Mass Production

Driving Innovation in Mass Production

How we help the Mass Production Industry

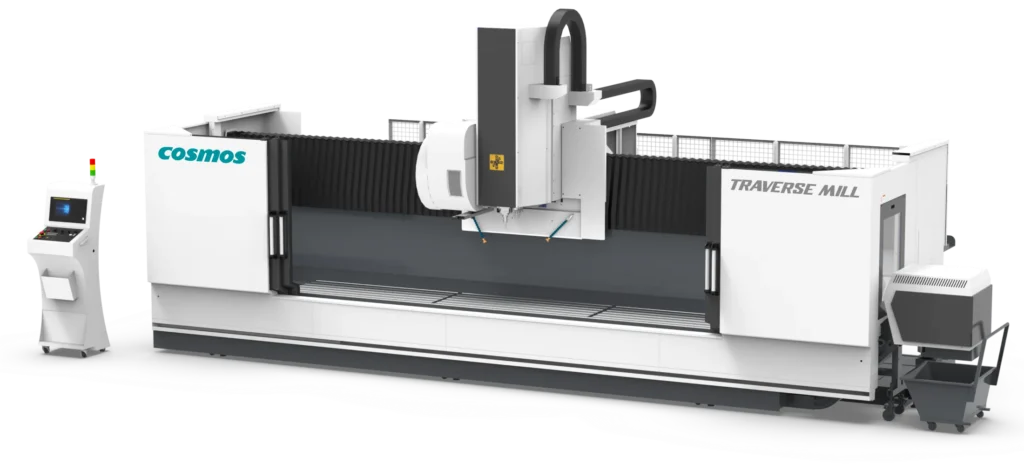

At Cosmos, we empower the mass production industry with precision-engineered CNC solutions that enhance system efficiency. Our advanced machines manufacture high-performance pumps and valves with unparalleled accuracy, ensuring reliability in demanding applications. Whether for industrial, oil and gas, or water treatment systems, Cosmos helps manufacturers improve durability and streamline production. With Cosmos, the pumps and valves industry can count on innovative technology to drive fluid systems forward with precision.

Impeller Blades

Pressure

Relief Valves

Pump Casing

All Other Components

Application Solutions for the Mass Production Industry

Pump Casings

The casing is the cornerstone of any pump, dictating its durability, flow efficiency, and pressure-handling capability. CNC machining ensures precise dimensions and smooth finishes for pump casings, whether they’re made of stainless steel, cast iron, or high-performance alloys. With the ability to endure extreme pressure and temperature, these components deliver consistent performance in industries like oil and gas, water treatment, and chemical processing.

Impellers

Impellers are at the heart of pump functionality, converting mechanical energy into fluid movement. CNC machining delivers unmatched precision, creating perfectly balanced impellers with optimised blade geometry for maximum efficiency. Whether for centrifugal pumps or axial flow systems, CNC-crafted impellers ensure smooth, vibration-free operation and enhanced fluid dynamics.

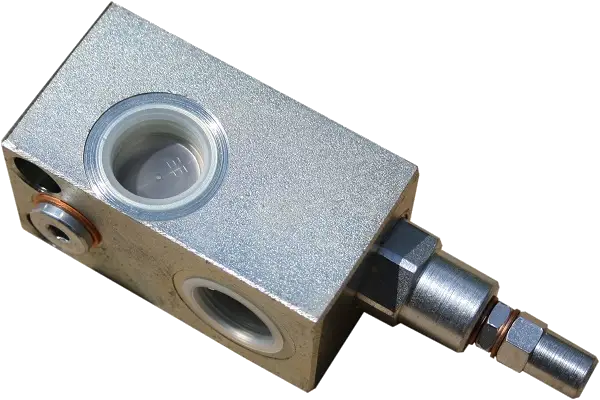

Valve Bodies

Valve bodies are critical to controlling the flow of fluids and gases in pipelines. CNC machining ensures the production of robust, leak-proof valve bodies that meet strict industry standards. From ball and gate valves to butterfly and globe valves, these components are designed for seamless integration and reliable performance under high-pressure and corrosive environments.

Shafts and Sleeves

Shafts and sleeves are vital to pump and valve performance, enabling smooth rotation and alignment. CNC machining creates these components with exceptional straightness, surface finish, and durability. These precision-engineered parts reduce wear and tear, extend service life, and ensure efficient energy transfer in every application.

Sealing Components

Sealing rings, gaskets, and packing components play a crucial role in preventing leakage and maintaining system integrity. CNC machining allows for the creation of intricate, tight-tolerance sealing components from materials like PTFE, rubber, or metal alloys. These seals guarantee reliability in high-pressure, high-temperature, and chemically aggressive environments.

Valve Stems

Valve stems are essential for the precise operation of valves, ensuring smooth and accurate actuation. CNC machining produces high-strength valve stems with flawless threads and finishes, enabling easy control and longer service life. These components are critical in achieving reliable flow control in a variety of industrial settings.

Control helps connecting your operator & machine in a mutually beneficial bond. Now operators can utilize on board dashboards and tools to maximize your Profits.

Dashboard Monitoring

Program Transfer

Alarm Analysis

Tool Cutting Time Information

All-in-one-Dashboard

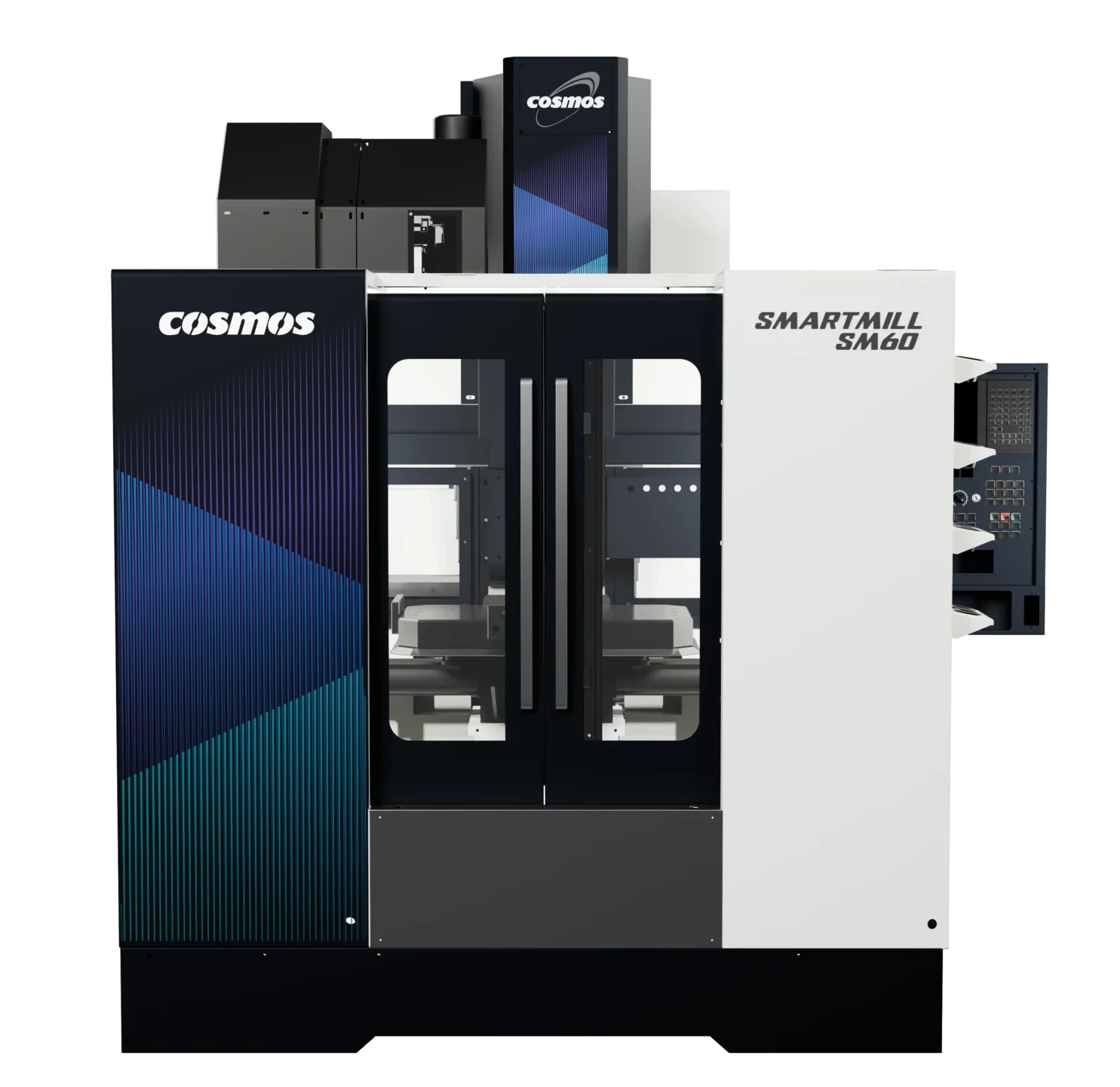

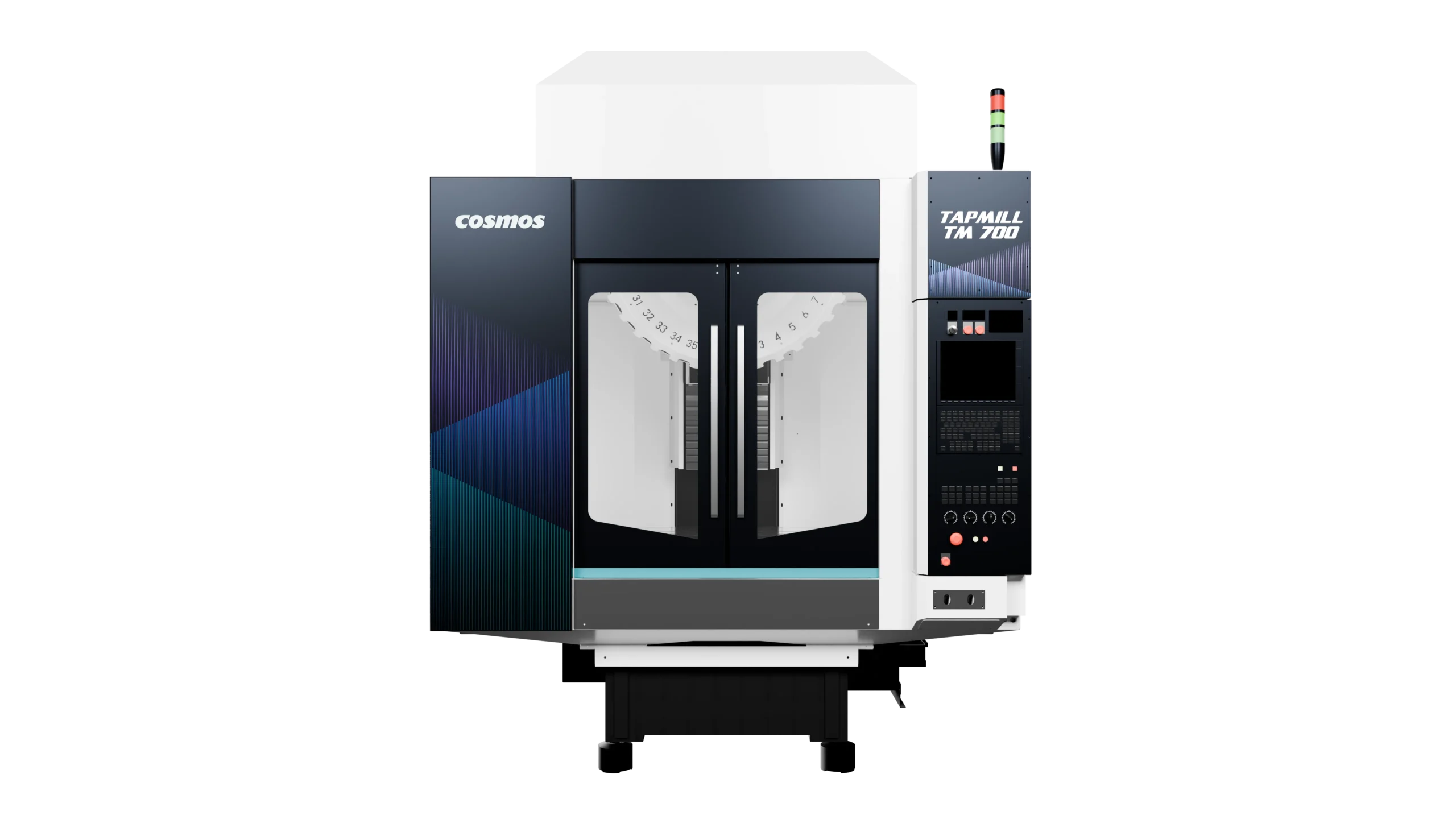

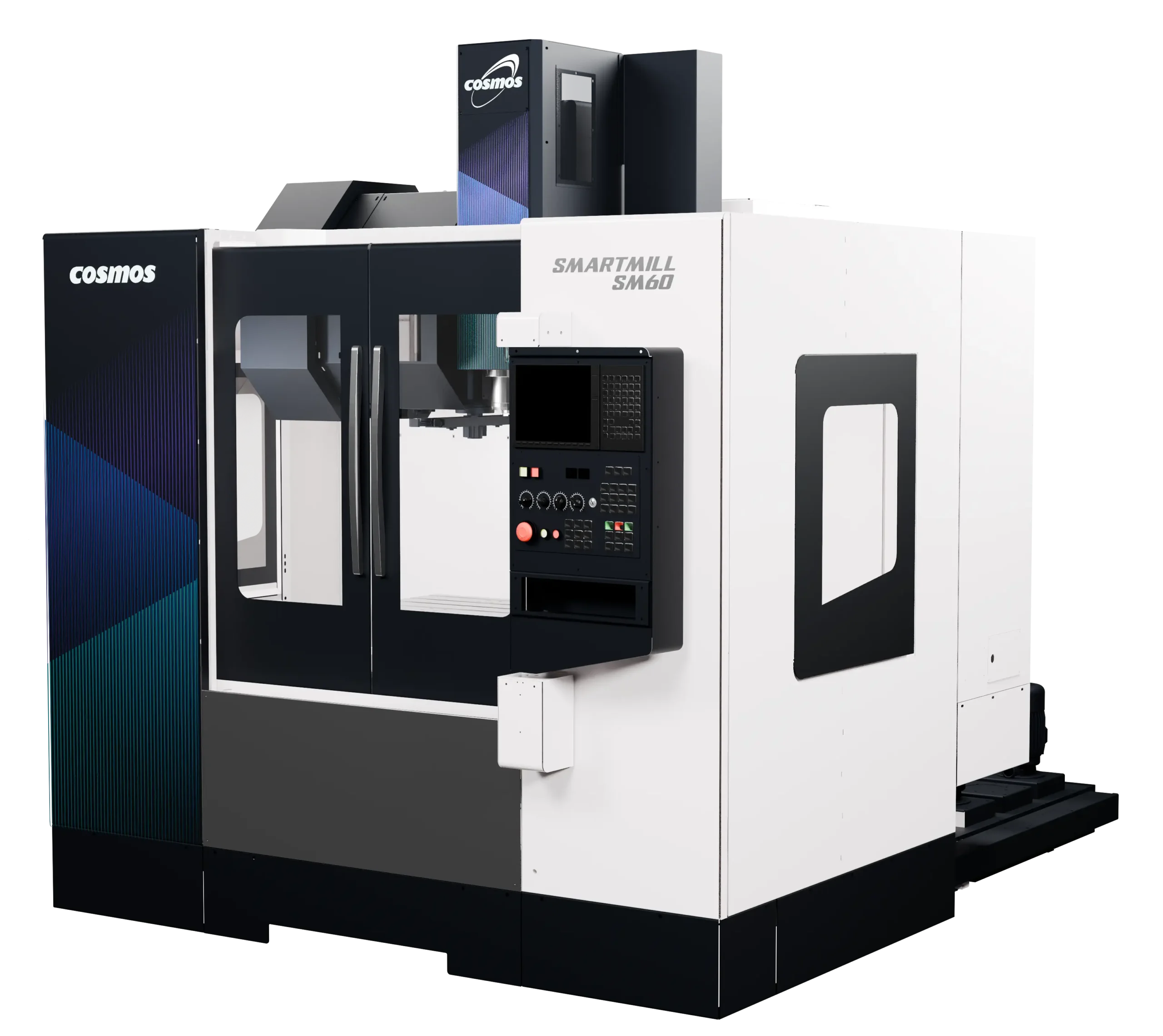

Product Information

Downtime Analysis

Email Alerts

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

FAQs

How do CNC machines optimise mass production processes?

CNC machines streamline mass production by offering consistent precision, automation, and repeatability, enabling high-volume manufacturing without compromising quality.

What types of industries rely on CNC machines for mass production?

CNC machines are widely used in industries like automotive, electronics, consumer goods, aerospace, and medical equipment, where high-volume, consistent output is essential.

Can Cosmos CNC machines handle 24/7 operations required for mass production?

Yes, Cosmos CNC machines are engineered for continuous operation with advanced cooling systems and durable components to ensure reliable performance round the clock.

What materials can be used for mass production with Cosmos CNC machines?

Cosmos CNC machines can process a wide range of materials, including metals, alloys, plastics, and composites, catering to diverse mass production needs.

How does Cosmos minimise downtime in mass production setups?

Cosmos machines are built for reliability and include diagnostic tools, predictive maintenance alerts, and quick part replacement options to reduce downtime.

Have a question about our products or services?

Submit Your Enquiry

Our team of experts is here to assist you. Fill out our quick enquiry form and let

us know how we can help you achieve progress.

For more information, write us at hrd3@cosmos.in