Medical Implants and Equipment

Advancing Innovation in Medical Implants and Equipment

How we help Medical Implants and Equipment Industry

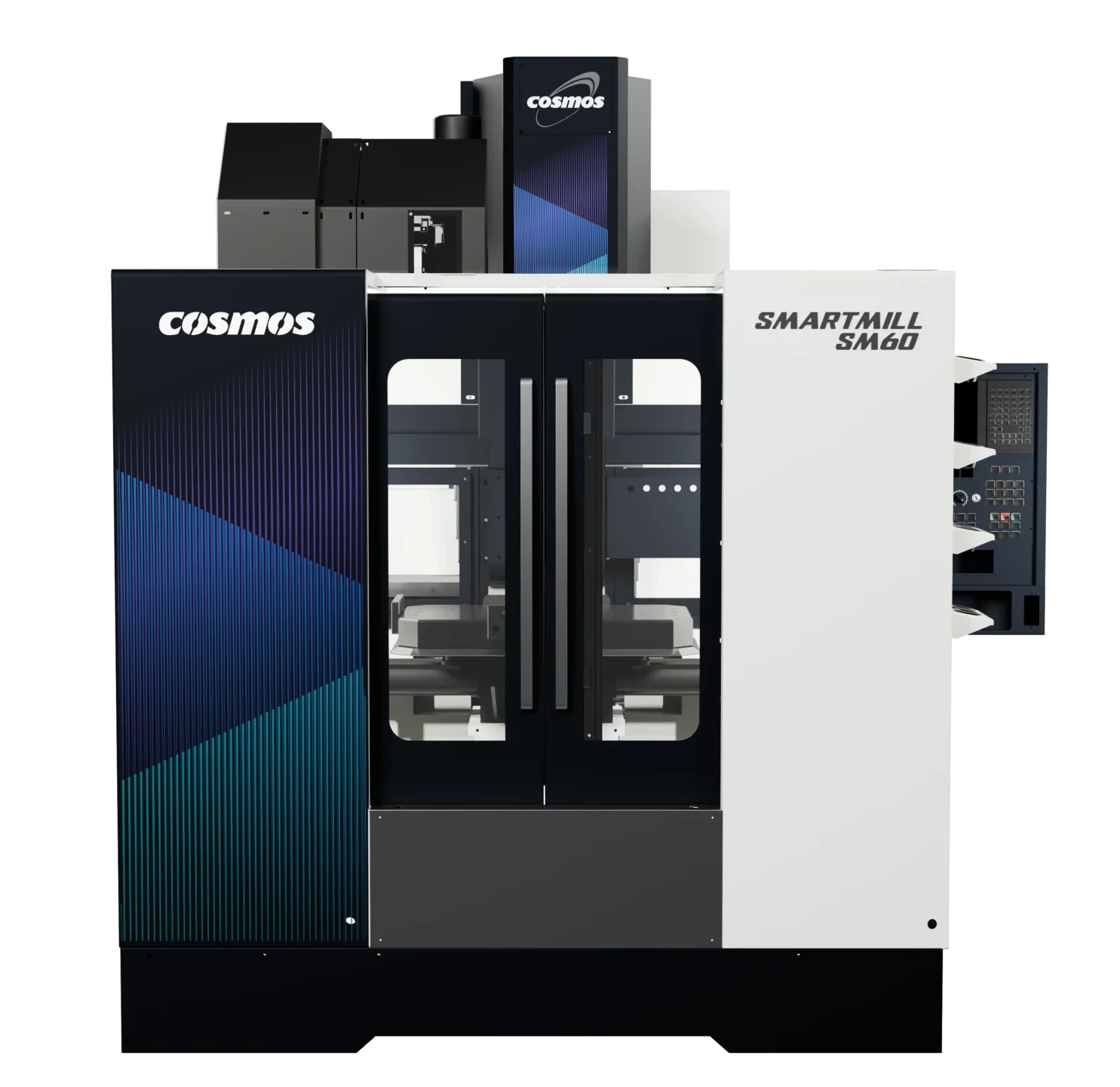

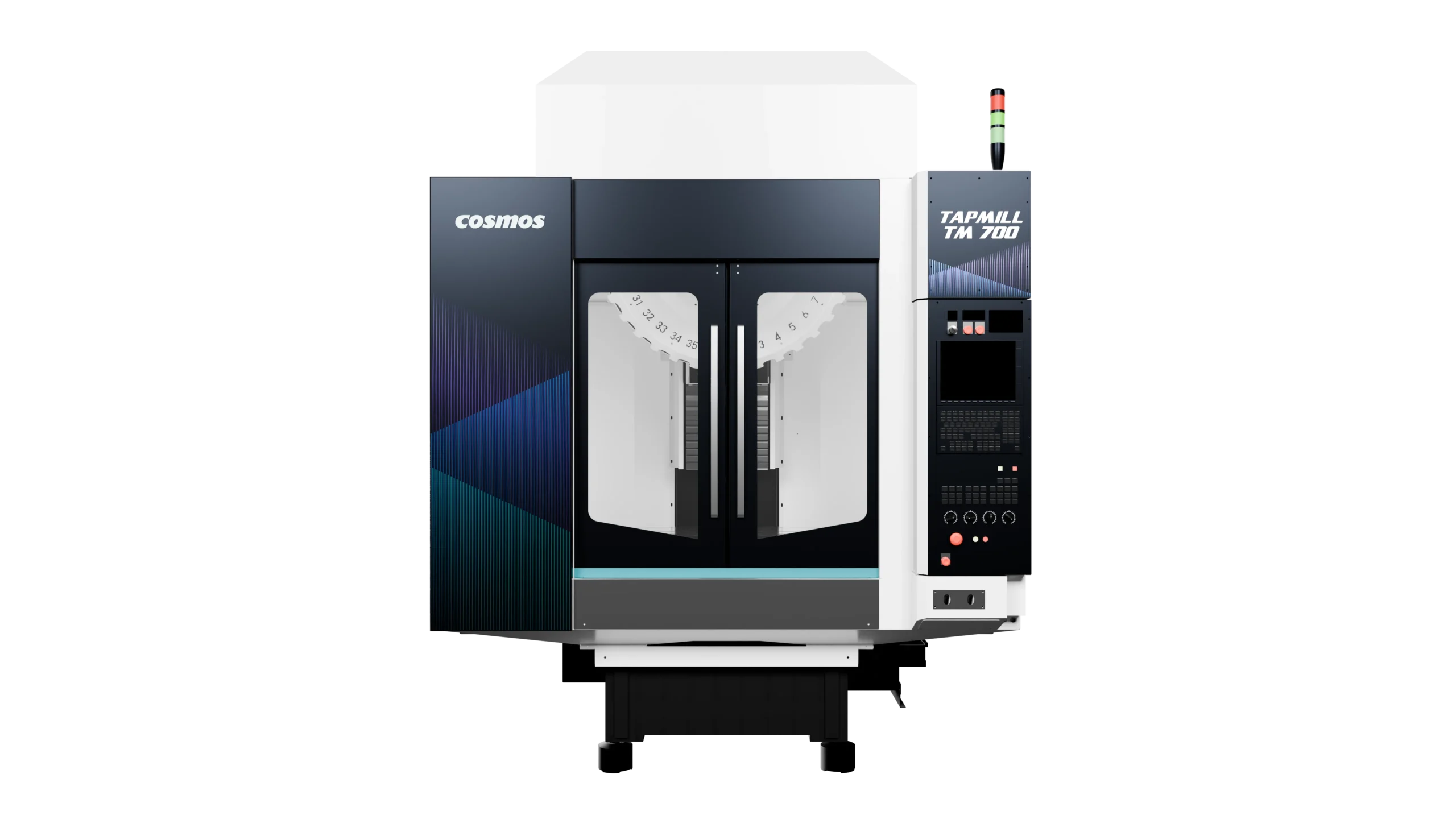

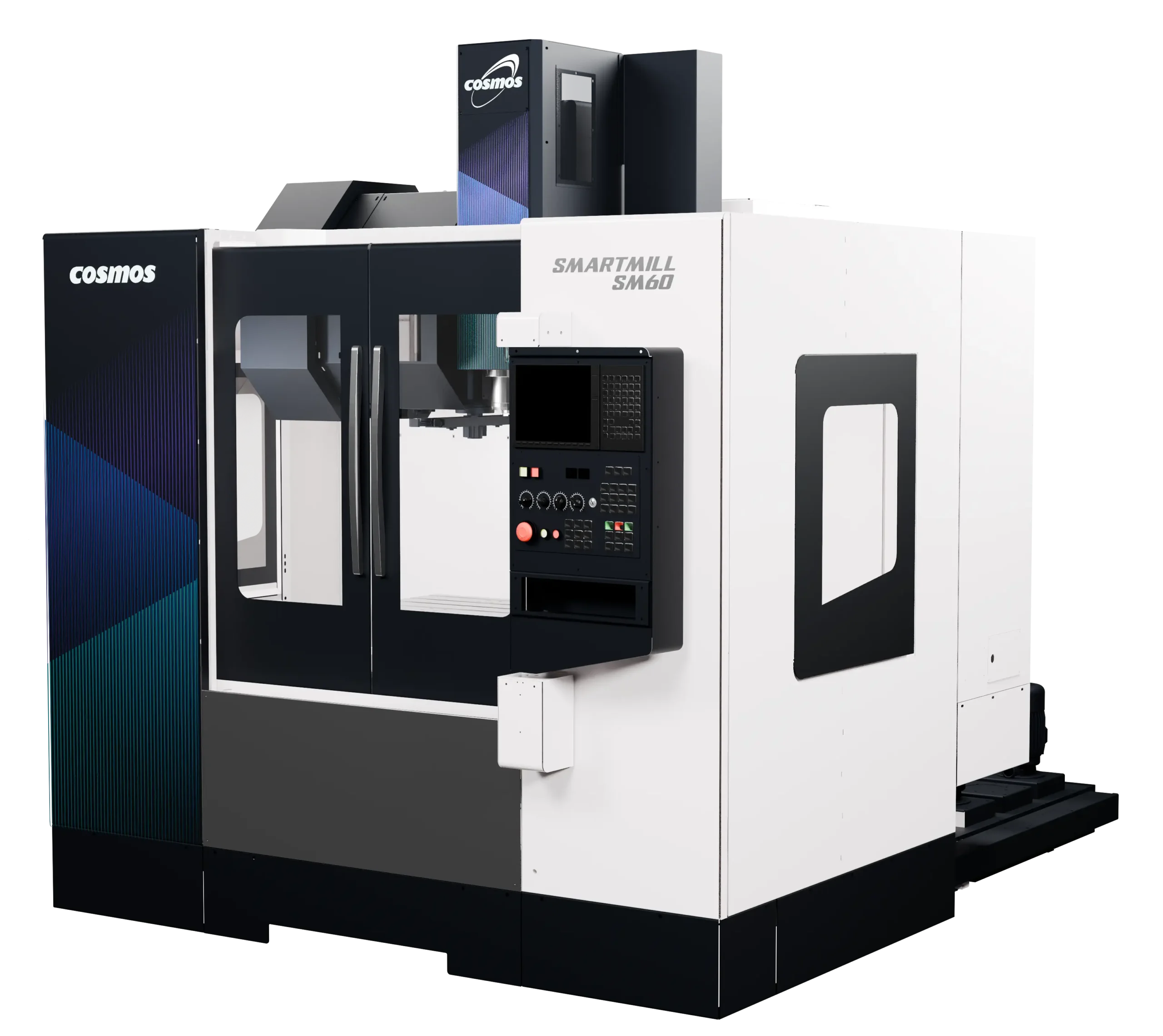

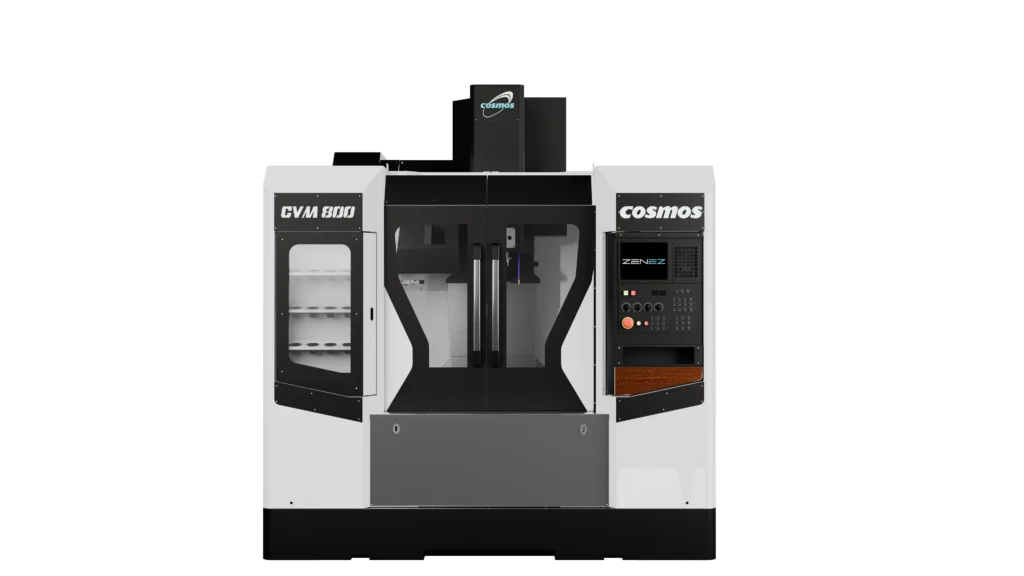

At Cosmos, we deliver precision CNC solutions for the medical implants and equipment industry, ensuring top-quality, reliable products. Our advanced machines craft custom implants and surgical tools with unmatched accuracy, supporting manufacturers in creating durable, high-performance solutions that improve patient care and advance healthcare. With Cosmos, medical innovators can rely on cutting-edge technology for life-saving products.

Joint Prostheses

Knee Implant

Orthopedic

Bone Plates

Spinal Implants

Application Solutions for the Medical Implants and Equipment Industry

Orthopaedic Implants

In the world of healthcare, precision is a matter of life and mobility. CNC machining enables the creation of orthopaedic implants such as hip joints, knee replacements, bone plates, and screws with micrometer-level accuracy. These components are designed to fit seamlessly within the human body, offering superior strength, biocompatibility, and longevity. Whether for trauma care or elective procedures, CNC-crafted implants restore mobility and improve quality of life.

Dental Implants and Prosthetics

From crowns and bridges to titanium dental implants, CNC machining ensures every dental component is a perfect fit. High-precision milling and grinding create smooth surfaces and precise geometries that align flawlessly with a patient’s dental anatomy. These durable and corrosion-resistant components ensure long-lasting comfort and functionality, enabling confident smiles.

Surgical Instruments

Surgical instruments demand unmatched precision and durability to perform delicate procedures safely. CNC machining delivers scalpels, forceps, retractors, and surgical drills that meet stringent medical standards. With a focus on ergonomic design and superior finishes, these tools provide surgeons with the reliability they need in the operating room.

Prosthetics and Orthotics Components

Advanced prosthetic and orthotic devices rely on CNC machining for lightweight, durable, and highly functional components. From custom sockets and joints to robotic limb parts, CNC technology allows for tailored solutions that enhance mobility and comfort for users. These precision-engineered components empower individuals to live active, independent lives.

Diagnostic Equipment Parts

Medical diagnostics rely on equipment that performs with absolute accuracy. CNC machining creates components for CT scanners, MRI machines, X-ray devices, and ultrasound systems, ensuring flawless operation. Every part, from housings to intricate internal mechanisms, is crafted to meet exacting tolerances, guaranteeing reliable results in life-critical diagnostics.

Implantable Devices

CNC machining plays a vital role in manufacturing implantable medical devices such as pacemaker casings, stents, and cochlear implants. These components require exceptional precision and biocompatible materials to ensure they function seamlessly within the body while maintaining patient safety and comfort.

Sterilisation Trays and Equipment Accessories

Sterilisation is critical in the healthcare industry, and CNC machining ensures the production of durable, corrosion-resistant trays and accessories for surgical instruments and medical devices. These products are designed for repeated use in high-temperature, high-pressure environments without compromising quality.

Control helps connecting your operator & machine in a mutually beneficial bond. Now operators can utilize on board dashboards and tools to maximize your Profits.

Dashboard Monitoring

Program Transfer

Alarm Analysis

Tool Cutting Time Information

All-in-one-Dashboard

Product Information

Downtime Analysis

Email Alerts

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

FAQs

How are CNC machines used in manufacturing medical implants and equipment?

CNC machines are utilised to produce highly precise and complex components such as orthopedic implants, surgical instruments, and prosthetics, ensuring accuracy and biocompatibility.

Can Cosmos CNC machines handle the micro-level precision required for medical implants?

Yes, Cosmos CNC machines are equipped with advanced multi-axis machining and high-speed spindles to achieve the micro-level tolerances critical for manufacturing medical implants.

How does Cosmos ensure biocompatibility in machined components?

Our CNC machines are designed to work seamlessly with biocompatible materials like titanium, stainless steel, and medical-grade polymers while maintaining the integrity of the materials during machining.

Are Cosmos CNC machines suitable for prototyping medical devices?

Absolutely. Cosmos CNC machines facilitate rapid prototyping, allowing manufacturers to develop and test medical devices quickly and efficiently before mass production.

How does Cosmos ensure the long-term reliability of CNC machines in medical manufacturing?

Cosmos prioritises precision engineering, robust construction, and user-friendly interfaces, combined with dedicated maintenance support, to ensure sustained performance and reliability in medical applications.

Have a question about our products or services?

Submit Your Enquiry

Our team of experts is here to assist you. Fill out our quick enquiry form and let

us know how we can help you achieve progress.

For more information, write us at hrd3@cosmos.in