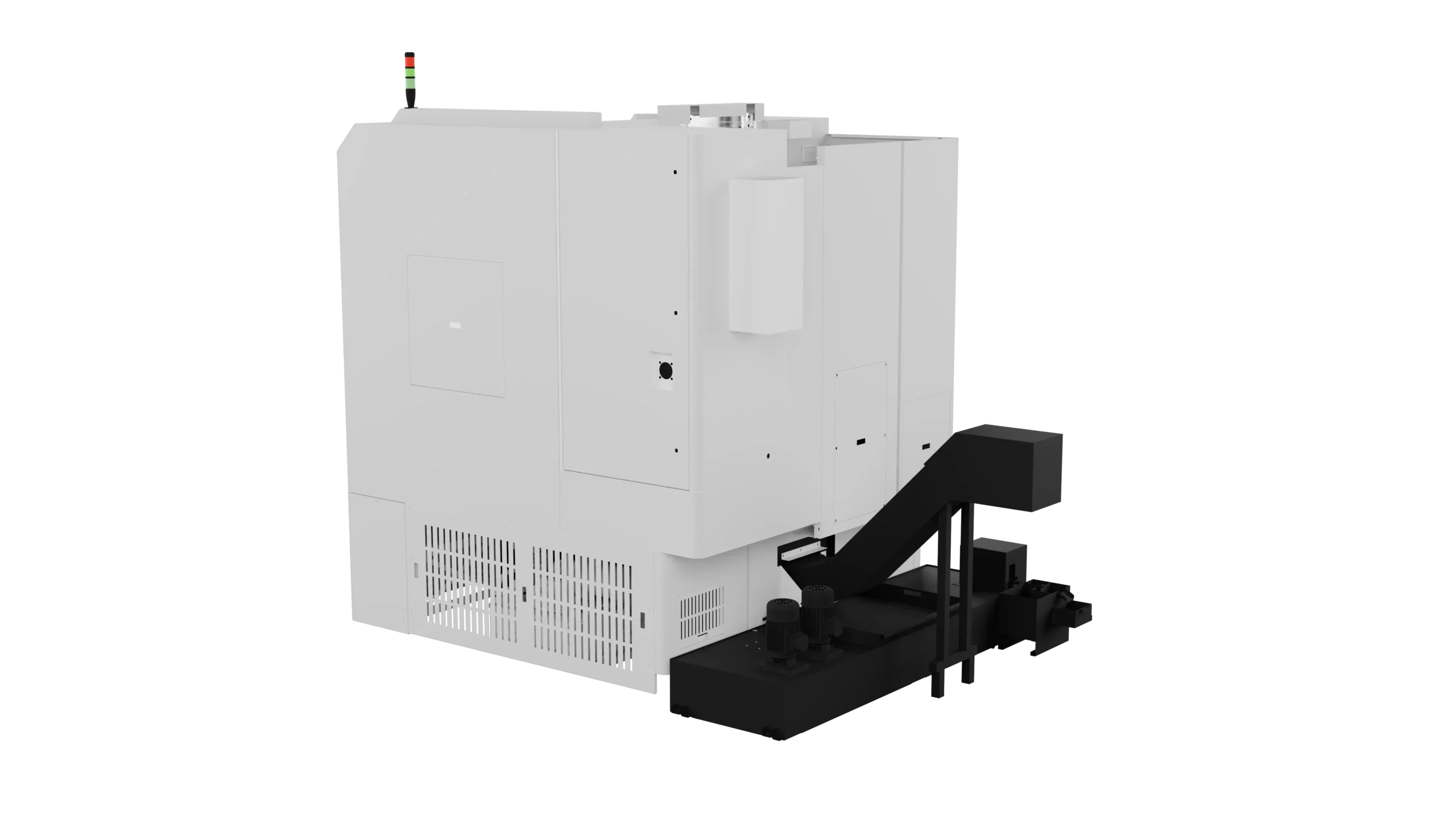

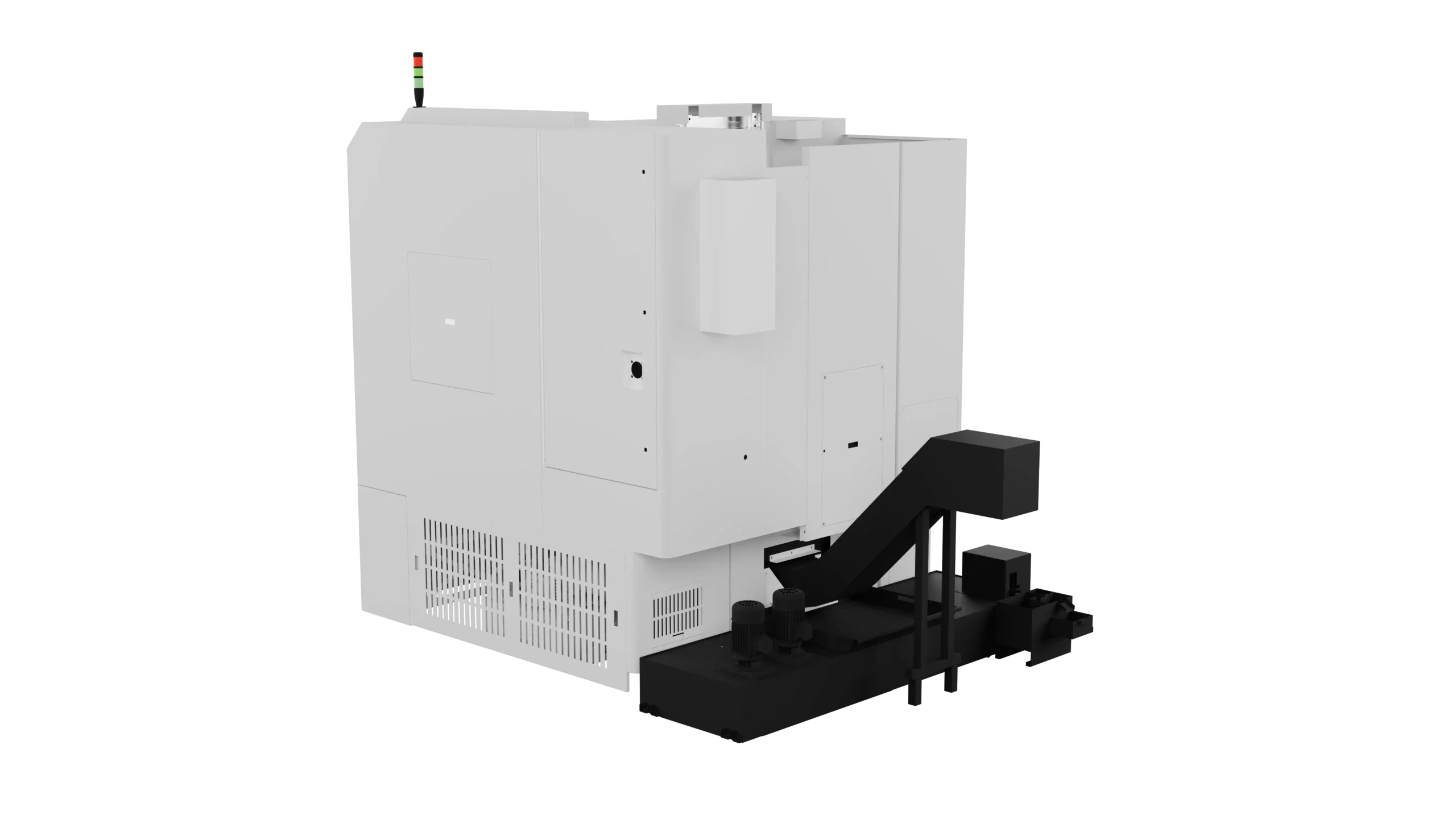

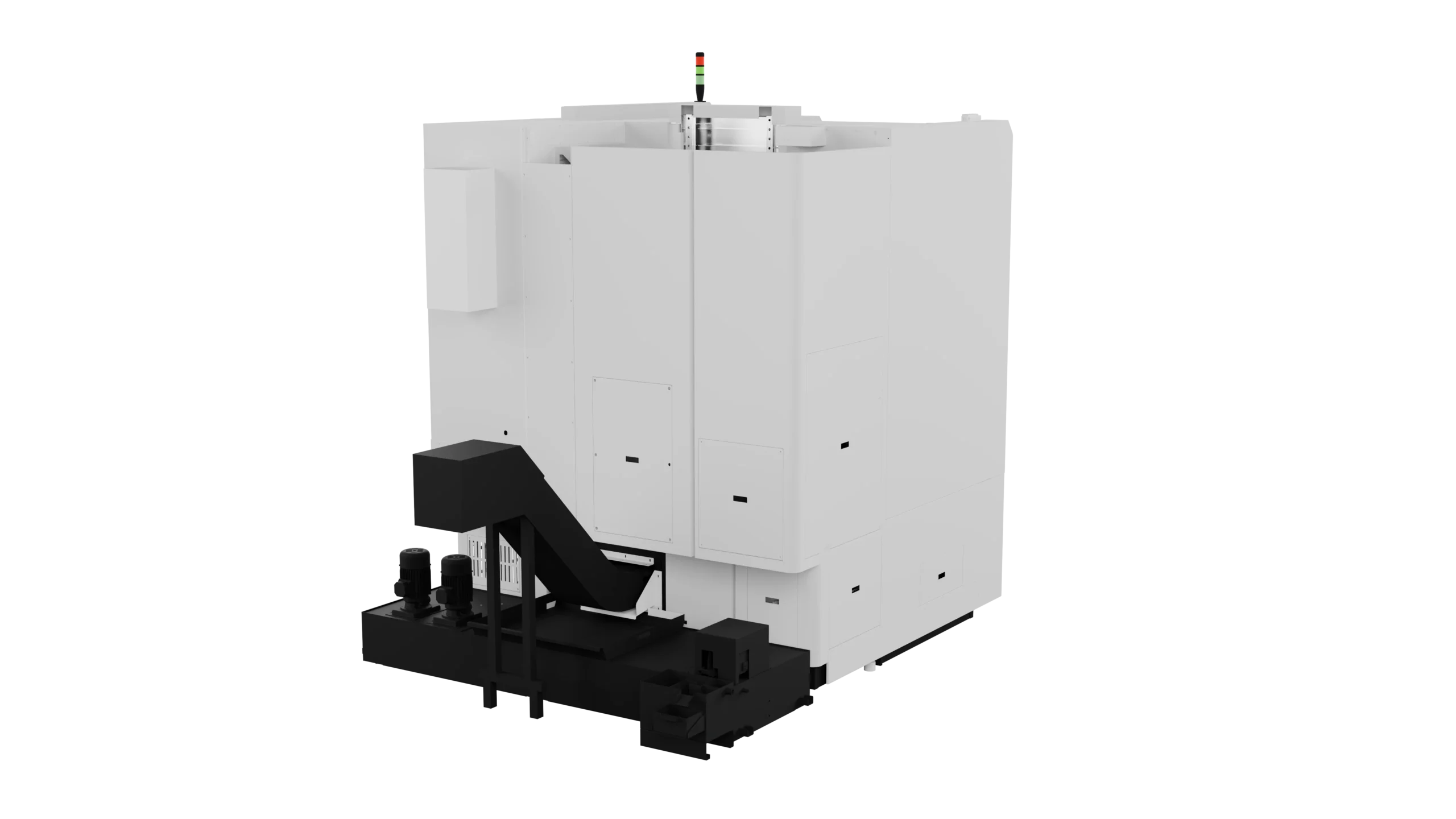

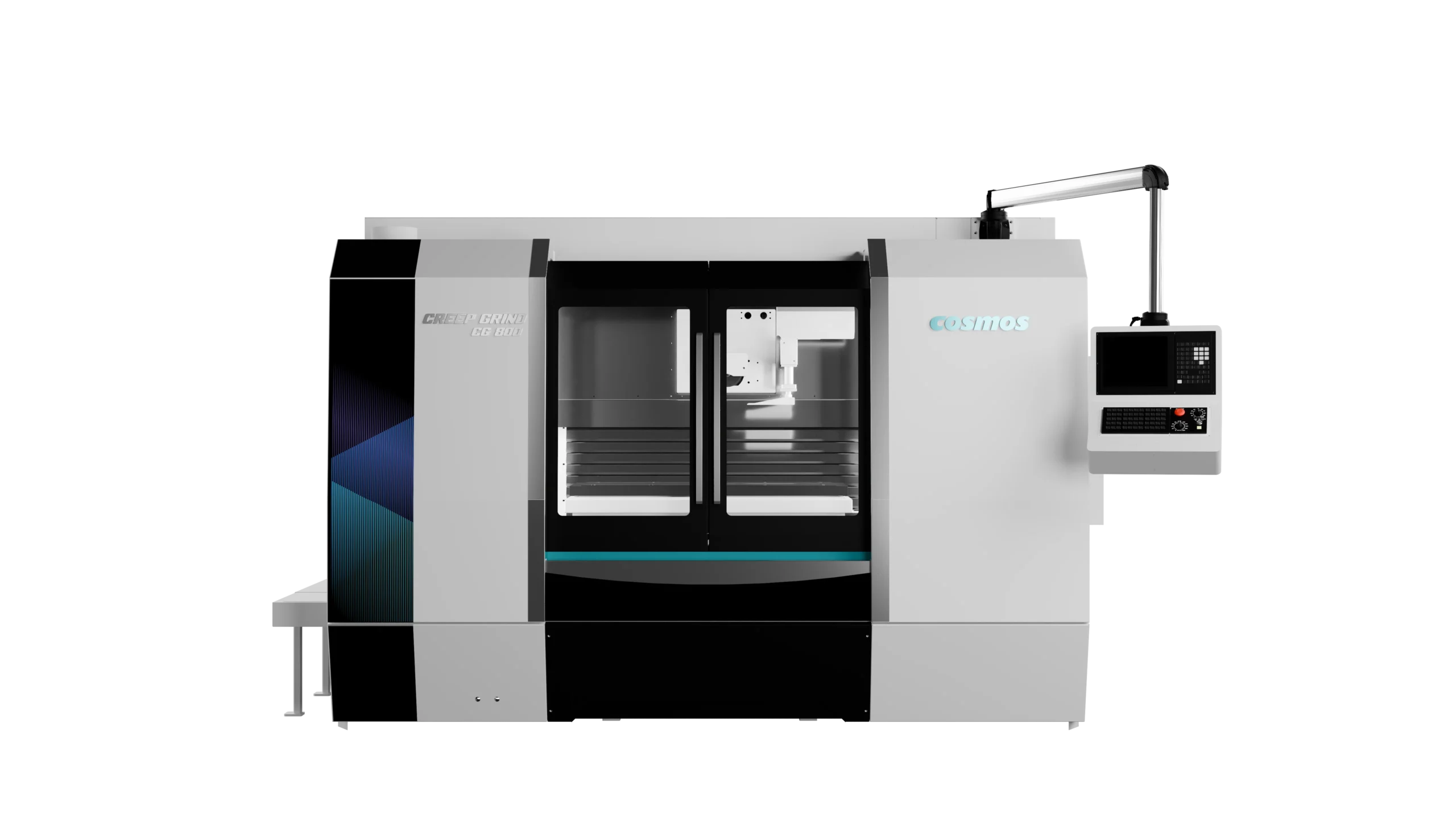

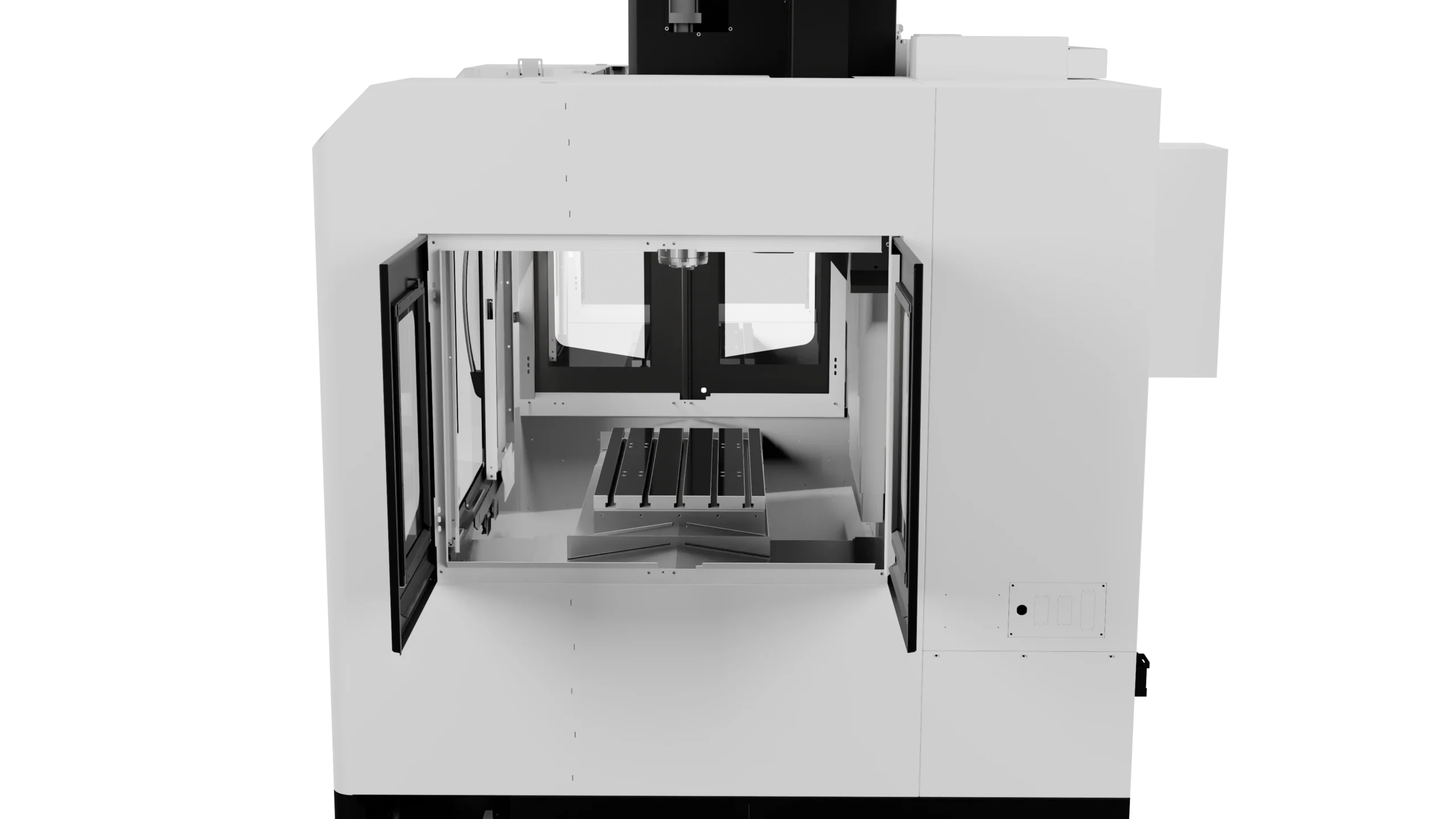

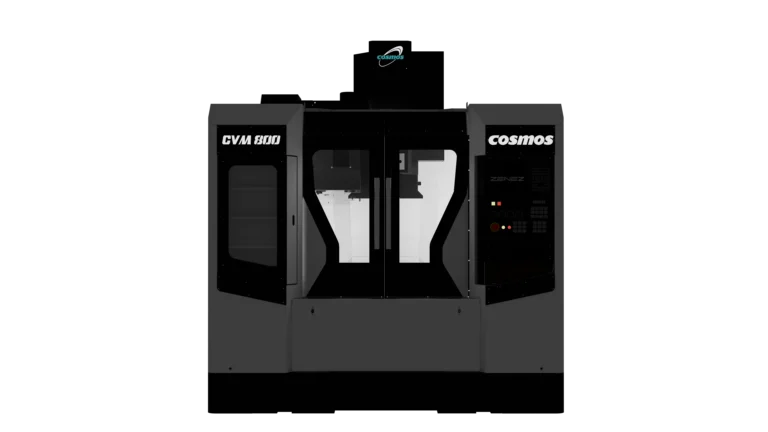

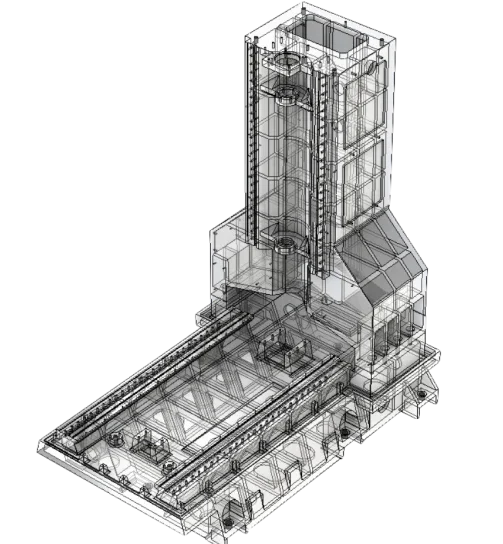

Machine Overview

The YCL series feature robustly designed structure. The transmission includes rigid roller guideways and C3 class precision ball screws. The extremely rigid Hydraulic Turrets provide ultimate stability to ensure heavy cutting and obtain best surface finish.

Backed by over 40 years of manufacturing expertise from our collaborators, the machines deliver reliability and exceptional performance.

Illuminated Design

All our machines are with LED lamps to create a well-lit working environment, ensuring optimal visibility and ease of operation. Built for durability and minimal maintenance.

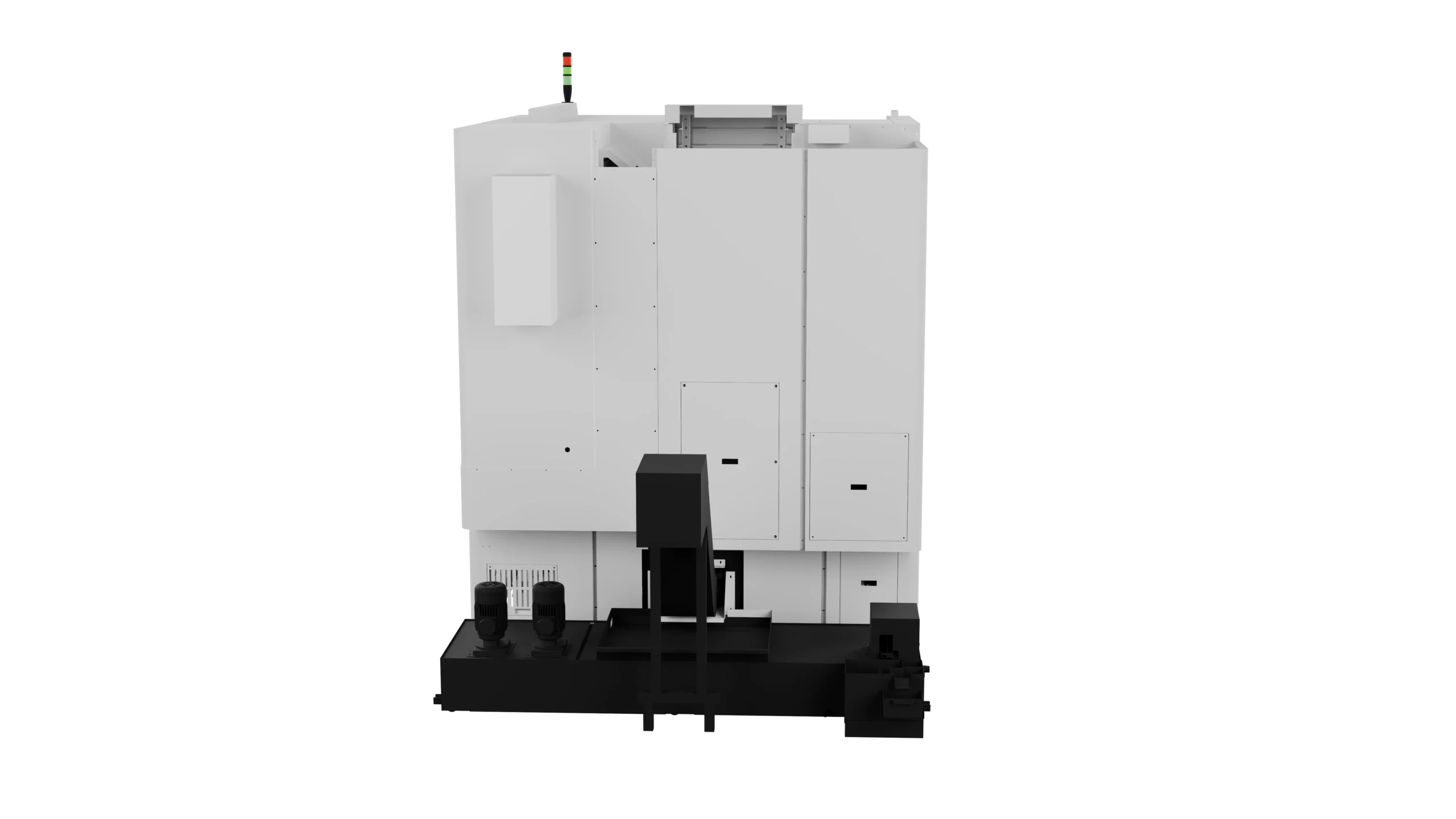

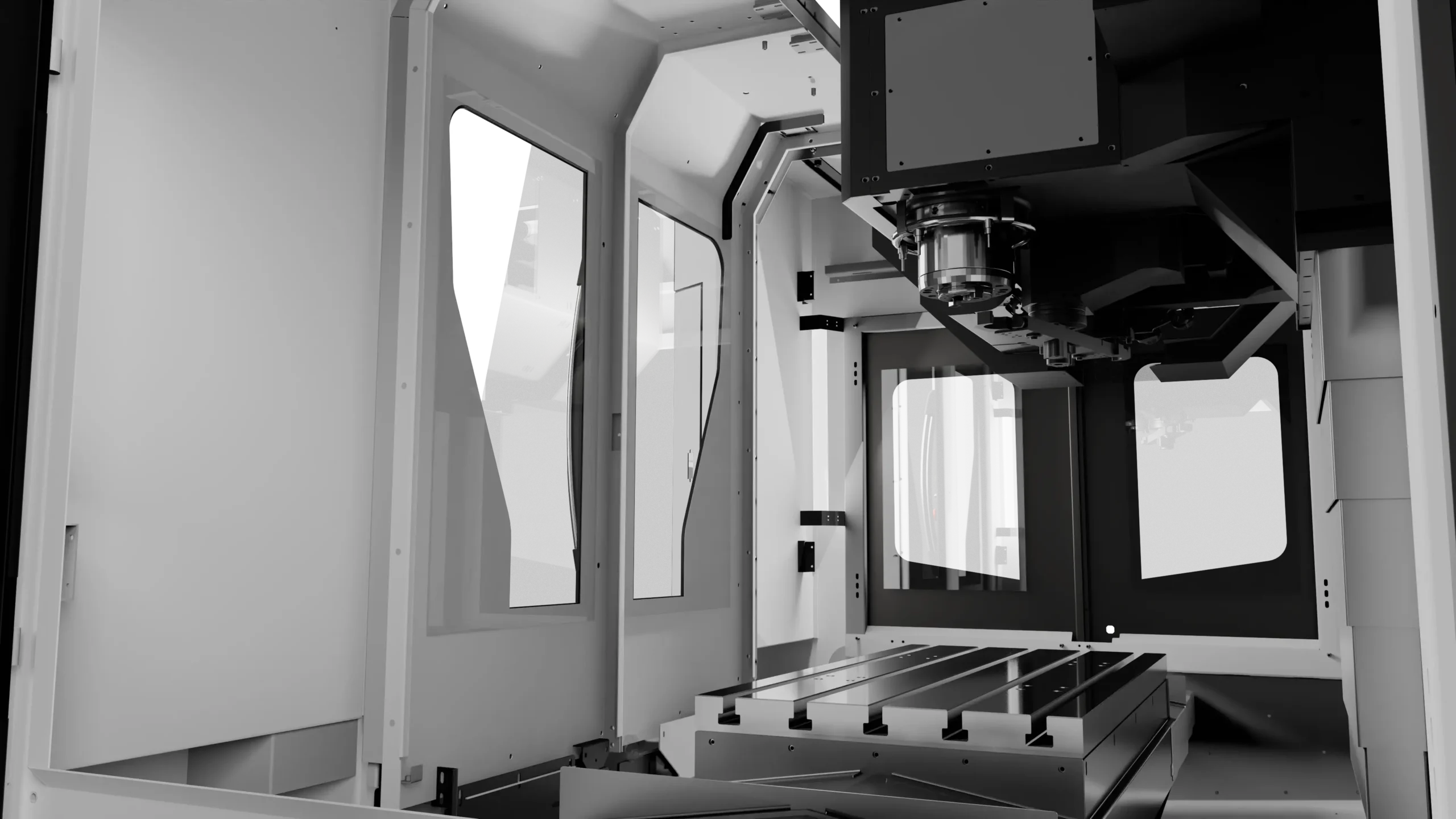

Easy Access Maintenance

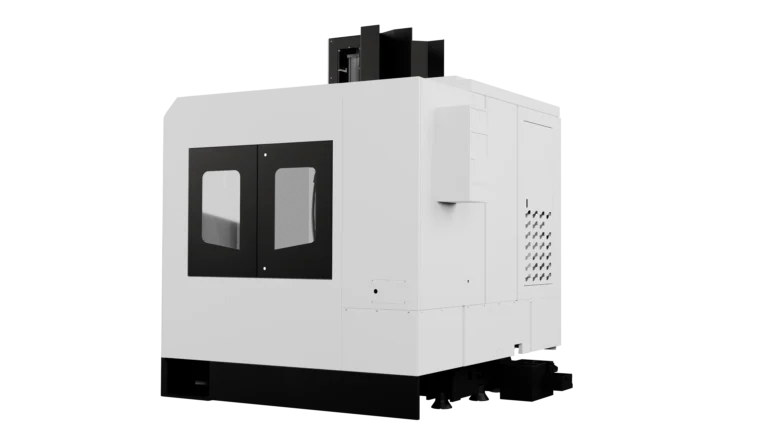

We’ve improved machine manageability with easy access windows to essential peripherals, streamlining maintenance and ensuring efficient operation.

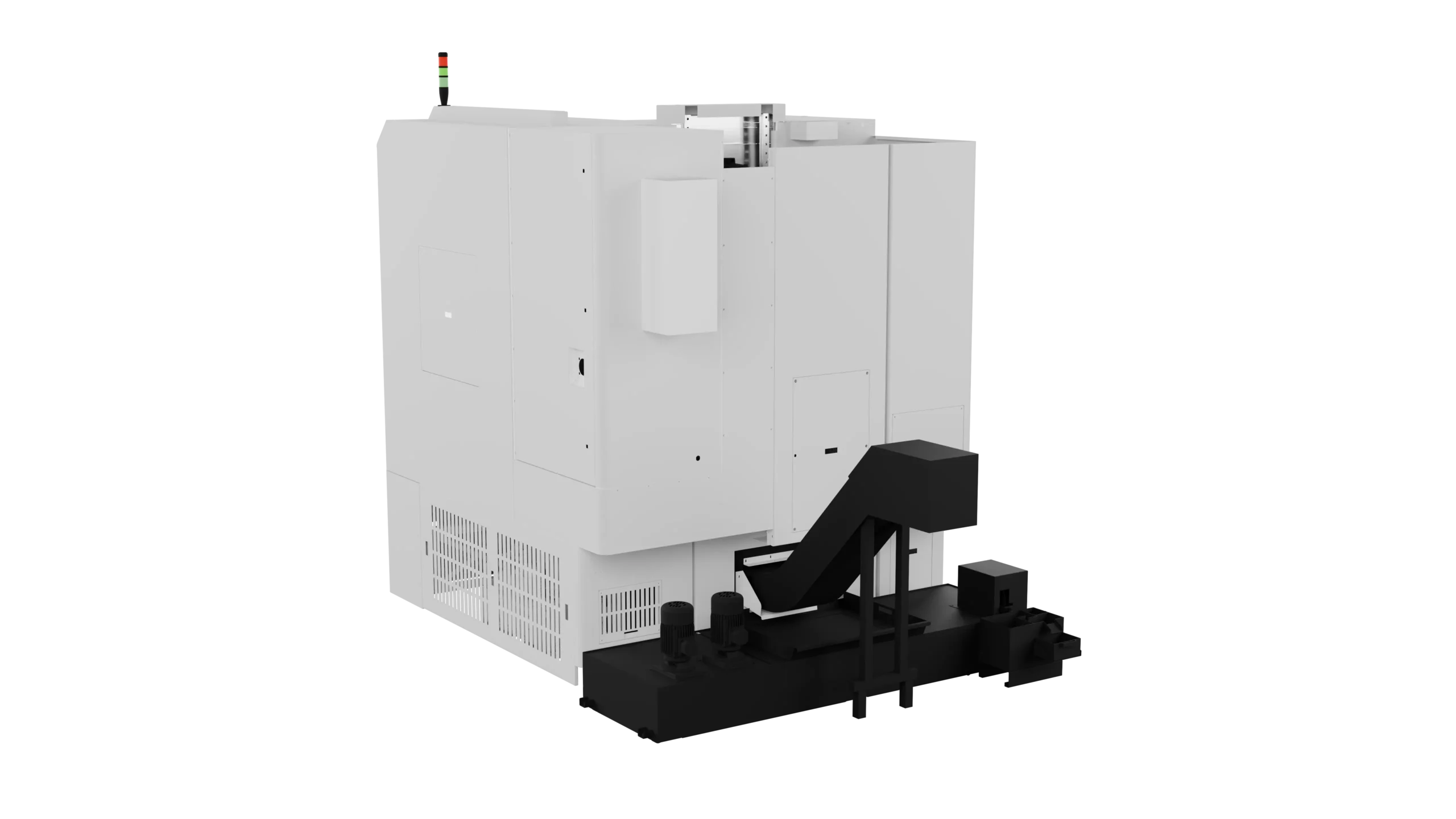

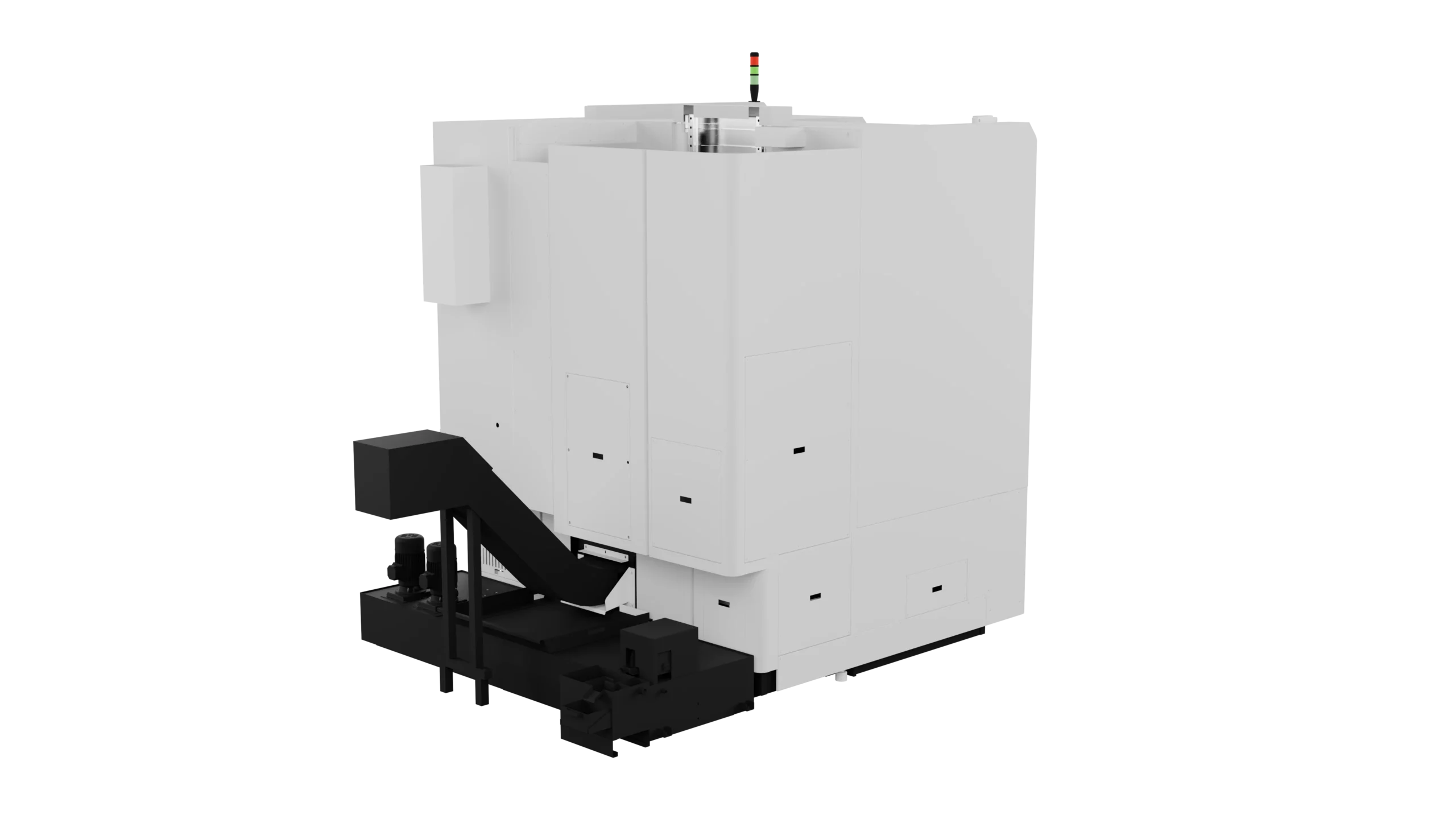

Excellent Chip Disposal

The machines feature steeply slanted telescopic sliding covers that excel in chip disposal performance, keeping your workspace clean and ensuring uninterrupted machining.

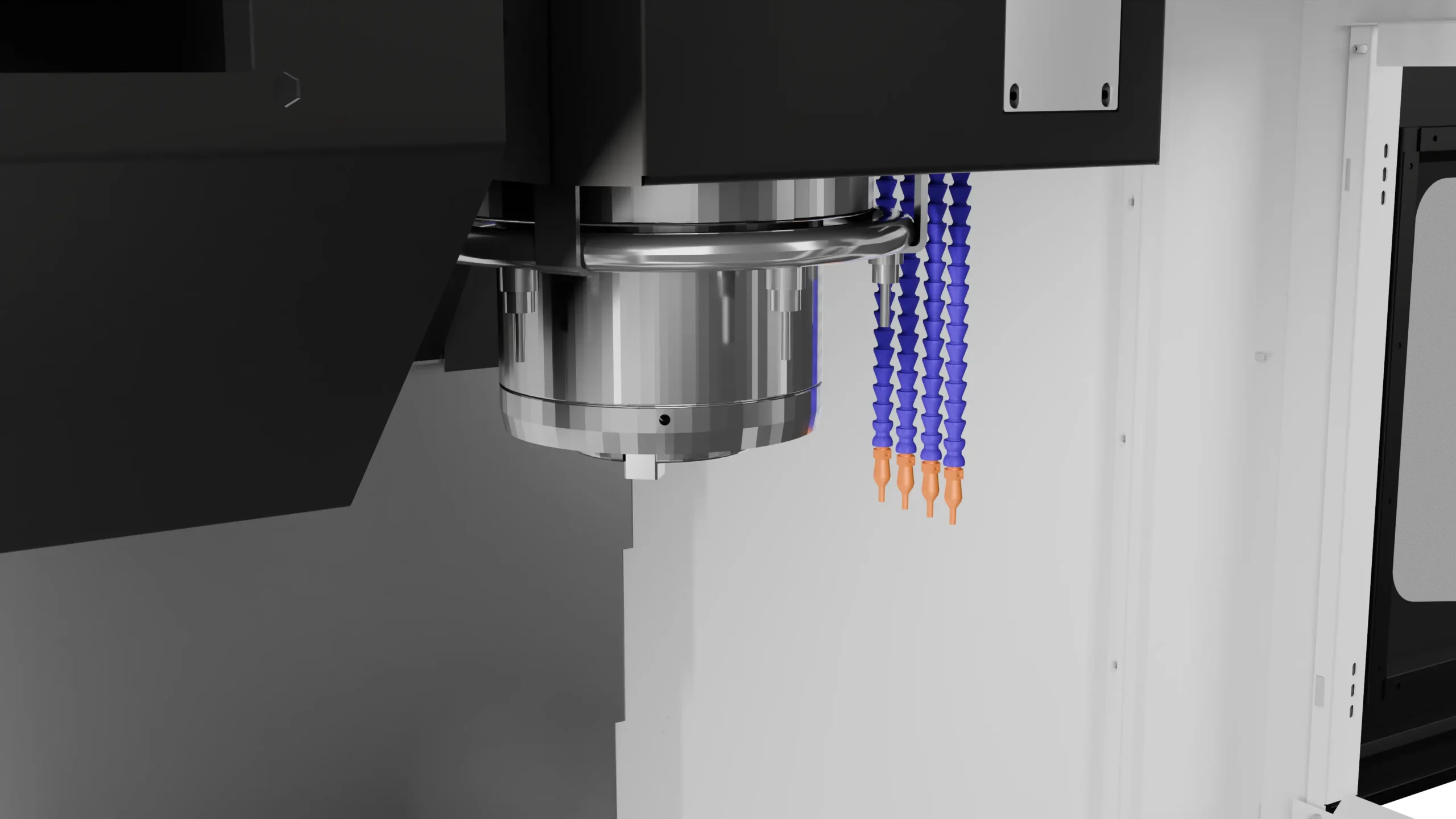

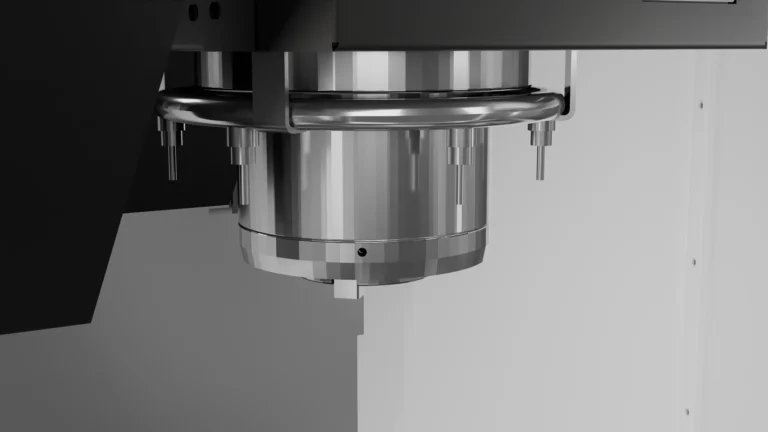

Ring Coolant

Our ring coolant nozzles, strategically positioned around the spindle, deliver coolant to the cutting area, ensuring performance, efficient heat dissipation, and an optimal machining experience.

Additional Features

STAINLESS STEEL SILL

PROTECTOR

BIG DUAL

SIDE WINDOWS

Fully Enclosed

Guarding

Inbuilt Tool

Stronge Cabinet

1 Air and 3 Coolant

Nozzles

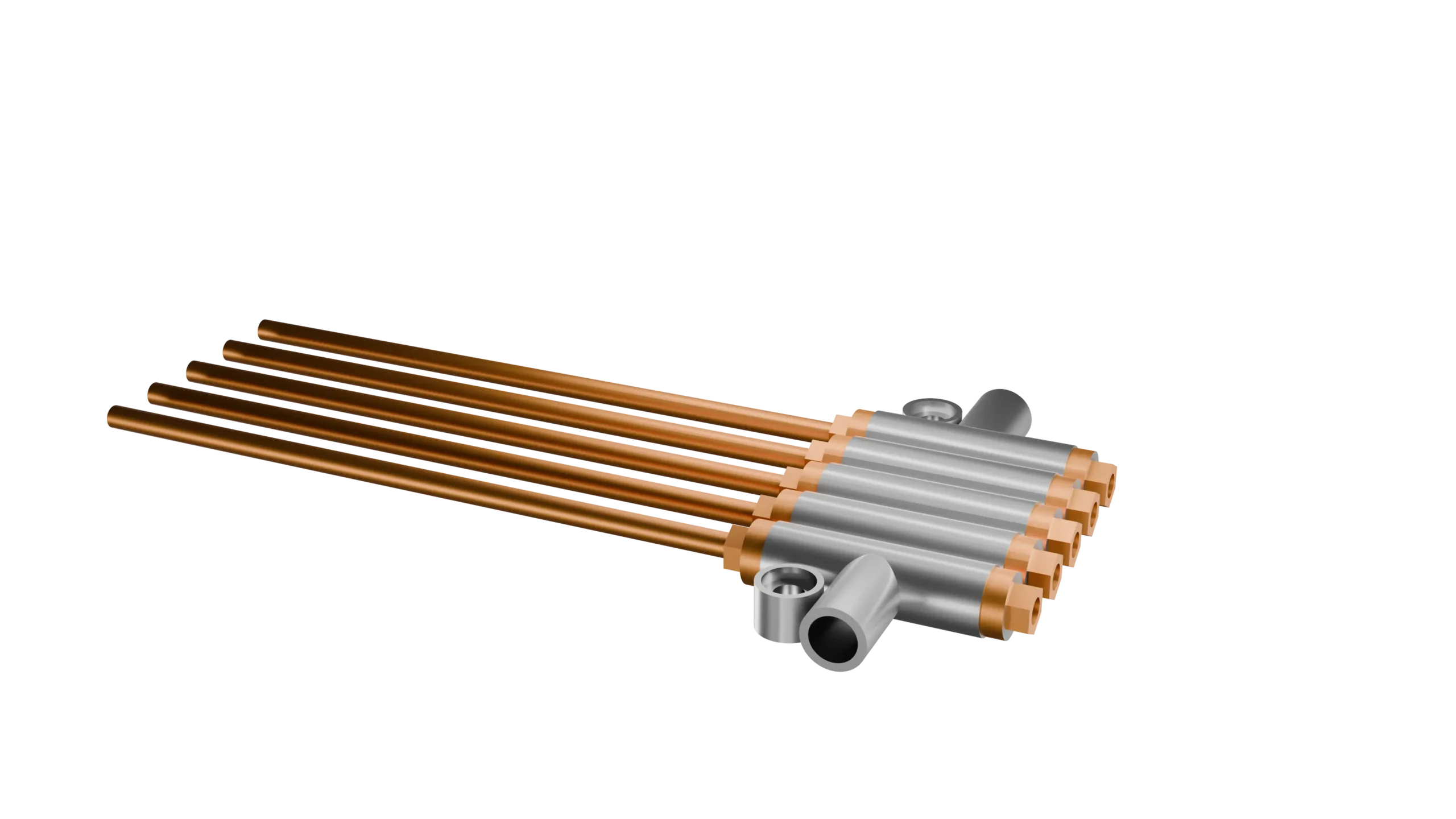

Copper Pipe

for Lubrication

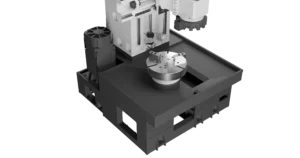

Designed for Heavy-duty Turning

The YouJi Vertical Lathe is built for heavy-duty turning, offering reliable performance, durability, and minimal maintenance for demanding applications.

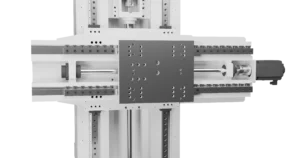

Robust Structure with Roller LM Guideways

The robust structure combined with advanced roller LM Guideways ensures exceptional rigidity, stability, and precision, delivering reliable performance even under heavy workloads.

Hydraulic turret with Powerful Spindle Motor

The hydraulic turret, paired with a powerful spindle motor, ensures exceptional cutting performance, enabling precise and efficient machining even in demanding operations.

Machine Specs

Max. Swing Diameter: 650 mm

Swing over Saddle: 500 mm

Max. Turning Diameter: Dia 600| L 120 mm

Max. Turning Height: 500 mm

Chuck Size: 15″

X-Axis Traverse: -25/+305 mm

Z-Axis Traverse: 520 mm

Spindle Speed: 2500 rpm

Spindle Nose Taper: A2-8

Max. Weight Capacity of Spindle (without chuck): 500 kg

Rapid Traverse X-Axis: 20 m/min

Rapid Traverse Z-Axis: 20 m/min

Max. Swing Diameter: 800 mm

Swing over Saddle: 600 mm

Max. Turning Diameter: Dia 700/L120 mm

Max. Turning Height: 700 mm

Chuck Size: 18″

X-Axis Traverse: -25/355 mm

Z-Axis Traverse: 520 mm

Spindle Speed: 2500 rpm

Spindle Nose Taper: A2-8

Max. Weight Capacity of Spindle (without chuck): 600 kg

Rapid Traverse X-Axis: 20 m/min

Rapid Traverse Z-Axis: 20 m/min

Max. Swing Diameter: 1000 mm

Swing over Saddle: 750 mm

Max. Turning Diameter: Dia 850/L120 mm

Max. Turning Height: 800 mm

Chuck Size: 21″ (24″)

X-Axis Traverse: -35/430 mm

Z-Axis Traverse: 820 mm

Spindle Speed: 2000 rpm

Spindle Nose Taper: A2-11

Max. Weight Capacity of Spindle (without chuck): 1000 kg

Rapid Traverse X-Axis: 20 m/min

Rapid Traverse Z-Axis: 20 m/min

Dimensions

| X Axis Travel -35/+430 mm | Y Axis Travel 820 mm |

| Machine Weight 9,500 | Spindle Nose Taper A2-11 | Speed 2,000 mm |

| Max. Weight Capacity of Spindle (without chuck) 1000 kg | Power Requirement (Controller) 50 KVA |

Capacity

| Max. Swing Diameterr 1000 | Swing over saddle 750 |

| Max. Turning Diameter 850 / 1,200 mm | Max. Turning Height 800 mm | Chuck Size 21″ (24″) mm |

Max. Swing Diameter: 1200 mm

Swing over Saddle: 850 mm

Max. Turning Diameter: Dia 1000/L120 mm

Max. Turning Height: 800 mm

Chuck Size: 24″

X-Axis Traverse: -35/530 mm

Z-Axis Traverse: 820 mm

Spindle Speed: 1500 rpm

Spindle Nose Taper: A2-11

Max. Weight Capacity of Spindle (without chuck): 1200 kg

Rapid Traverse X-Axis: 20 m/min

Rapid Traverse Z-Axis: 20 m/min

Dimensions

| X Axis Travel -35/+530 mm | Y Axis Travel 1,000 mm |

| Machine Weight 10,500 | Spindle Nose Taper A2-11 | Speed 1,500 mm |

| Max. Weight Capacity of Spindle (without chuck) 1,200 kg | Power Requirement (Controller) 60 KVA |

Capacity

| Max. Swing Diameterr 1200 | Swing over saddle 850 |

| Max. Turning Diameter 1,000 / 1,200 mm | Max. Turning Height 1,000 mm | Chuck Size 24″ mm |

| YCL 600 | YCL 700 | YCL 850 | YCL 1000 | |

|---|---|---|---|---|

| Chuck Size | 18" | 18" | 21" / 24" | 24" |

| Spindle Motor - Mitsubishi/Fanuc | 18.5/22 kW | 18.5/22 kW | 18.5/22 kW | 18.5/22 kW |

| Spindle Power - Siemens | 16/28 kW | 16/28 kW | 16/28 kW | 16/28 kW |

| Max. Speed | 2500 rpm | 2500 rpm | 2000 rpm | 1500 rpm |

| Max. Weight | 600 kgs | 600 kgs | 1000 kgs | 1200 kgs |

Motor

| Spindle Power – Siemens 16 / 28 kw | Spindle Power – Fanuc 18.5 / 22 kw |

Axis Drive

| Rapid Traverse X-Axis 20 m/min | Rapid Traverse Z-Axis 20 m/min |

Base

The YCL base is engineered to withstand heavy loads and absorb vibrations during demanding machining operations. Its robust monoblock construction, made from cast iron, ensures exceptional stability. The base's steep slope and high-capacity flushing system ensure efficient chip disposal, enhancing performance in demanding machining conditions.

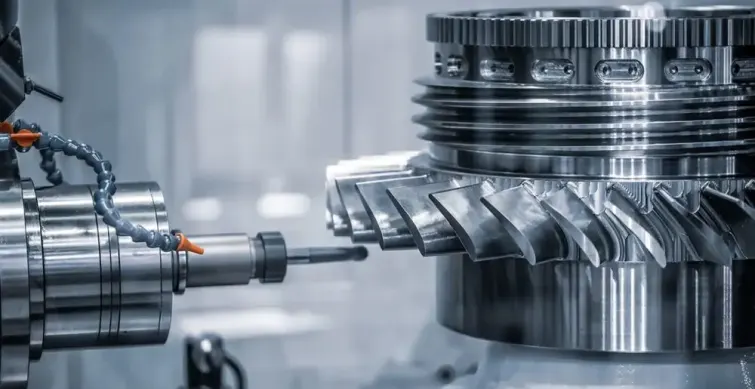

Heavy Construction Spindle

YCL series spindles are built to provide unsurpassed turning of tough steels as well as difficult materials like titanium, Inconel, nickel-base superalloys, and other challenging materials. Coupled with a rigid cylindrical roller and an angular contact ball, which are used to withstand radial and axial loads during machining, precision and performance are assured.

Strong Saddle

The robust saddle design ensures superior cutting performance and provides rigid support for the heavy-duty hydraulic turret, delivering enhanced durability and precision. Its advanced engineering minimises vibration, ensuring consistent accuracy with every cut. Built for reliability, it guarantees optimal performance even in the most demanding applications.

Column

The column is heavily ribbed, offering a balanced structure for heavy-duty cutting. The roller guideway, combined with the integrated motor mounting bracket on the saddle, ensures vibration-free performance, delivering high precision and durability. This design optimises load distribution, ensuring consistent performance under extreme machining conditions.

MACHINING STABILITY ENSURED

Our machines are distinguished by the extraordinary power of our signature ribs, the cornerstone of strength and quality in our construction. These ribs are strategically positioned to fortify our machines, elevating their structural integrity and amplifying overall robustness.

For heavy-duty cutting tasks, our ribs are the secret to success. They stand out in enhancing torsional rigidity, expertly reducing vibrations, and virtually eliminating deformation. The outcome is a level of machining precision and reliability that’s second to none – a testament to the enduring quality and unwavering strength of our ribs. Place your trust in the bedrock of excellence; rely on our ribs to deliver.

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

It focuses on customised dashboards and tools that help the operator to simplify his daily activity. The overall feature and package can reduce the time lost due to the complexity of the controller GUI; as a result, Zenez can significantly increase the machine output and profitability. • 10.4-inch display or large 15-inch display.

- 10.4-inch display or large 15-inch display

- Multi-touch User Interface

- Fully functional vertical and horizontal soft-keys for non-touch usage

- Crystal Type

- Enhanced hardware to ensure reliability

digiFAC Features

Dashboard Monitoring

- Live information of the entire factory.

- Categorise machines (Unit-wise).

- View regular utilisation of the machine.

Program Transfer

- Upload programs from computer to machine remotely.

- Download programs and edit them from anywhere around the globe.

Alarm Analysis

- Alarm history by code/machine.

- Time and duration of all alarms generated by a separate machine.

Tool Cutting Time Informationt

- No more unidentified dry-runs.

- Program path optimisation in-sight.

- Tool usage clarity.

- Shorter cycle-times (if modified).

- Eliminate NVA air time and improve your process.

All-in-One Dashboard

- Overview of all data of one machine on one screen.

- Find out the machine's status right away.

- One machine's information is displayed on a single screen.

Production Information (Utilisation)

- Detailed production information report: An automated daily production report.

- All reports are available in Excel format.

Downtime Analysis

- See total machine downtime.

- Monitor downtime and the reasons for it (Macro Downtime Feature).

- Focus and easily get the classified major losses/downtimes and work on optimisation .

Email Alerts

- Set a time for machines' idle condition and receive or get alarm notifications via email.

- Management Reporting: Receive daily production reports and downtime analysis reports by email on a daily basis.

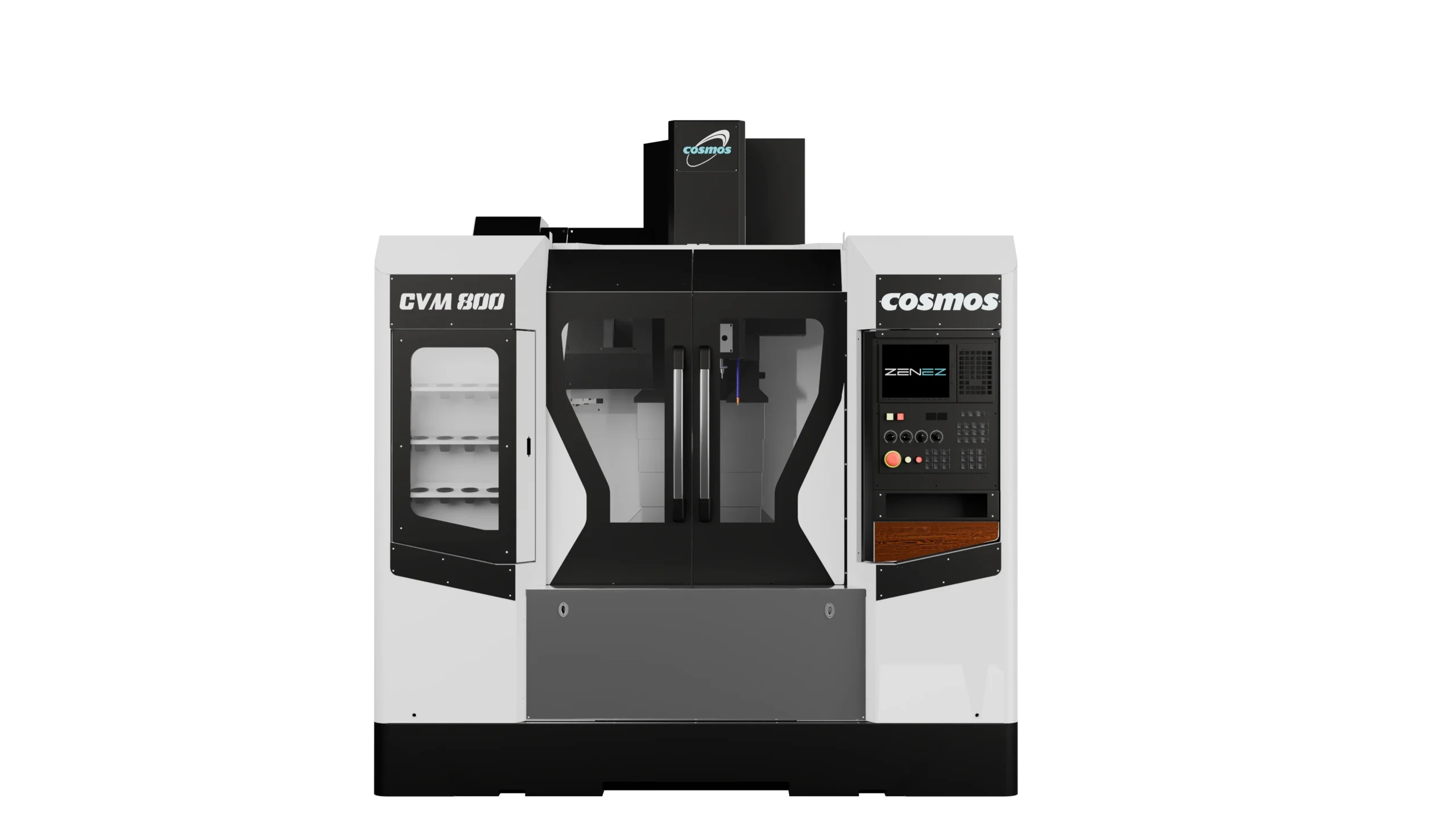

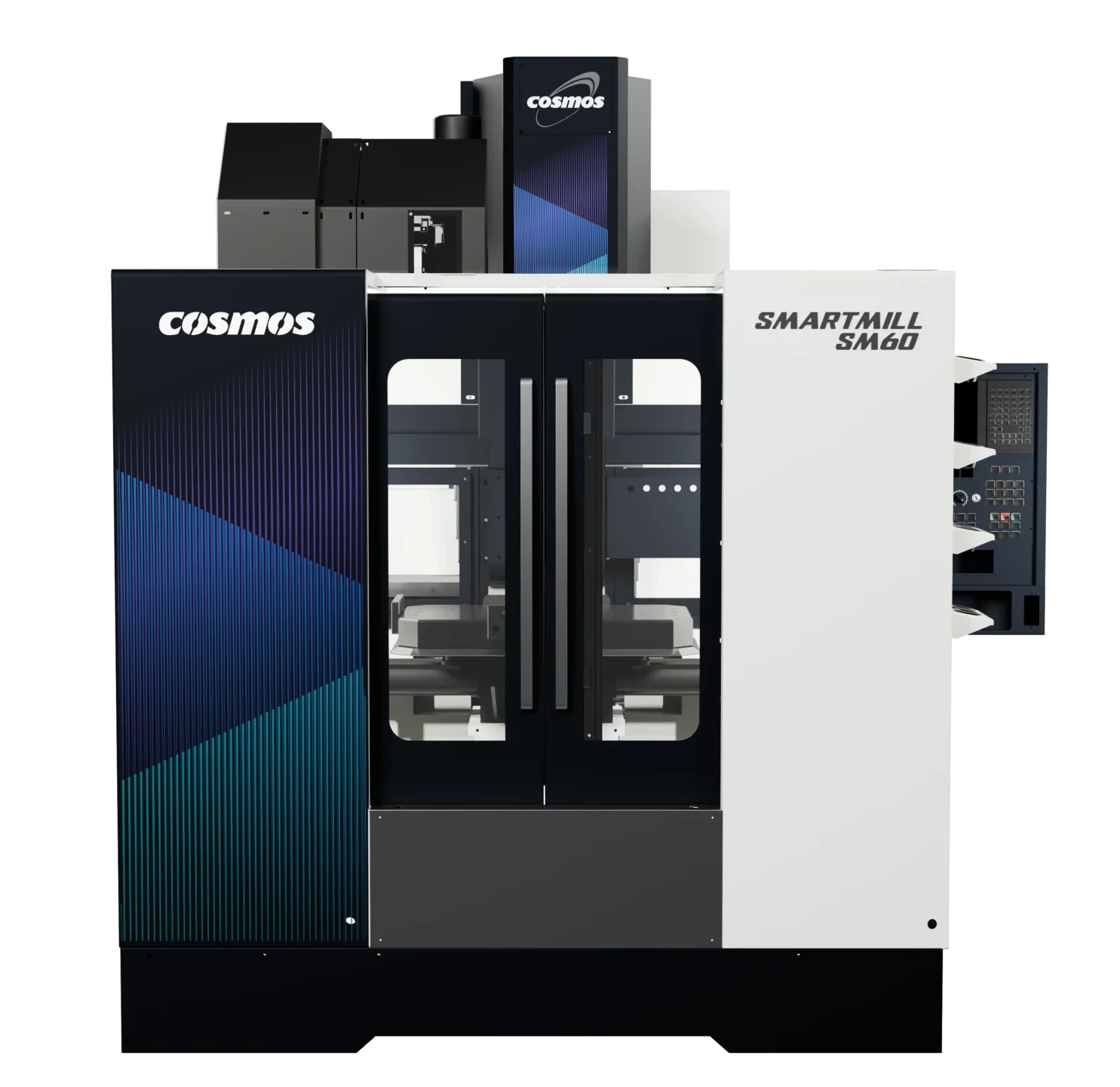

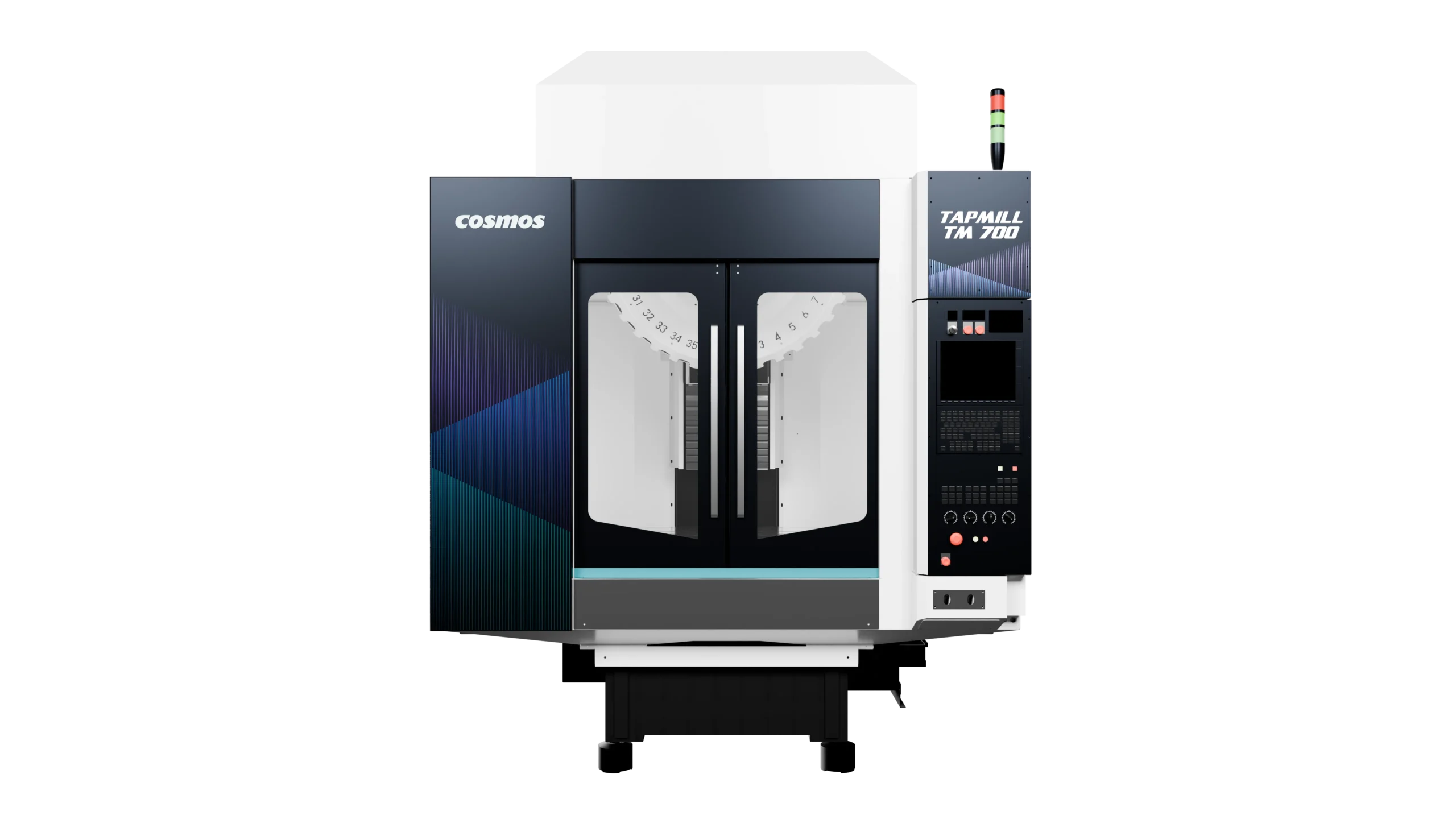

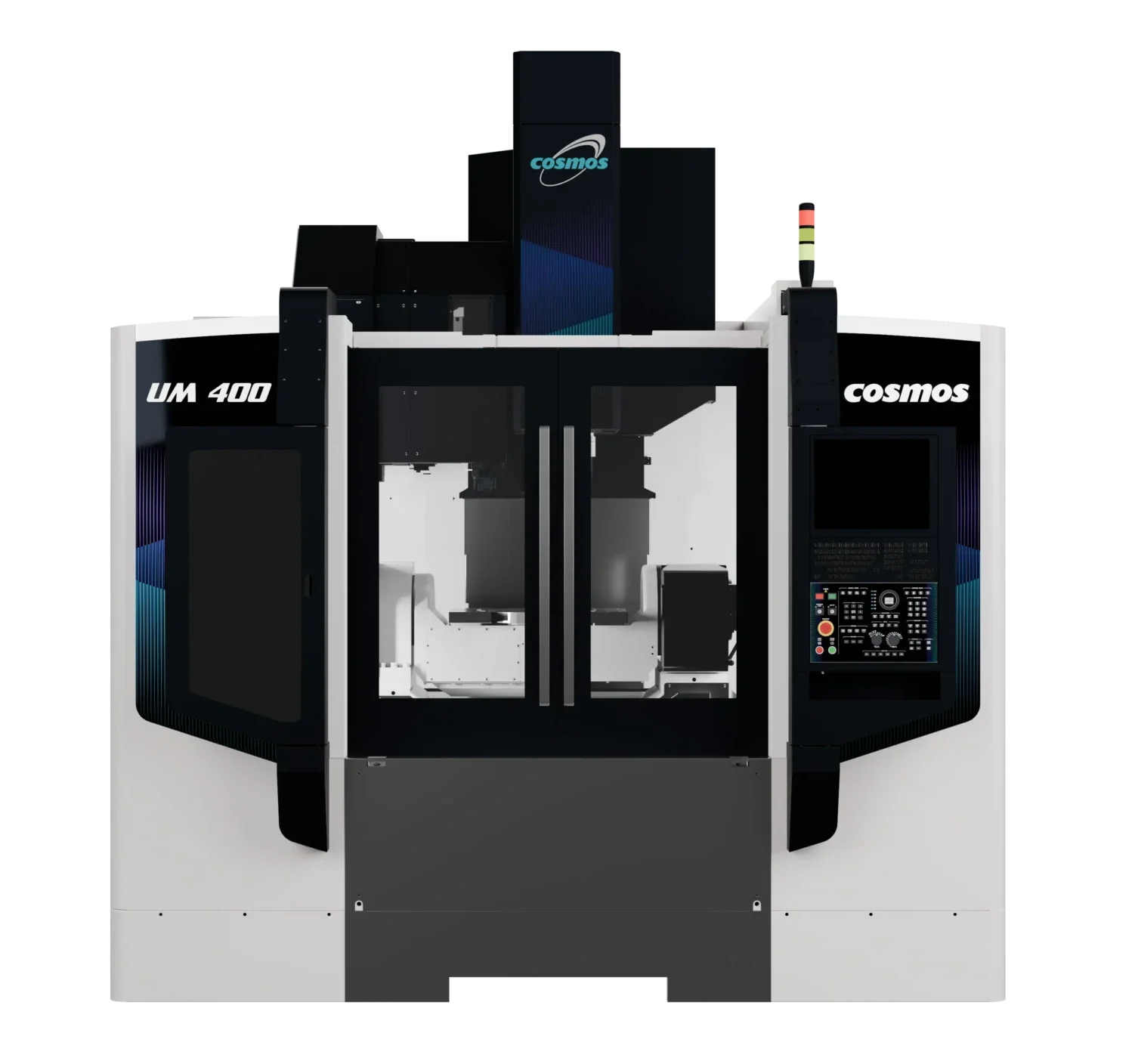

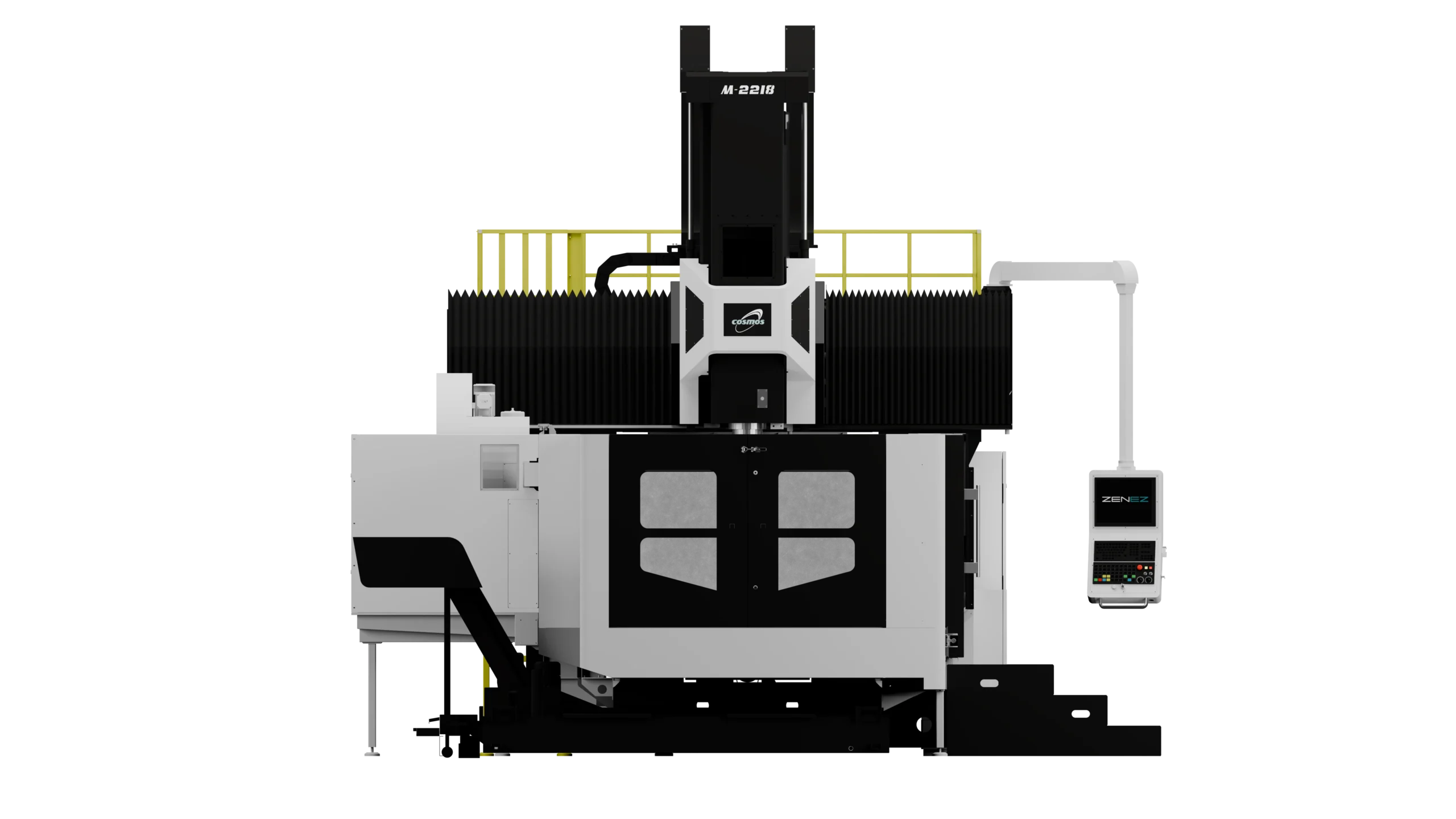

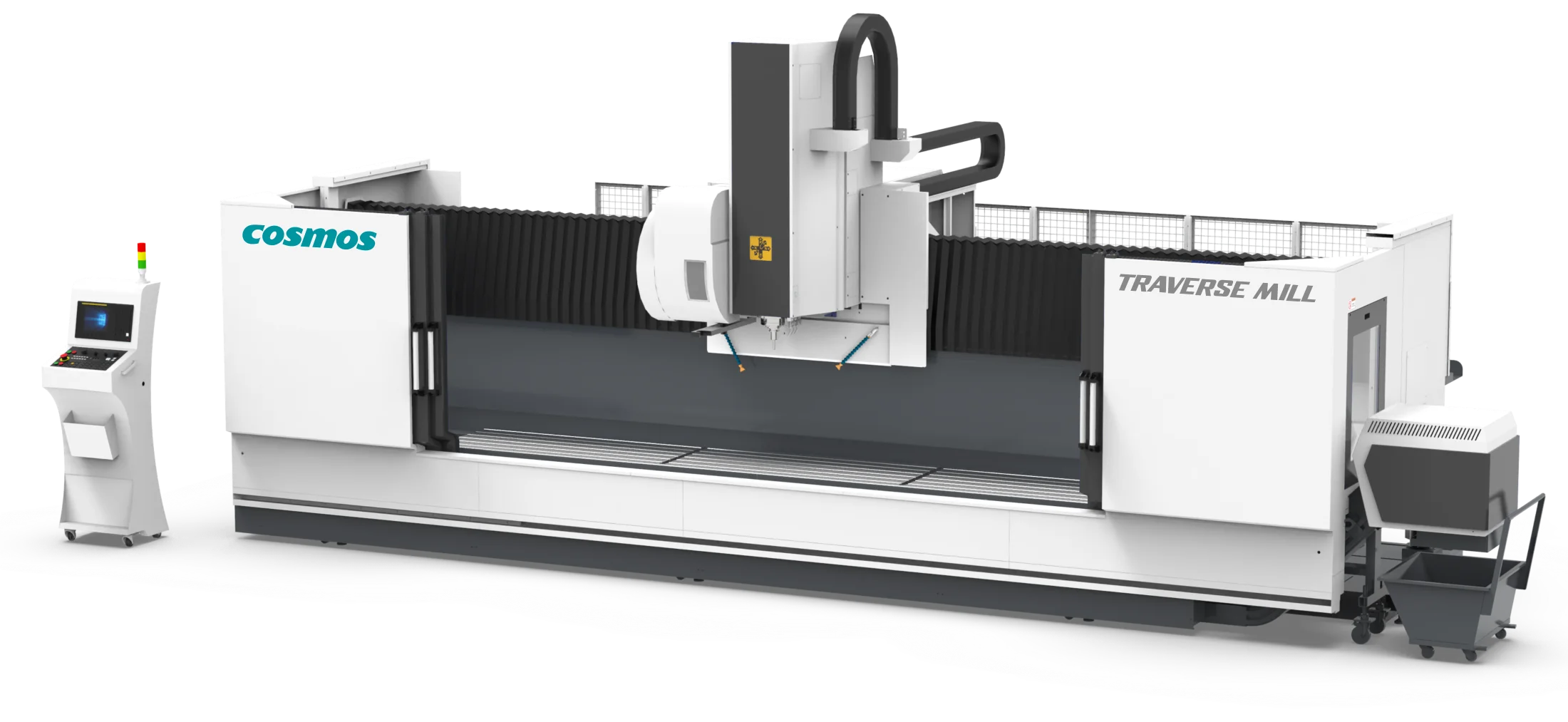

Our Other Range of Excellence

High-tech Products For Unmatched Performance