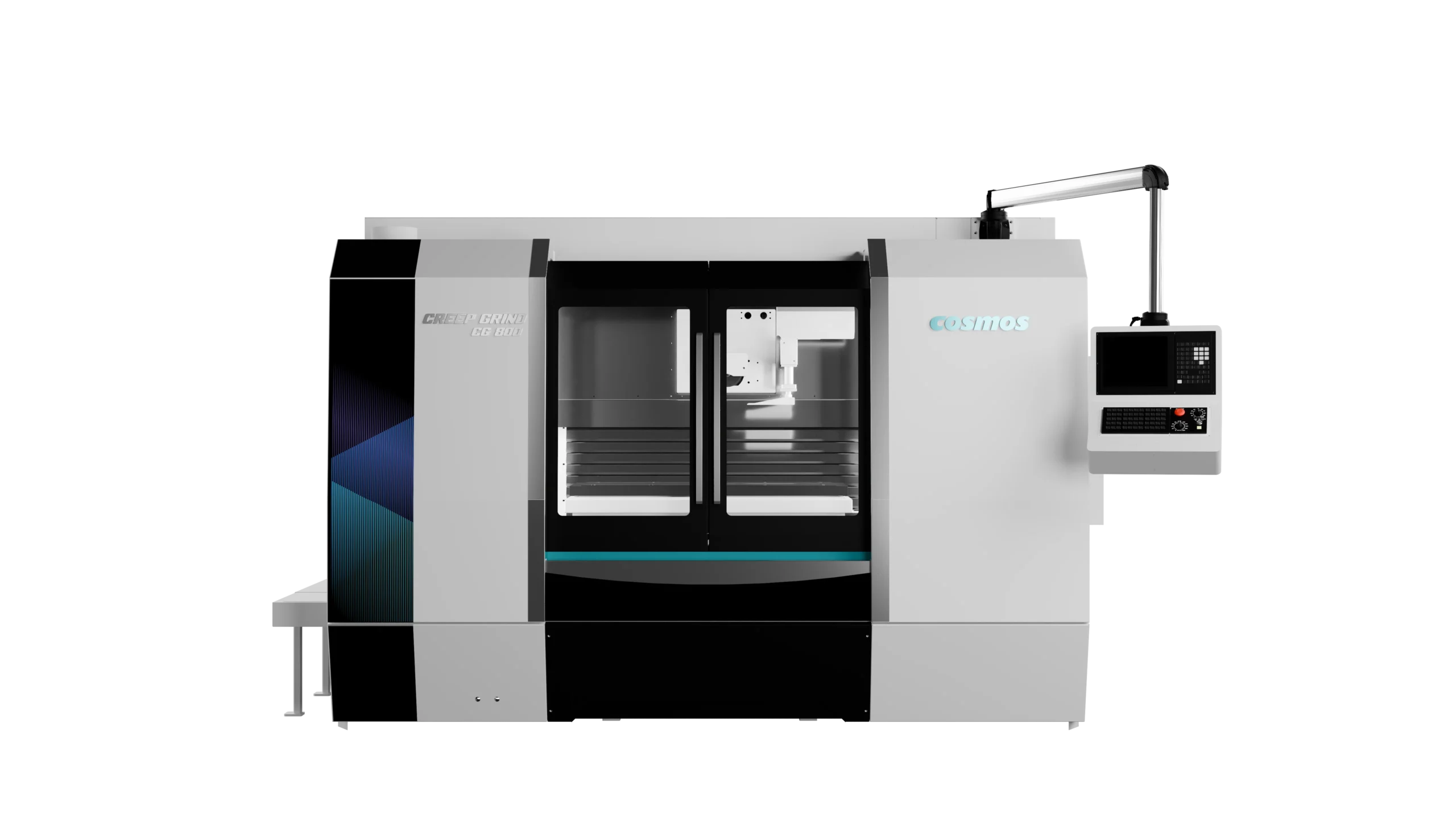

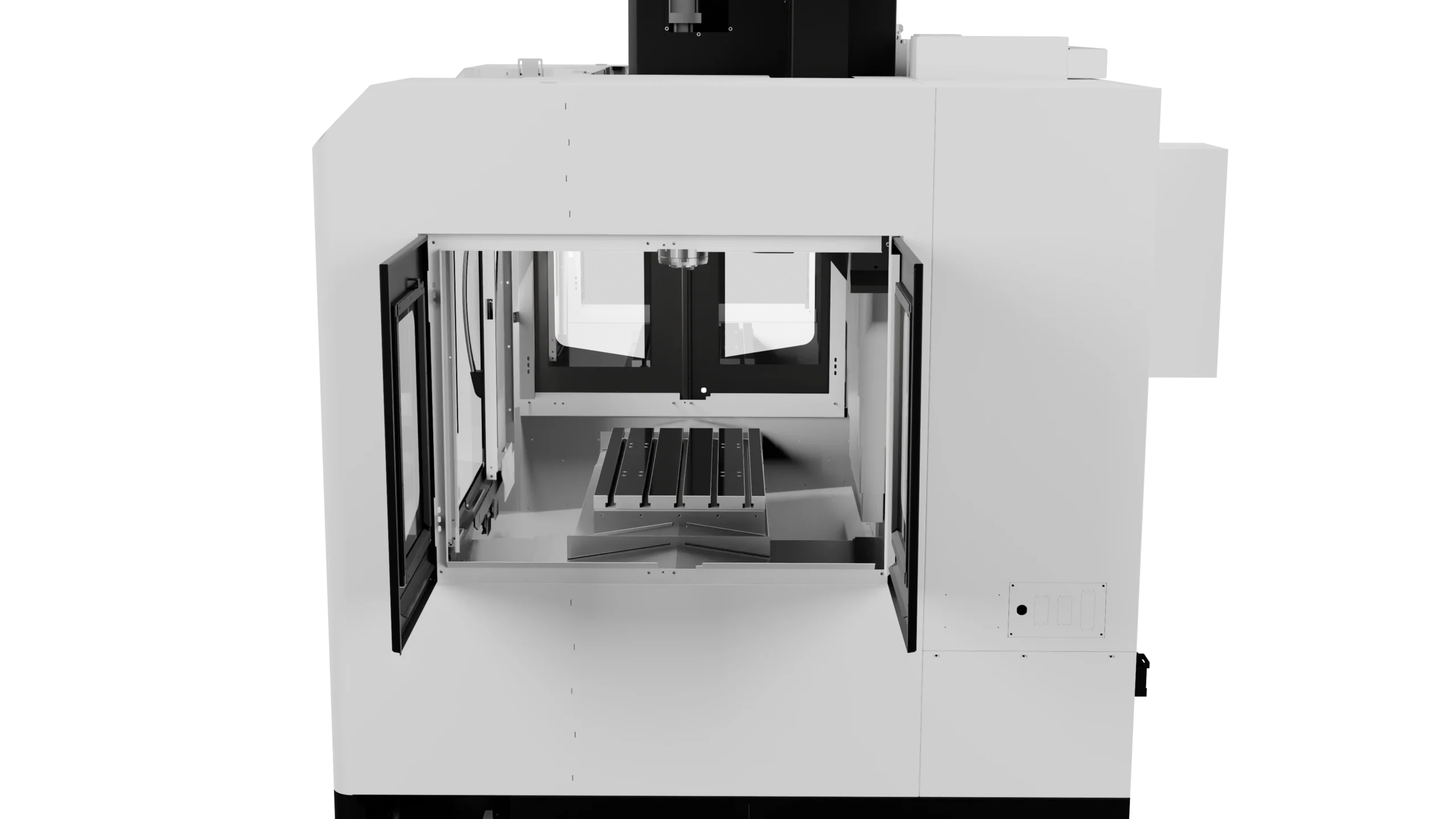

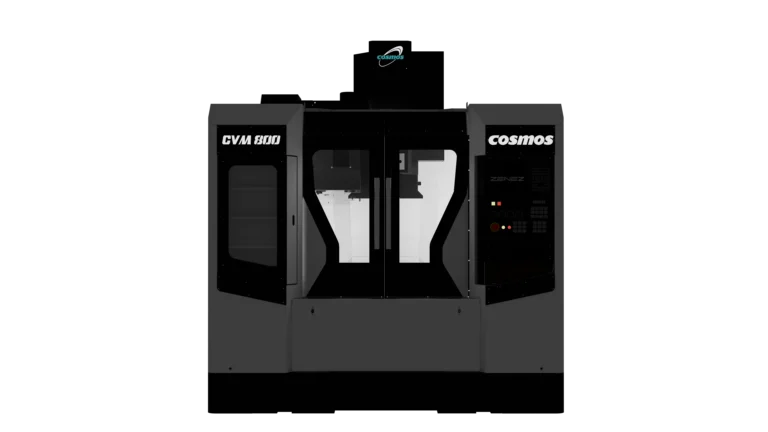

Machine Overview

The AutoMill Series is a revolutionary self-loading machine, designed to deliver fully automated high-performance solutions for a wide range of production needs. Whether it's High-Volume, Low Variety or Low-Volume, High Variety production the AutoMiII enhances consistency, speed and overall output, ensuring peak efficiency across all operations.

With internally linked software for seamless setup and operation. The AutoMill simplifies the automation process, minimising human intervention while maintaining exceptional precision and reliability. This cutting-edge solution empowers manufacturers to achieve faster, more efficient workflow, making it the ideal choice for modern, high-productivity environments.

Key Features

No Programming

Required

Quick Part

Changeovers

30 Visualisation

Fast and Accurate

Calibration

Smart Task

Automation

Collision

Avoidance

Illuminated Design

All our machines are with LED lamps to create a well-lit working environment, ensuring optimal visibility and ease of operation. Built for durability and minimal maintenance.

Easy Access Maintenance

We’ve improved machine manageability with easy access windows to essential peripherals, streamlining maintenance and ensuring efficient operation.

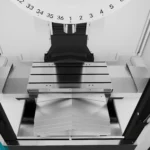

Excellent Chip Disposal

The machines feature steeply slanted telescopic sliding covers that excel in chip disposal performance, keeping your workspace clean and ensuring uninterrupted machining.

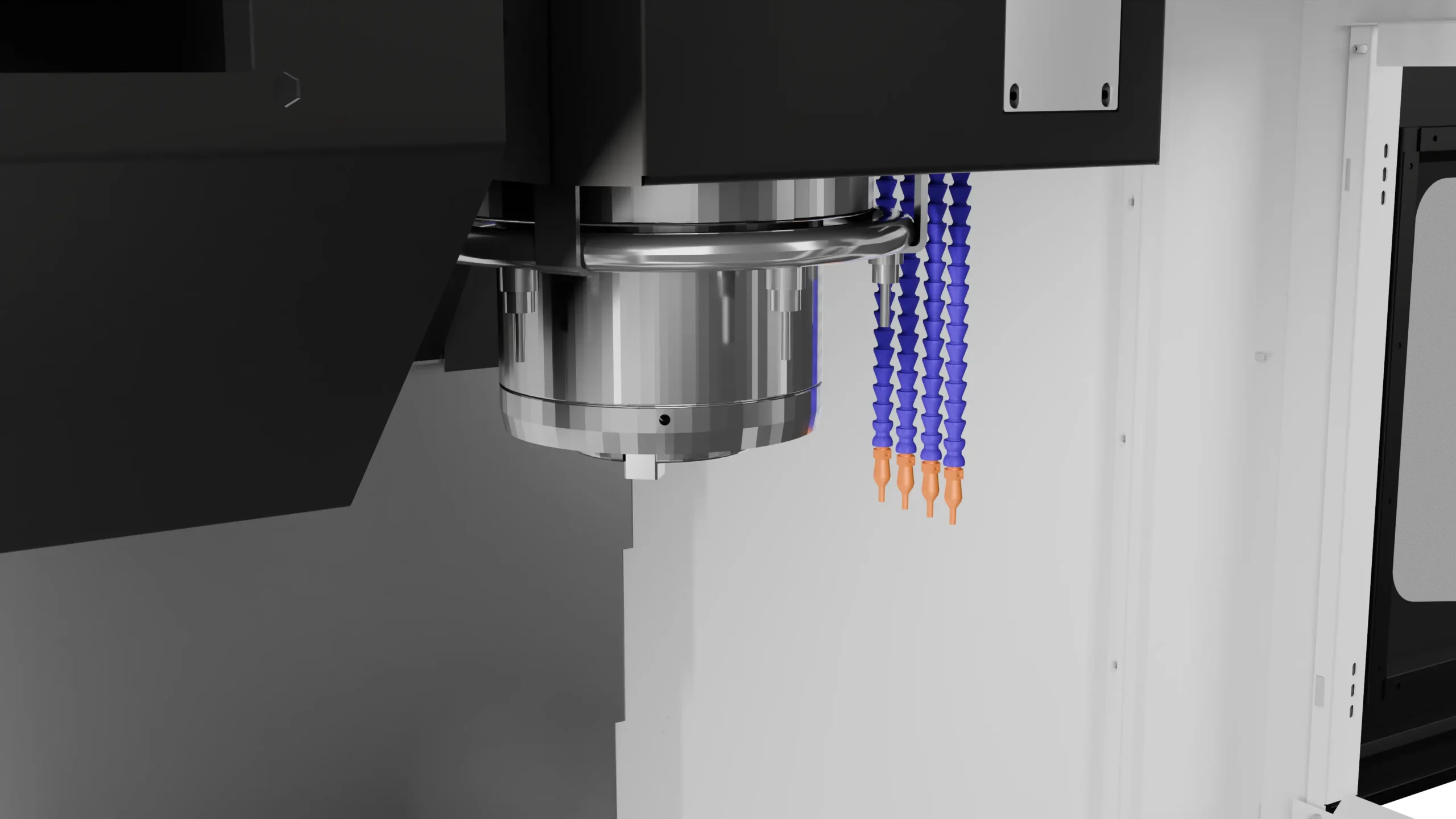

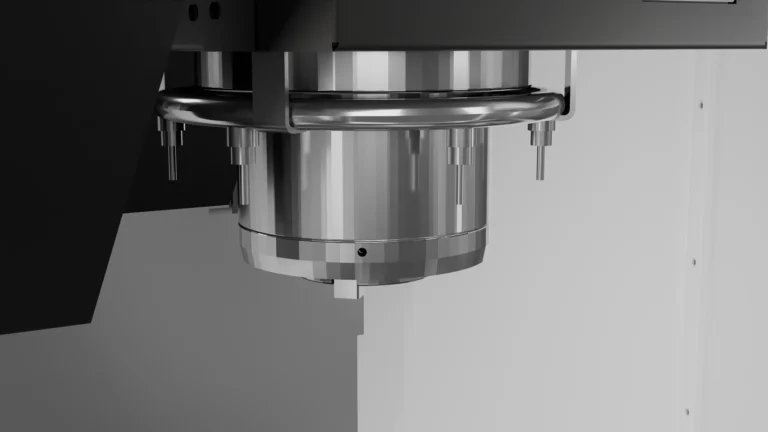

Ring Coolant

Our ring coolant nozzles, strategically positioned around the spindle, deliver coolant to the cutting area, ensuring performance, efficient heat dissipation, and an optimal machining experience.

Additional Features

Stainless Steel Sill

Protector

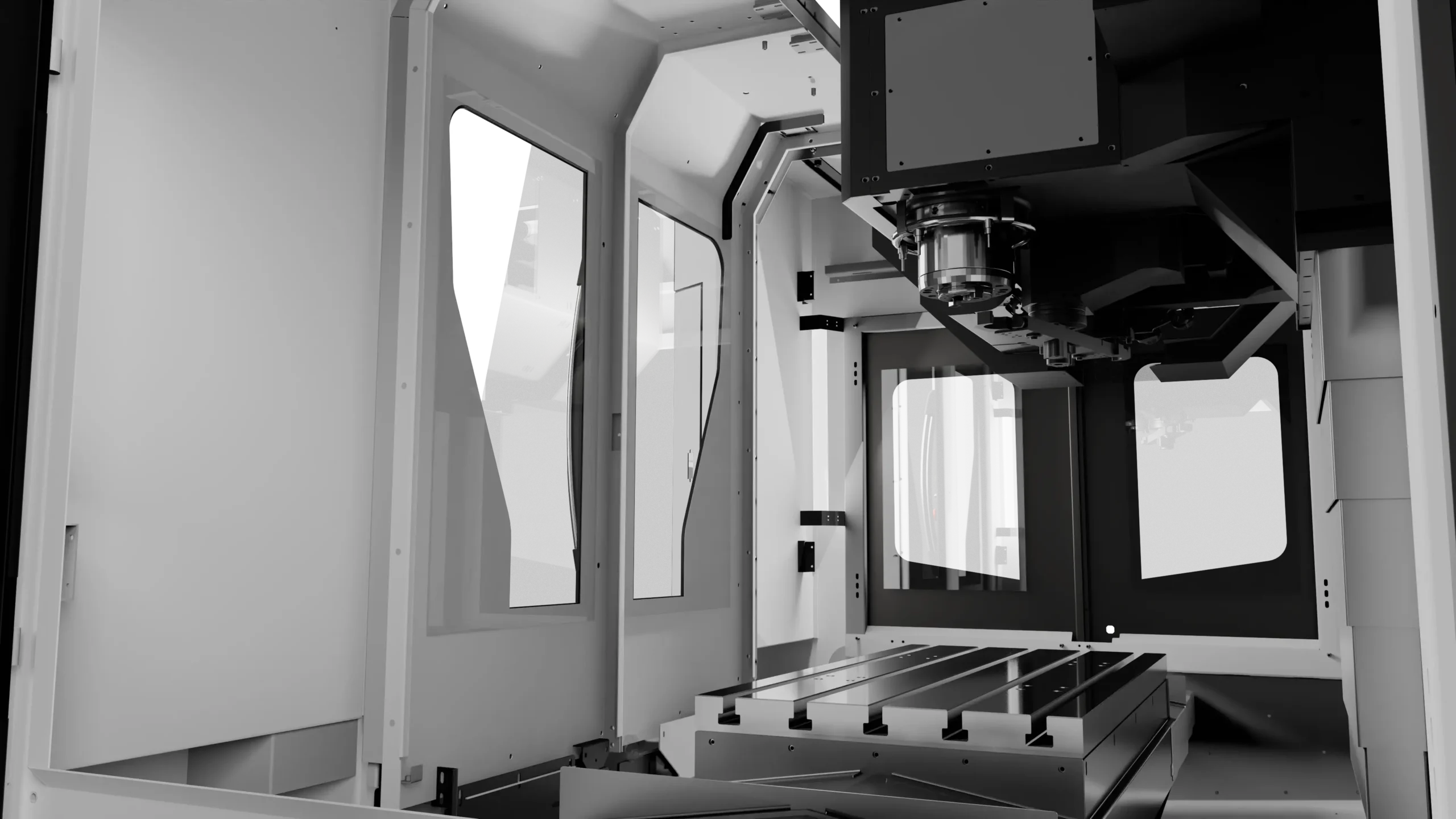

Big Dual

Side Windows

Fully Enclosed

Guarding

Inbuilt Tool

Stronge Cabinet

1 Air and 3 Coolant

Nozzles

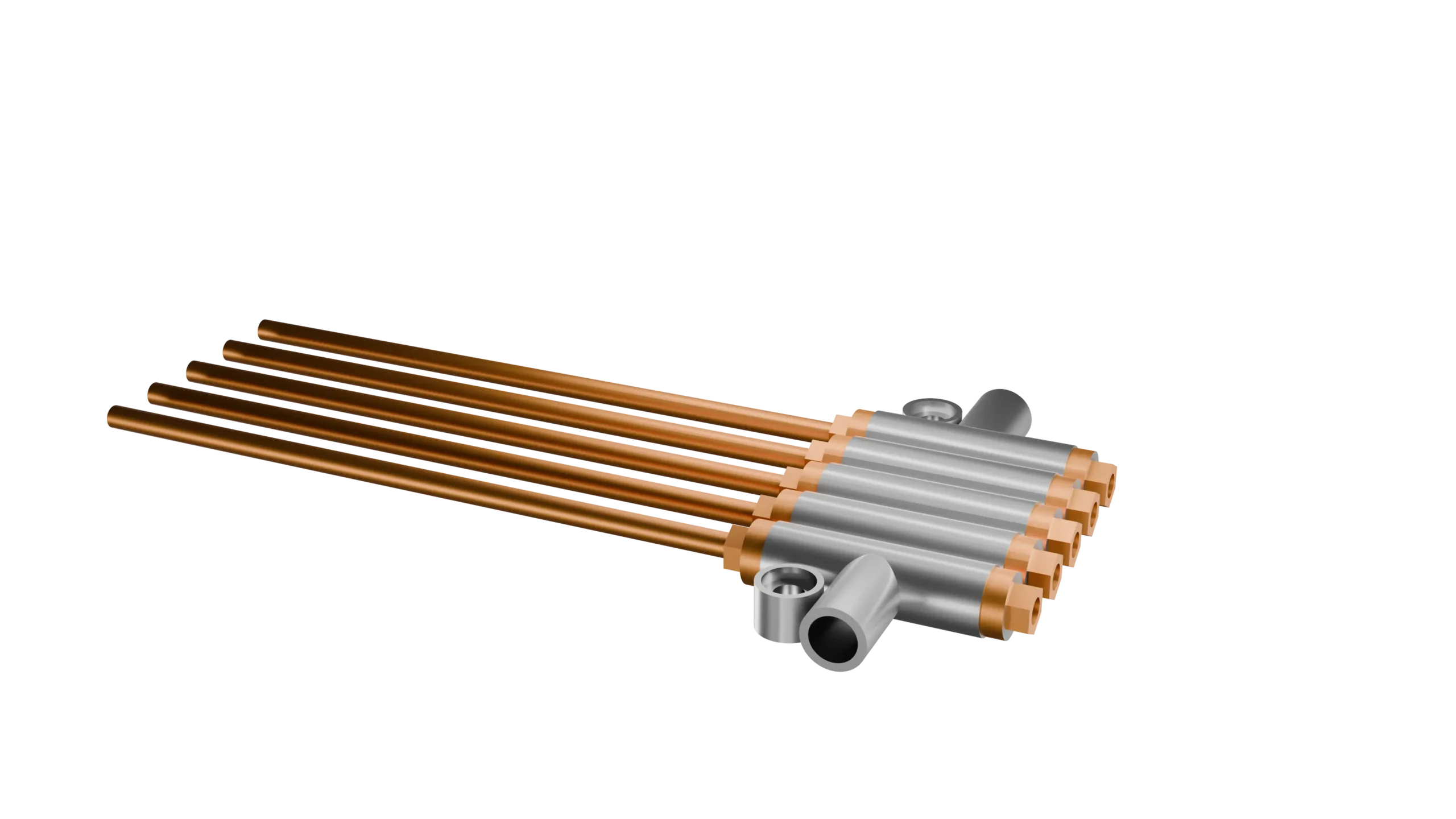

Copper Pipe

for Lubrication

High Visibility Front Doors

The front doors are constructed using heavy-duty, shatterproof polycarbonate material. The generously sized window provides operators with clear and unobstructed visibility, making it effortless to monitor machining processes.

Secure Tool Storage: Enclosed Cabinet With Adjustable Rack

All CVM machines come equipped with endorsed cabinets featuring racks, providing a safe and organised space to store your valuable tools. The adjustable design ensures flexibility to accommodate tools of various sizes with ease.

Holster For Your Guns

The machines feature scuffless steel panels equipped with holsters for the coolant and air guns. This thoughtful design ensures your guns are securely stored, preventing paint scratches, accidental drops, and messy coolant drips, enhancing both efficiency and workplace safety.

Stainless Steel Protector

Front panels often bear the brunt of scratches and rust from operator handling of tools, tackle, and components. Our solution? Stainless steel protection to eliminate these issues, ensuring lasting durability and a pristine appearance. Say goodbye to scratches and rust concerns.

Brilliantly Illuminated for Optimal Visibility

Designed for optimal visibility in low light, CVM machines include a dual work lamp with white LEDs, a three-colour tower lamp, ambient tool cabinet lighting, and an illuminated machine name, ensuring a well-lit workspace for operator ease.

Seamless Access: Spacious Side Doors

Generously sized side doors are designed for easy access to the machine. These doors are strategically positioned below the table height, ensuring convenience during extended use. Work comfortably and efficiently with hassle-free access to your machine. (Except 640)

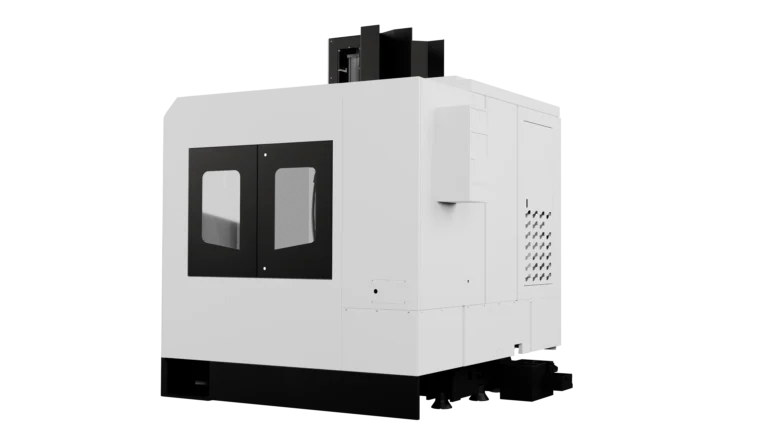

Versatile 360° Machine Design

Our machines feature a smooth, flush design on all four faces, offering you the freedom to position the machine in any orientation within your factory. Enjoy a sleek appearance from every angle.

Machine Specs

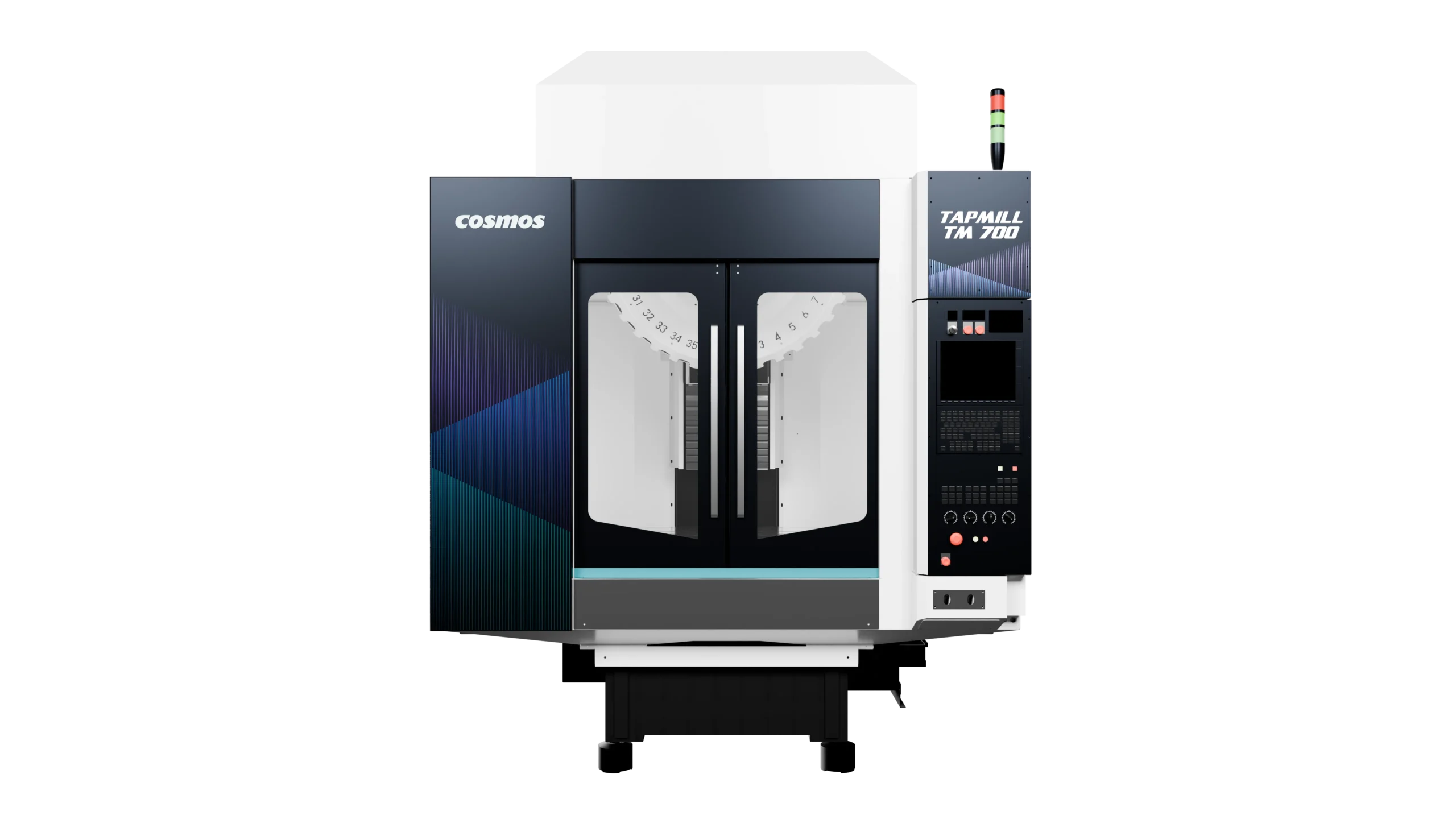

X-Axis Travel: 500 mm

Y-Axis Travel: 400 mm

Z-Axis Travel: 330 mm

Table Dimension: 650 × 400 mm

Max. Safe Load on Table: 250 kg

Spindle Taper: BBT 30

Spindle Speed: 12,000 DDS

Spindle Motor Output (Mitsubishi): 3.7/11 kW

Rapid Traverse X/Y/Z Axes (Mitsubishi): 60/60/60 m/min

Cutting Feedrates: 20 m/min

Dimensions

| X Axis Travel 1300 mm | Y Axis Travel 700 mm | Z Axis Travel 700 mm | Table Size 1450X650 mm |

| Spindle Nose to Table Surface 150-850 mm | Spindle Center to Sliding Cover Face 716 mm | Table T-Slot 18X5X125 mm |

| Machine Weight (with ATC) 8300 kg | Power Requirement (Controller) 35 KVA |

Capacity

| Spindle Taper BBT 40 | Guideway Type Ball LM Type | Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw | Fanuc Motor power(OPT) 11/15/18.5 kw | Siemens Motor power(OPT) 12/18 kw |

| Rapid Traverse Rate (Opt) 30 m/min | Cutting Feed Rate 10 m/min | Tool Capacity 30 |

X-Axis Travel: 700 mm

Y-Axis Travel: 400 mm

Z-Axis Travel: 330 mm

Table Dimension: 850 × 400 mm

Max. Safe Load on Table: 250 kg

Spindle Taper: BBT 30

Spindle Speed: 12,000 DDS

Spindle Motor Output (Mitsubishi): 3.7/11 kW

Rapid Traverse X/Y/Z Axes (Mitsubishi): 60/60/60 m/min

Cutting Feedrates: 20 m/min

Dimensions

| X Axis Travel 1500 mm | Y Axis Travel 700 mm | Z Axis Travel 700 mm | Table Size 1450X650 mm |

| Spindle Nose to Table Surface 150-850 mm | Spindle Center to Sliding Cover Face 706 mm | Table T-Slot 18X5X125 mm |

| Machine Weight (with ATC) 9000 kg | Power Requirement (Controller) 35 KVA |

Capacity

| Spindle Taper BBT 40 | Guideway Type Ball LM Type | Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw | Fanuc Motor power(OPT) 11/15/18.5 kw | Siemens Motor power(OPT) 12/18 kw |

| Rapid Traverse Rate (Opt) 30 m/min | Cutting Feed Rate 10 m/min | Tool Capacity 30 |

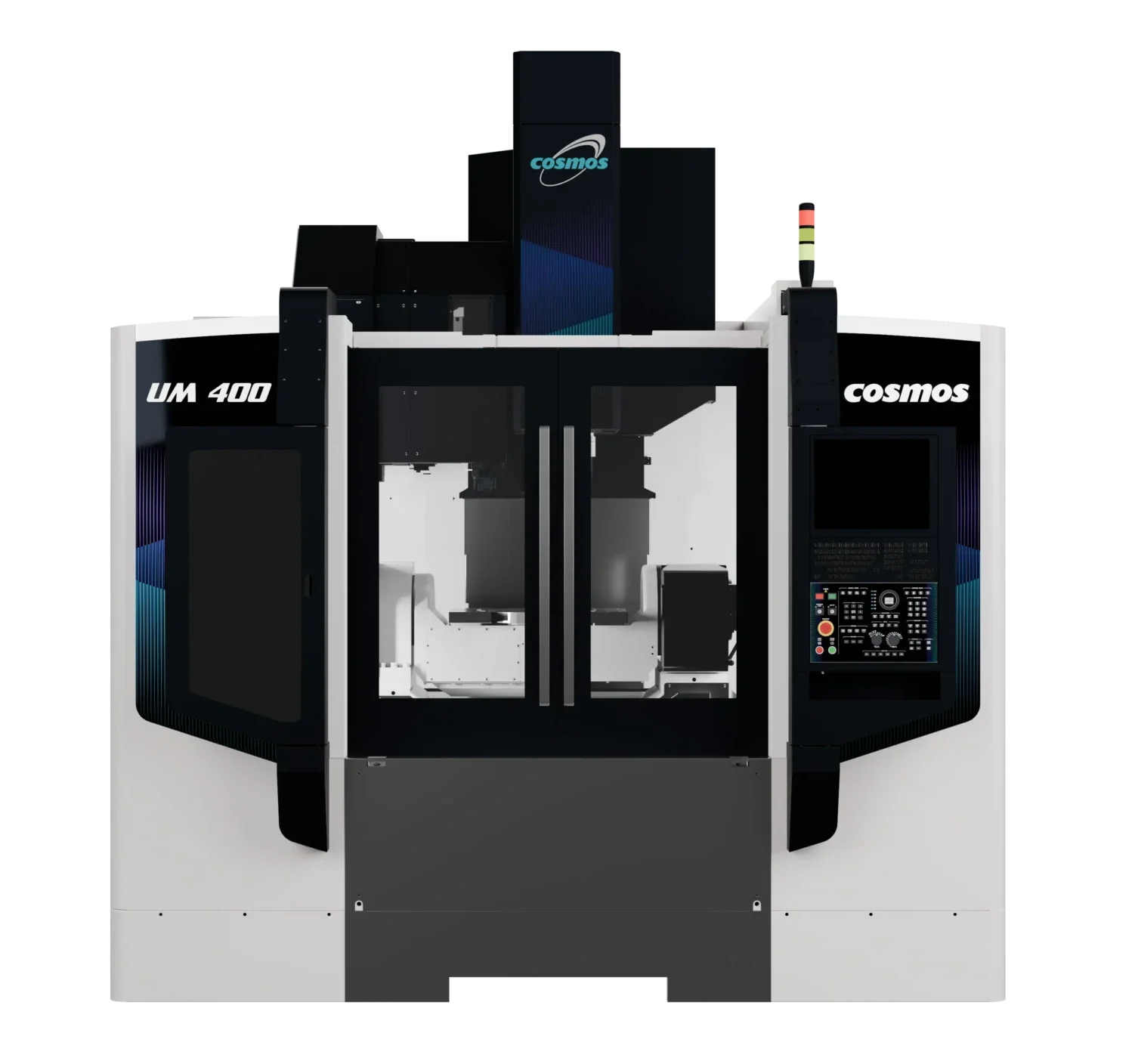

X-Axis Travel: 600 mm

Y-Axis Travel: 450 mm

Z-Axis Travel: 500 mm

Table Dimension: 750 × 450 mm

Max. Safe Load on Table: 300 kg

Spindle Taper: BBT 40

Spindle Speed: 8,000 Belt

Spindle Motor Output (Mitsubishi): 7.5/11/15 kW

Rapid Traverse X/Y/Z Axes (Mitsubishi): 48/48/48 m/min

Cutting Feedrates: 10 m/min

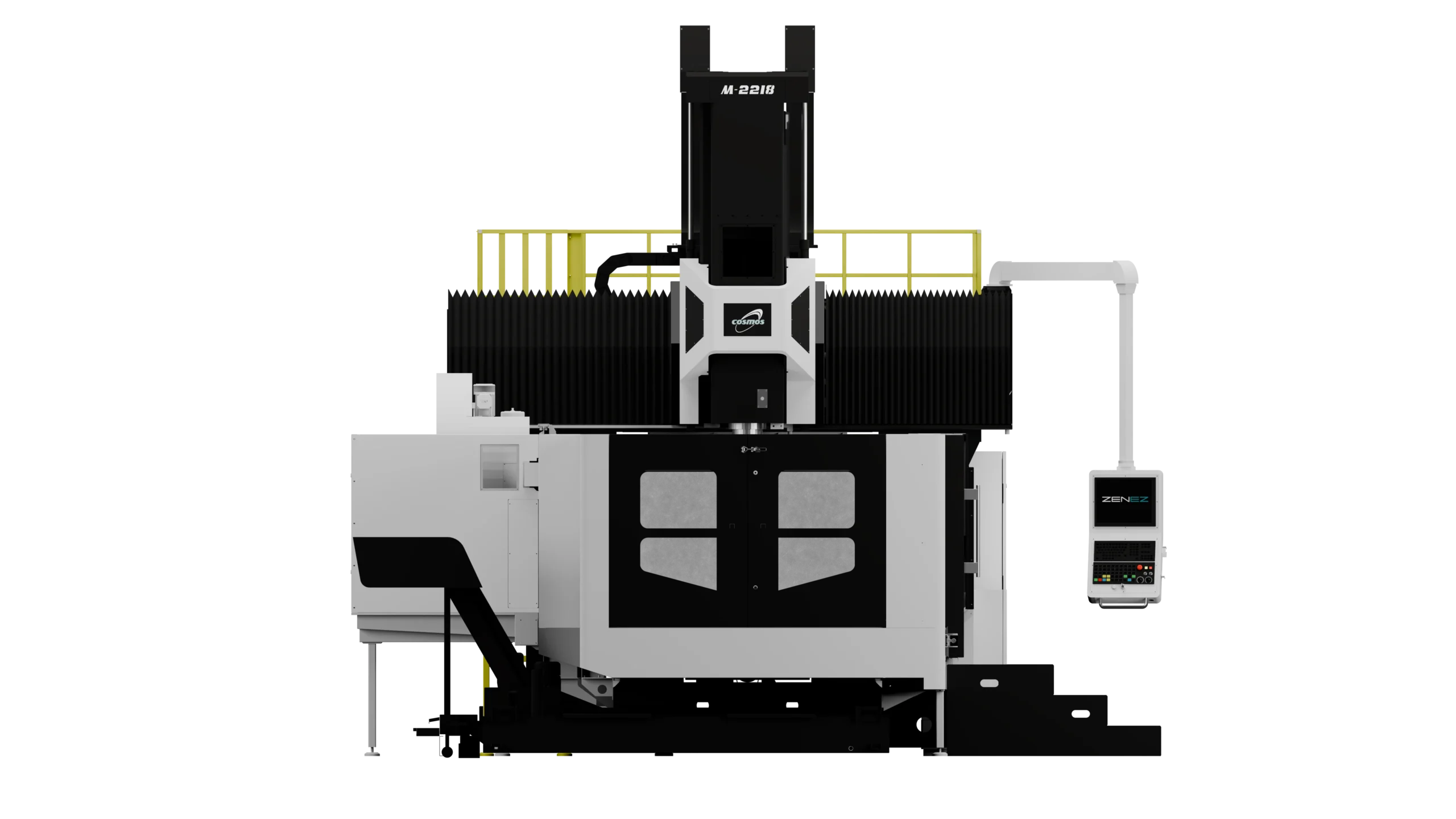

Dimensions

| X Axis Travel 1600 mm | Y Axis Travel 800 mm | Z Axis Travel 800 mm | Table Size 1750X800 mm |

| Spindle Nose to Table Surface 100-900 mm | Spindle Center to Sliding Cover Face 830 mm | Table T-Slot 18X5X150 mm |

| Machine Weight (with ATC) 12300 kg | Power Requirement (Controller) 40 KVA |

Capacity

| Spindle Taper BBT 40 | Guideway Type Ball LM Type | Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 15/18.5 kw | Fanuc Motor power(OPT) 15/18.5 kw | Siemens Motor power(OPT) - |

| Rapid Traverse Rate (Opt) 24/24/20 m/min | Cutting Feed Rate 10 m/min | Tool Capacity 24 |

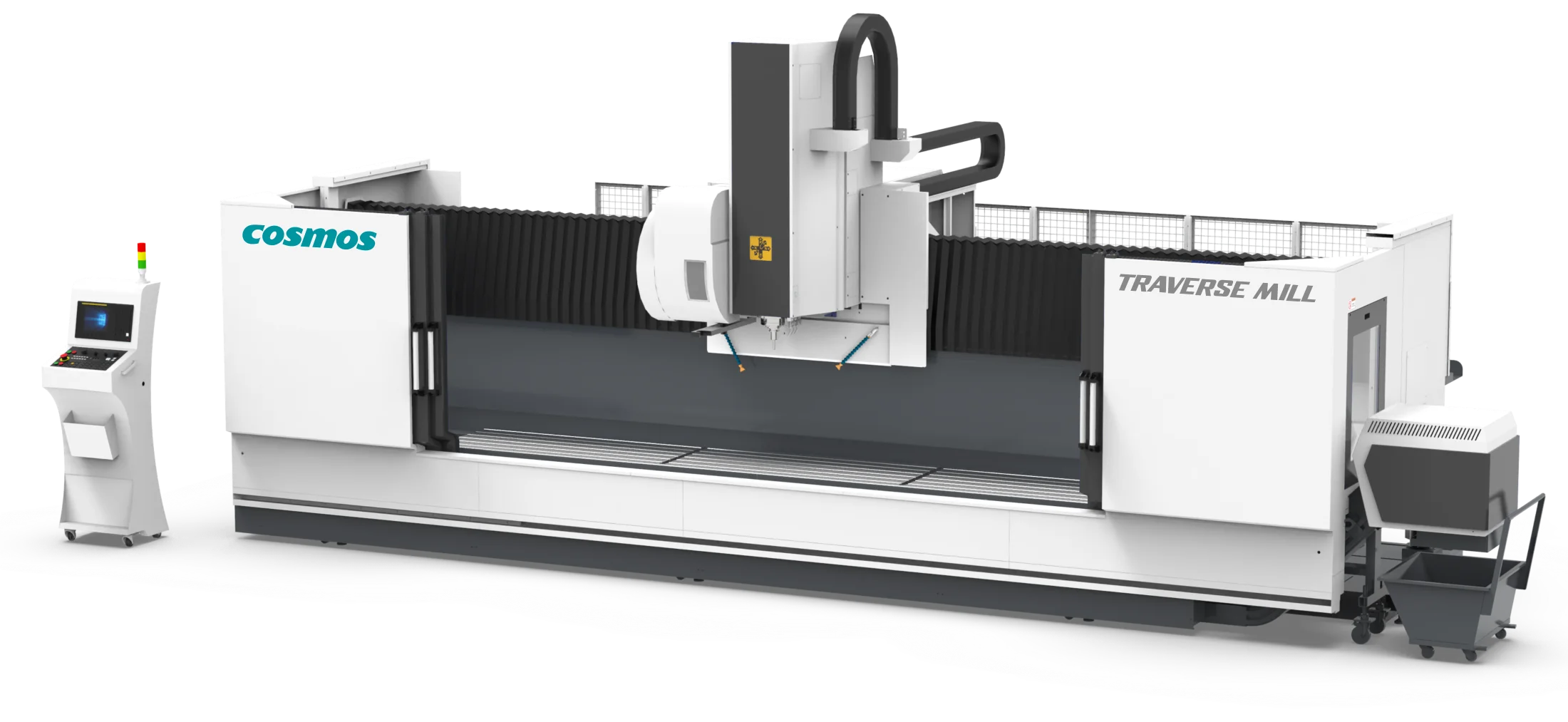

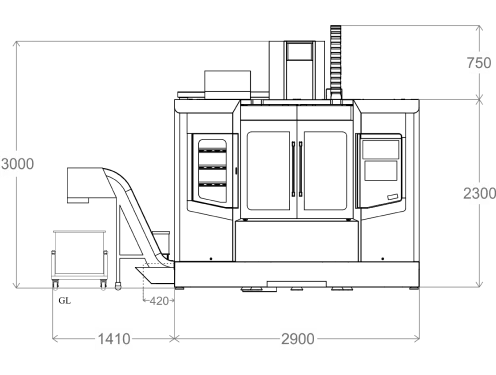

X-Axis Travel: 800 mm

Y-Axis Travel: 450 mm

Z-Axis Travel: 500 mm

Table Dimension: 1000 × 500 mm

Max. Safe Load on Table: 600 kg

Spindle Taper: BBT 40

Spindle Speed: 8,000 Belt

Spindle Motor Output (Mitsubishi): 11/15/18.5 kW

Rapid Traverse X/Y/Z Axes (Mitsubishi): 48/48/48 m/min

Cutting Feedrates: 10 m/min

Dimensions

| X Axis Travel 1600 mm | Y Axis Travel 800 mm | Z Axis Travel 800 mm | Table Size 1750X800 mm |

| Spindle Nose to Table Surface 100-900 mm | Spindle Center to Sliding Cover Face 830 mm | Table T-Slot 18X5X150 mm |

| Machine Weight (with ATC) 12300 kg | Power Requirement (Controller) 40 KVA |

Capacity

| Spindle Taper BBT 40 | Guideway Type Ball LM Type | Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 15/18.5 kw | Fanuc Motor power(OPT) 15/18.5 kw | Siemens Motor power(OPT) - |

| Rapid Traverse Rate (Opt) 24/24/20 m/min | Cutting Feed Rate 10 m/min | Tool Capacity 24 |

Tools

| Maximum Tool Length 250 mm | Tool Charging Timer 2 sec | Maximum Tool Weight 8 Kg | Tool Capacity 24 |

| Tool Diameter (with Adjacent Tool) 080 | Tool Diameter (without Adjacent Tool) 0150 |

Accuracy

| Positioning Accuracy 0.01 mm | Positioning Repeatability + 0.003 |

Flexible working Area

Capable of fitting 4th Axis rotary or fixture to satisfy different jobs requirement.

Excellent Chip Disposal

The machines feature steeply slanted telescopic sliding covers that excel in chip disposal performance, keeping your workspace clean and ensuring uninterrupted machining.

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

It focuses on customised dashboards and tools that help the operator to simplify his daily activity. The overall feature and package can reduce the time lost due to the complexity of the controller GUI; as a result, Zenez can significantly increase the machine output and profitability. • 10.4-inch display or large 15-inch display.

- 10.4-inch display or large 15-inch display

- Multi-touch User Interface

- Fully functional vertical and horizontal soft-keys for non-touch usage

- Crystal Type

- Enhanced hardware to ensure reliability

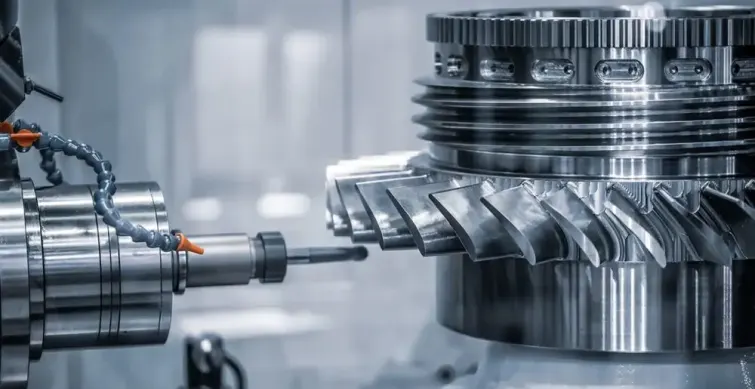

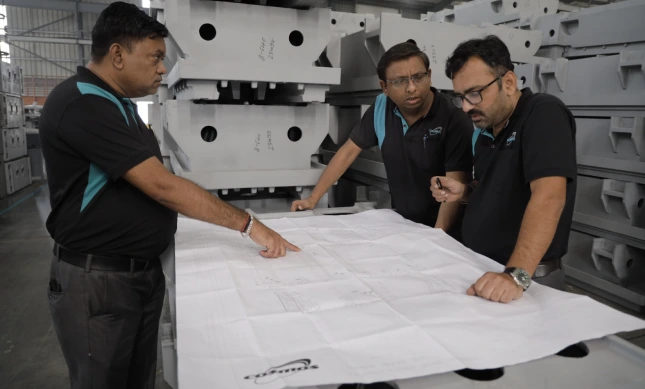

Our Other Range of Excellence

High-tech Products For Unmatched Performance