety.

Hydraulic and Pneumatic Components

Steel and energy industries rely on hydraulic and pneumatic systems for smooth and efficient operations. CNC machining creates critical parts like pistons, cylinders, and valves with high precision, ensuring consistent performance under demanding conditions. These components play a key role in controlling energy flow and supporting heavy-duty machinery.

Gear and Drive Components

From conveyor systems in steel plants to drives in energy production facilities, gears and shafts are the unsung heroes of industrial efficiency. CNC machining ensures these components are crafted with exceptional precision, guaranteeing smooth power transmission and minimal wear. By reducing friction and maximising durability, CNC technology keeps operations running seamlessly.

Structural Components for Energy Infrastructure

The backbone of energy infrastructure lies in its structural components. CNC machining delivers precision-crafted parts for wind turbine towers, solar panel mounting systems, and power plant frameworks. These components are designed to endure harsh environmental conditions, ensuring stability, longevity, and reliable performance across diverse energy applications.

Machines for Automotive

SM 60 + APC

Vertical Machining Centres

Automill 80

Auto Tending Machining Centres

YCL 1000

Vertical Turning Lathes

TM 700

High Speed Tapping Centres

CVM 1365

Vertical Machining Centres

SM 60

Compact Vertical Machining Centres

Control helps connecting your operator & machine in a mutually beneficial bond. Now operators can utilize on board dashboards and tools to maximize your Profits.

Dashboard Monitoring

Program Transfer

Alarm Analysis

Tool Cutting Time Information

All-in-one-Dashboard

Product Information

Downtime Analysis

Email Alerts

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

FAQs

How are CNC machines used in the steel and energy sectors?

CNC machines are essential in the steel and energy industries for manufacturing high-precision components like turbine blades, pipelines, flanges, and structural steel parts with consistent accuracy.

How does Cosmos ensure durability in CNC machines for heavy-duty applications?

Cosmos uses advanced engineering, wear-resistant components, and high-torque spindles to ensure machines withstand the rigorous demands of steel and energy applications.

Are Cosmos CNC machines capable of machining components for renewable energy projects?

Yes, Cosmos CNC machines support renewable energy sectors by manufacturing precision parts for wind, solar, and hydroelectric energy projects with exceptional quality and efficiency.

Can Cosmos CNC machines help improve production efficiency in steel and energy manufacturing?

Absolutely. Cosmos CNC machines optimize workflows with high-speed machining, multi-axis capabilities, and automation, significantly reducing lead times and boosting efficiency.

How do Cosmos CNC machines contribute to sustainability in energy manufacturing?

Cosmos CNC machines enhance sustainability by minimising material waste, enabling efficient energy use, and supporting the production of components for green energy projects.

Have a question about our products or services?

Submit Your Enquiry

Our team of experts is here to assist you. Fill out our quick enquiry form and let

us know how we can help you achieve progress.

For more information, write us at hrd3@cosmos.in