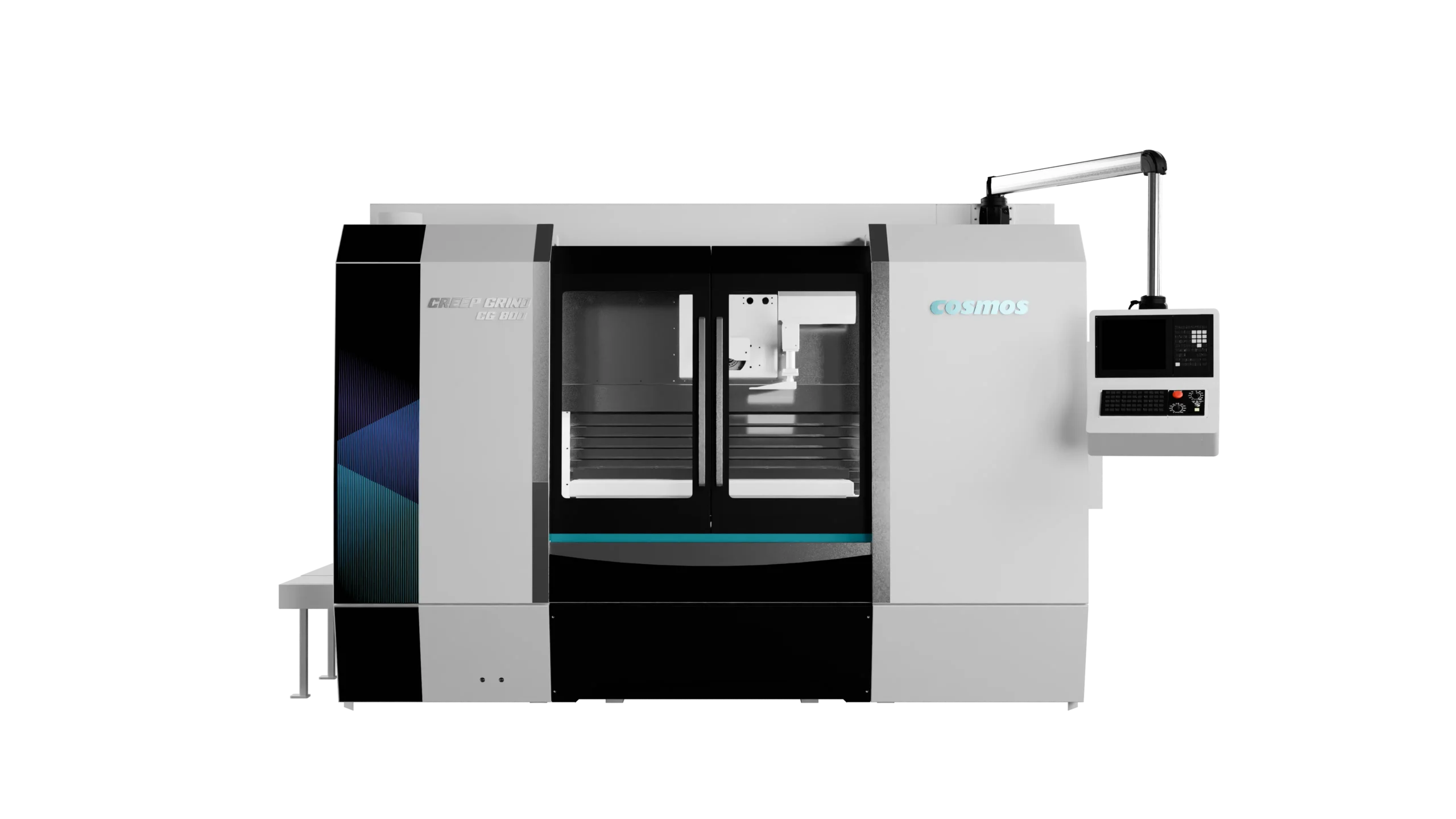

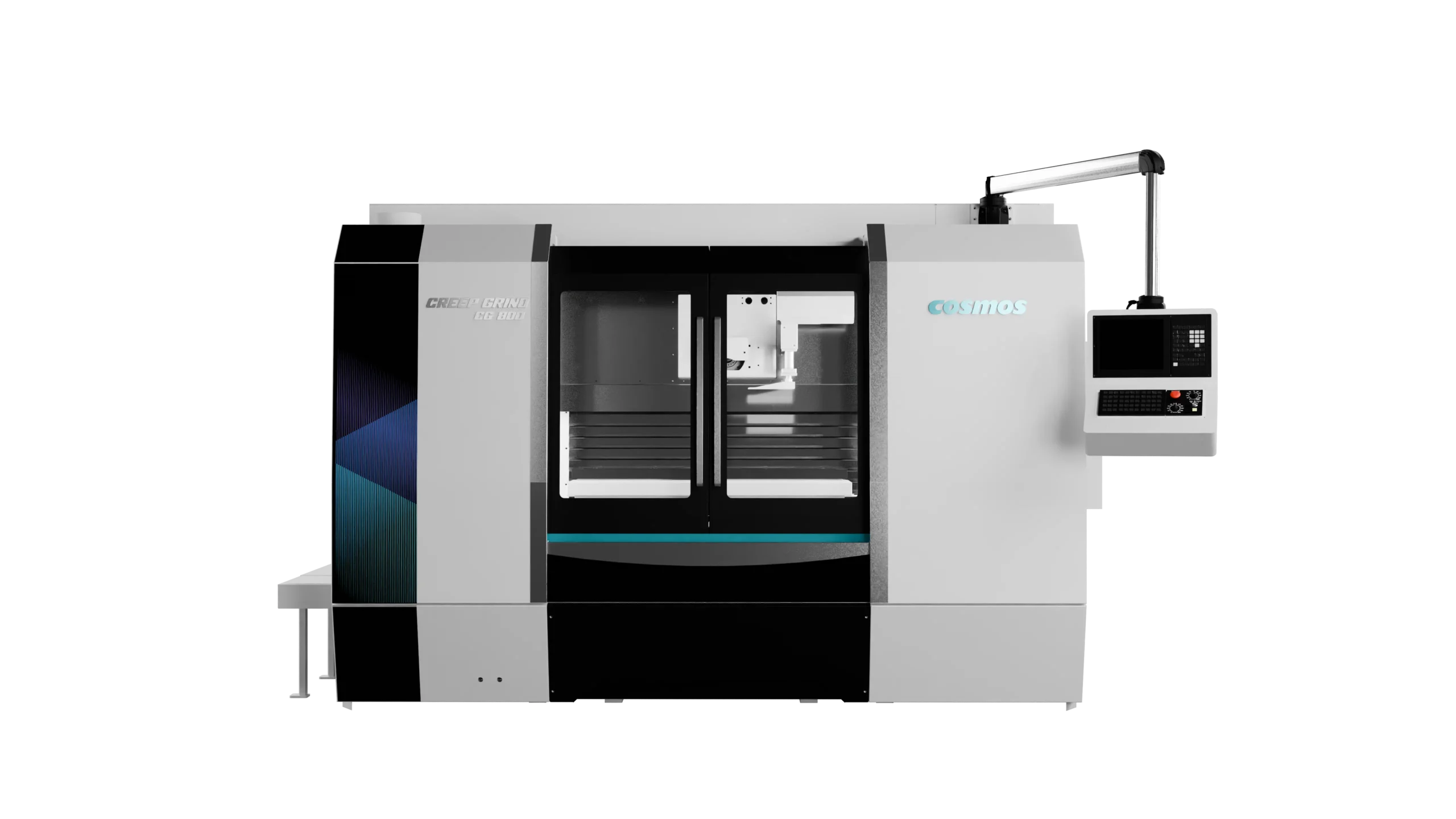

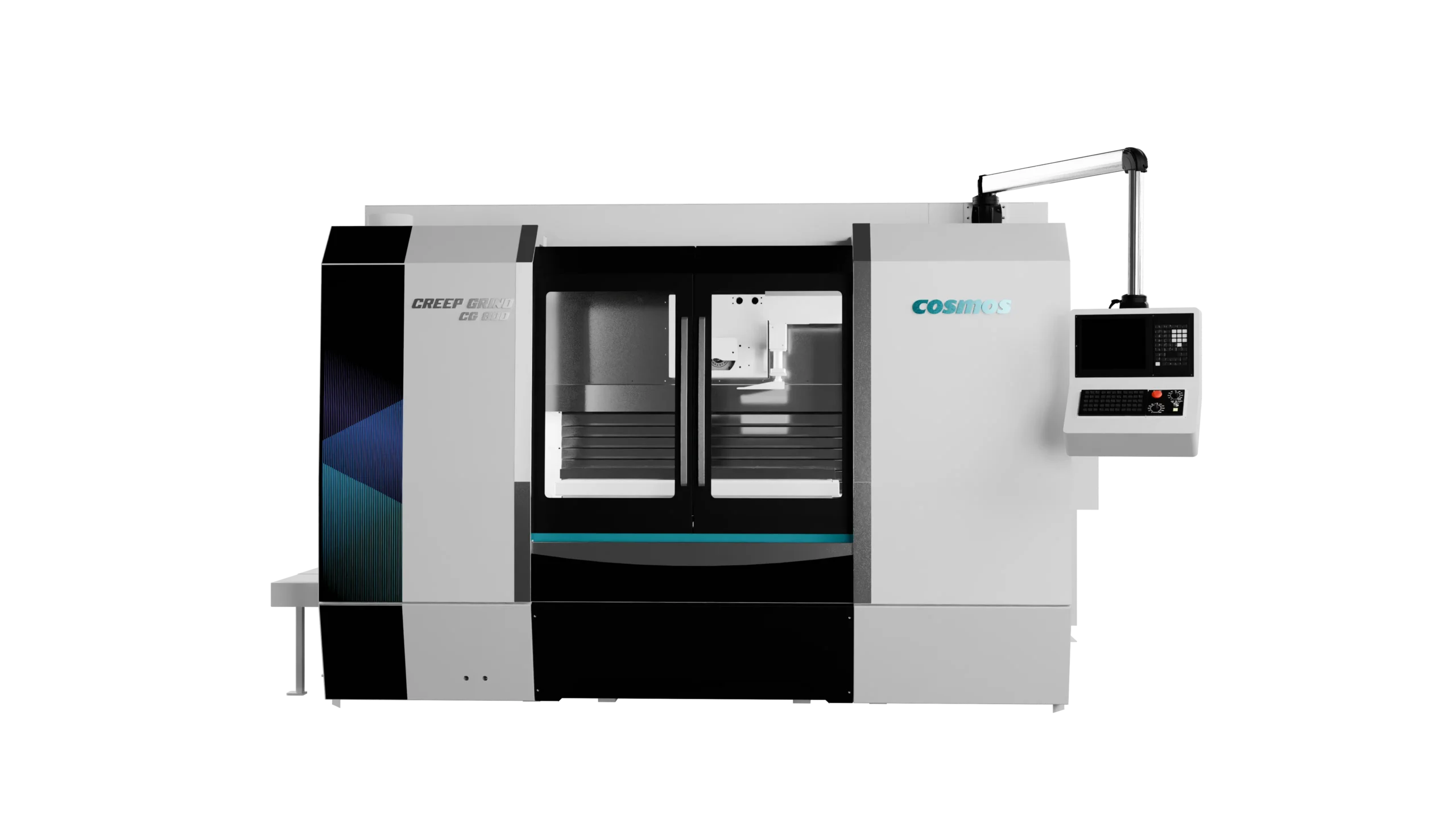

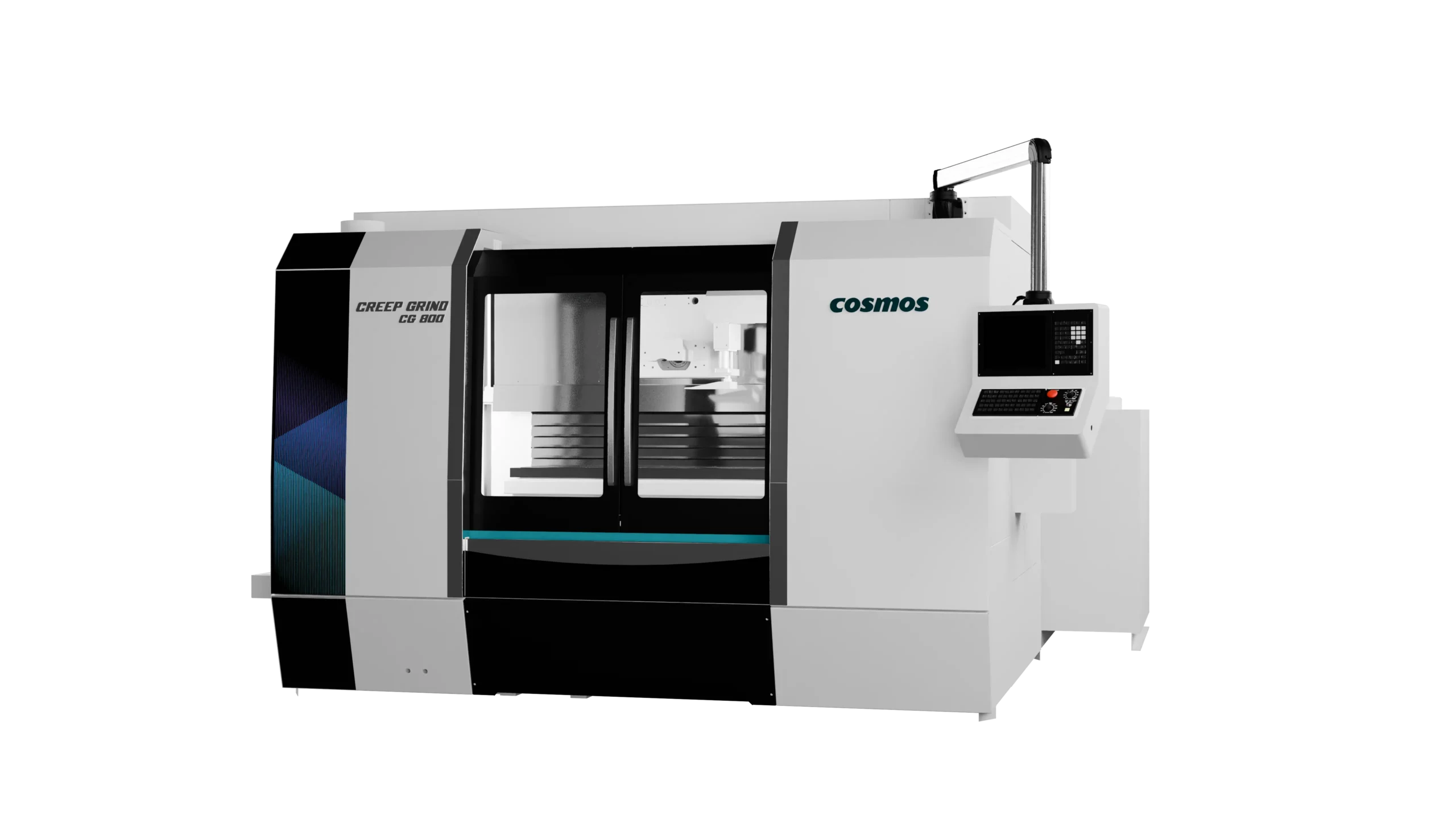

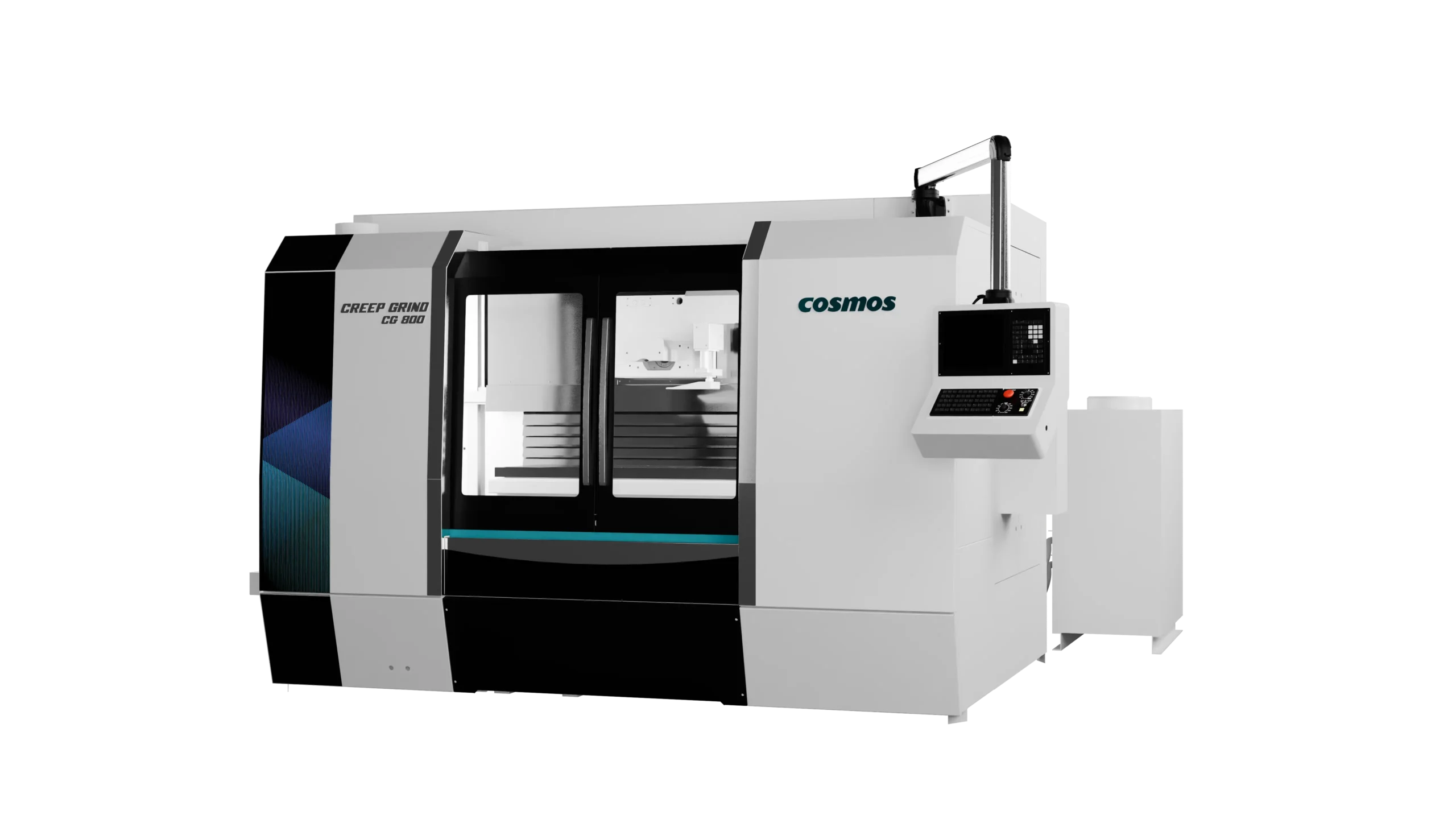

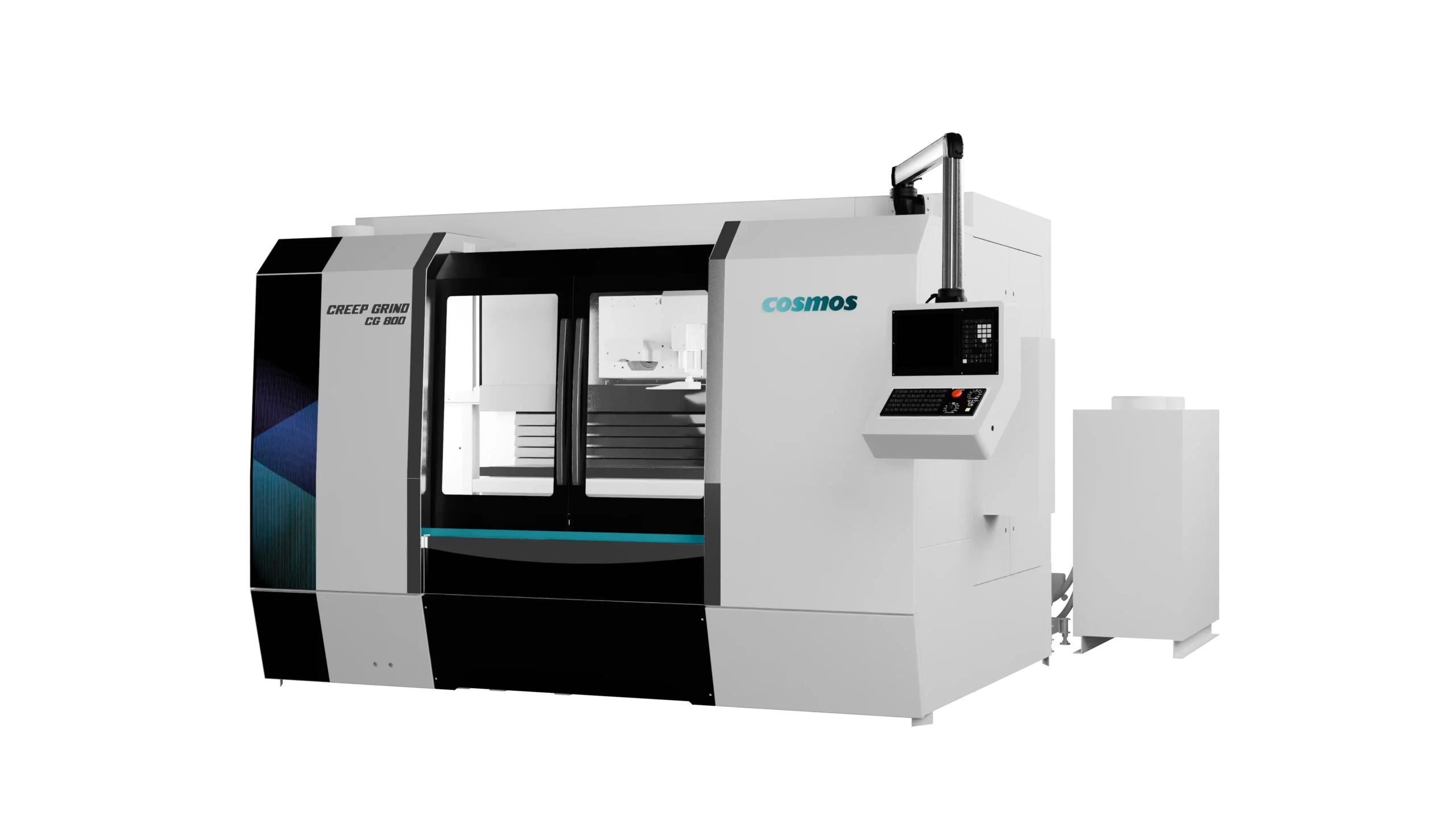

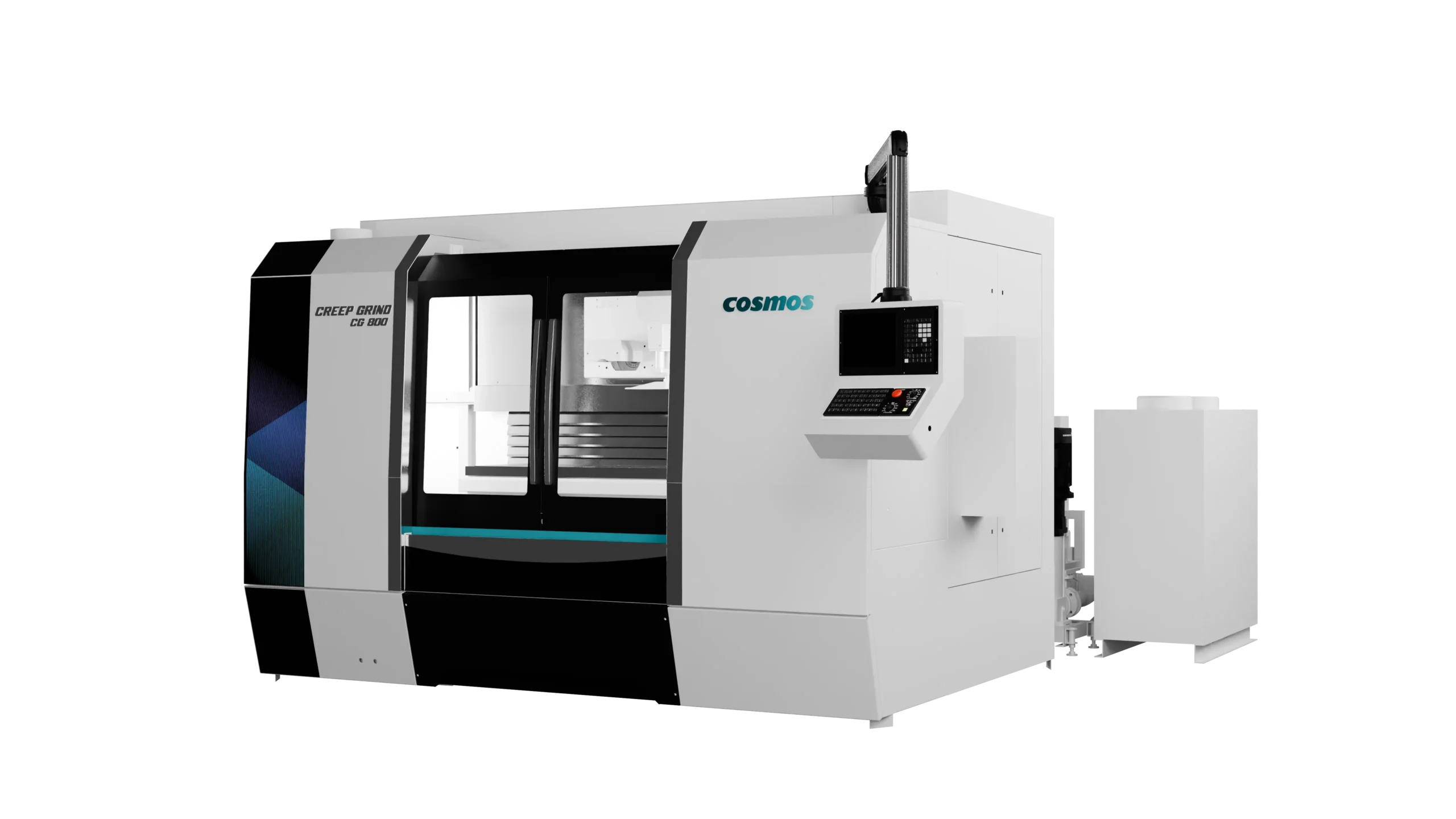

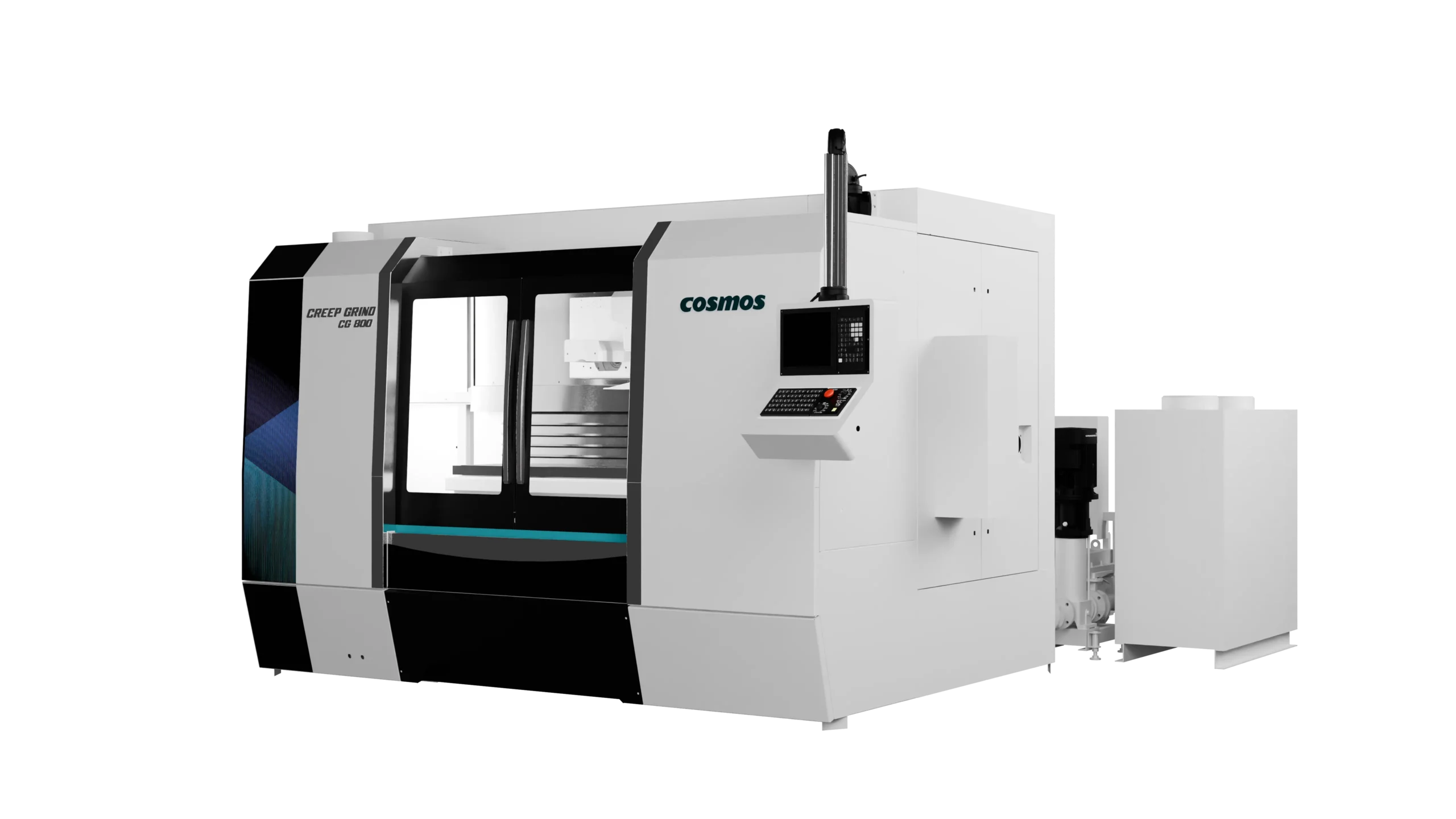

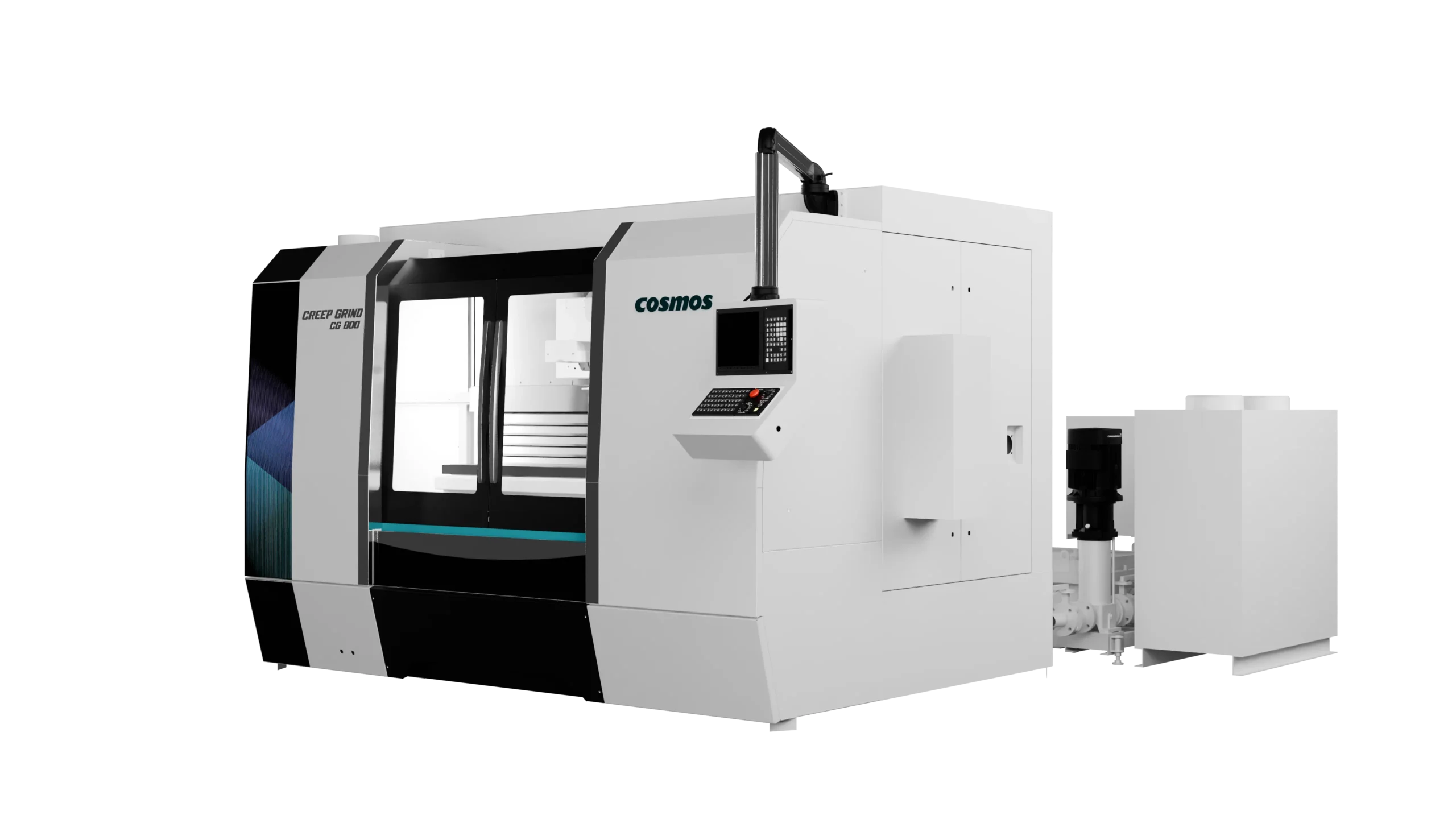

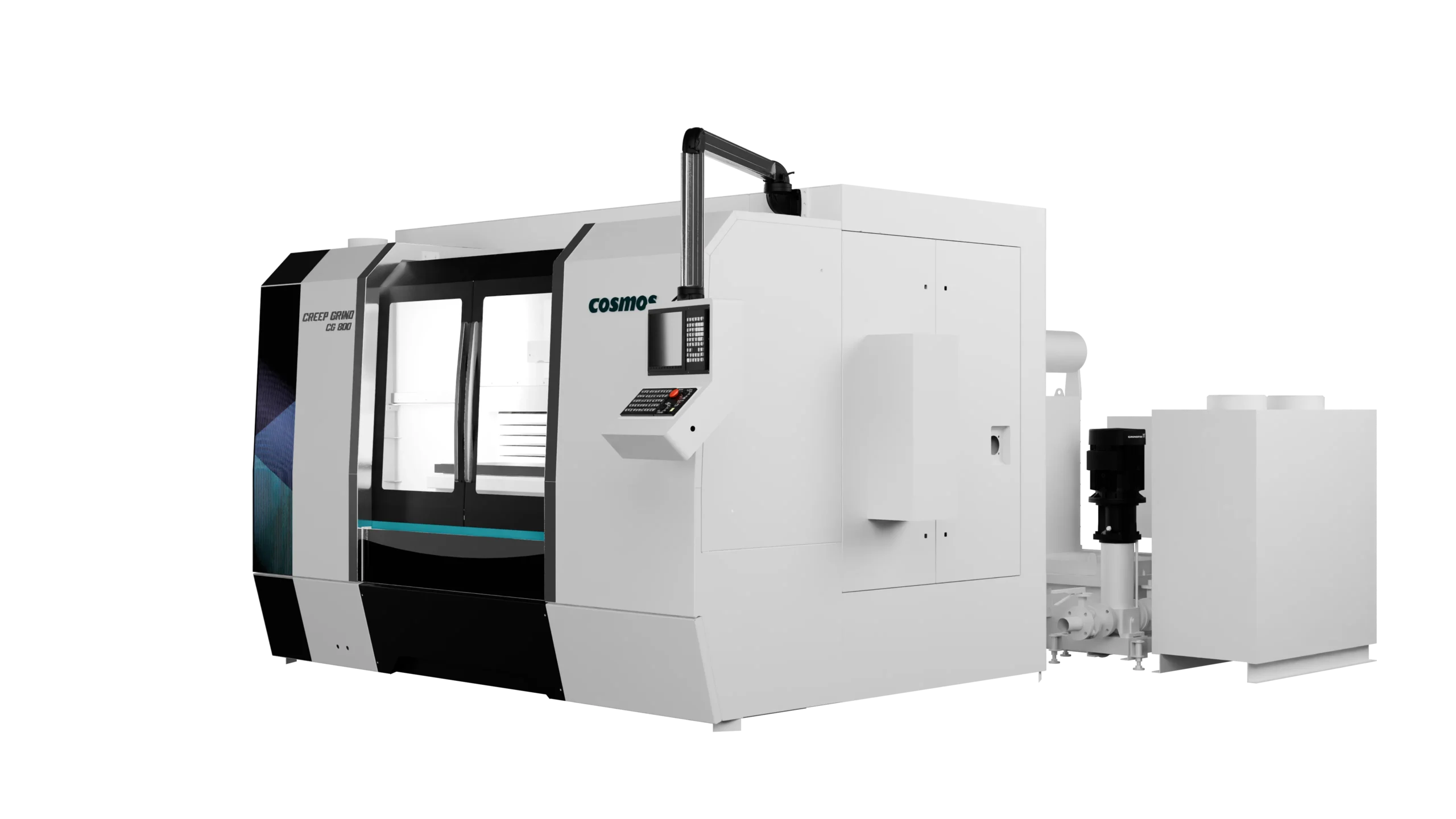

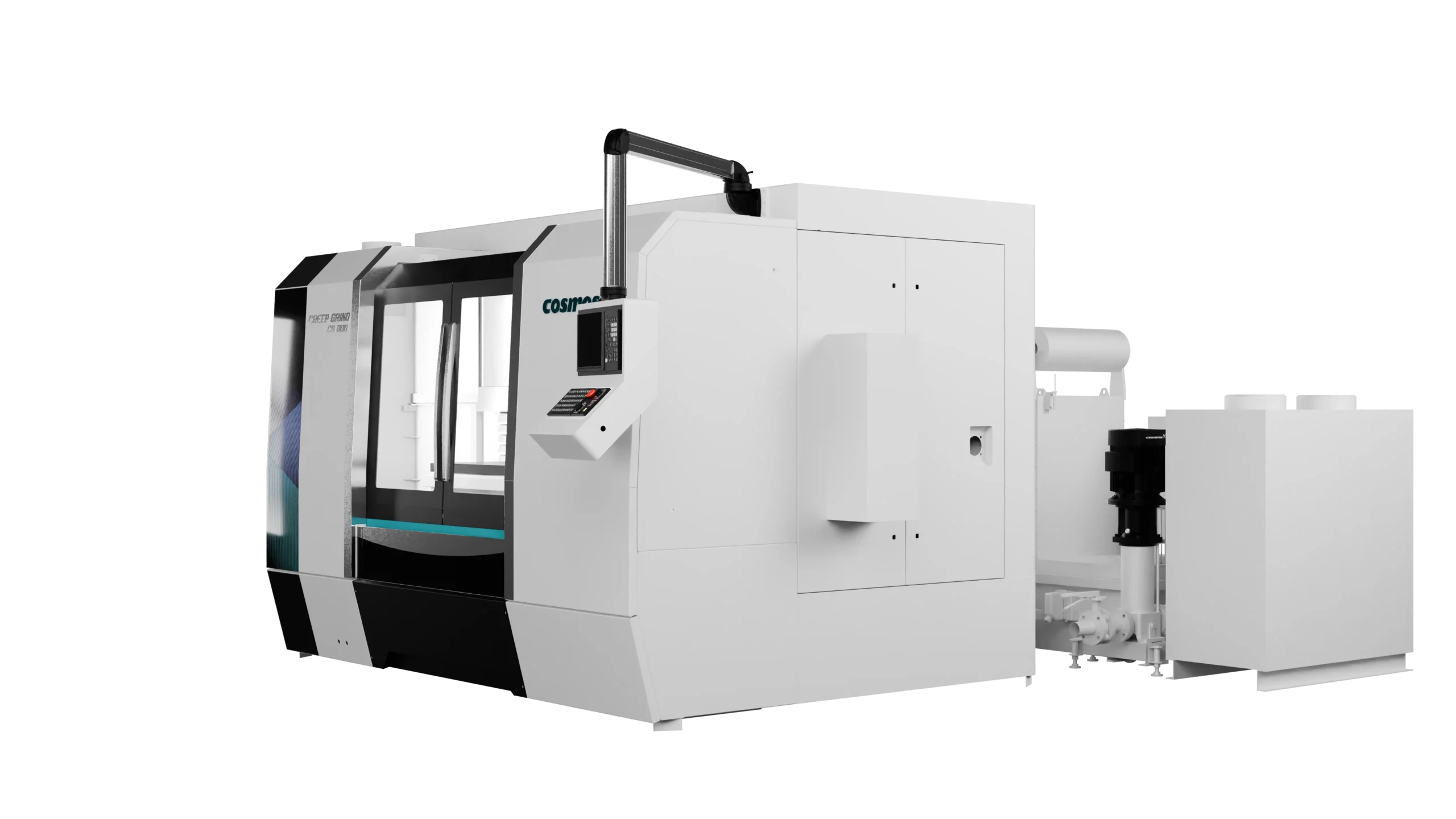

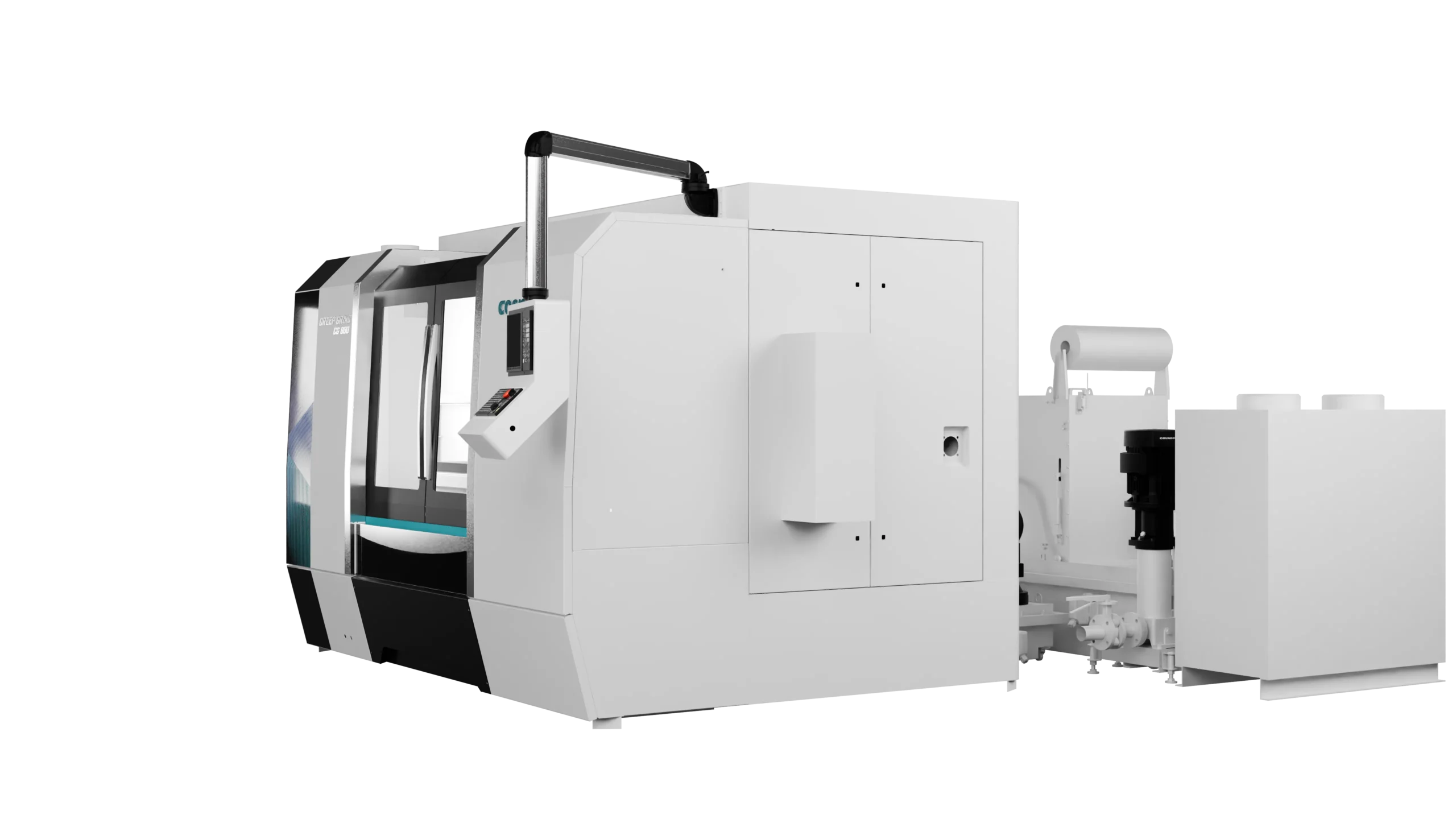

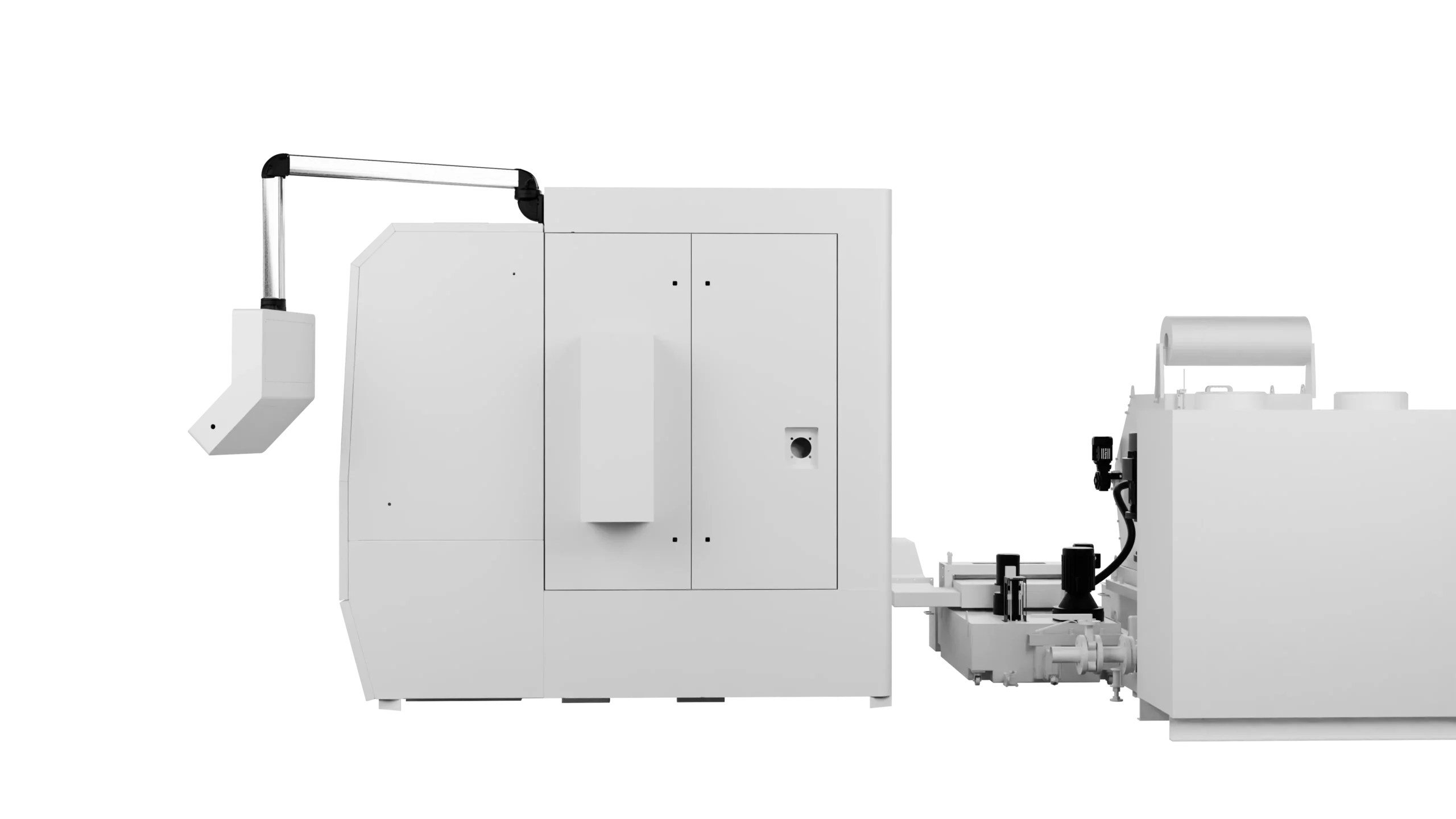

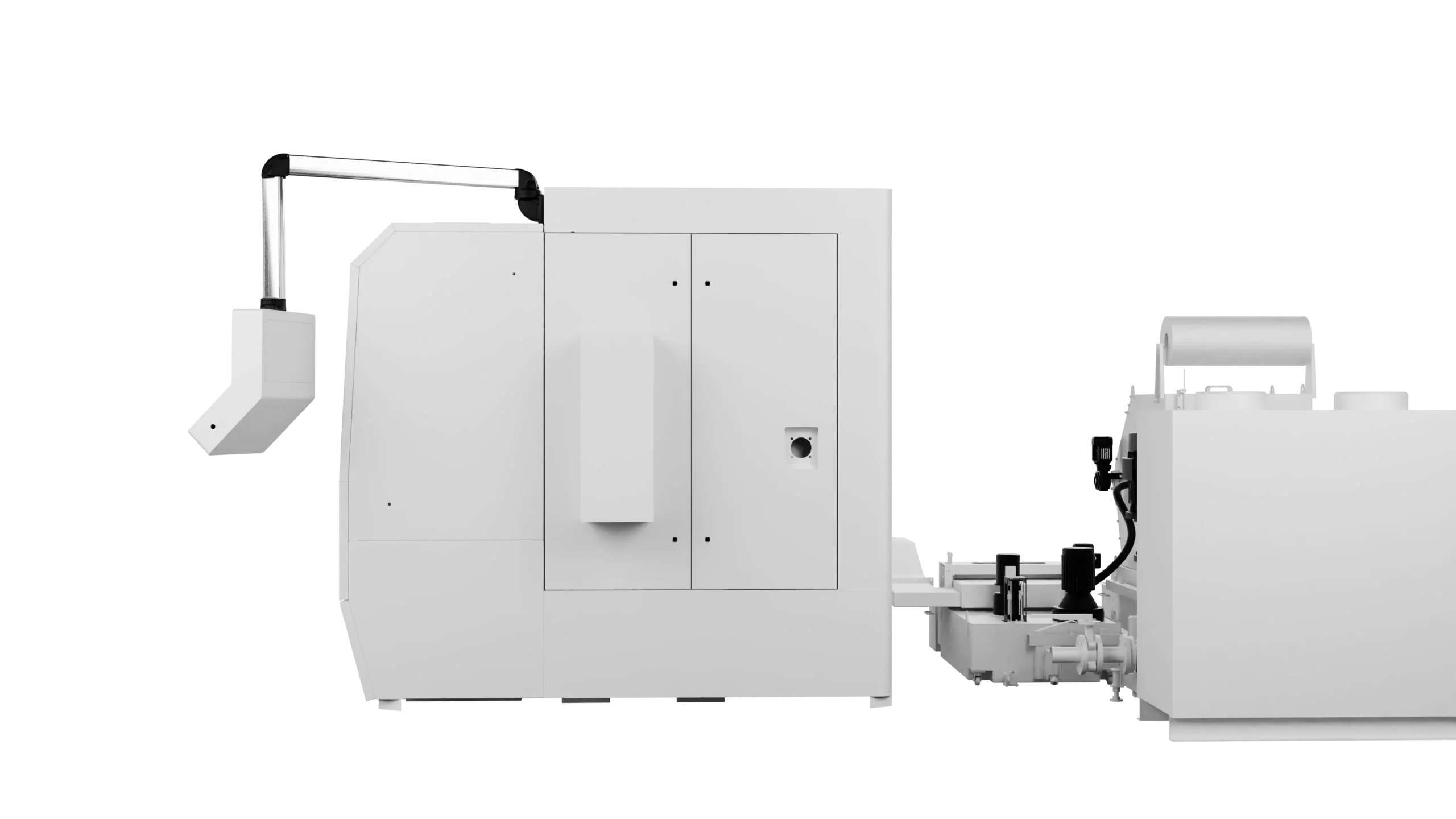

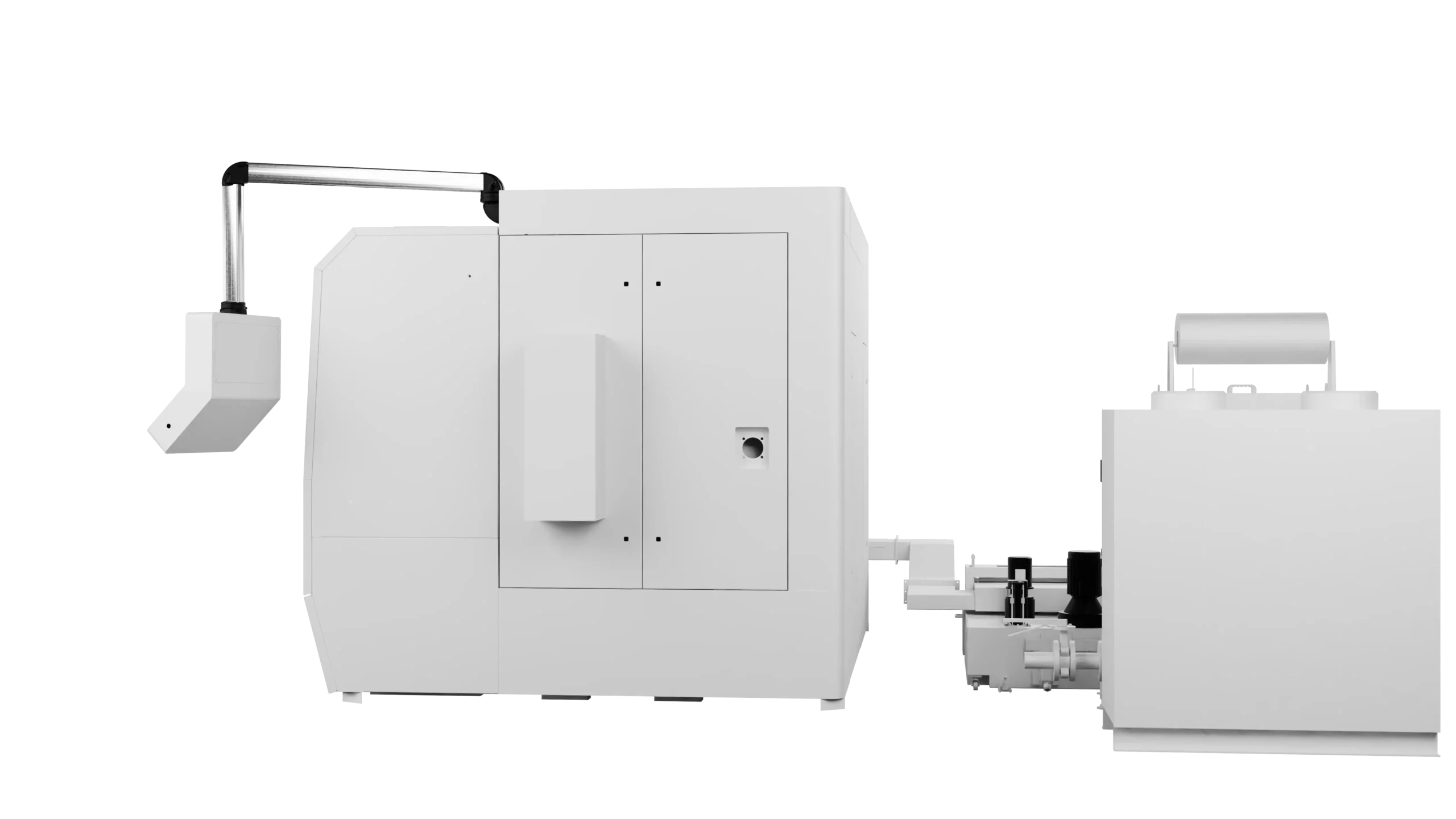

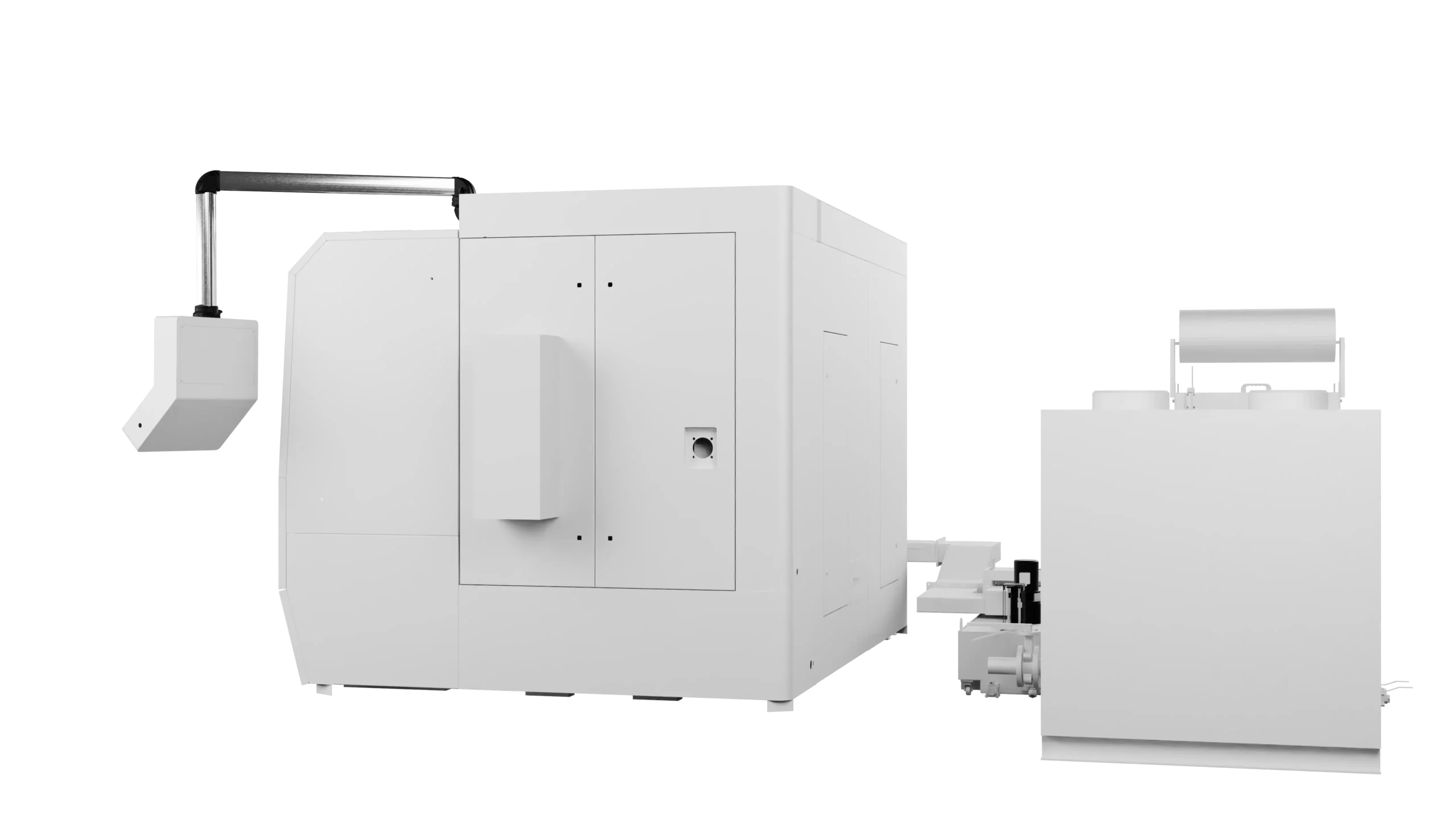

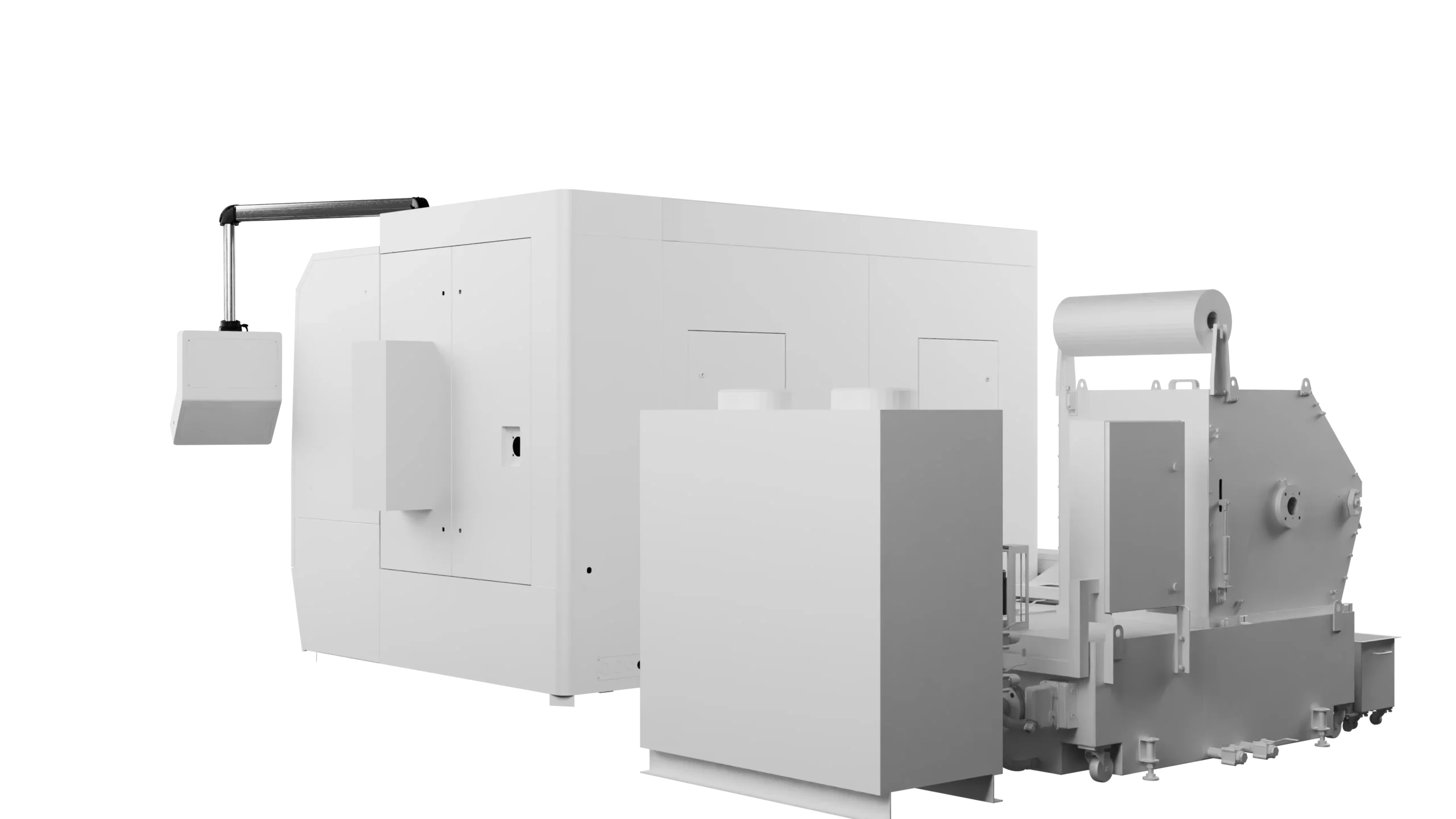

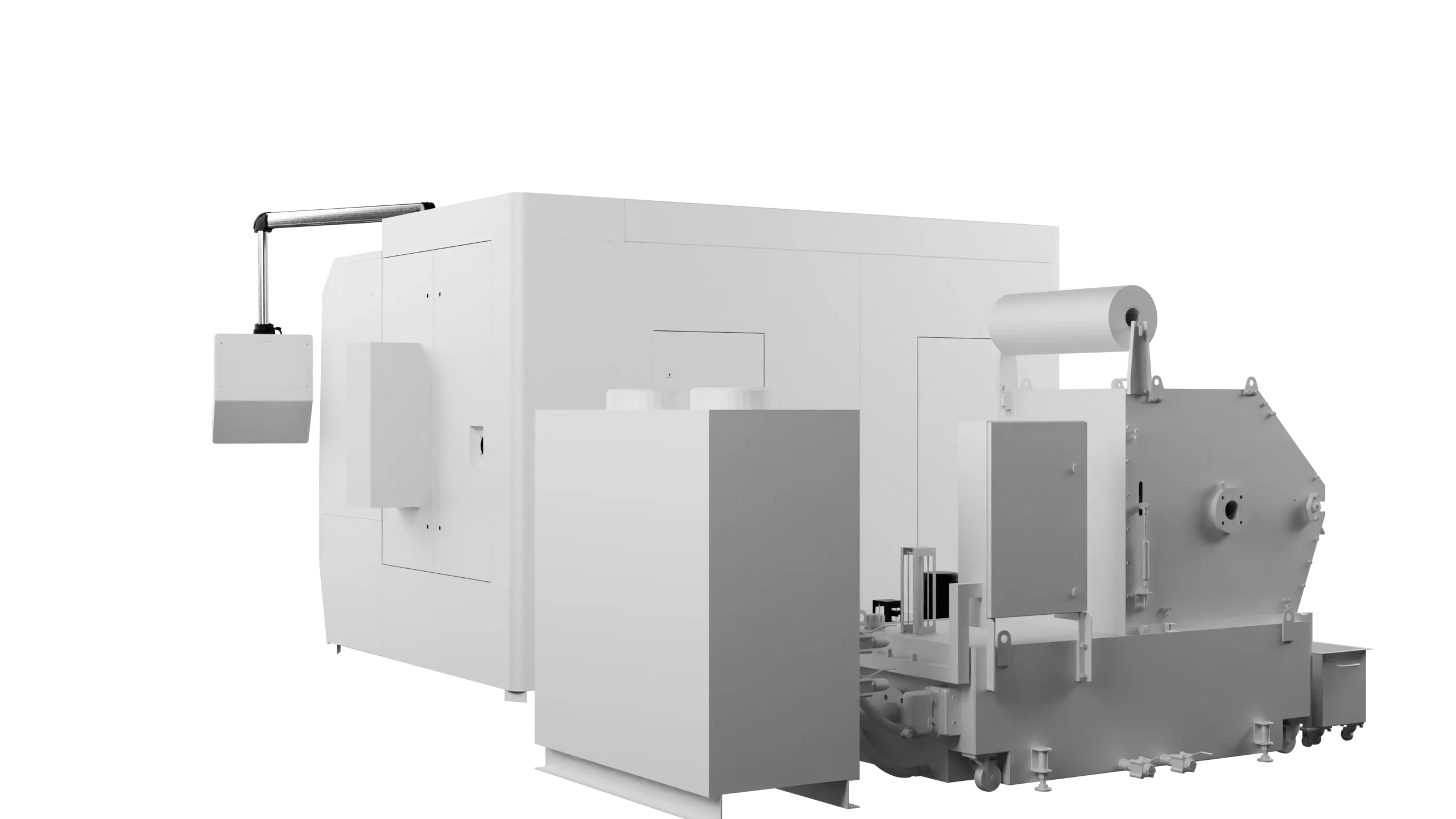

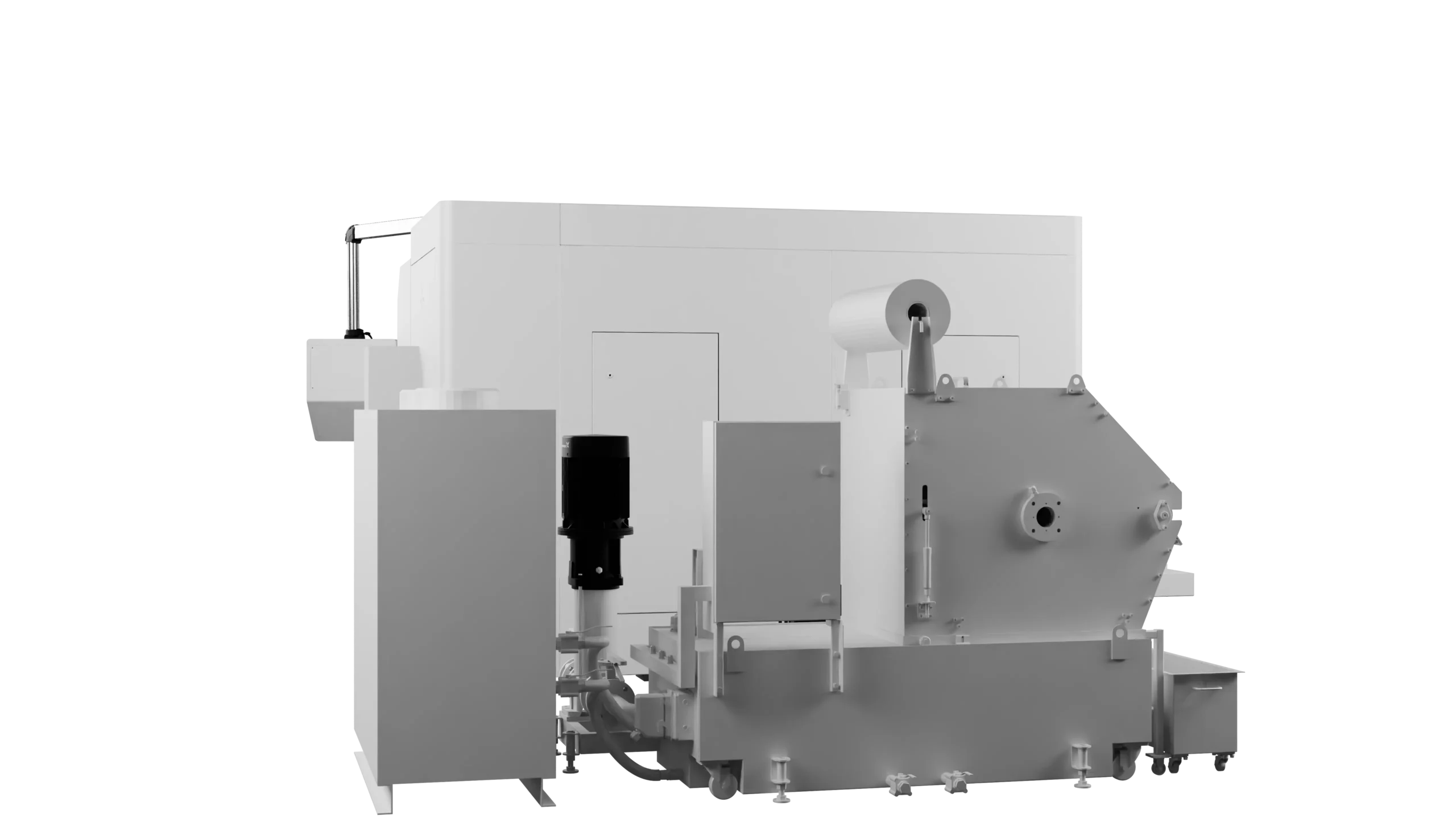

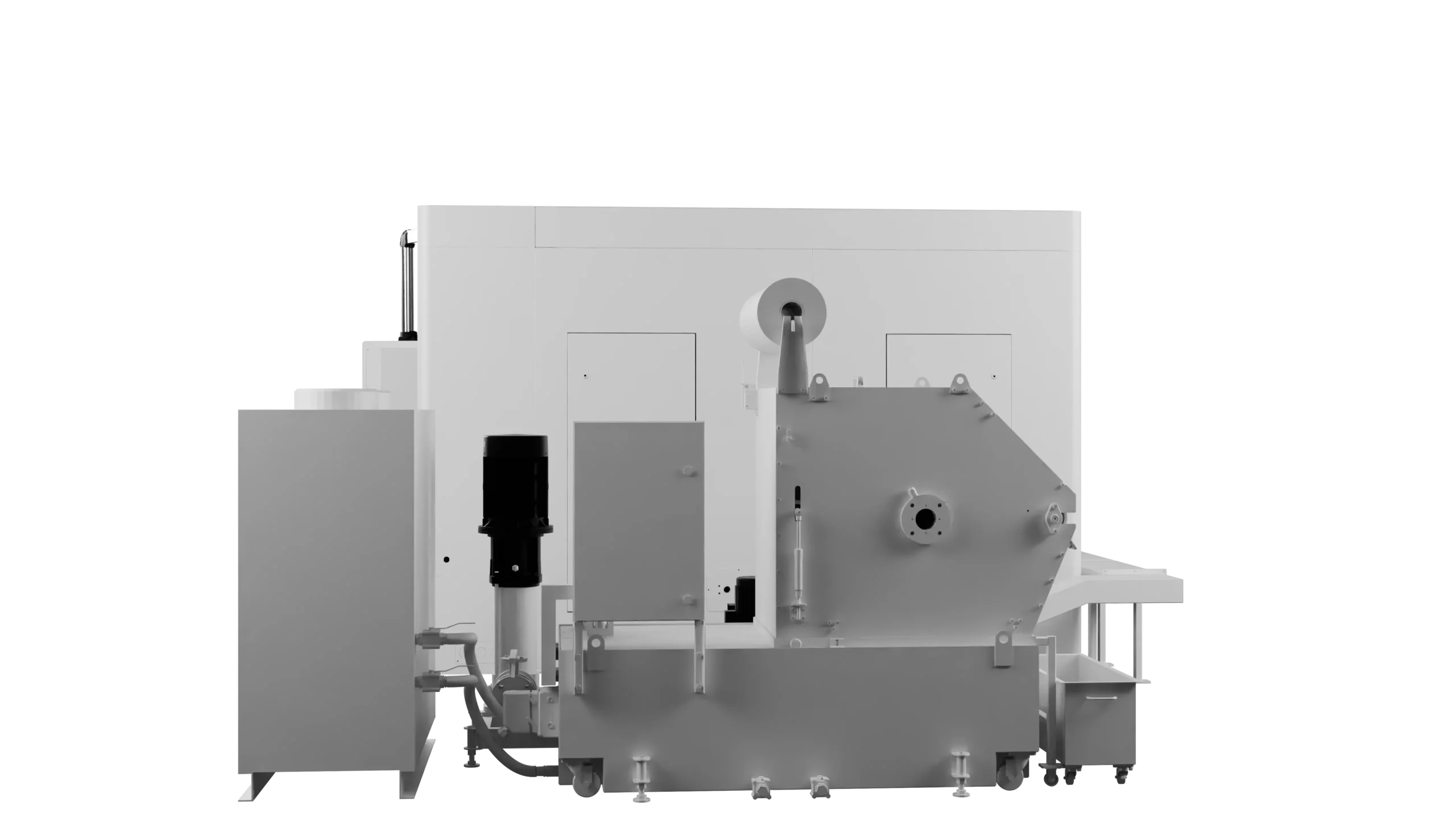

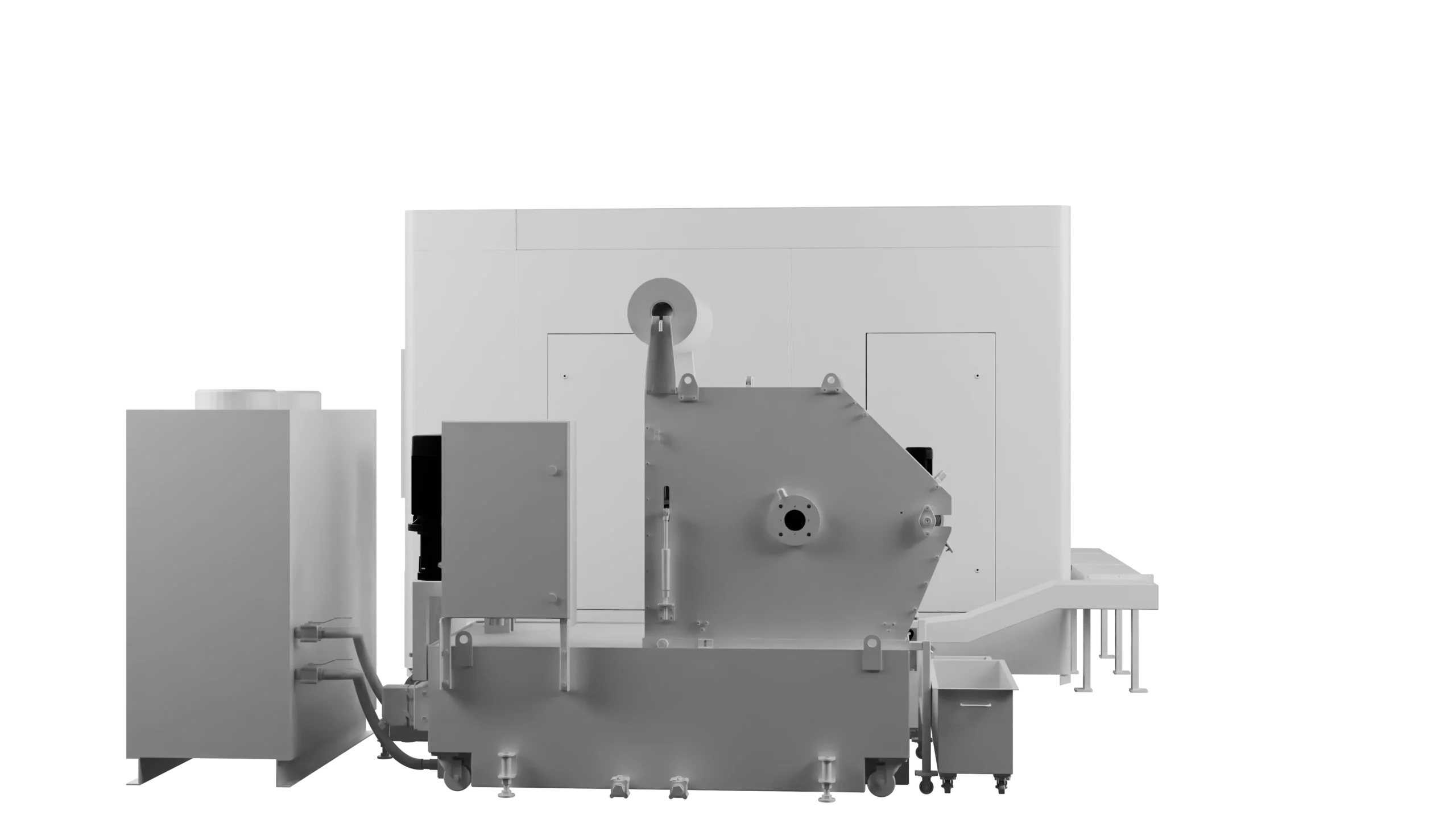

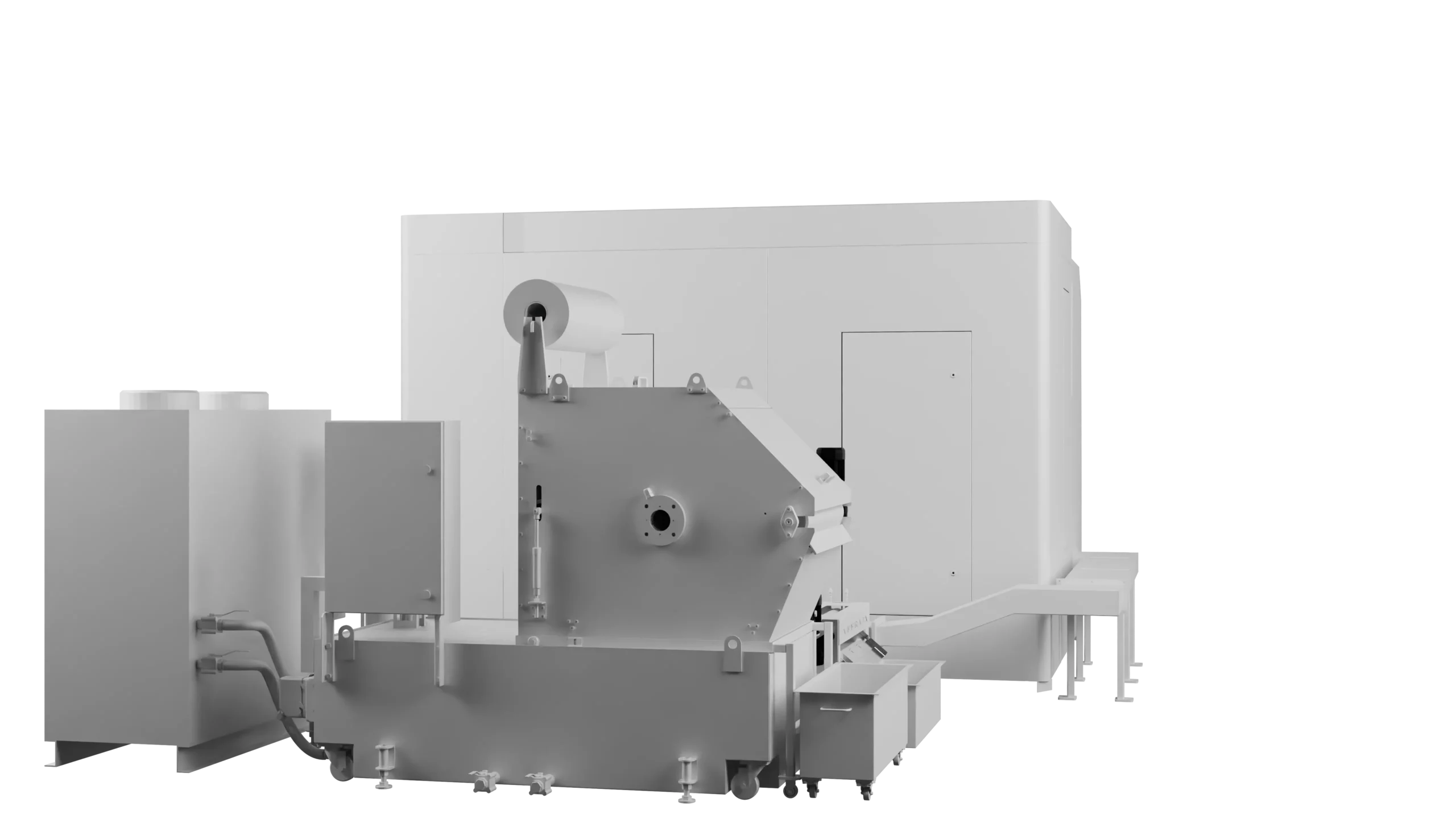

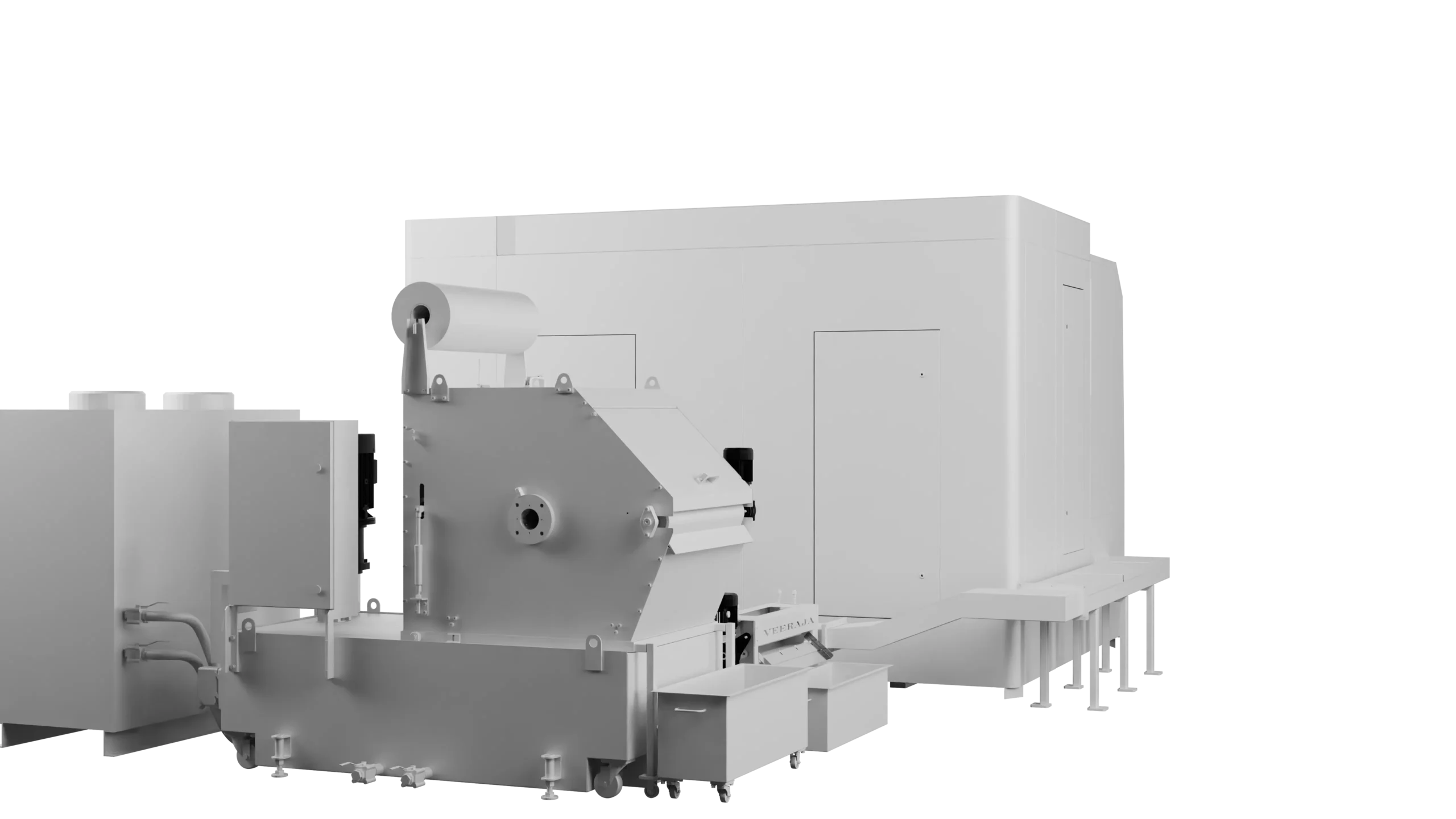

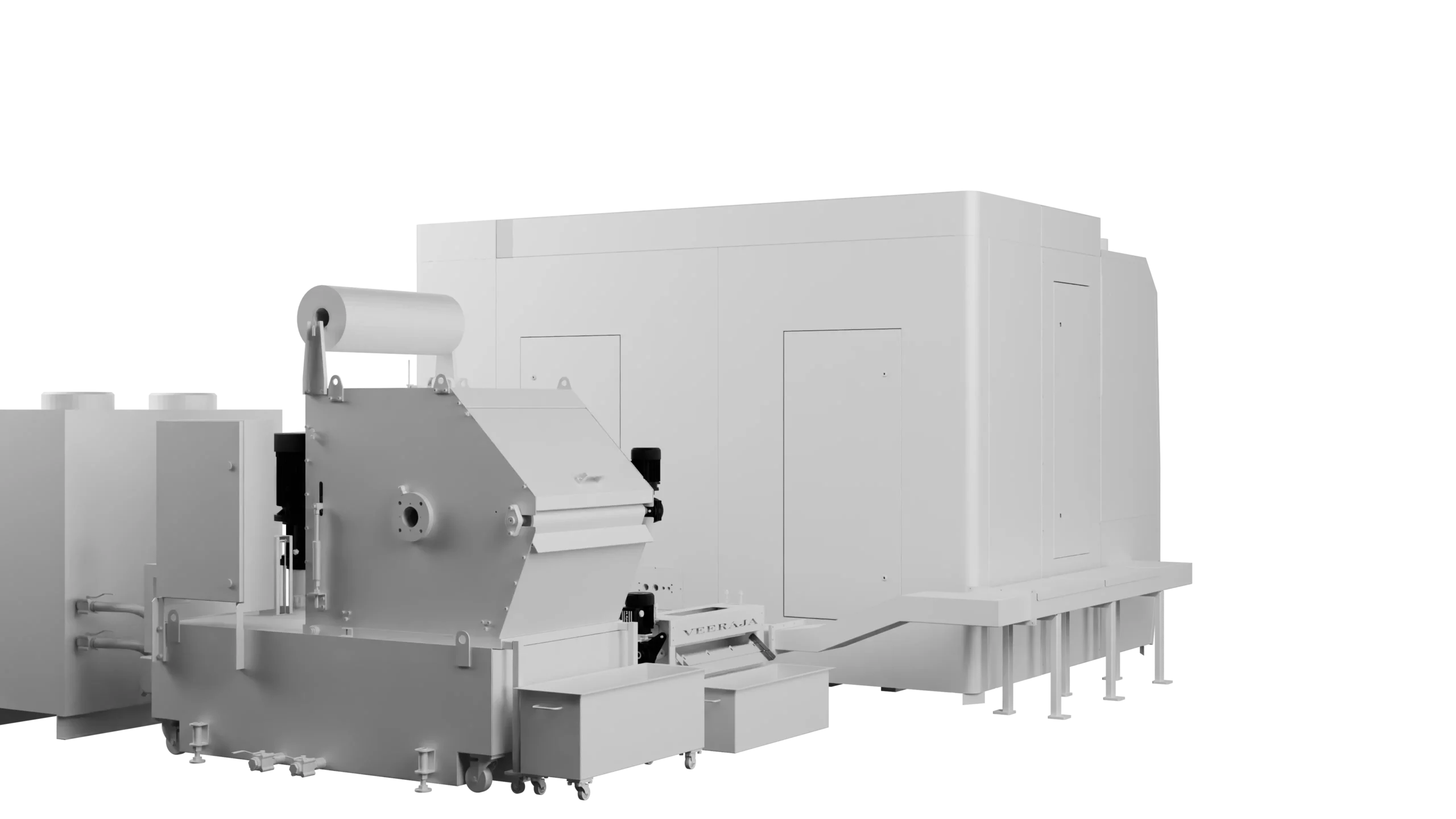

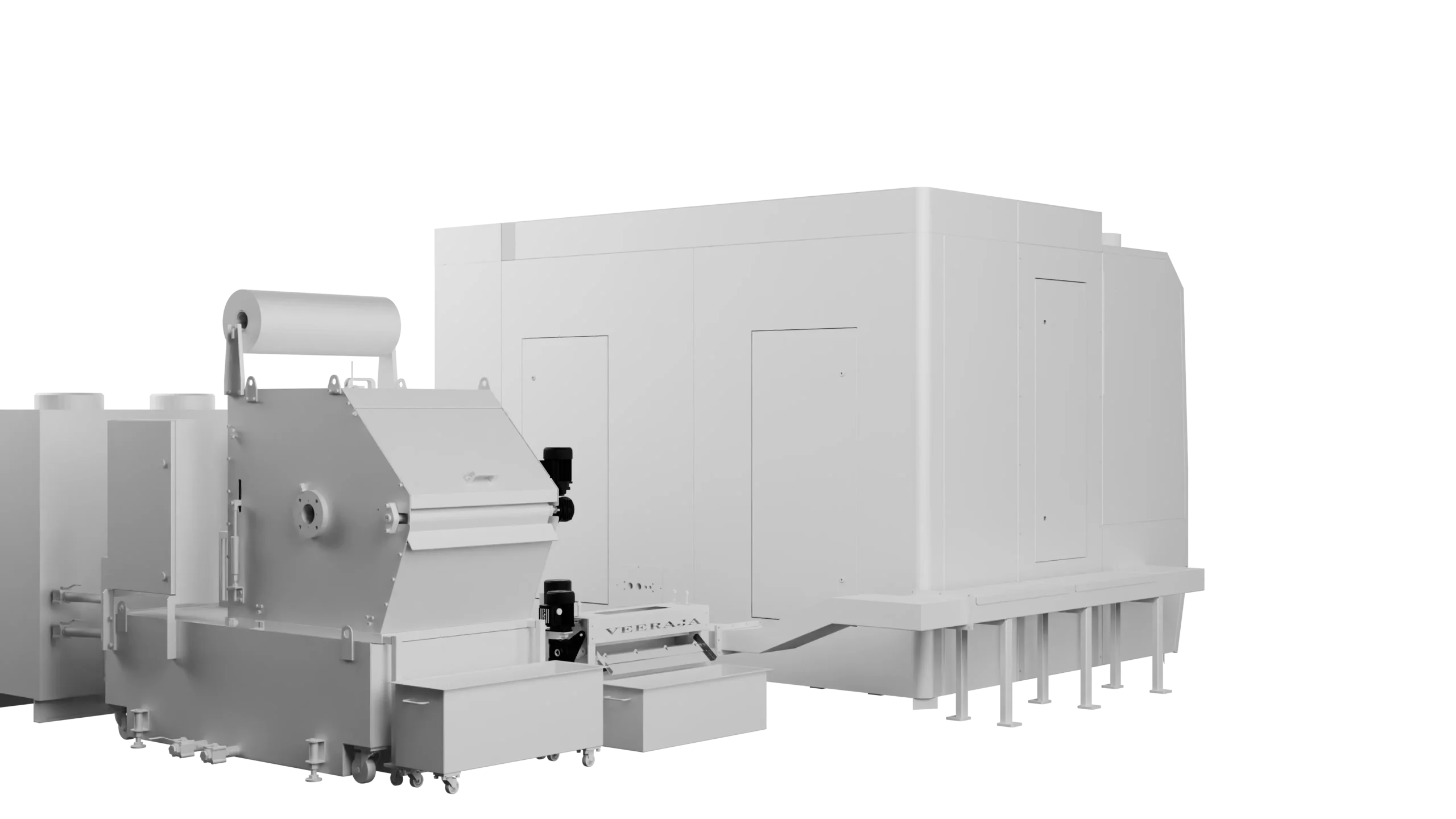

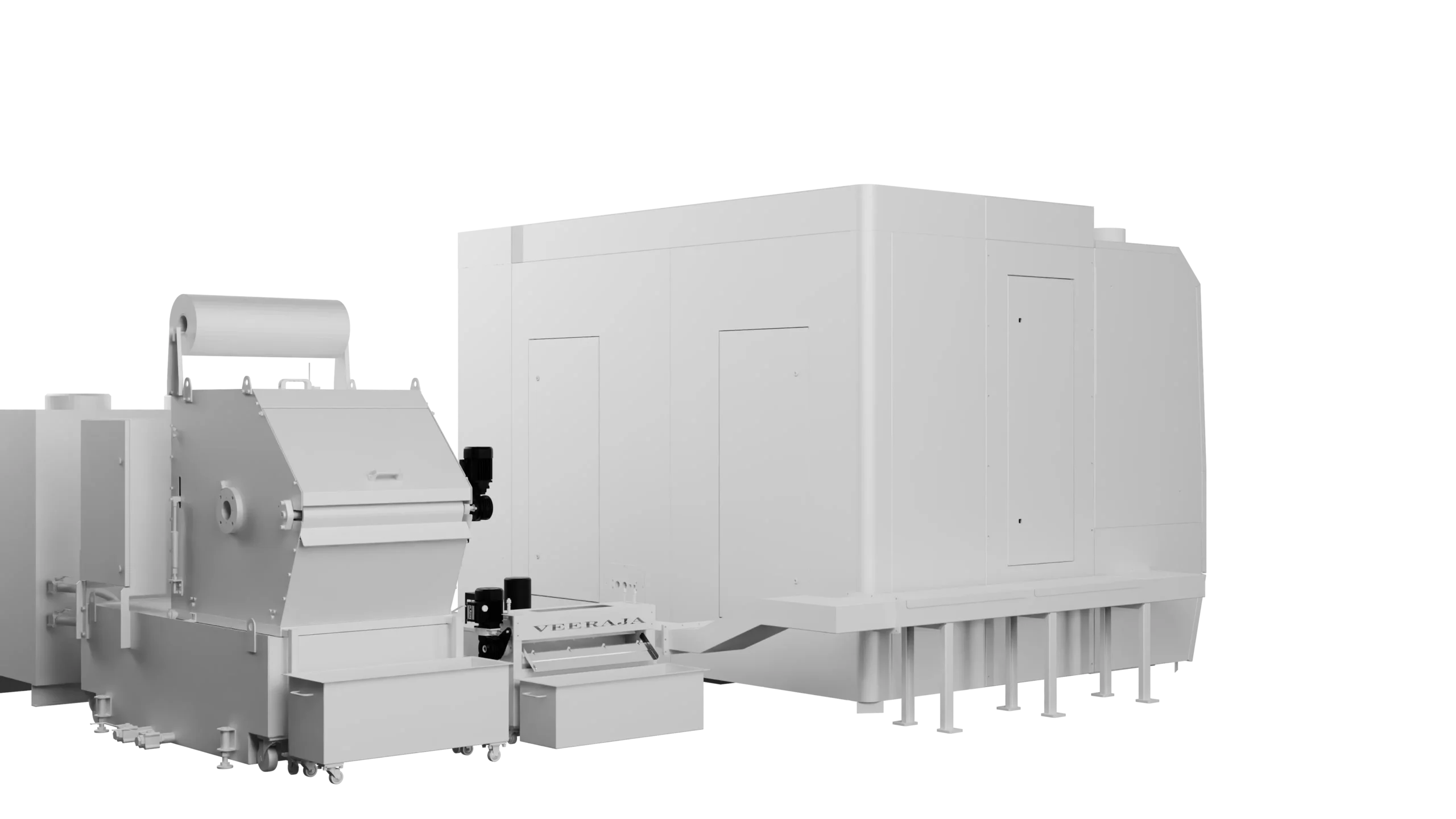

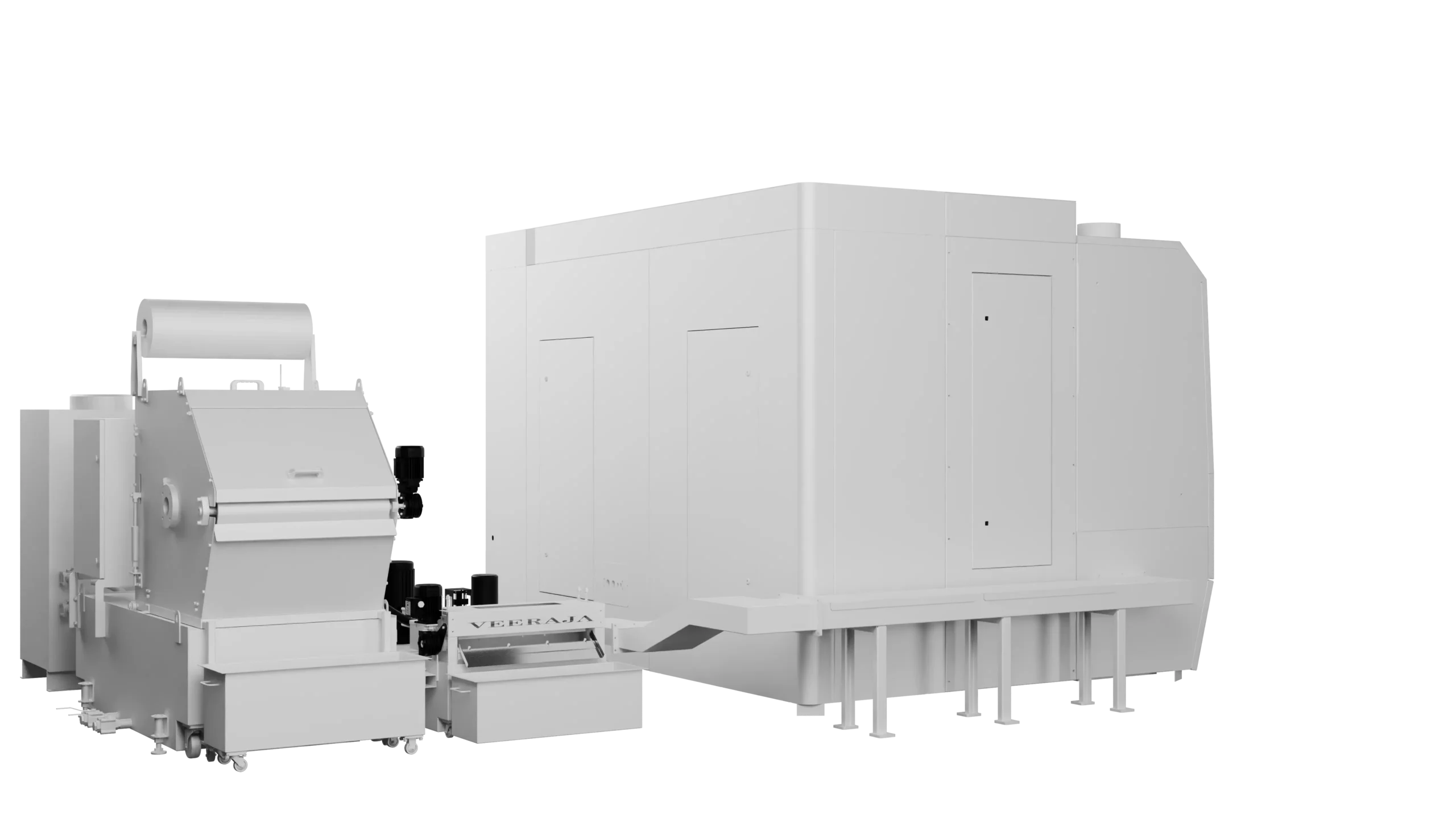

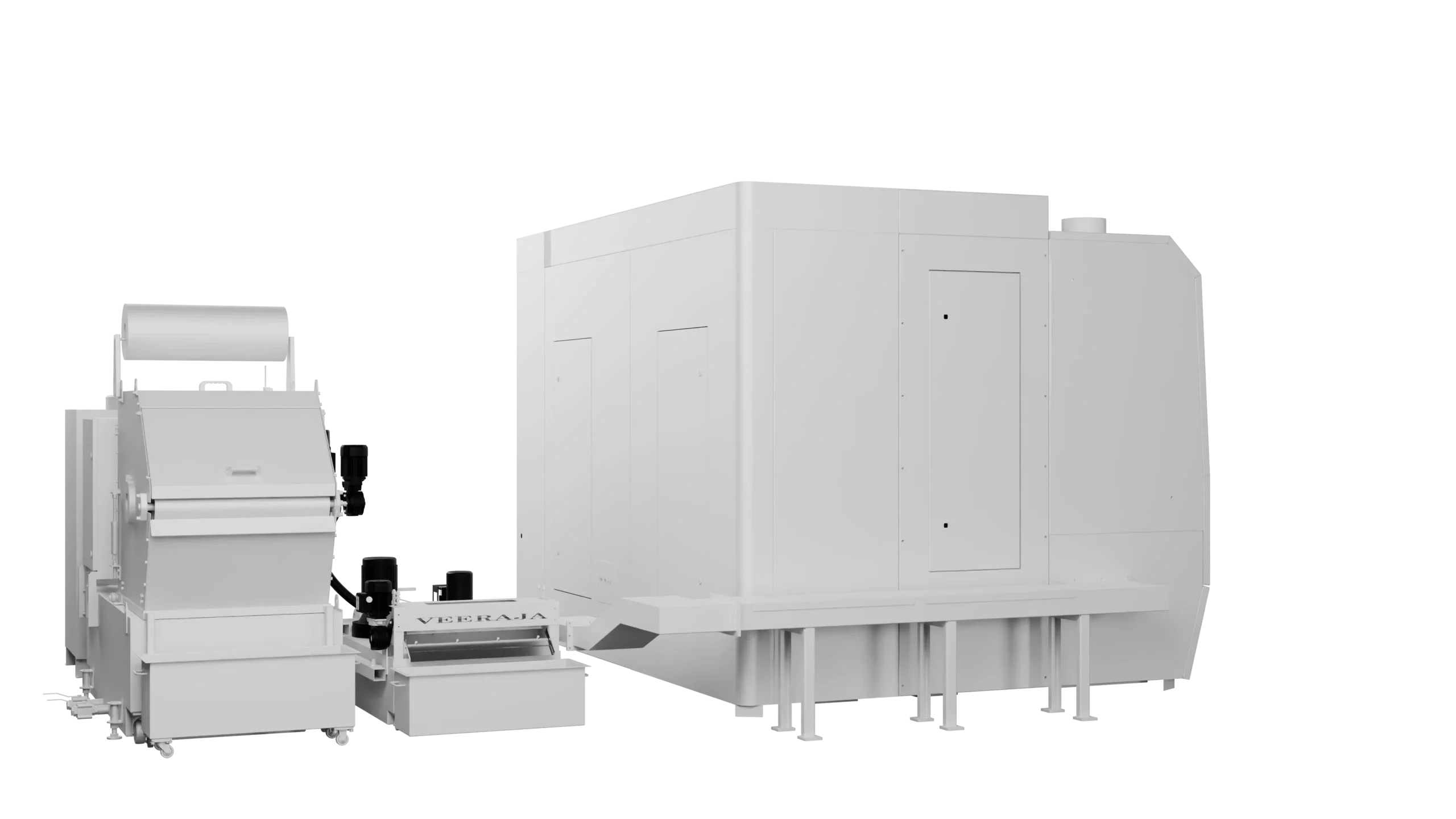

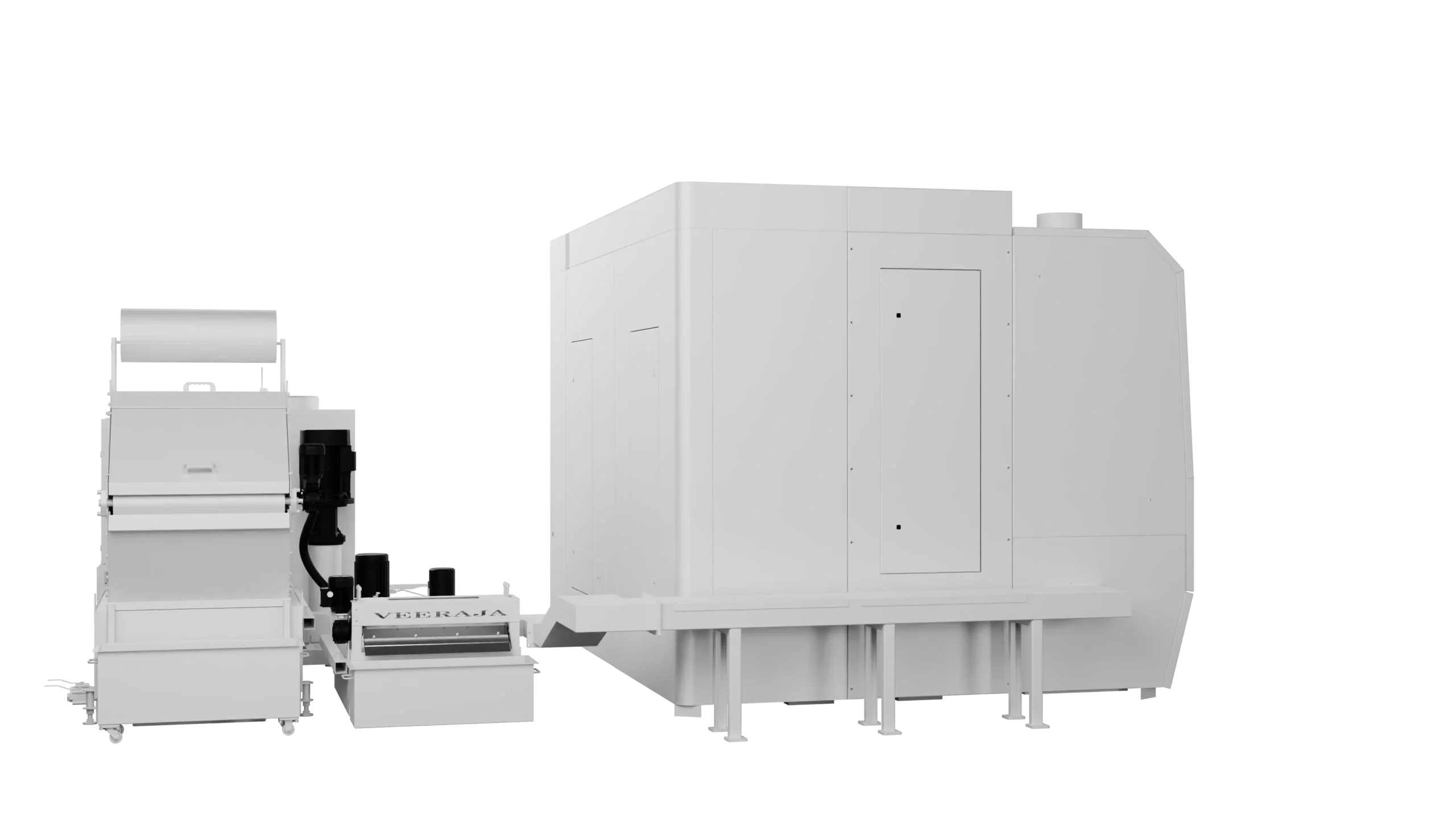

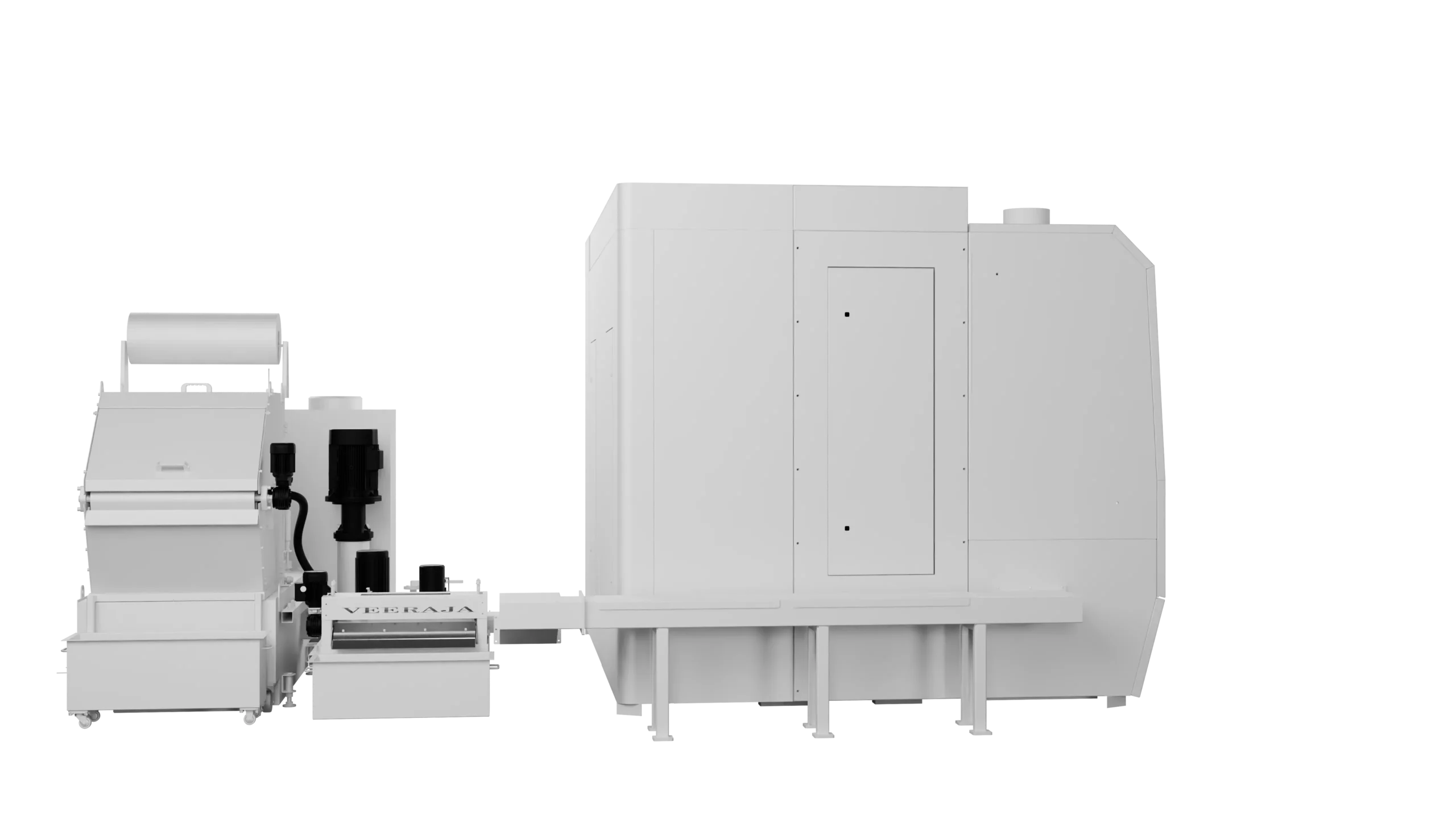

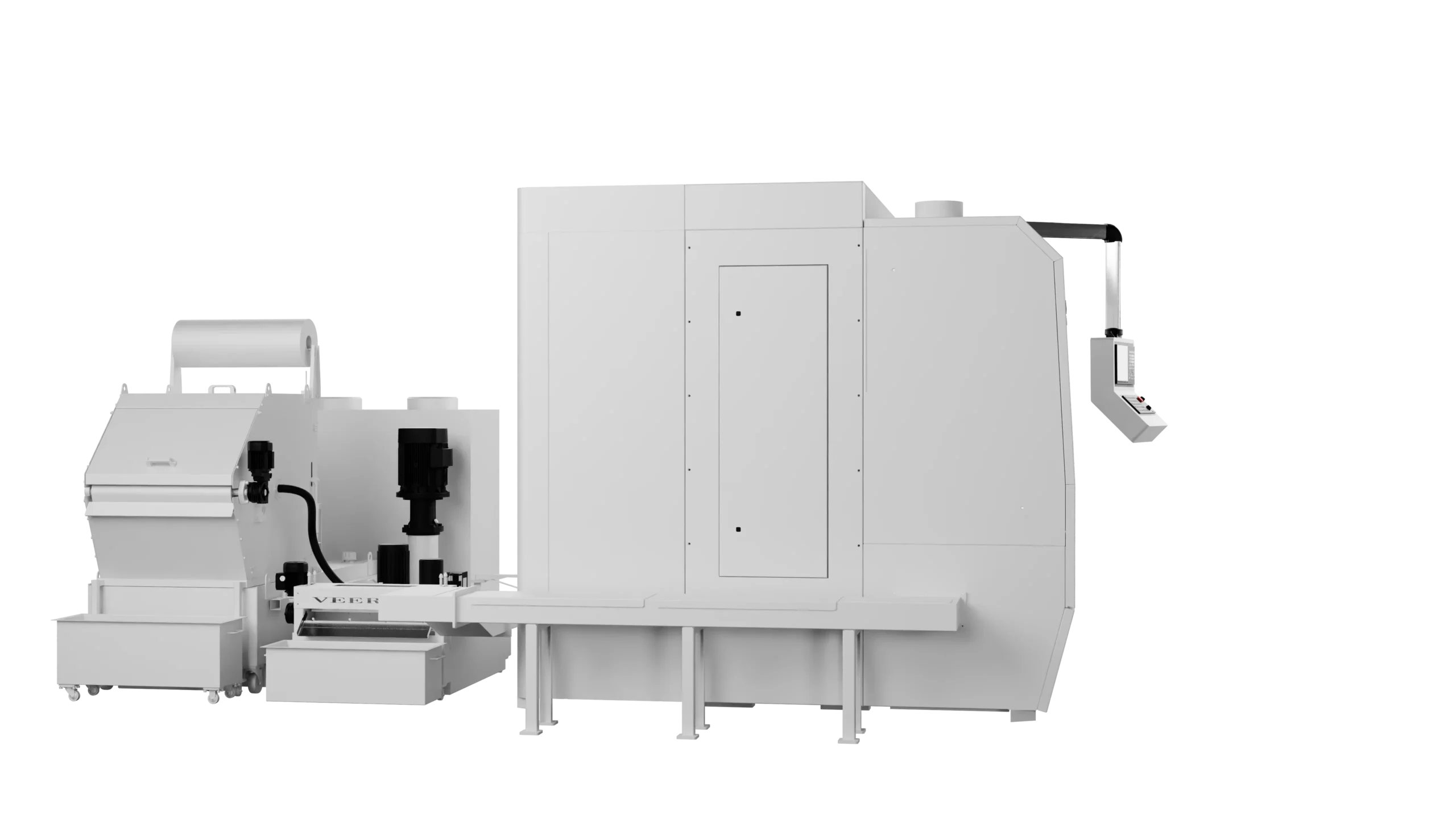

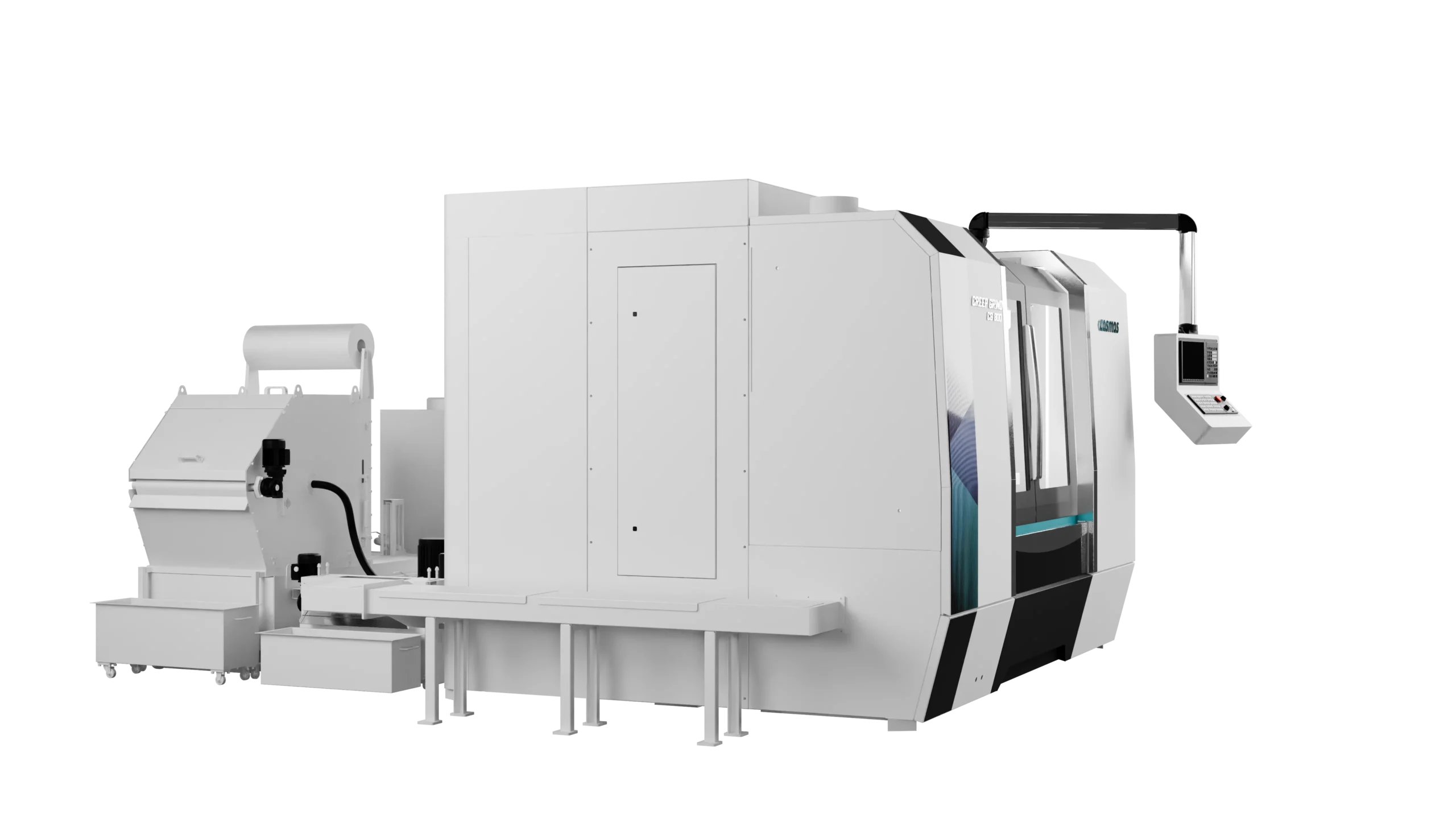

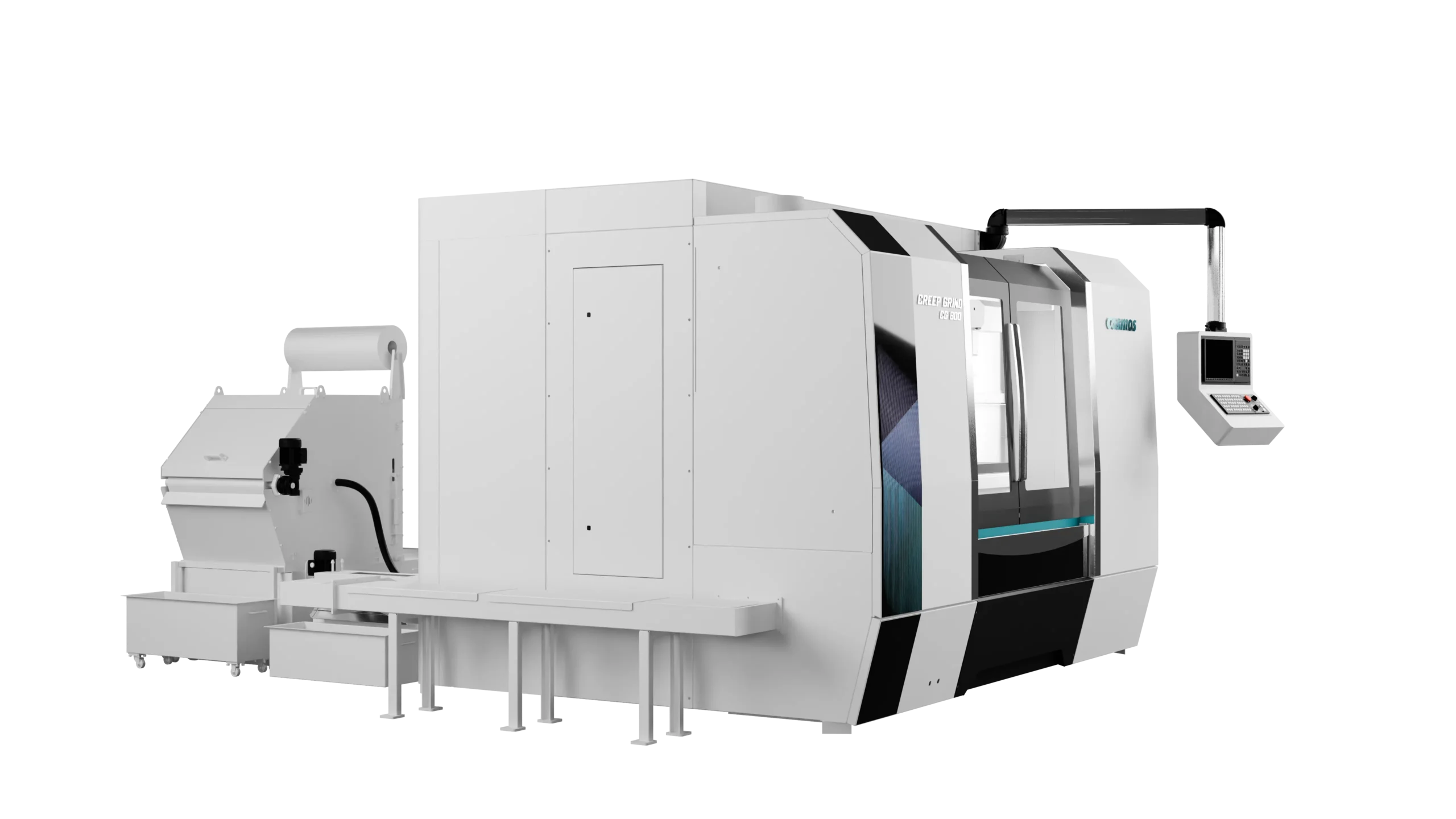

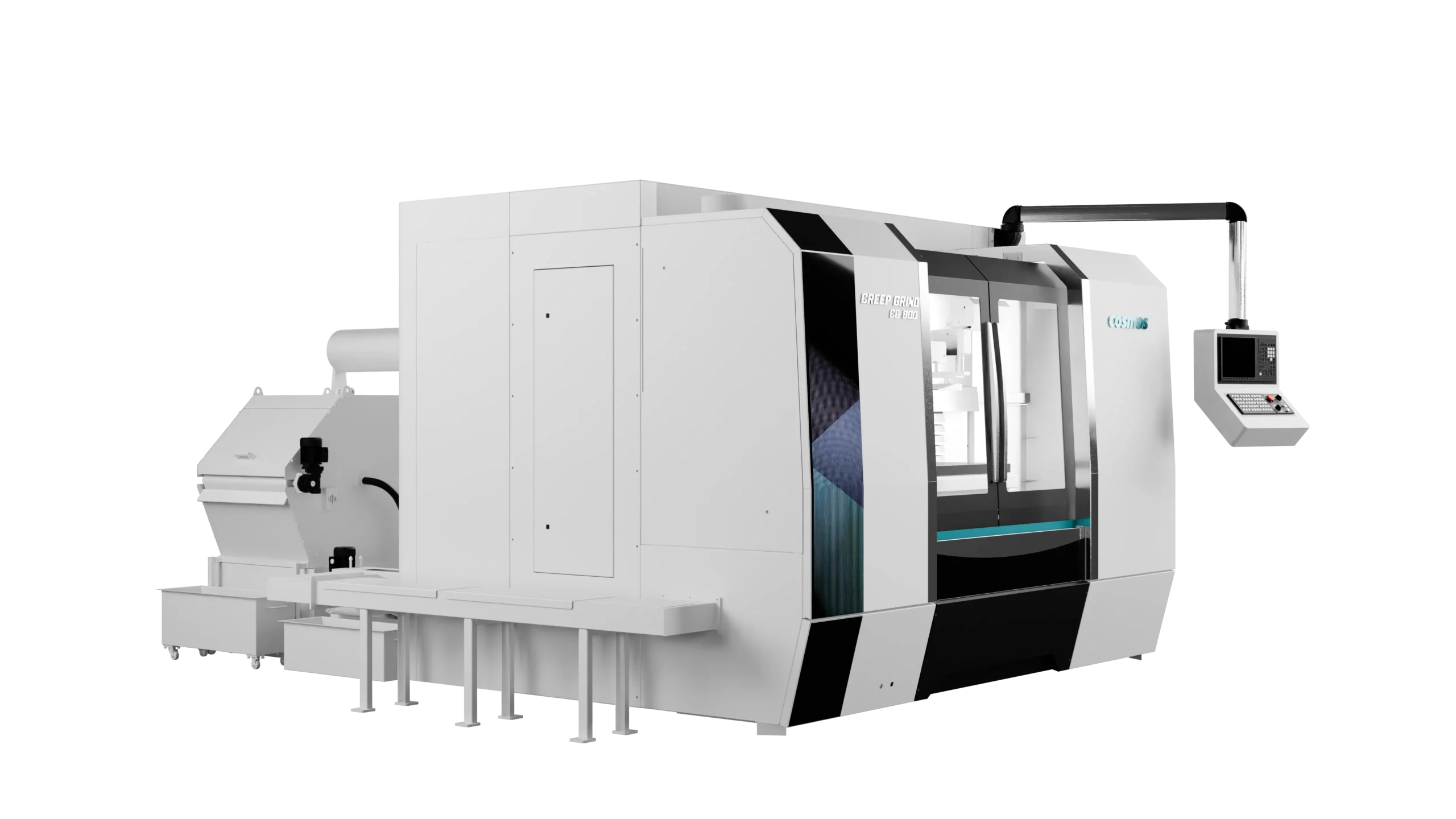

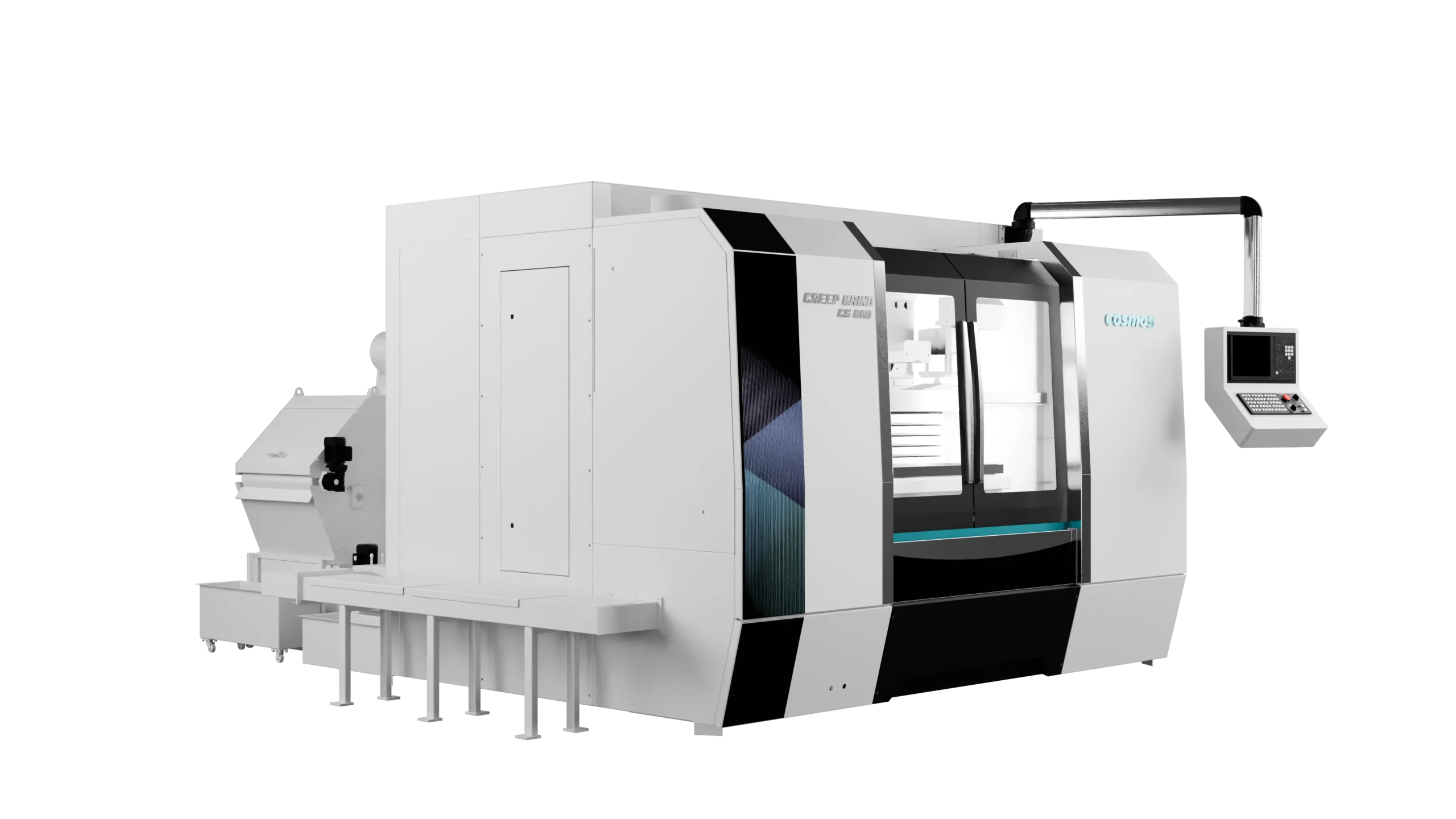

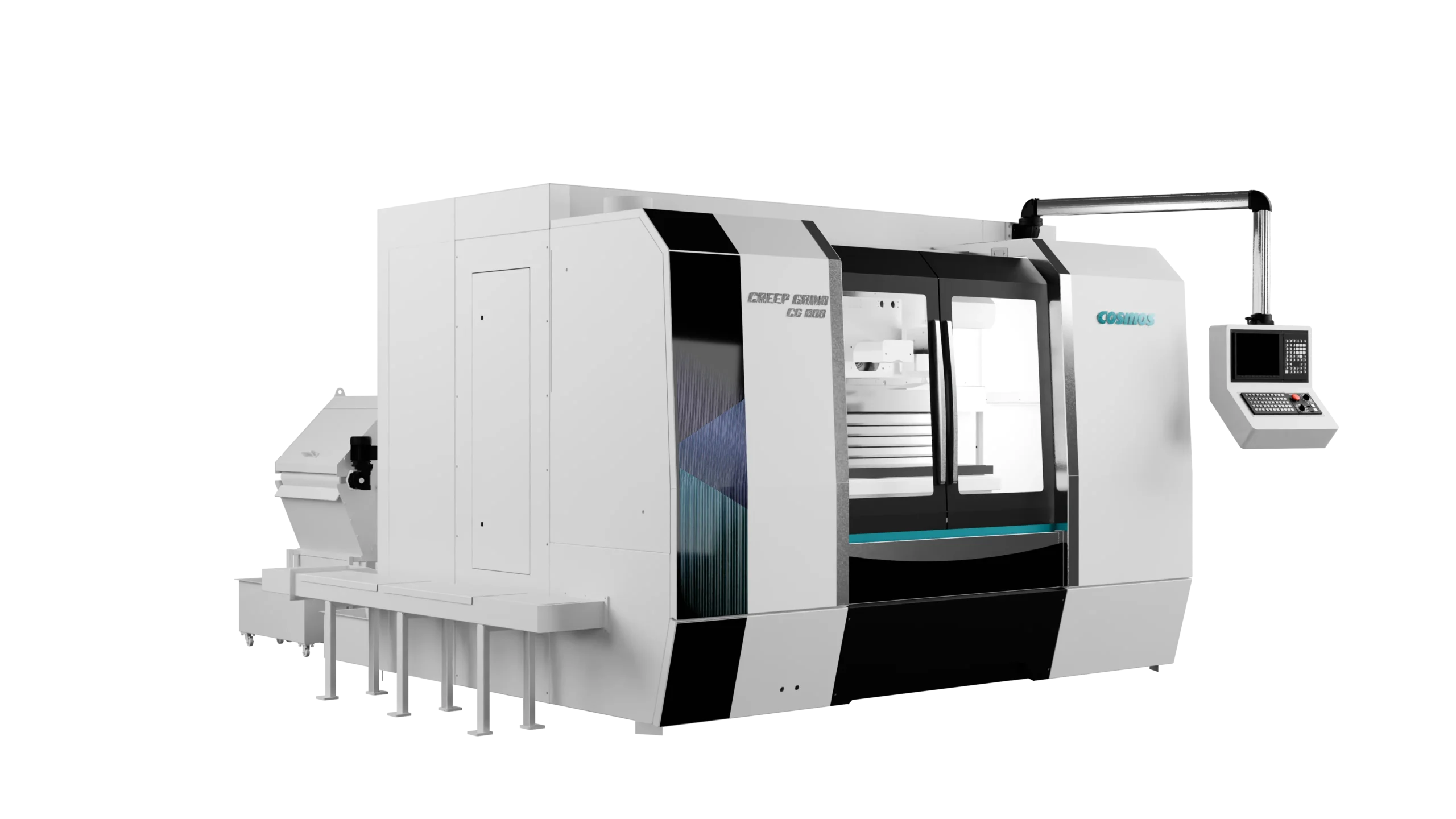

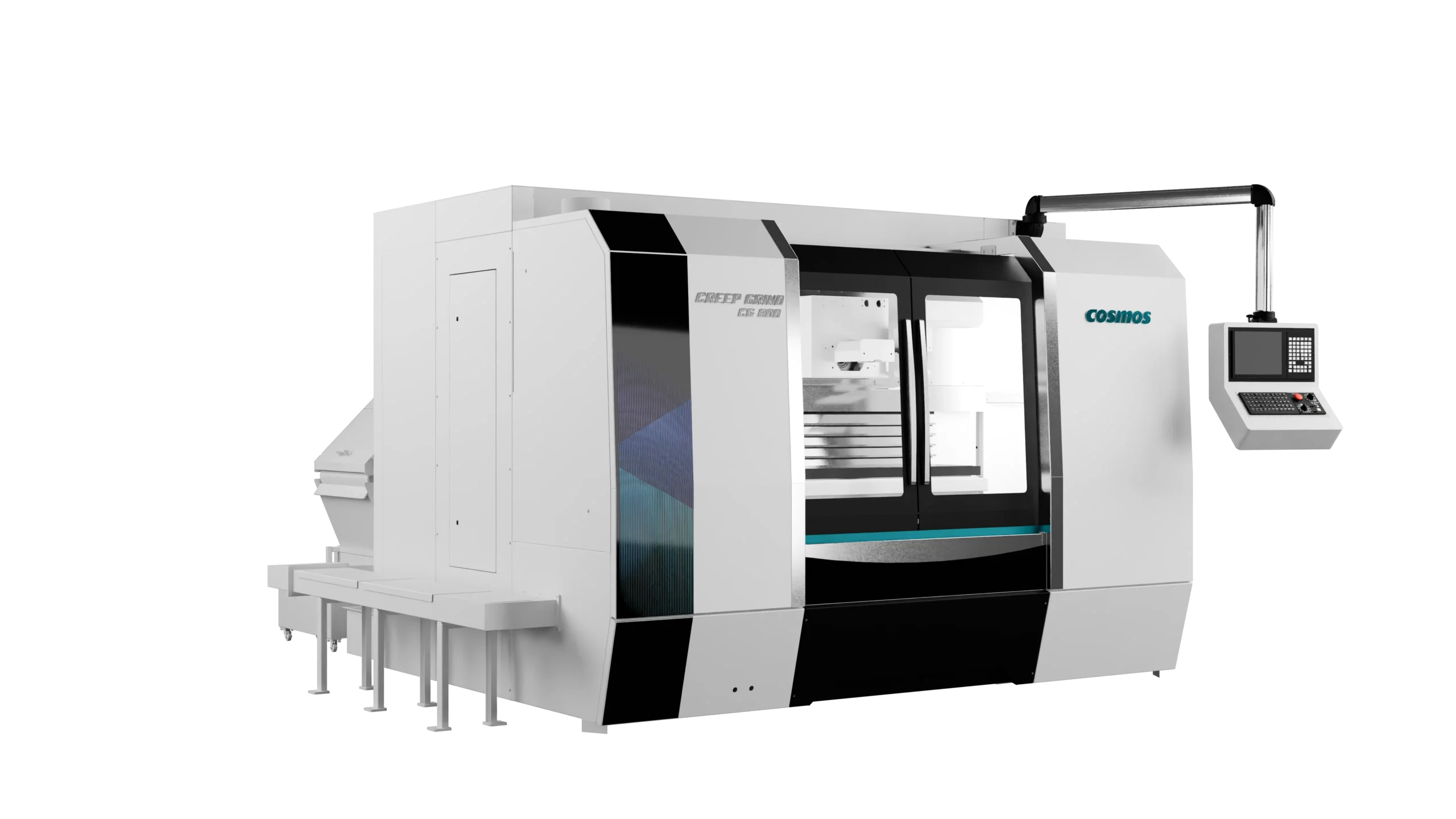

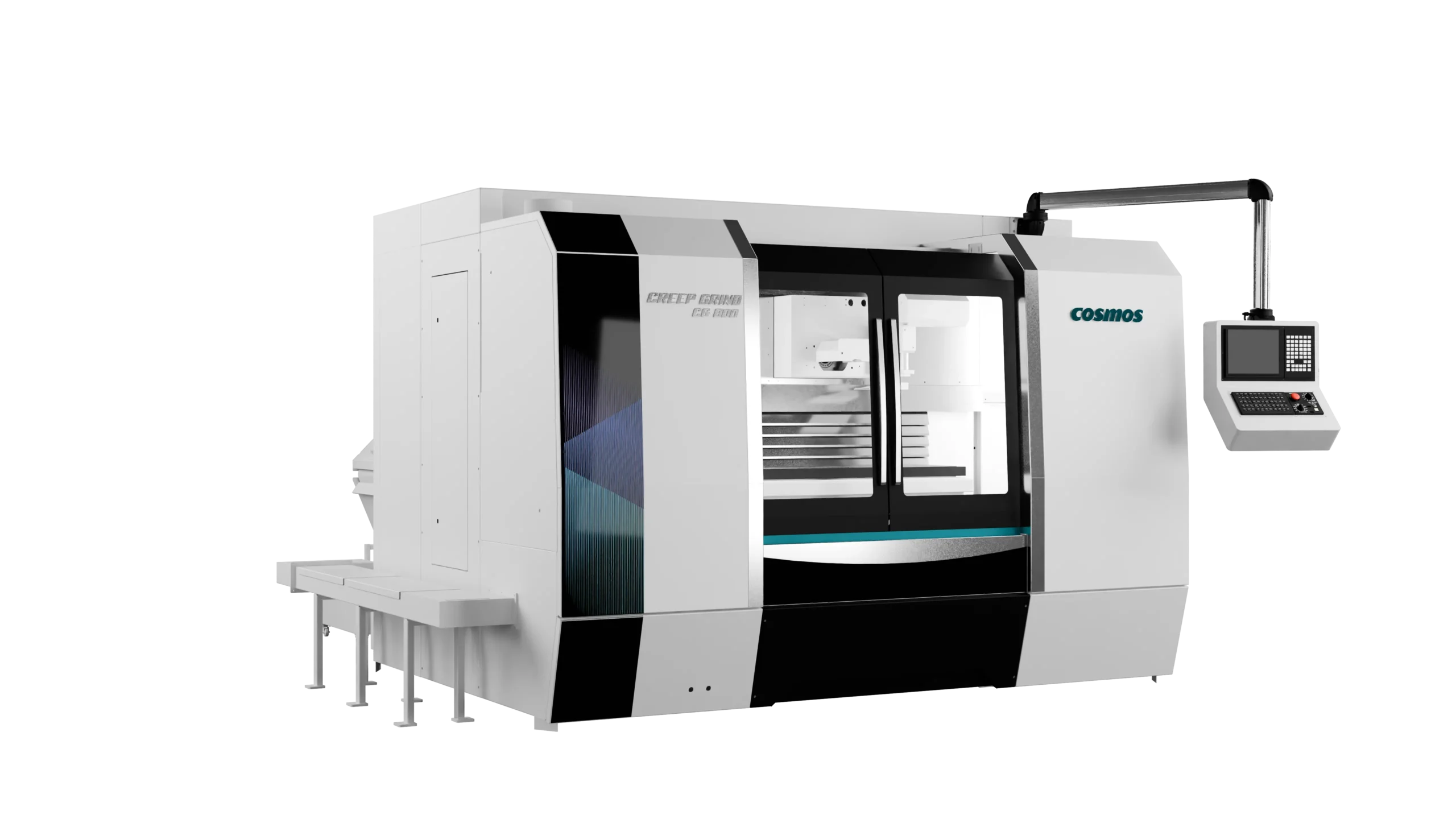

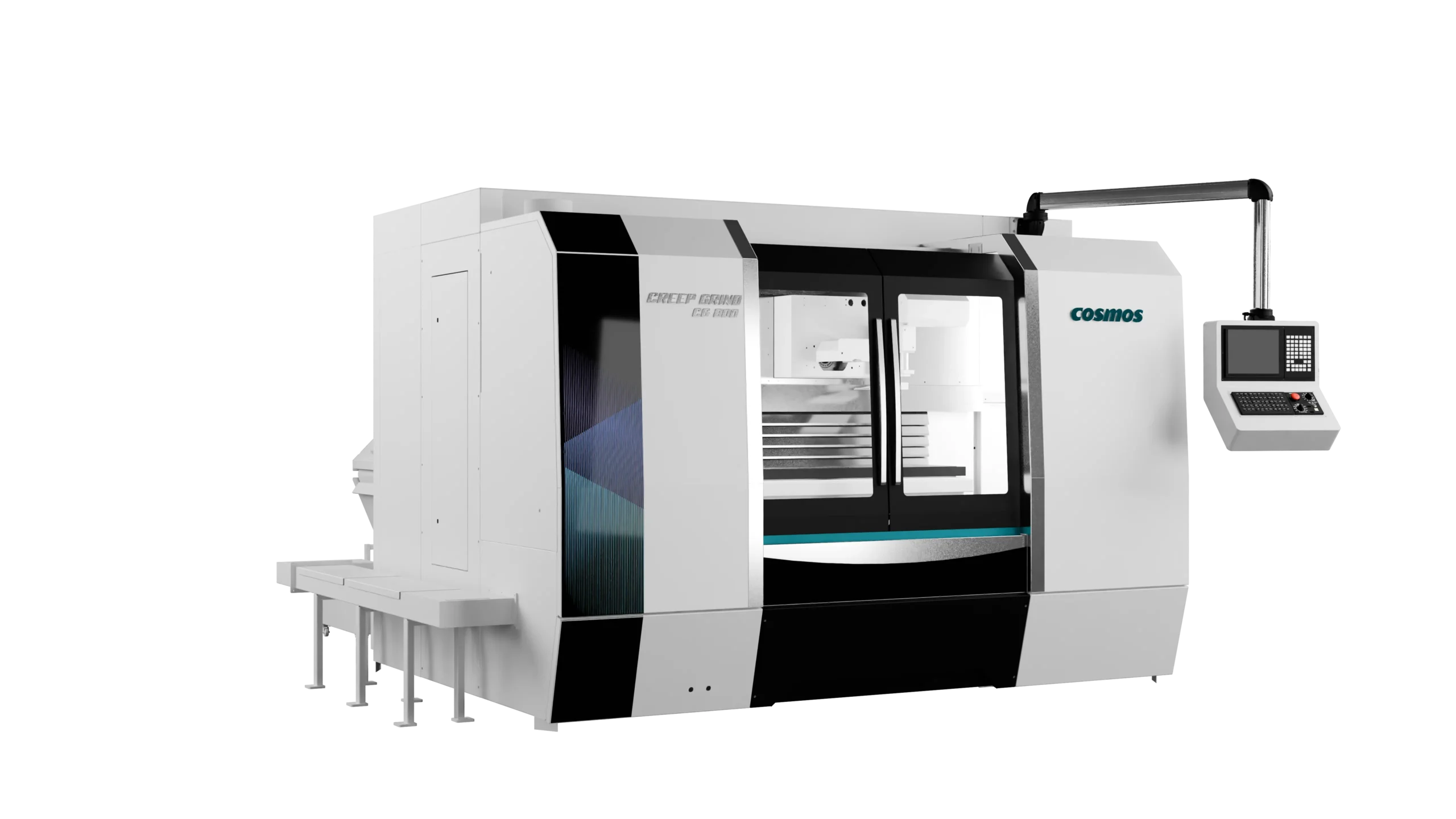

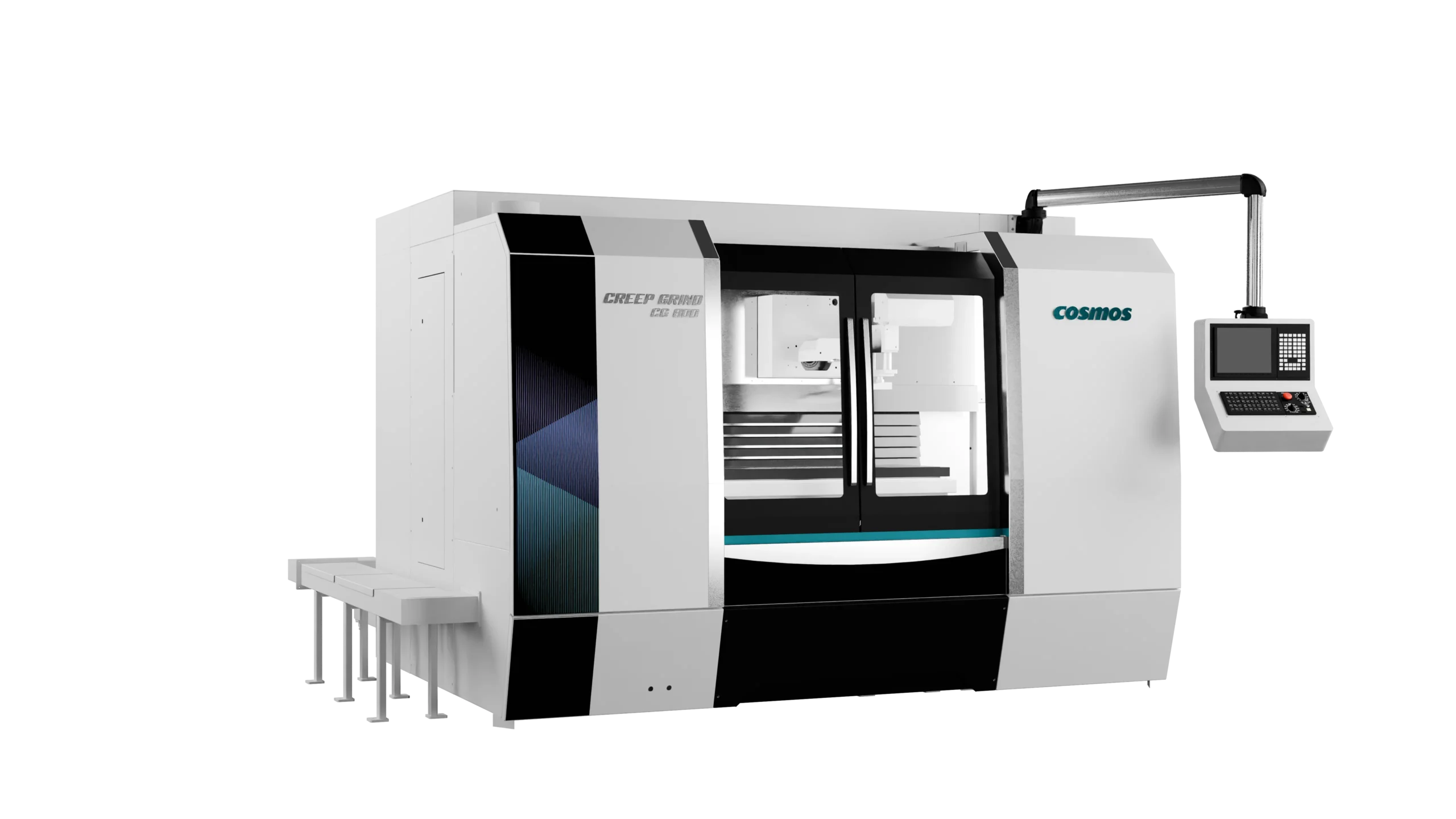

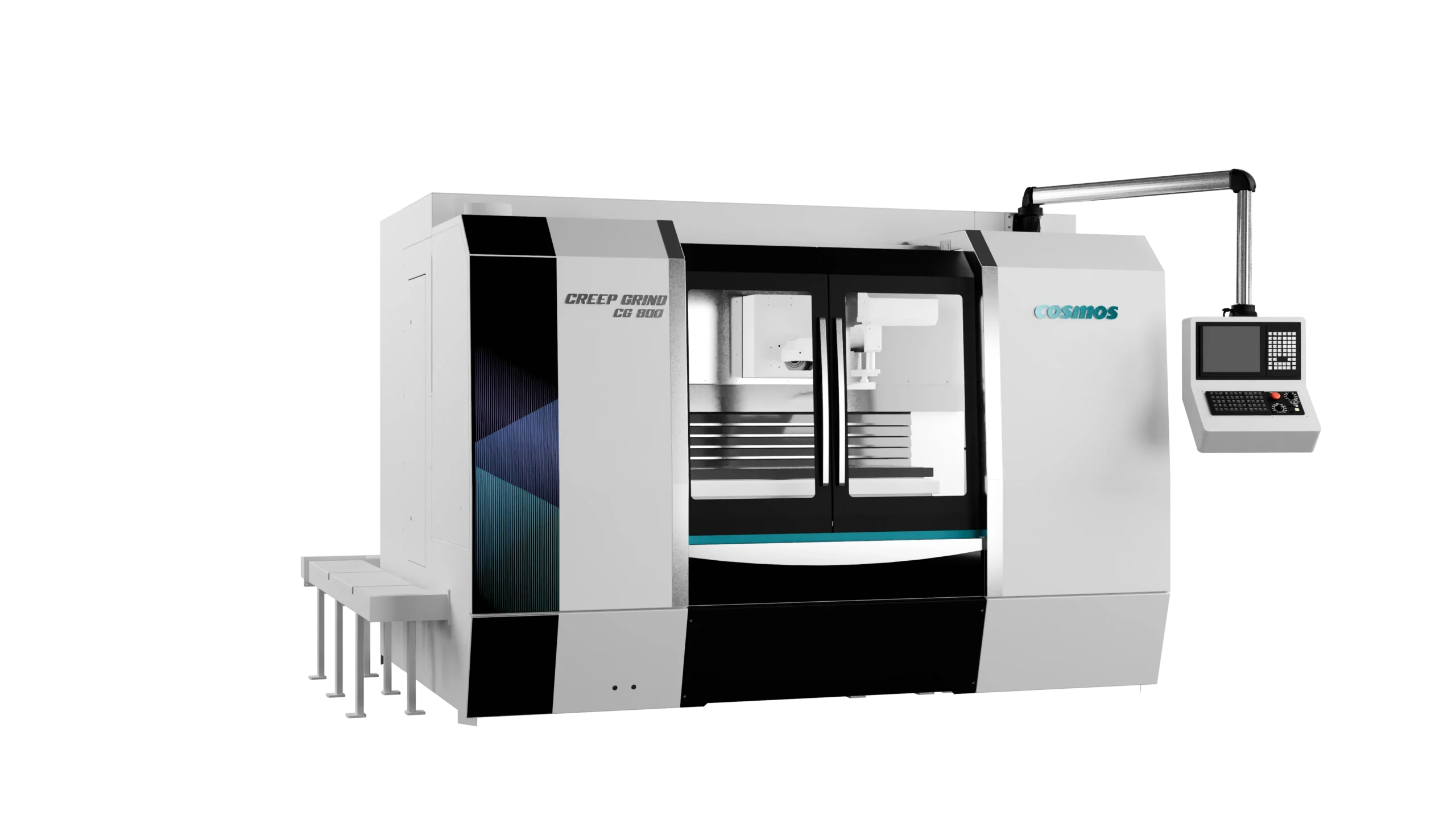

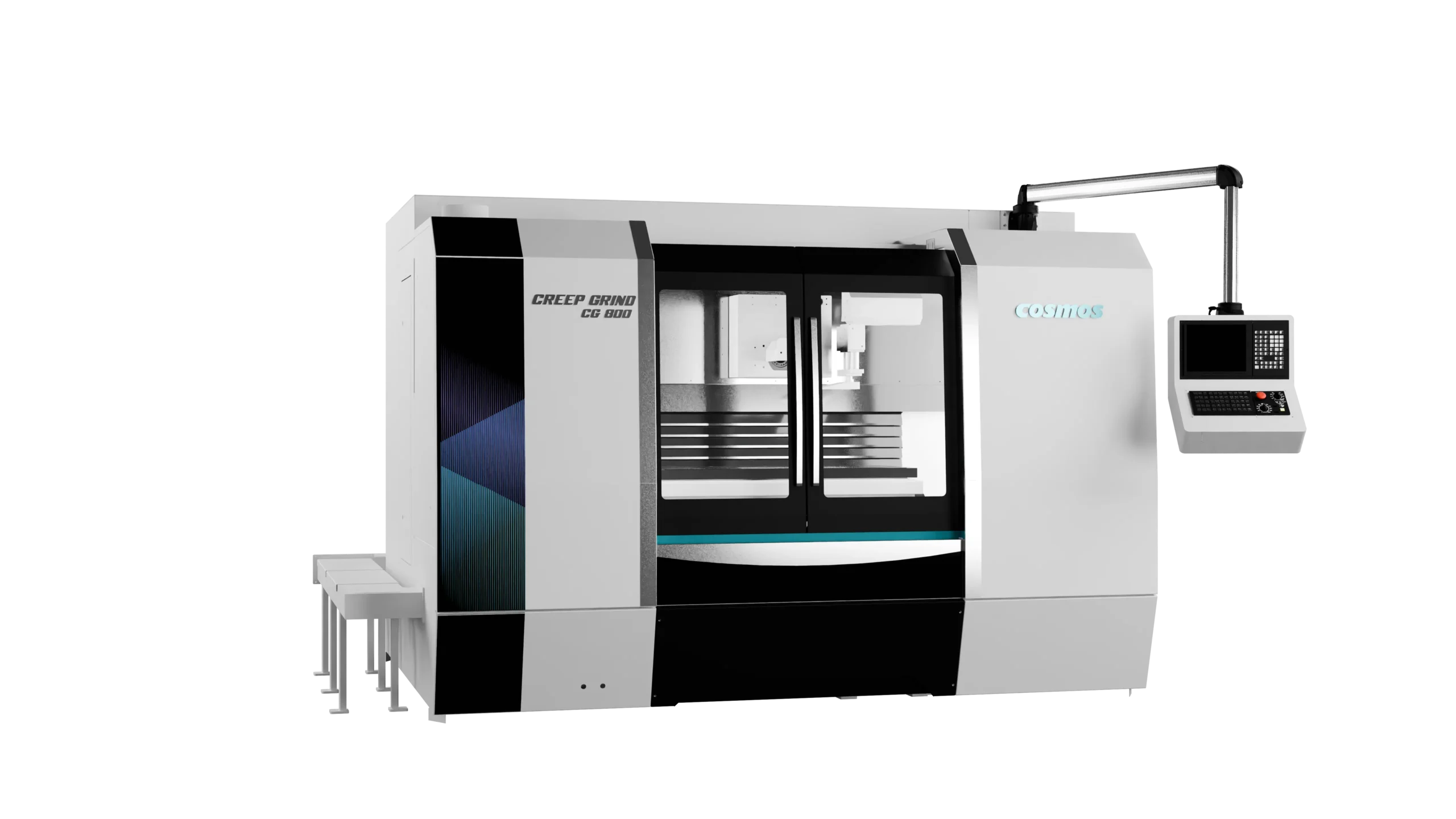

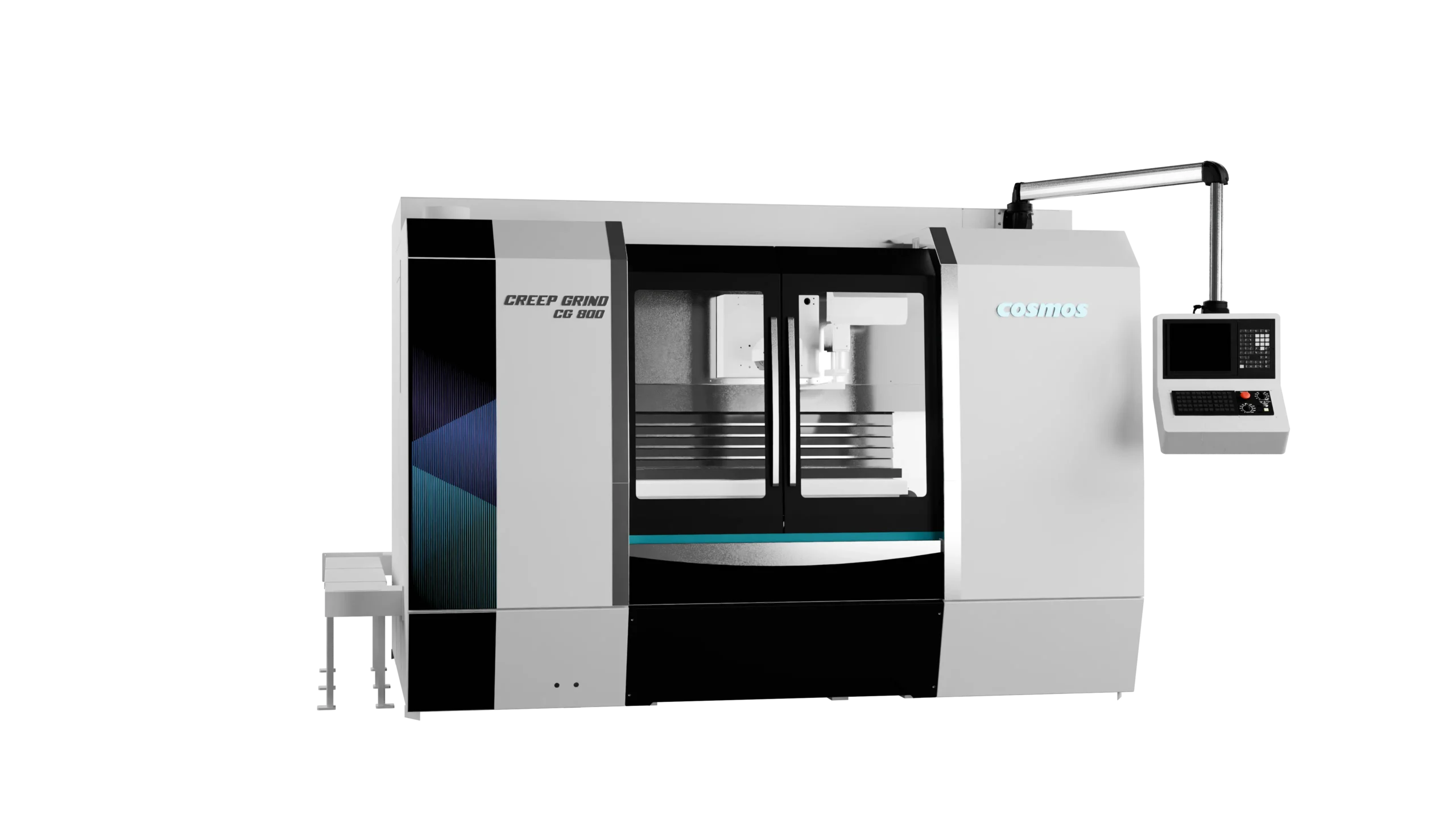

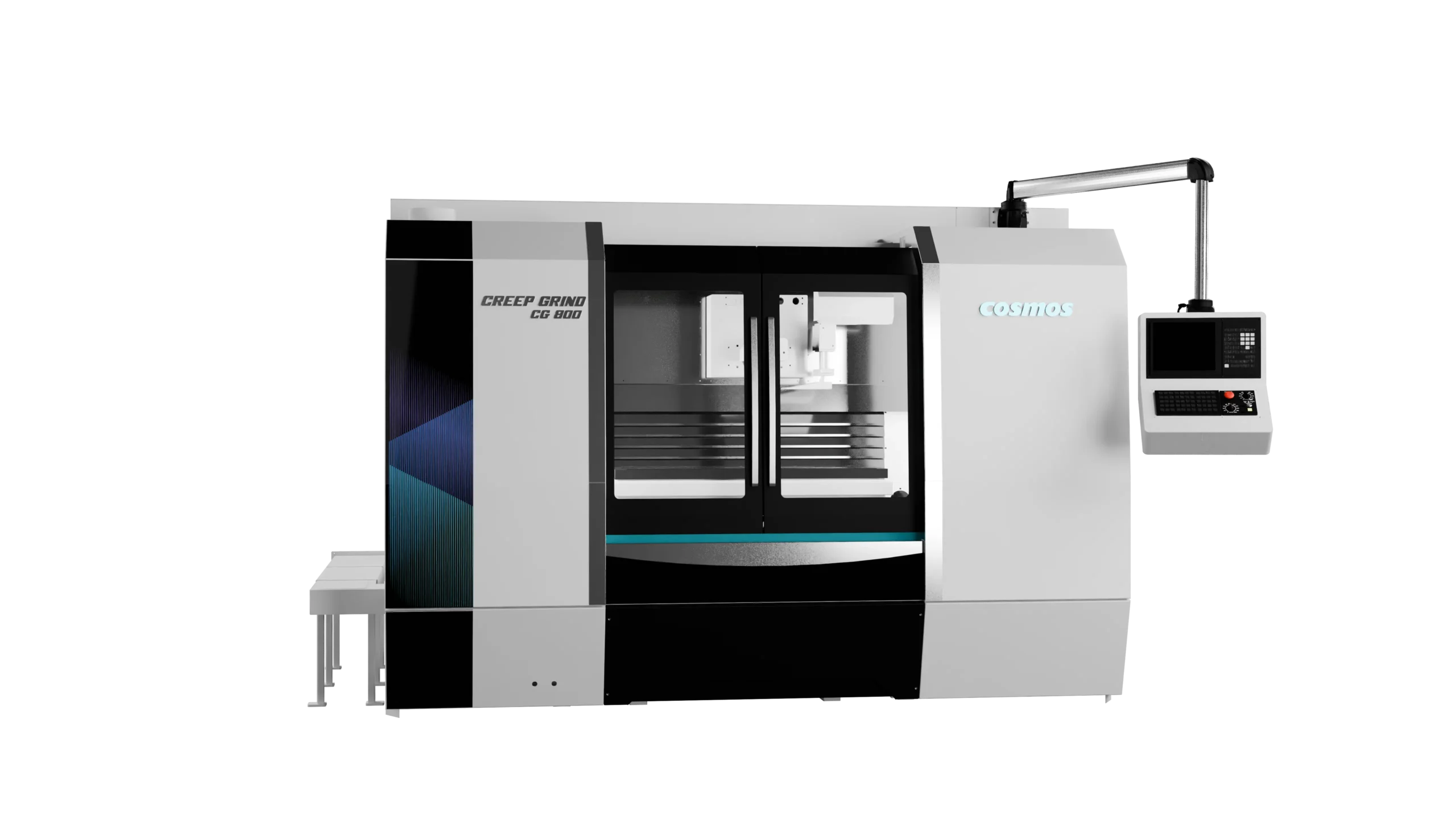

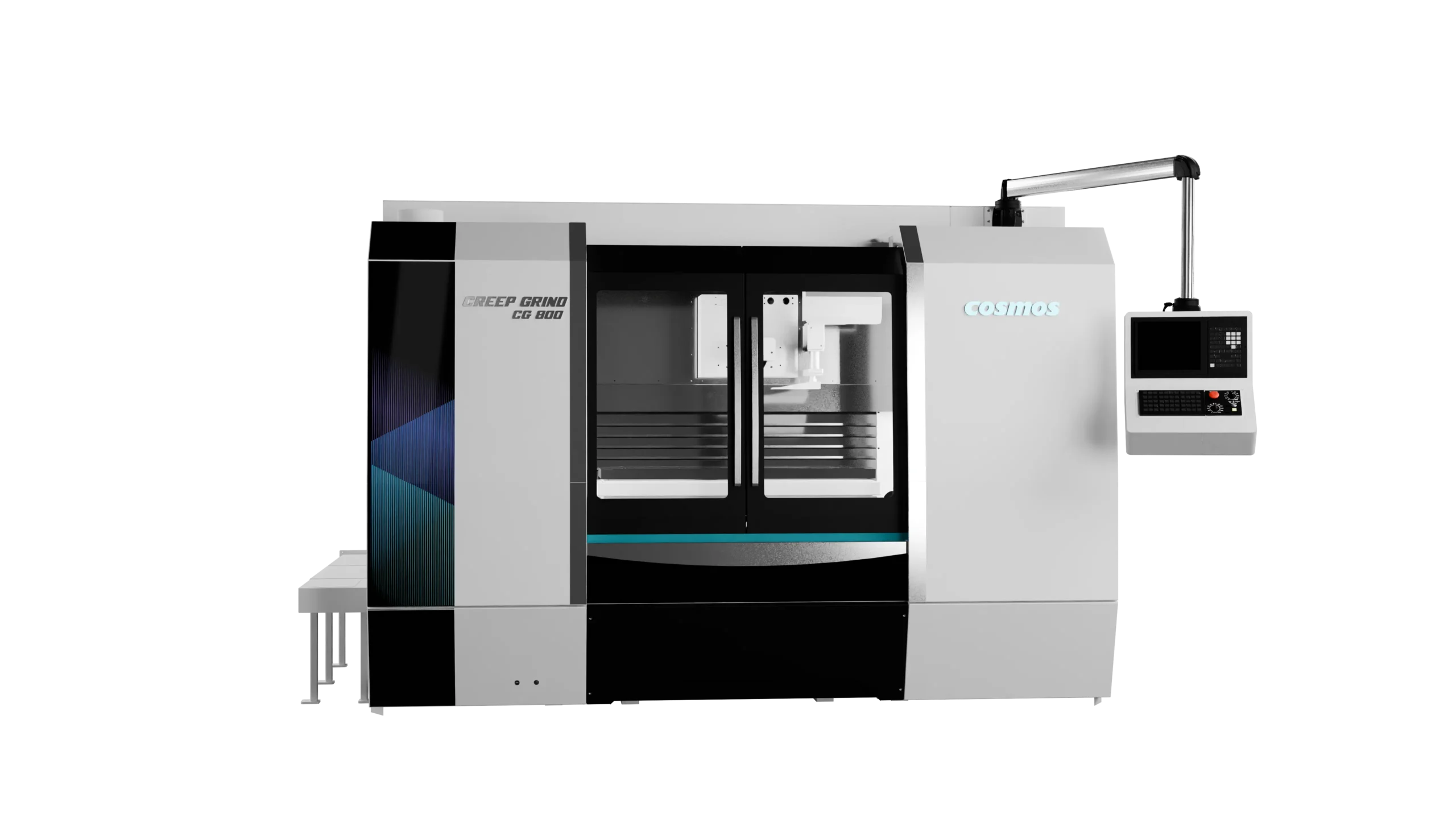

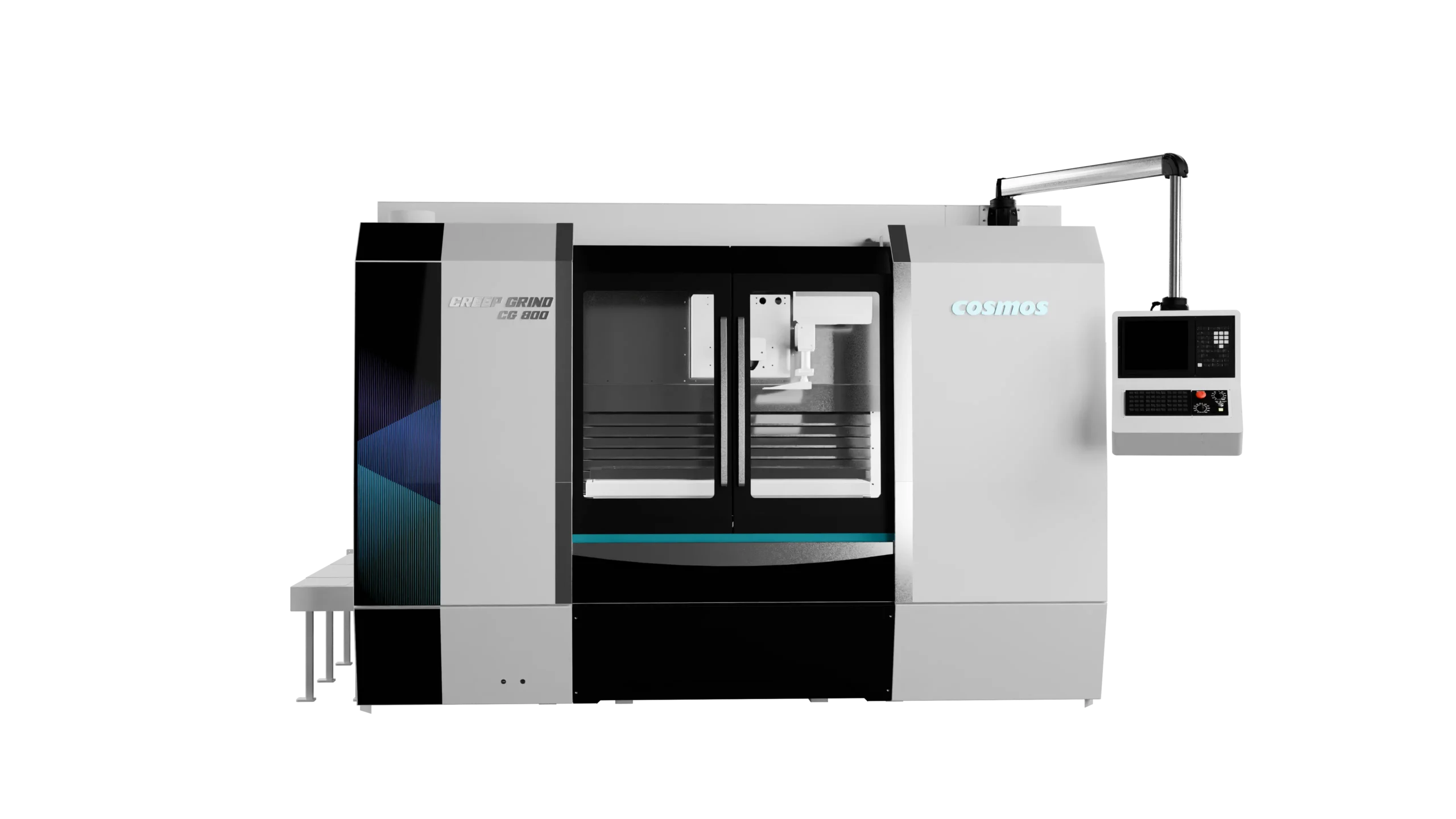

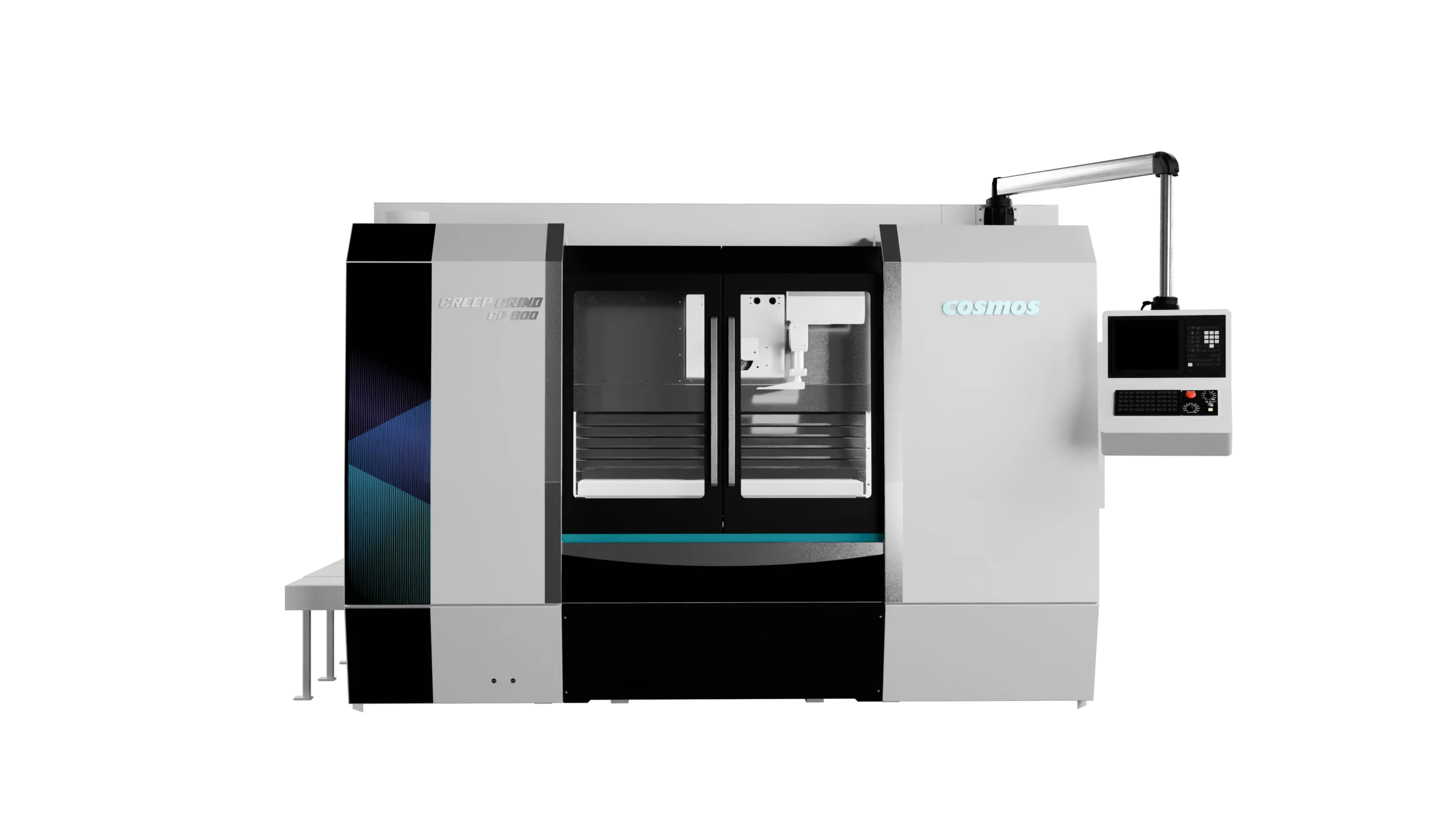

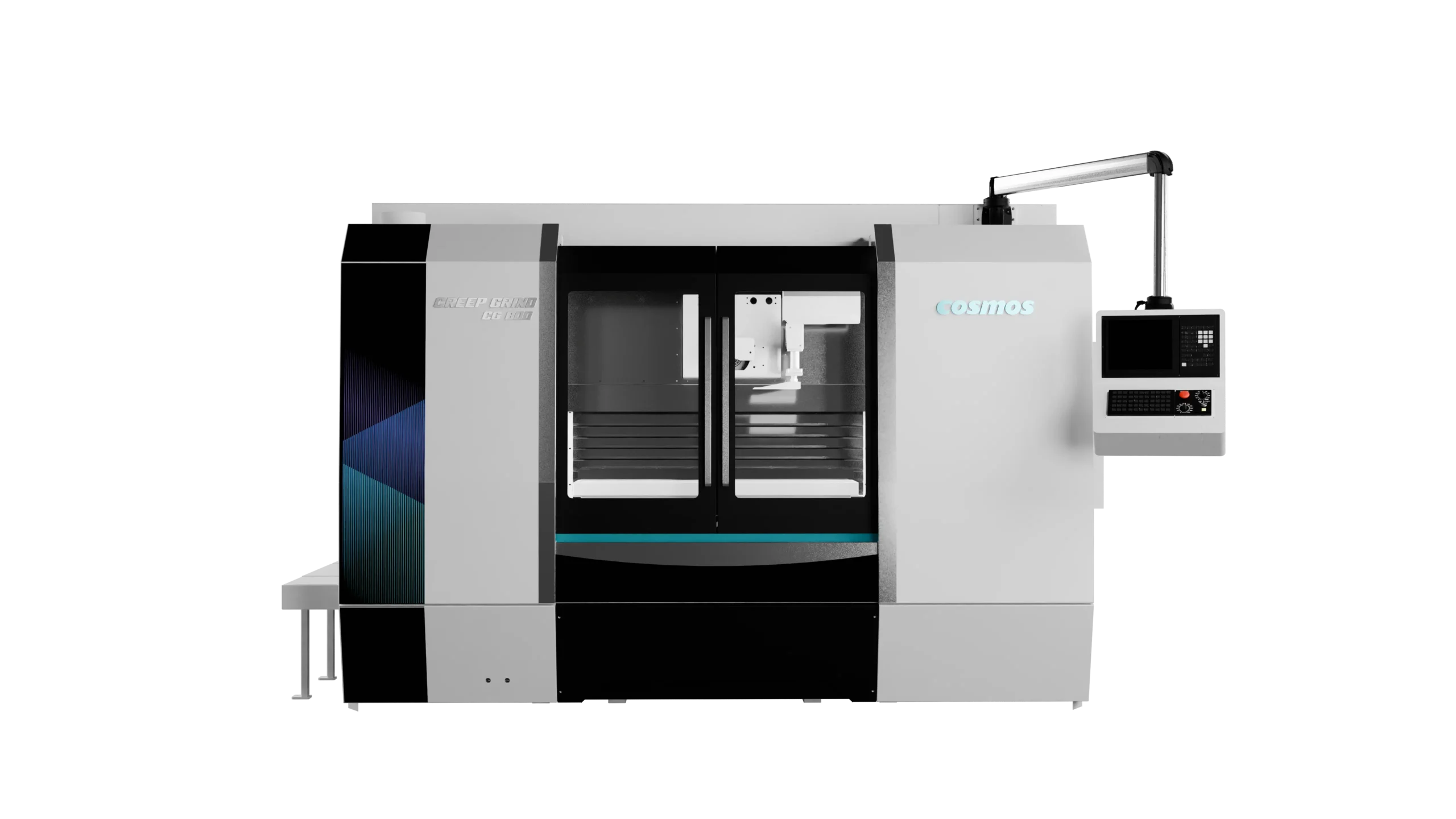

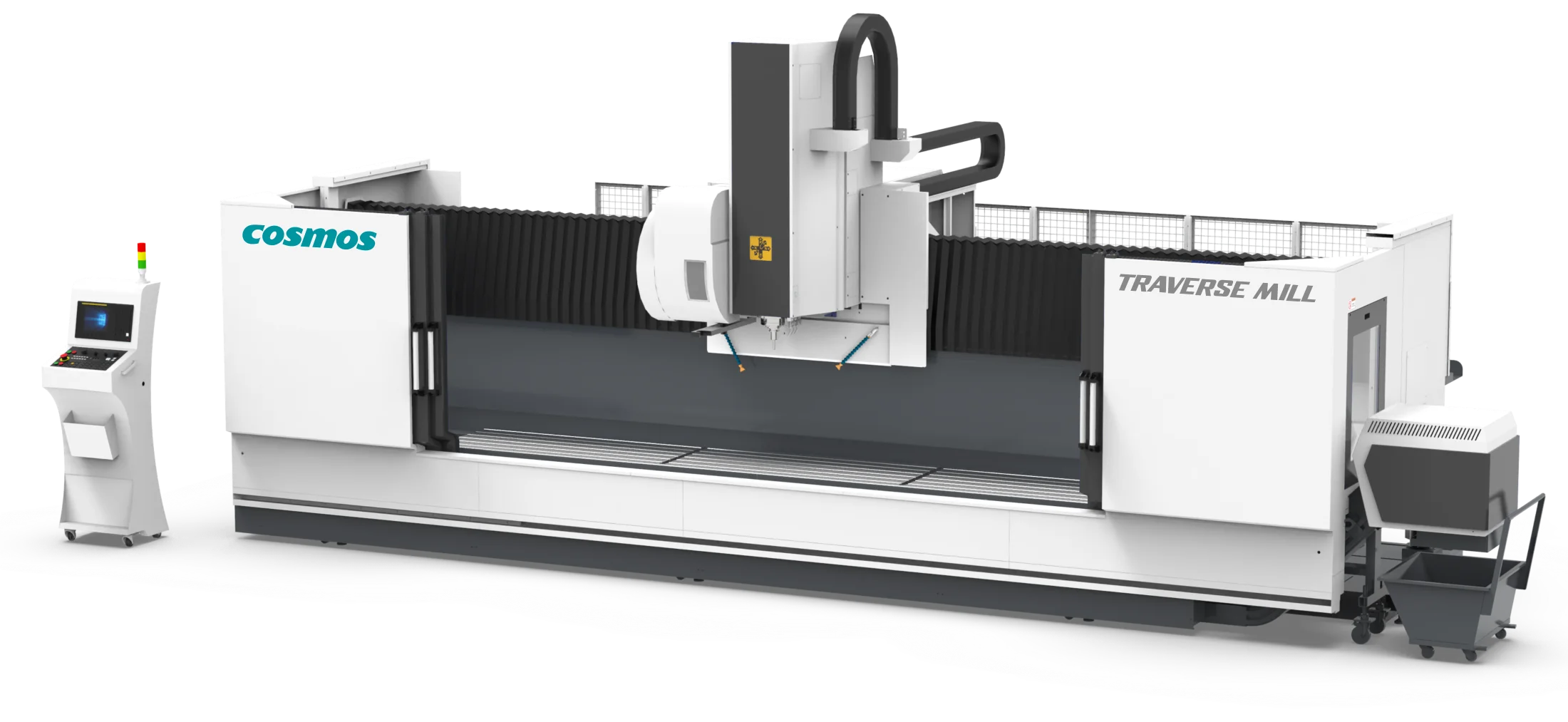

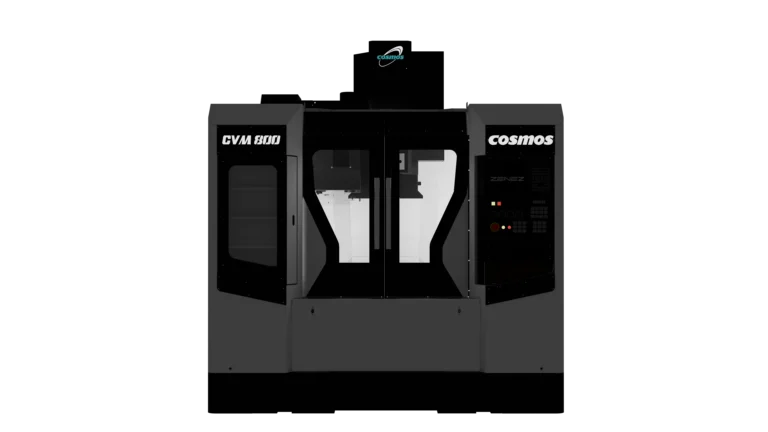

Machine Overview

Creep Feed Grinding is a precision grinding method where the grinding wheel carves a full-depth contour into the workpiece in a single, slow pass. This process is ideal for creating intricate shapes, profiles, and features that are challenging to achieve through conventional grinding methods.

- High Static and Dynamic Stability of the Machine Tool

- Infinitely Variable Spindle Speed

- Consistent Table Speed, especially in the Lower Speed Range

- High-pressure Cooling and Cleaning System

- Integrated Dressing Devices

- CNC Programmable

- Automatic Wheel Balancing

- High Power Spindle Motor

- Automatic Compensation for Wheel Dressing

HIGH MATERIAL

REMOVAL RATE

SHORT

CYCLETIME

REDUCED

MACHINE WEAR

LOW HEAT AT

WORKPIECE

ELIMINATE

MACHINING

LONGER

WHEEL LIFE

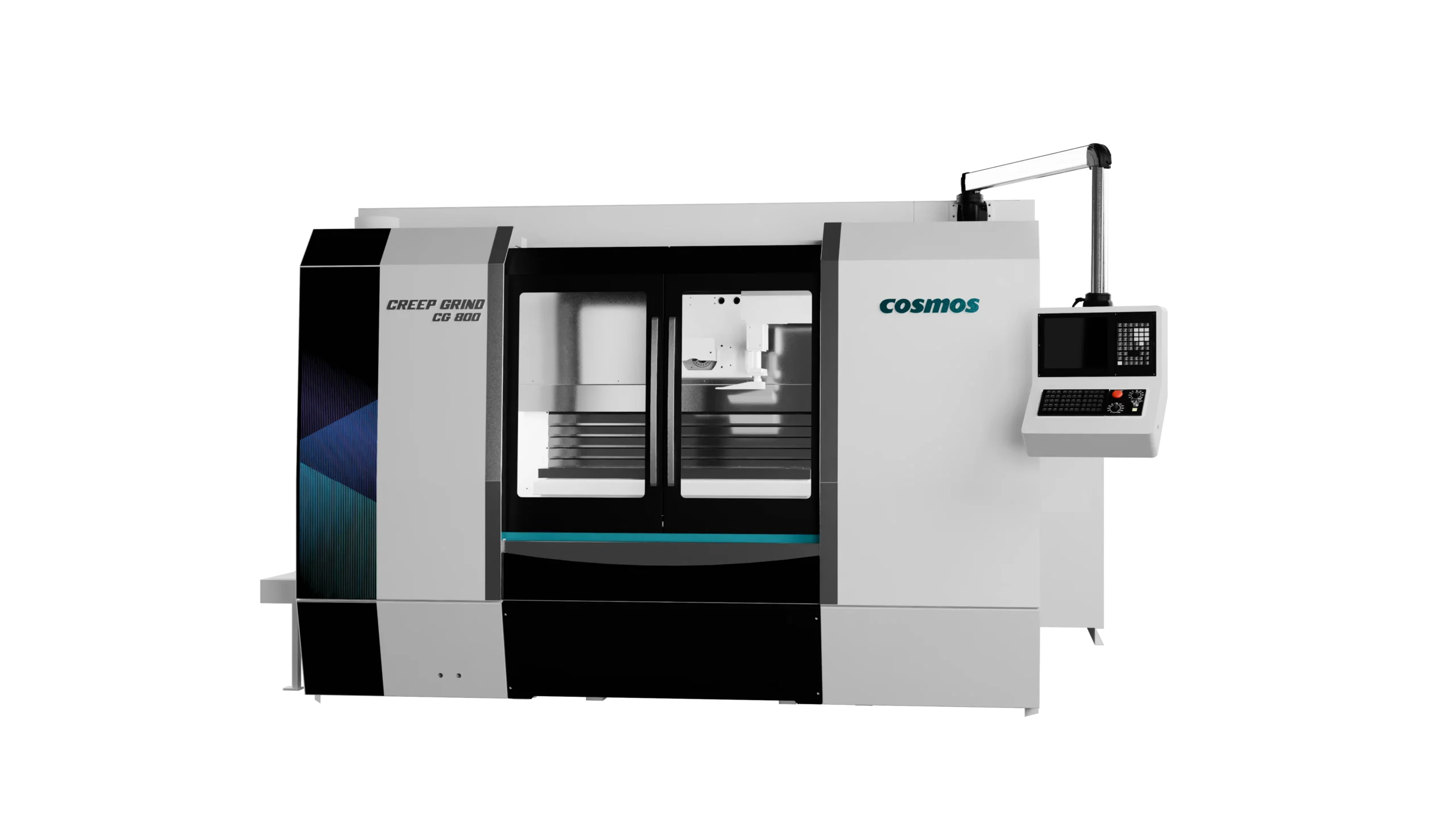

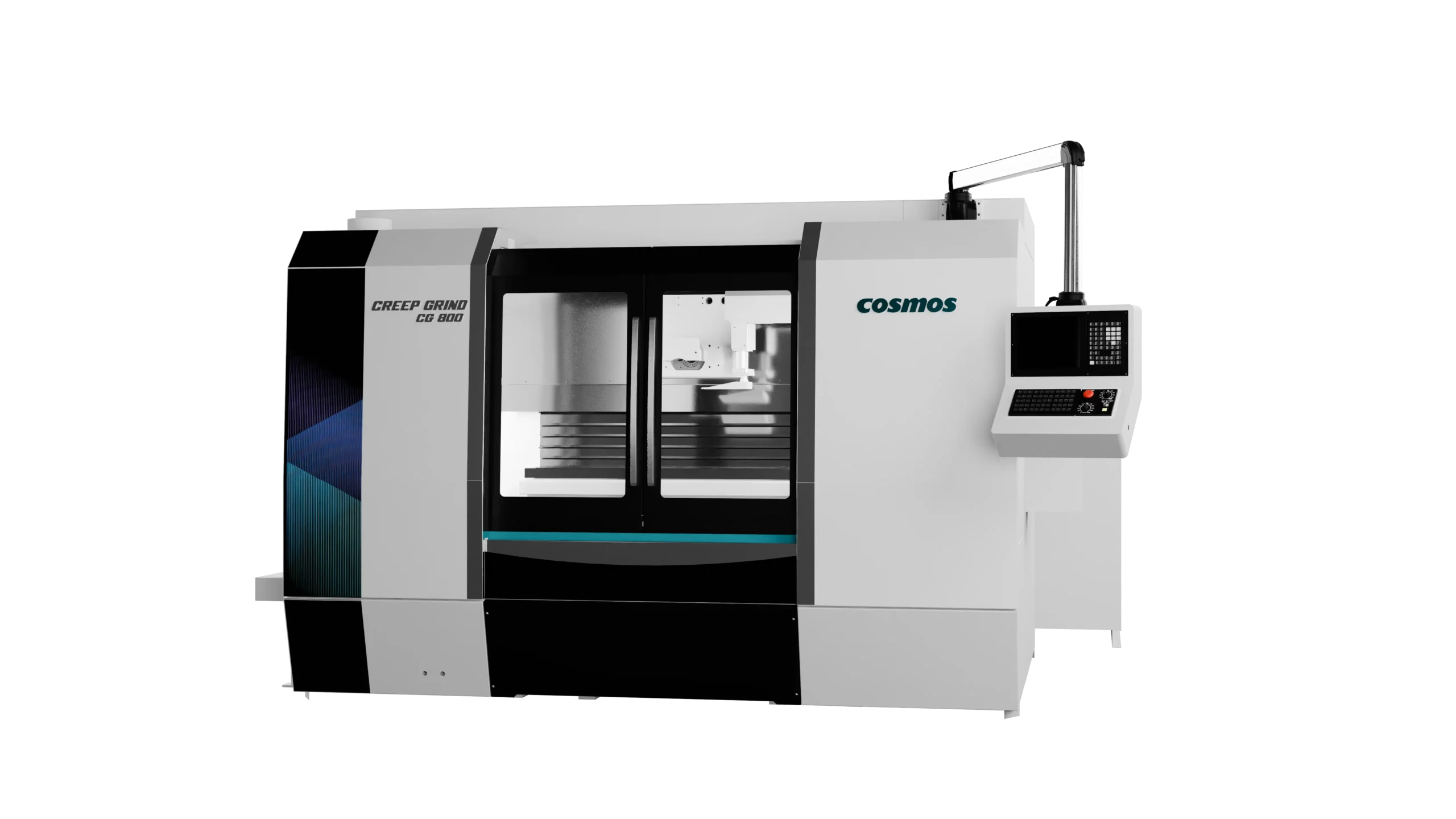

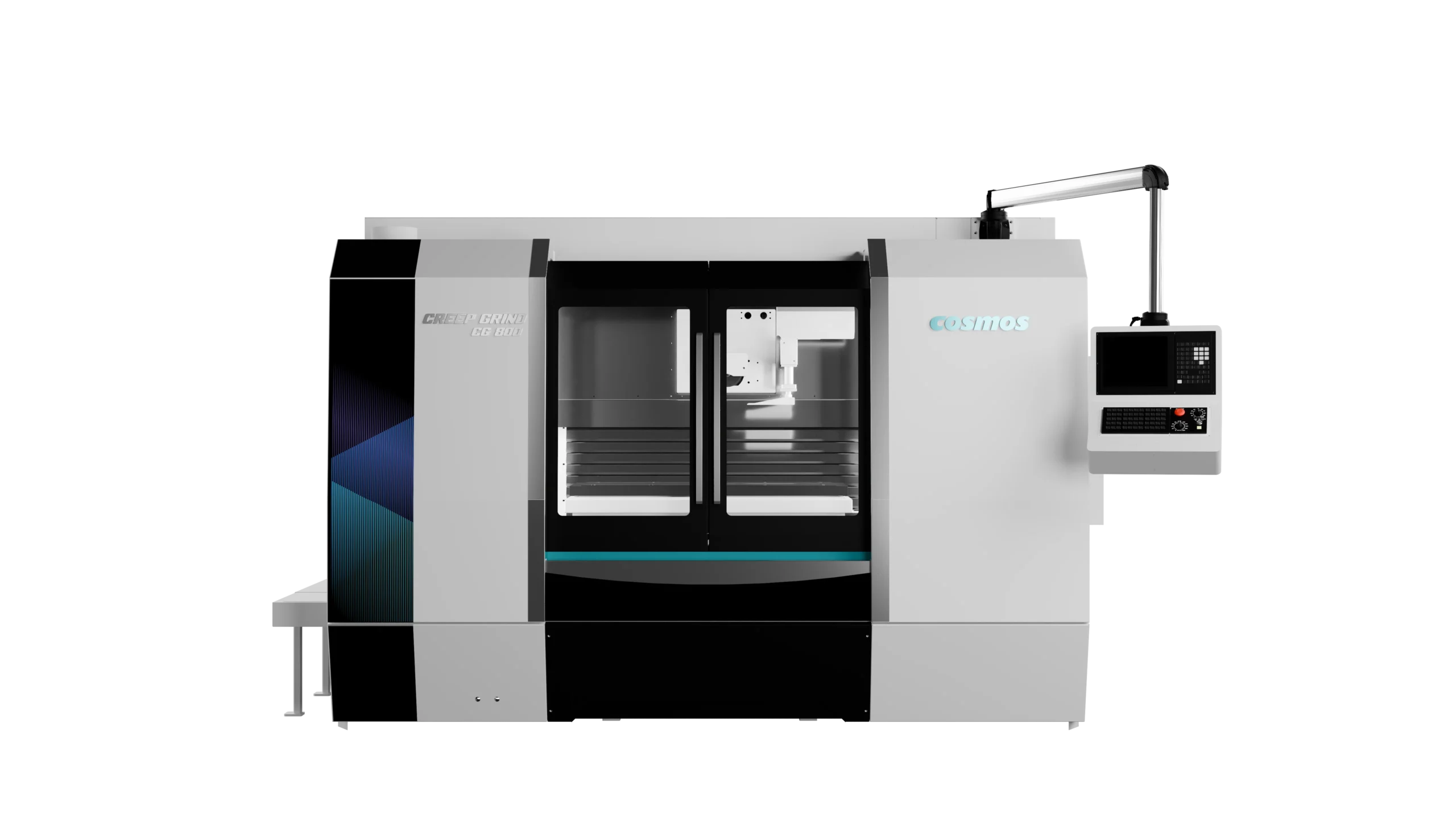

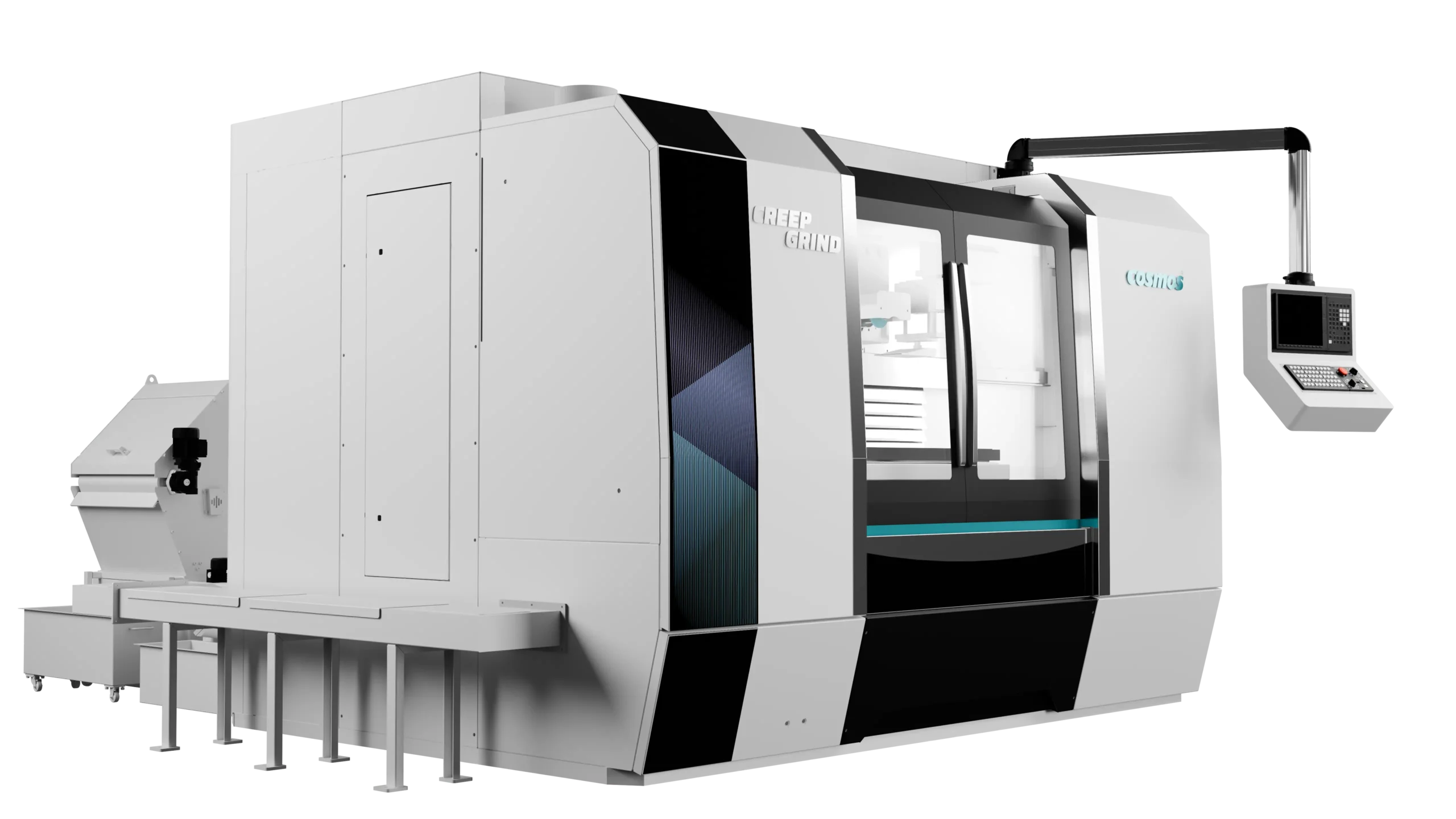

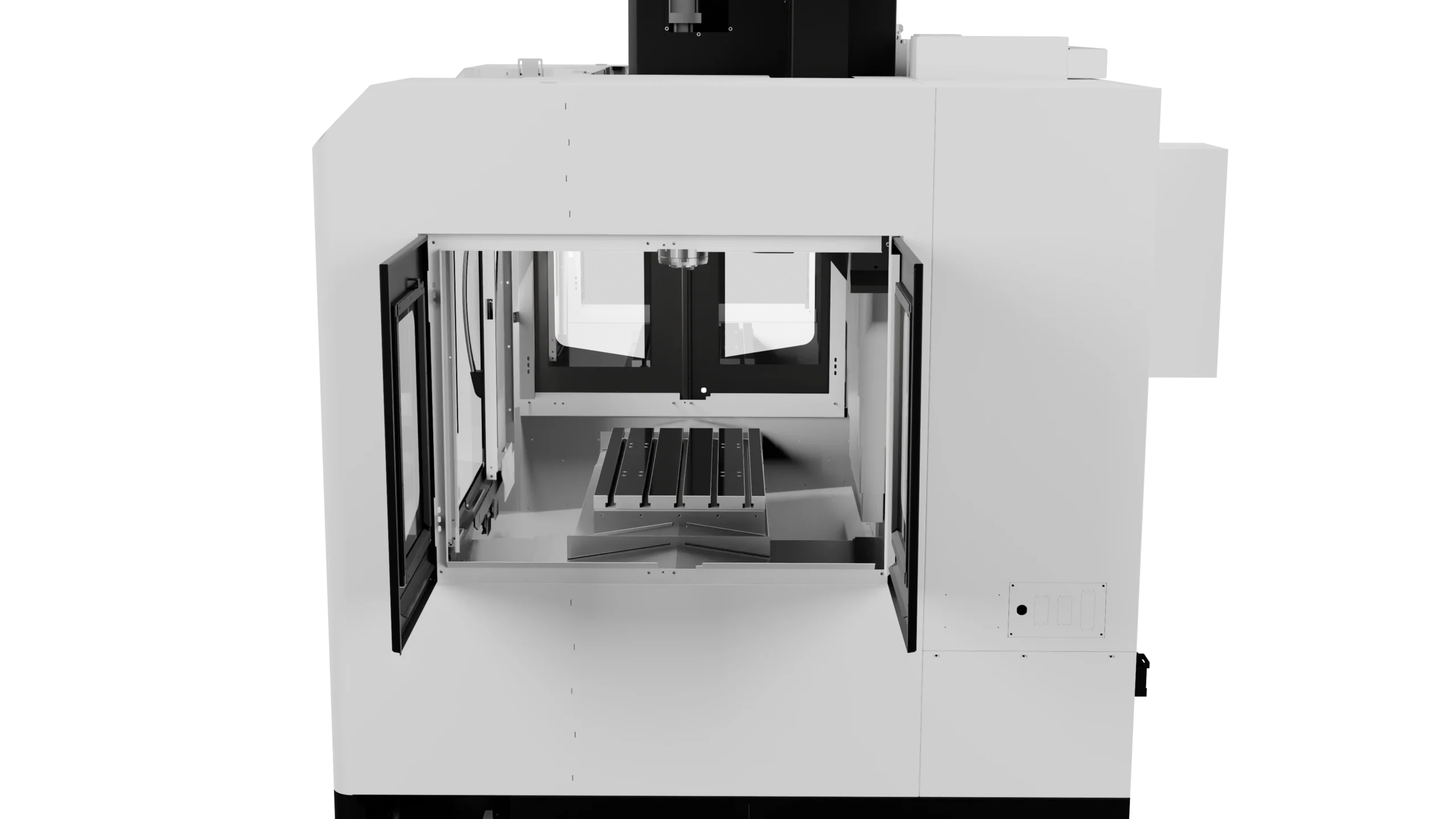

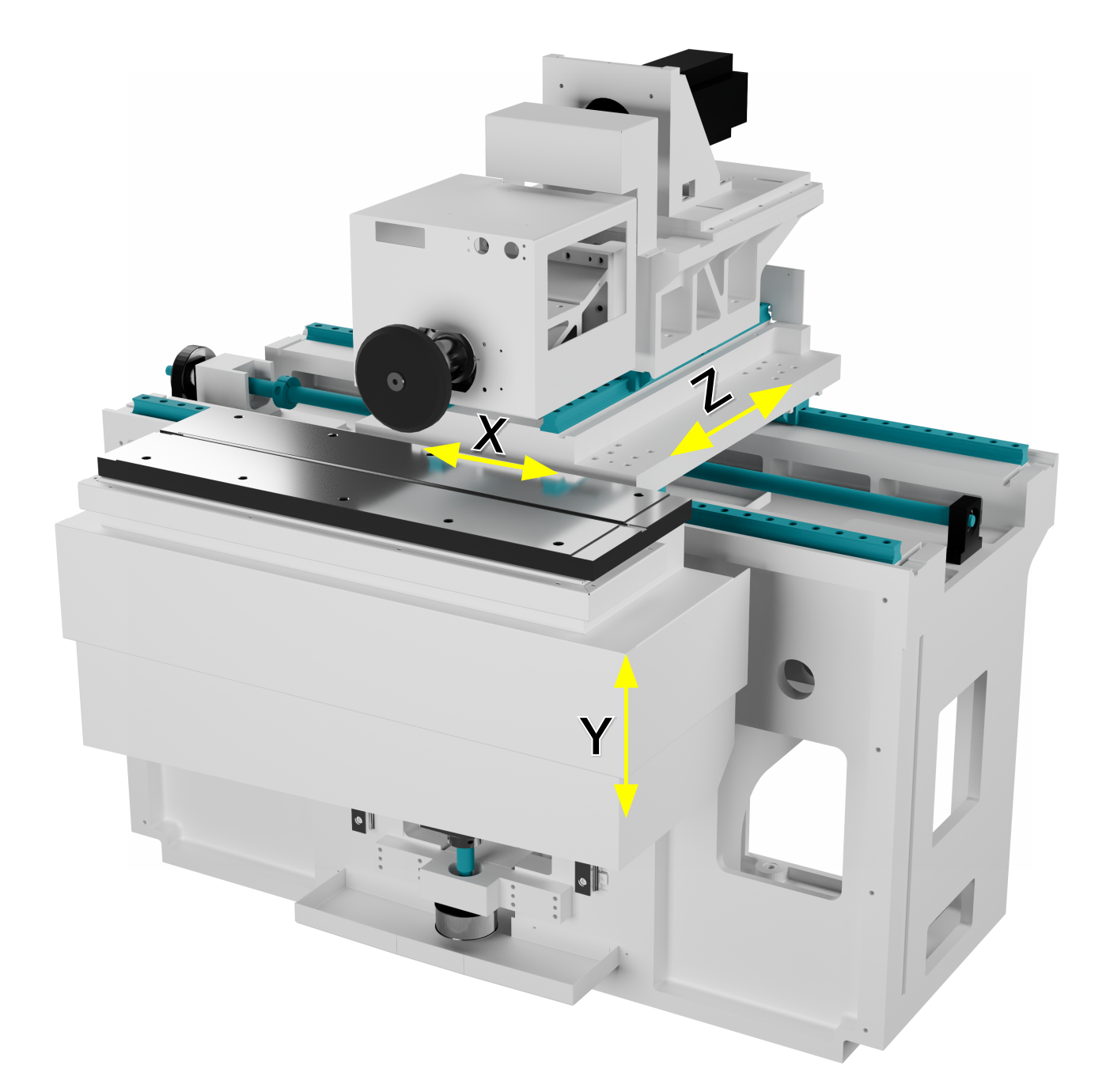

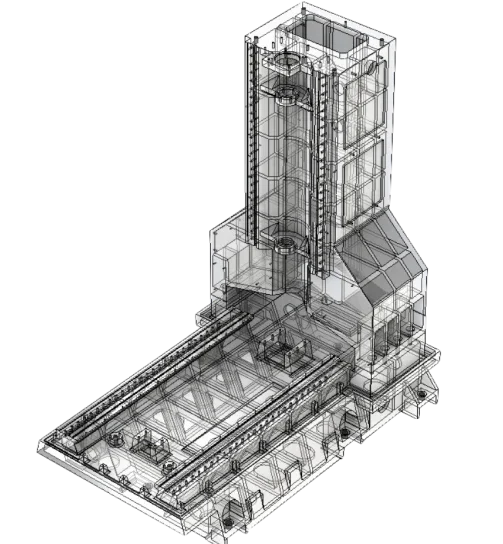

Column Moving Design

Column moving design with independent movement of all three axes. Making it long last for years and years to come. All axis move independently resulting in perfect perpendicularity in between the three axis. This ensures better flatness and parallelism.

V and Flat Guideways

Hand scraping creates contact points and oil pockets (high and low spots) between mating surfaces, ensuring a perfect match between components. This process improves surface conformity and promotes even oil distribution for smoother motion.

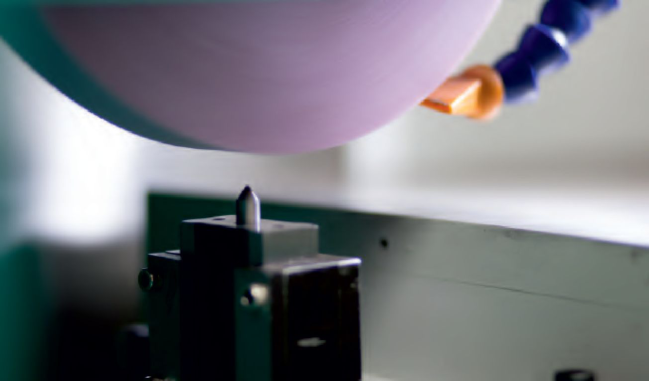

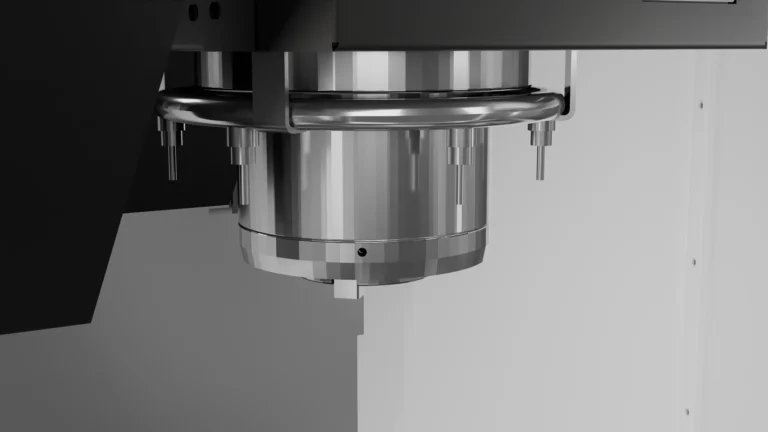

Automatic Dressing

Smart feature for automatic dressing on table and when the grinder enters an automatic dress cycle, the table automatically positions itself where the diamond is set to dress and compensate according to operator settings and continues grinding.

Additional Features

Stainless Steel Sill

Protector

Big Dual

Side Windows

Fully Enclosed

Guarding

Inbuilt Tool

Stronge Cabinet

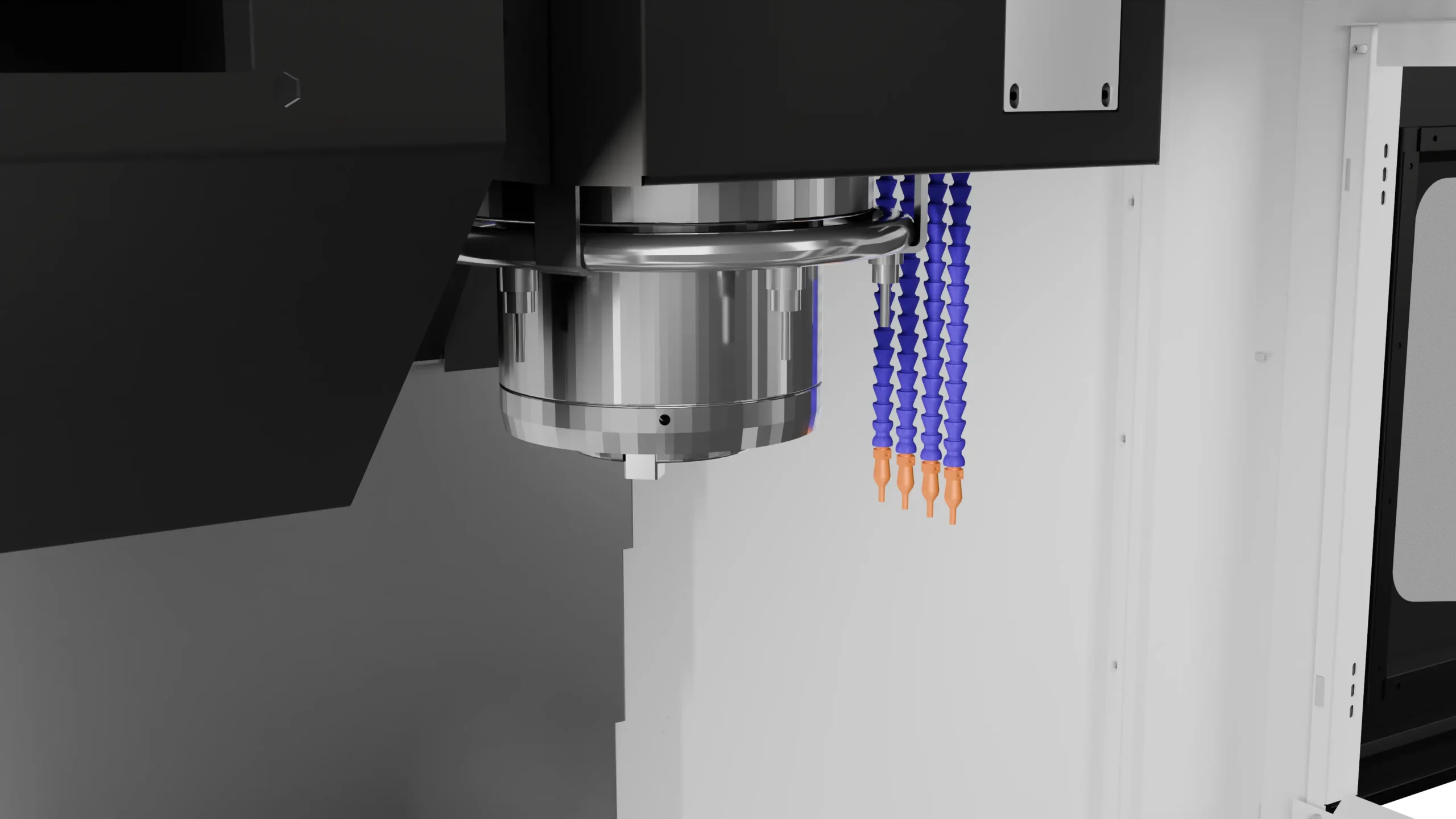

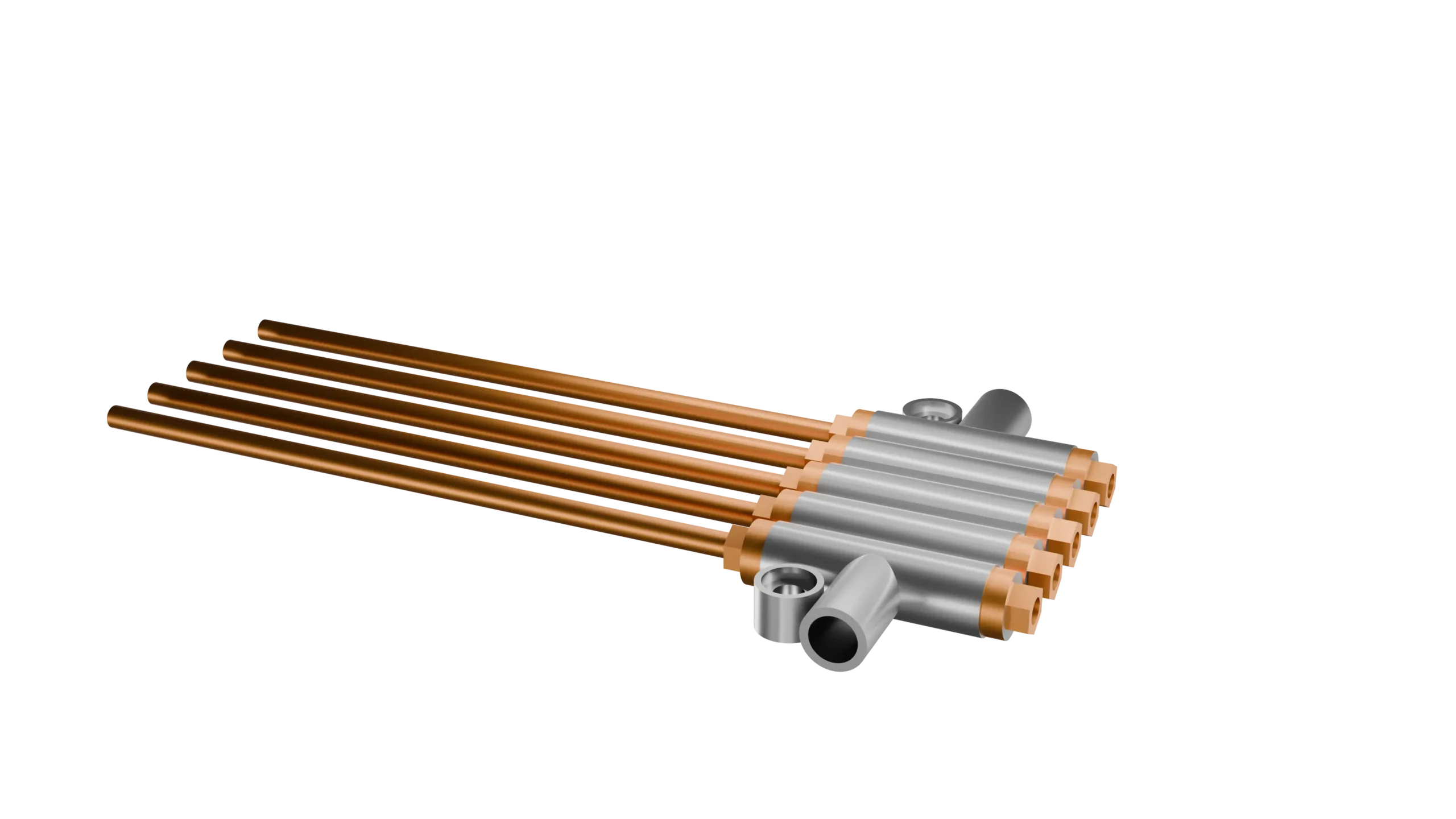

1 Air and 3 Coolant

Nozzles

Copper Pipe

for Lubrication

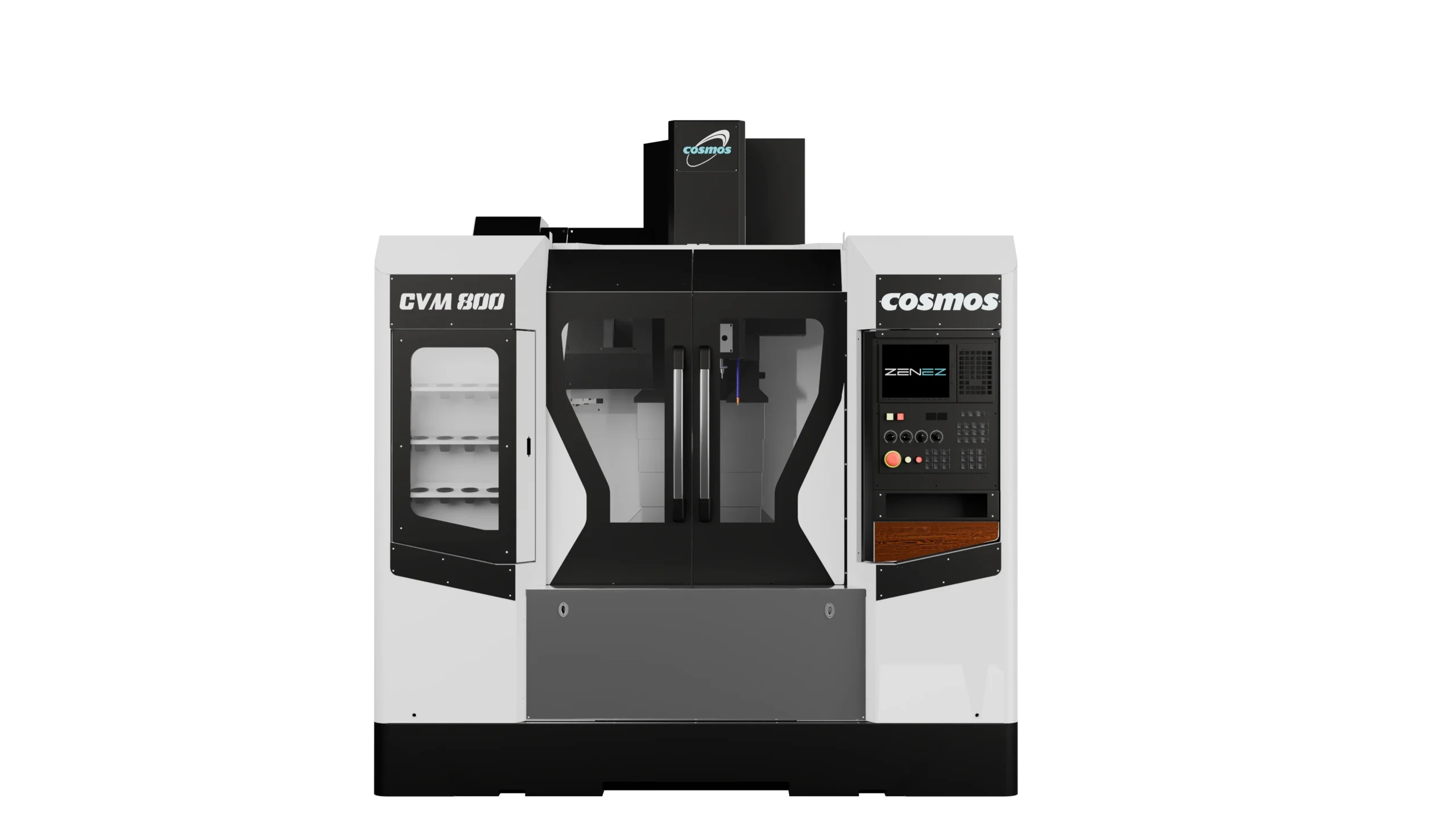

12-Station (24 Position) BMT Turret

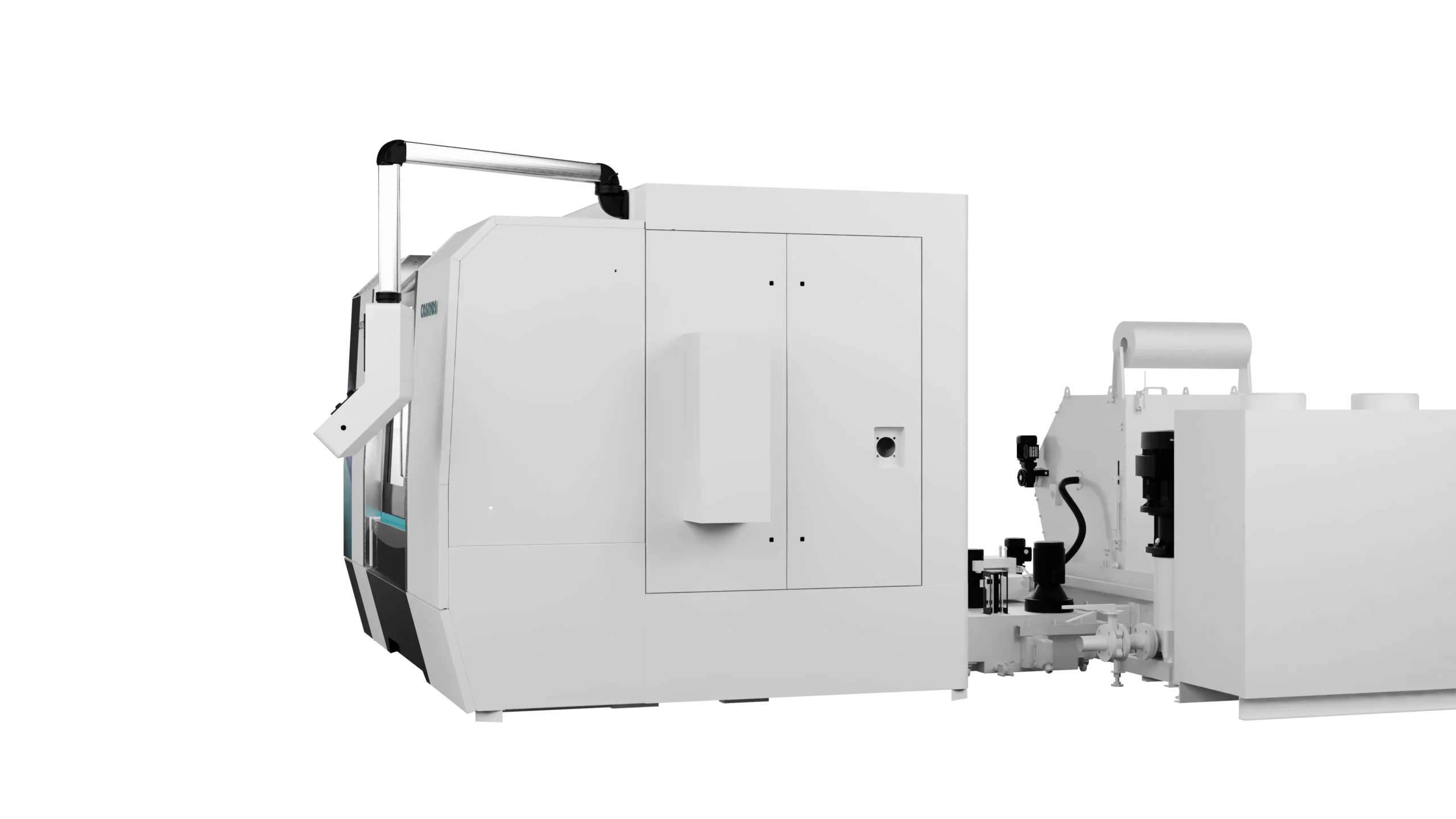

The front doors are constructed using heavy-duty, shatterproof polycarbonate material. The generously sized window provides operators with clear and unobstructed visibility, making it effortless to monitor machining processes.

Secure Tool Storage: Enclosed Cabinet With Adjustable Rack

All CVM machines come equipped with endorsed cabinets featuring racks, providing a safe and organised space to store your valuable tools. The adjustable design ensures flexibility to accommodate tools of various sizes with ease.

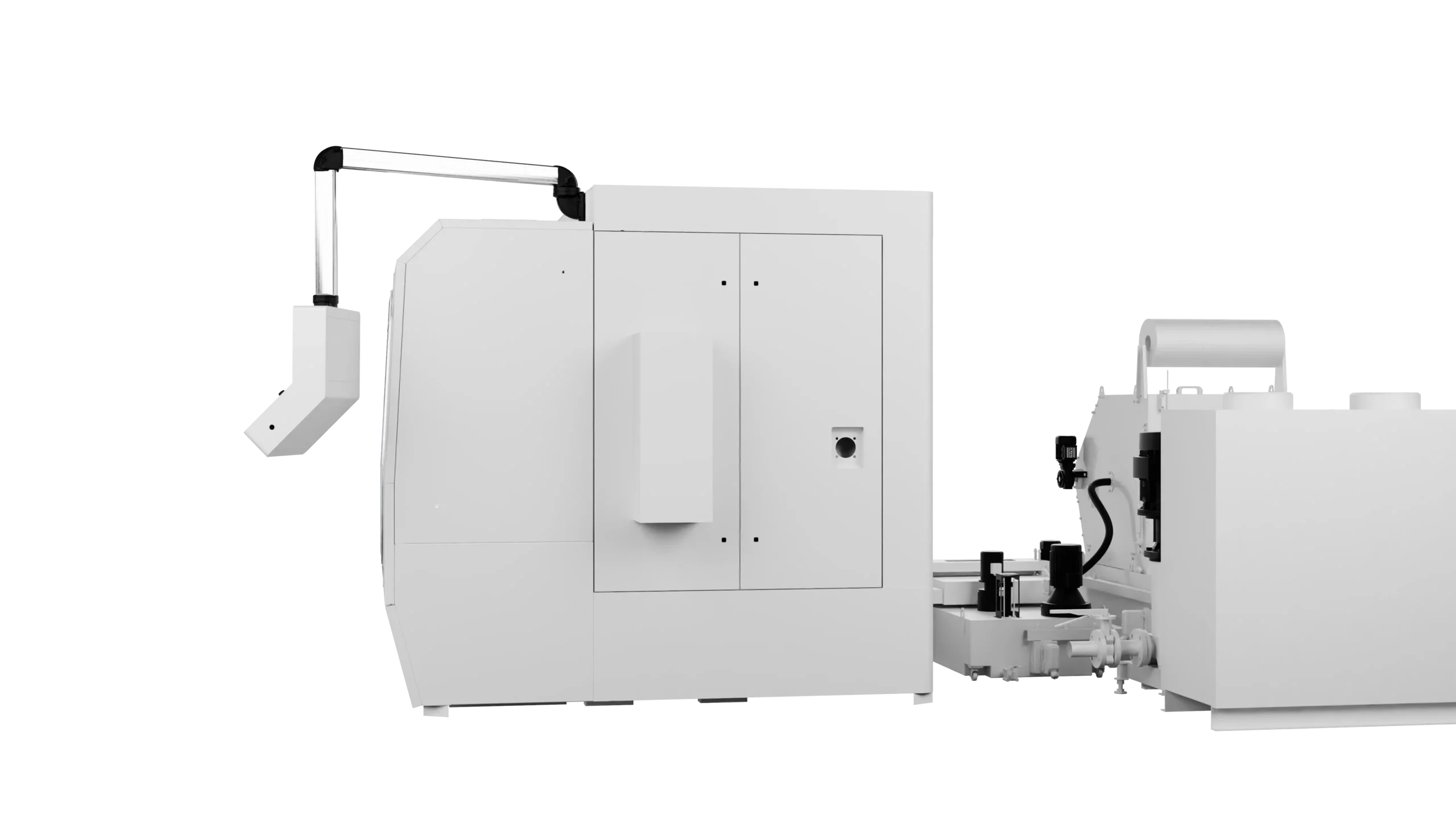

Holster For Your Guns

The machines feature scuffless steel panels equipped with holsters for the coolant and air guns. This thoughtful design ensures your guns are securely stored, preventing paint scratches, accidental drops, and messy coolant drips, enhancing both efficiency and workplace safety.

Stainless Steel Protector

Front panels often bear the brunt of scratches and rust from operator handling of tools, tackle, and components. Our solution? Stainless steel protection to eliminate these issues, ensuring lasting durability and a pristine appearance. Say goodbye to scratches and rust concerns.

Brilliantly Illuminated for Optimal Visibility

Designed for optimal visibility in low light, CVM machines include a dual work lamp with white LEDs, a three-colour tower lamp, ambient tool cabinet lighting, and an illuminated machine name, ensuring a well-lit workspace for operator ease.

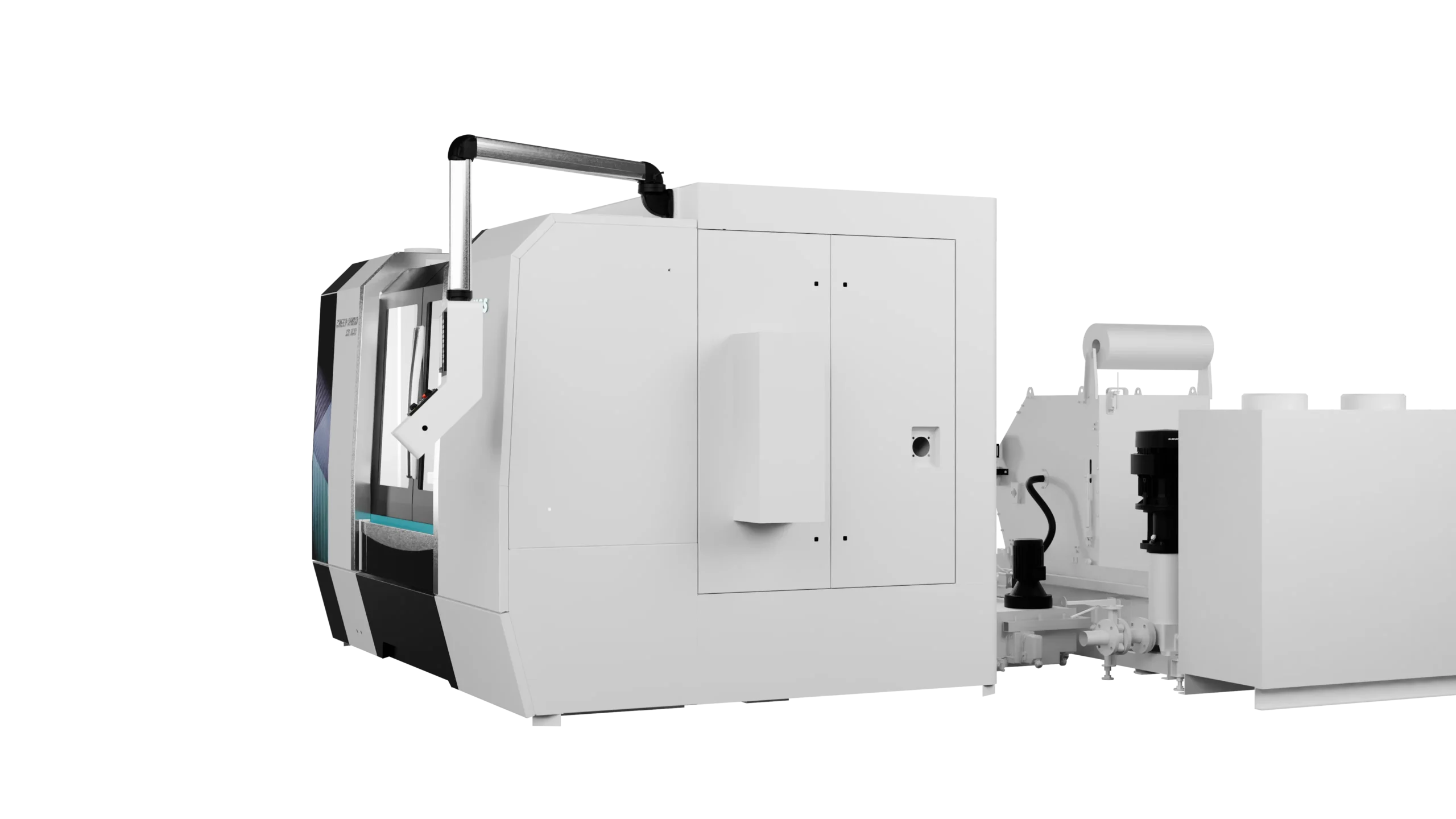

Seamless Access: Spacious Side Doors

Generously sized side doors are designed for easy access to the machine. These doors are strategically positioned below the table height, ensuring convenience during extended use. Work comfortably and efficiently with hassle-free access to your machine. (Except 640)

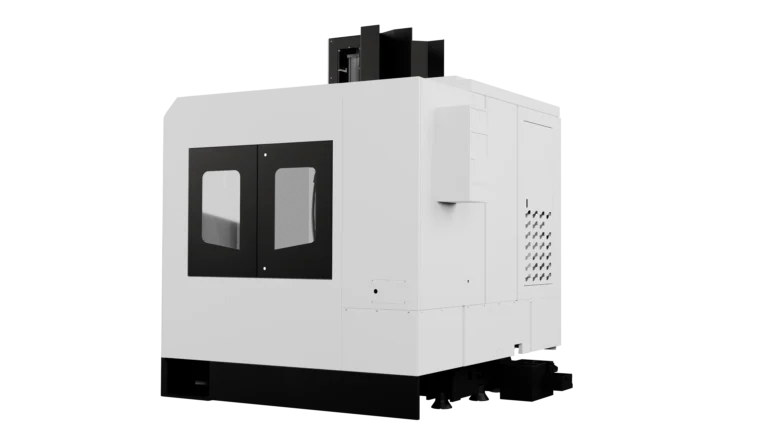

Versatile 360° Machine Design

Our machines feature a smooth, flush design on all four faces, offering you the freedom to position the machine in any orientation within your factory. Enjoy a sleek appearance from every angle.

Machine Specs

Grinding Area: 800 × 350 mm

Longitudinal Travel: 800 mm

Cross Travel: 350 mm

Vertical Travel: 300 mm

Max. Load on Table: 300 kg

Spindle Motor: 22 kW

Spindle Speed: 1000–3000 rpm

Grinding Wheel Size Max. (OD × Width × ID): 400 × 100 × 127 mm

Rapid Traverse X Axis: 10,000 mm/min

Rapid Traverse Y Axis: 5,000 mm/min

| Sr. No. | Machine Model | Length (l) | Travel (t) | Depth (d) | Height (h) |

|---|---|---|---|---|---|

| 1 | SG-7040 | 2755 | 3150 | 1975 | 2550 |

| 2 | SG-8040 | 3350 | 3750 | 2500 | 1950 |

| 3 | SG-1050 | 3530 | 4690 | 2475 | 2900 |

| 4 | SG-1260 | 3780 | 5100 | 2730 | 2900 |

| 5 | SG-1570 | 4825 | 6475 | 3305 | 3075 |

| 6 | SG-2070 | 6335 | 8500 | 3540 | 3100 |

Drive

| Longitudinal Hydraulic | Vertical Servo Motor with Ball Screw |

Easy User Interface

Operator skill level and fatigue reduced by eliminating manual machine operation. The complete grinding is done in auto cycle by feeding the required data in our user-friendly interface HMI. However, in case any manual operation is specifically required, it can be done by using MPG mode.

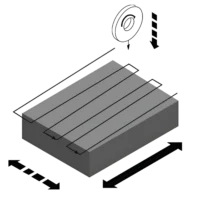

Plunge Cycle

Plunge Grinding Cycle is used for slot or side face grinding operation. It can also be utilised for top face grinding when component width is lower than wheel width. Here cross axis is fixed, and only vertical axis will move downward after each table reversal.

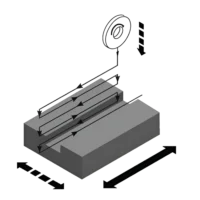

Intermittent Traverse Cycle

In Intermittent Traverse Cycle, the cross axis will move further after each table reversal for surface grinding operation.

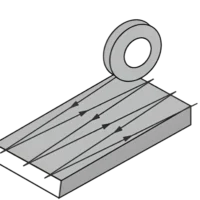

Continuous Traverse Cycle (OPT)

In Continuous Traverse Cycle, the longitudinal and cross axis will move simultaneously.

This feature is only available with machine having servo motor in cross axis.

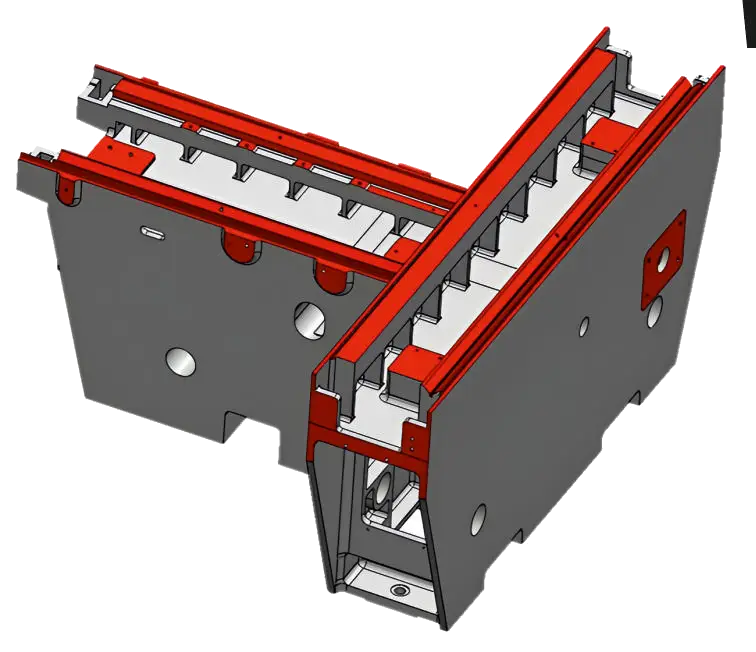

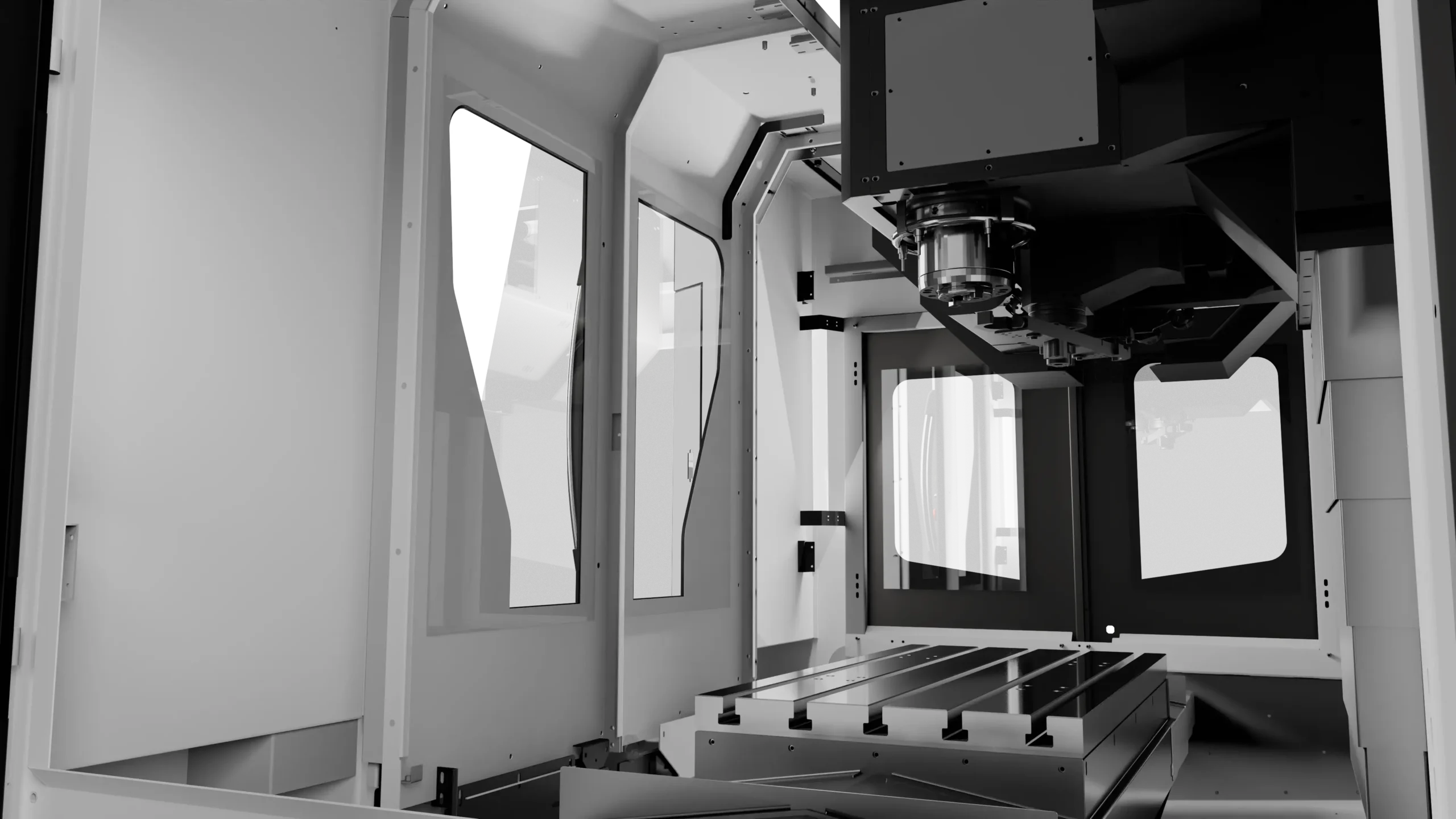

MACHINING STABILITY ENSURED

Our machines are distinguished by the extraordinary power of our signature ribs, the cornerstone of strength and quality in our construction. These ribs are strategically positioned to fortify our machines, elevating their structural integrity and amplifying overall robustness.

For heavy-duty cutting tasks, our ribs are the secret to success. They stand out in enhancing torsional rigidity, expertly reducing vibrations, and virtually eliminating deformation. The outcome is a level of machining precision and reliability that’s second to none – a testament to the enduring quality and unwavering strength of our ribs. Place your trust in the bedrock of excellence; rely on our ribs to deliver.

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

It focuses on customised dashboards and tools that help the operator to simplify his daily activity. The overall feature and package can reduce the time lost due to the complexity of the controller GUI; as a result, Zenez can significantly increase the machine output and profitability. • 10.4-inch display or large 15-inch display.

- 10.4-inch display or large 15-inch display

- Multi-touch User Interface

- Fully functional vertical and horizontal soft-keys for non-touch usage

- Crystal Type

- Enhanced hardware to ensure reliability

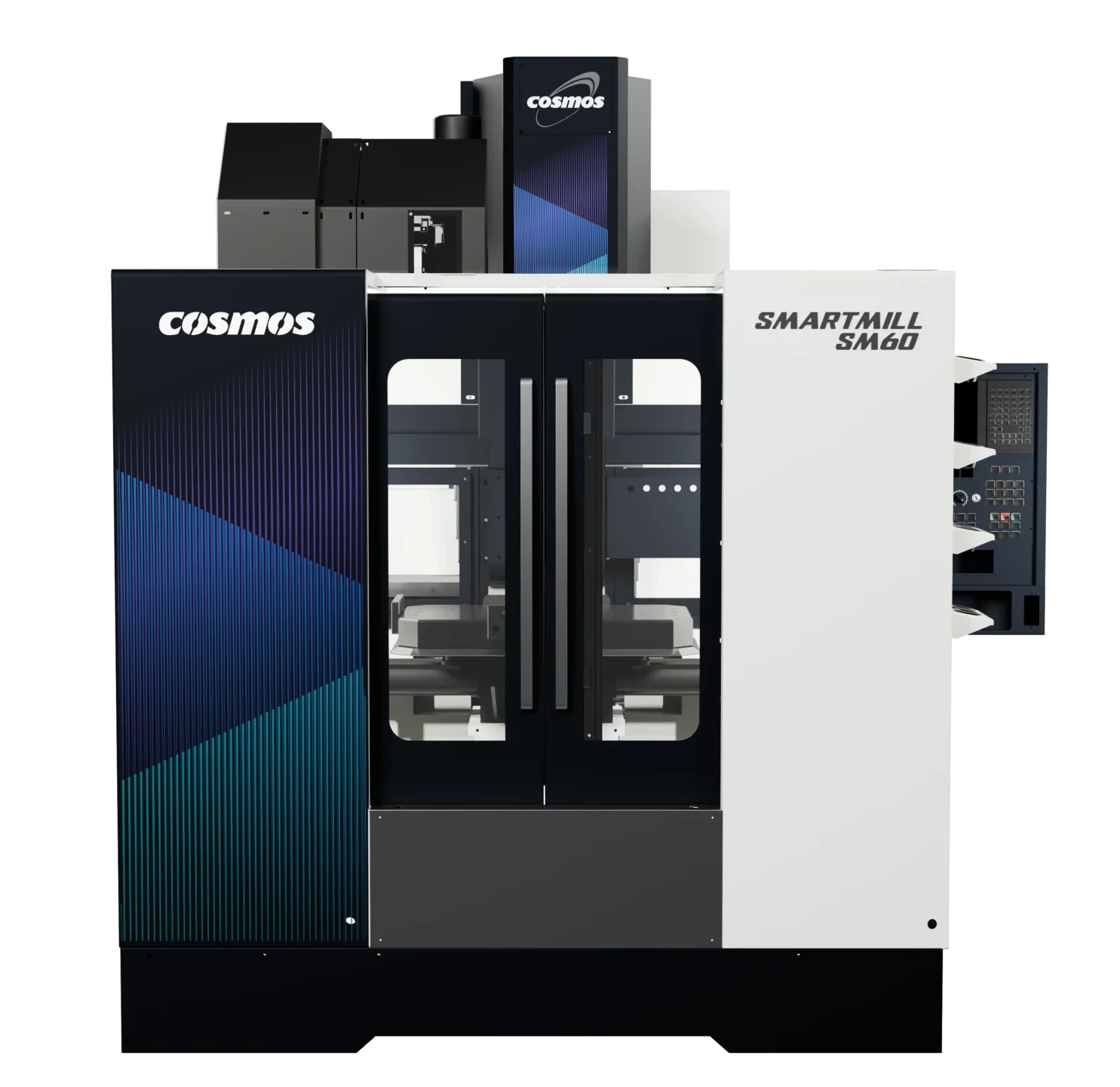

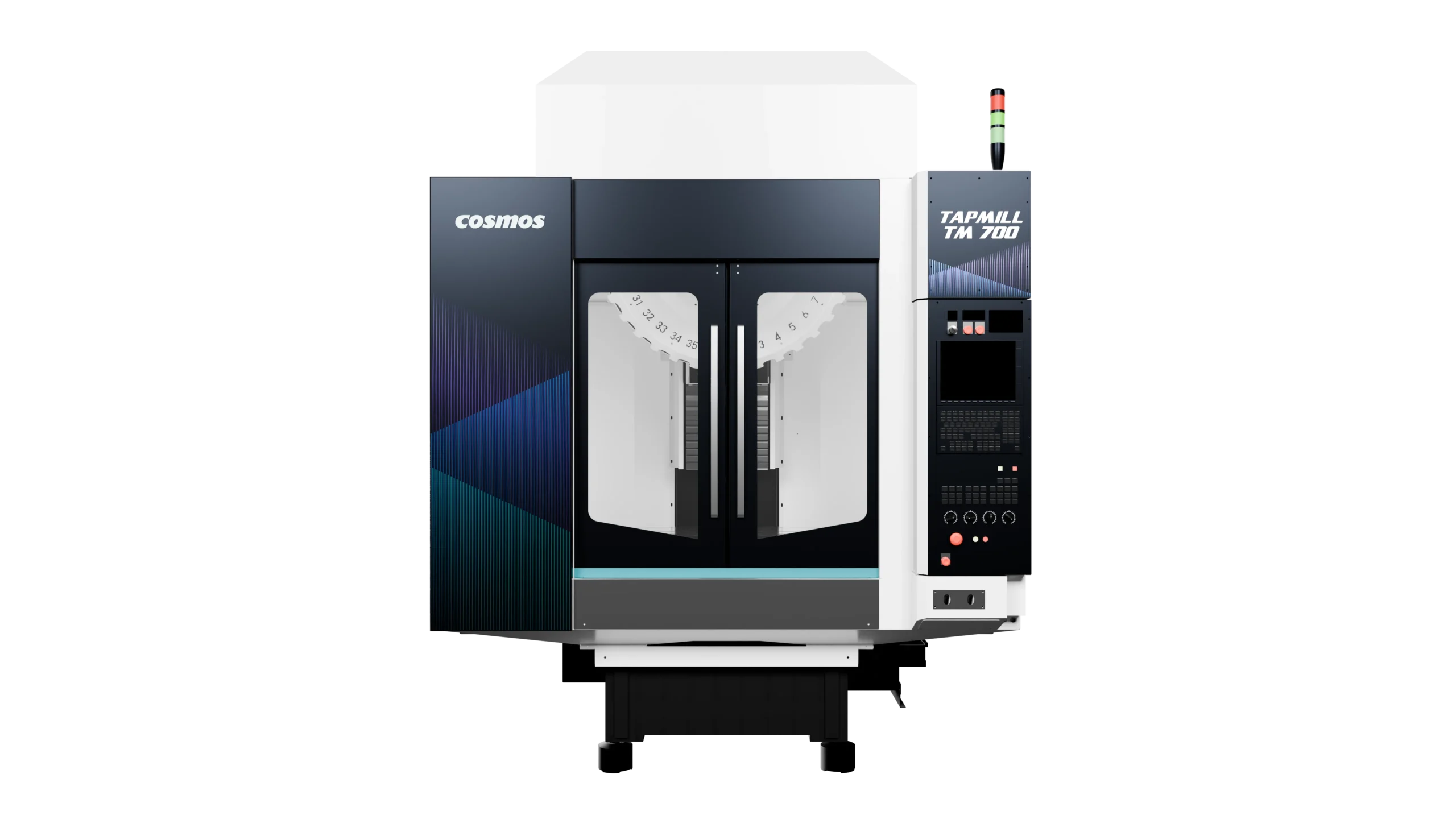

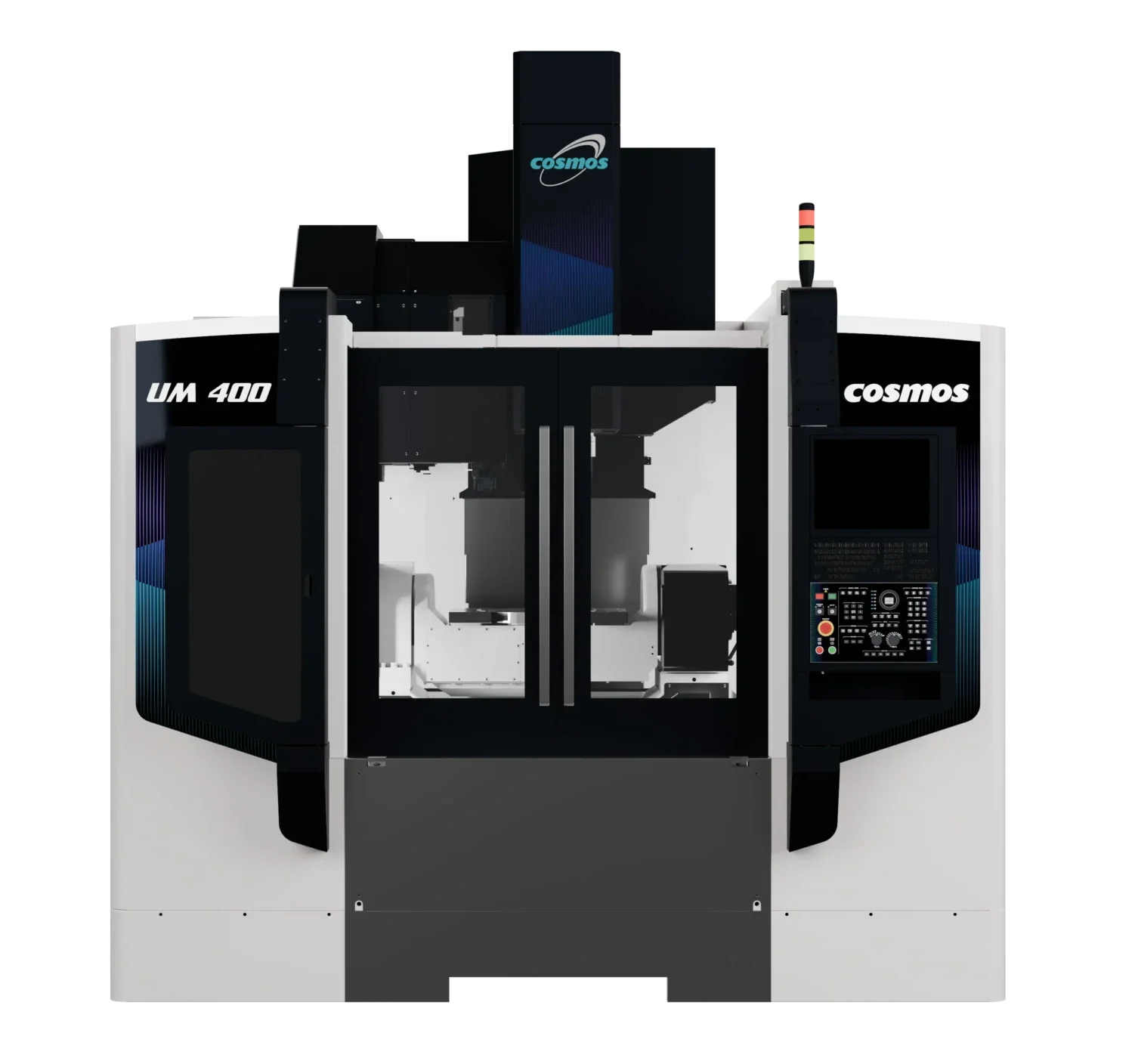

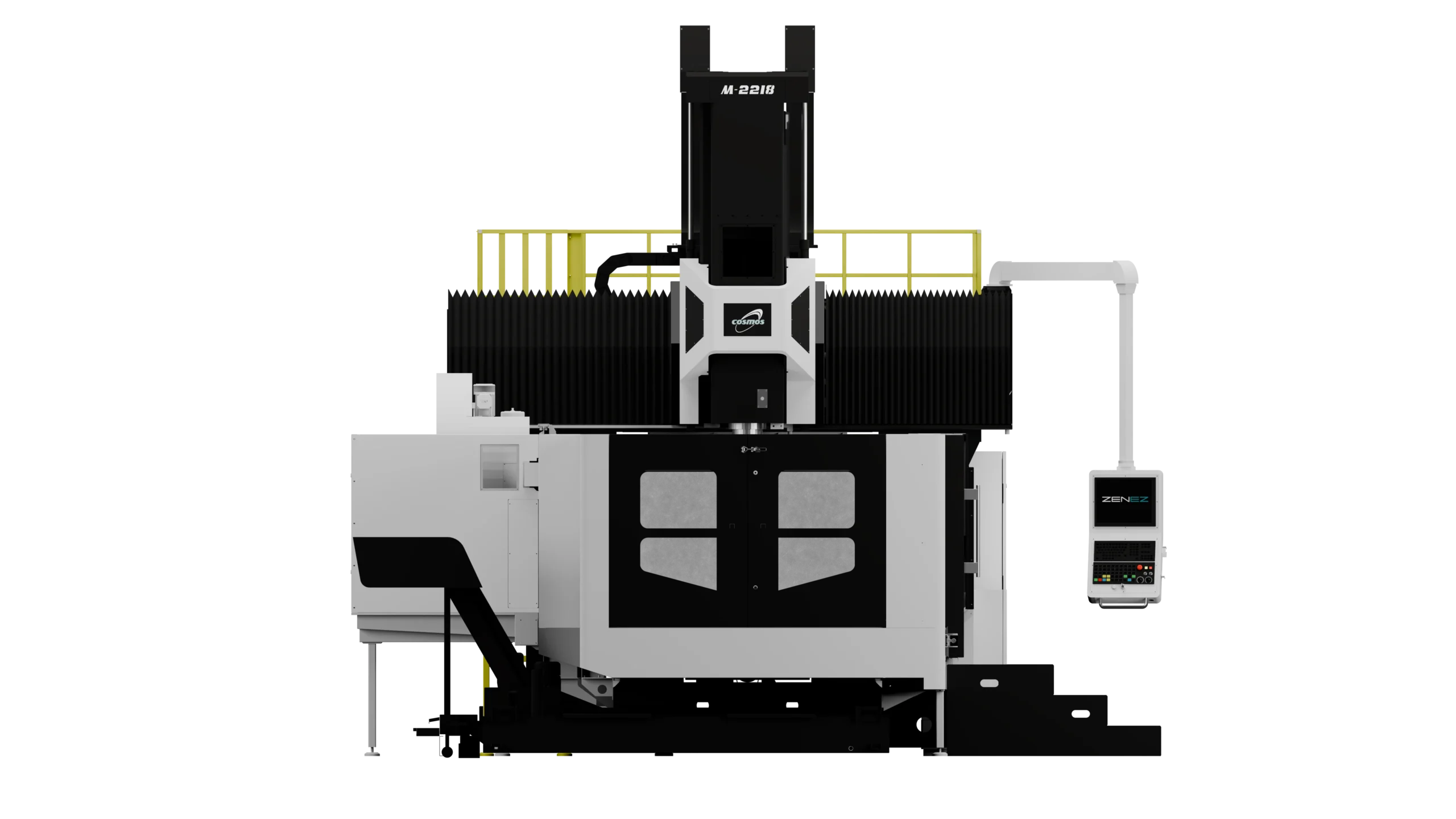

Our Other Range of Excellence

High-tech Products for Unmatched Performance