Oil and Gas

Shaping the Future of Energy with Precision Engineering

How we help the Oil and Gas Industry

At Cosmos, we empower the oil and gas industry with precision engineering solutions that push the boundaries of performance and resilience. Our advanced CNC technology is engineered to produce critical components that endure the harshest conditions, from deep-sea drilling to remote refinery operations. Whether enhancing the efficiency of extraction systems or optimising transportation infrastructure, Cosmos ensures reliability and superior functionality. With our commitment to innovation, we provide the tools that drive operational excellence, helping the oil and gas industry meet the complex challenges of tomorrow’s energy landscape.

1.2x More

Running capacity

Lorem ipsum

99%

Data Accuracy

powered by ZENEZ

25%

Efficiency on programs

powered by ZENEZ

1.4x More

Running capacity

powered by DigiFac

Carbon Steel Flange

Manifold

Valve Body 2

Valve Body

Application Solutions for the Oil and Gas Industry

Drilling Components

In the oil and gas industry, precision is critical for drilling operations that push the limits of engineering. From drill bits to downhole tools, CNC machining ensures these components are manufactured to withstand extreme pressures, high temperatures, and corrosive environments. With durable materials and precise tolerances, our CNC solutions enable efficient extraction processes, reducing downtime and maximising operational safety in even the harshest conditions.

Valves and Flow Control Systems

Efficient flow control is essential in the oil and gas sector, where precision valves and actuators regulate the movement of fluids and gases. CNC machining delivers the accuracy required to create leak-proof valves, fittings, and flow-control systems that operate seamlessly under high-pressure scenarios. These components play a vital role in maintaining process safety, optimising flow rates, and ensuring regulatory compliance in every application.

Pipeline Components

Pipelines form the backbone of oil and gas transport, requiring components that are tough, reliable, and flawlessly crafted. From flanges and connectors to elbows and tees, CNC machining produces pipeline parts with exact specifications, ensuring seamless connections and leak-proof performance. By guaranteeing uniformity and durability, our CNC solutions help maintain the integrity of critical infrastructure over extended periods of use.

Refinery Equipment

Refineries rely on robust equipment to process crude oil into valuable products. CNC machining enables the production of heat exchangers, reactors, and pump components with exceptional precision. These parts ensure efficiency and durability in refining operations, minimising wear and tear while maintaining optimal performance in demanding environments.

Miscellaneous Precision Parts

The smallest parts often make the biggest impact in the oil and gas industry. From seals and fasteners to specialised couplings, these components are critical to the safe and efficient operation of equipment. CNC machining ensures these precision parts meet strict tolerances and deliver the reliability needed in complex industrial systems. Each component is crafted to handle the unique demands of this high-stakes industry, proving that no detail is too small when it comes to performance and safety.

Control helps connecting your operator & machine in a mutually beneficial bond. Now operators can utilize on board dashboards and tools to maximize your Profits.

Dashboard Monitoring

Program Transfer

Alarm Analysis

Tool Cutting Time Information

All-in-one-Dashboard

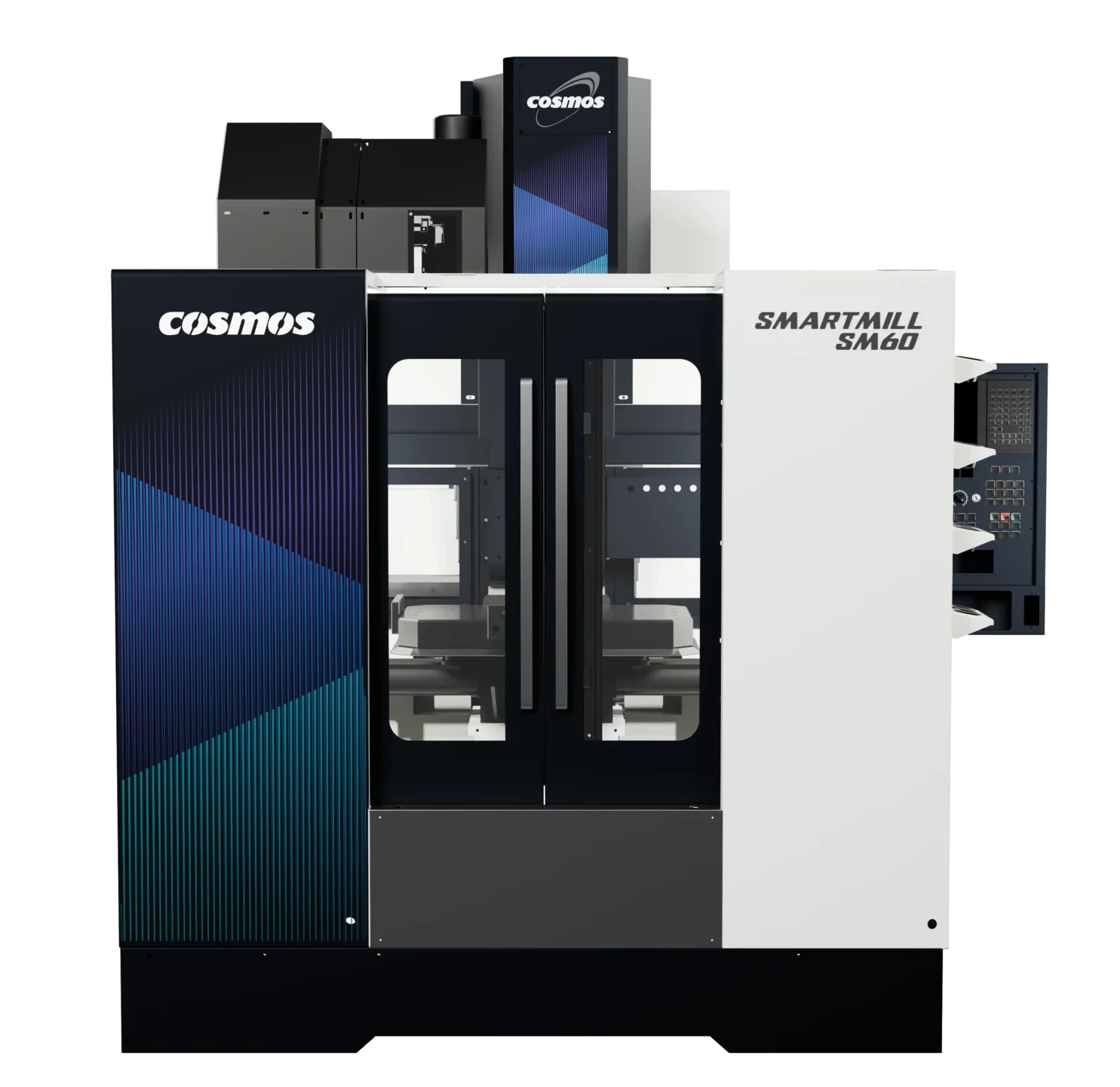

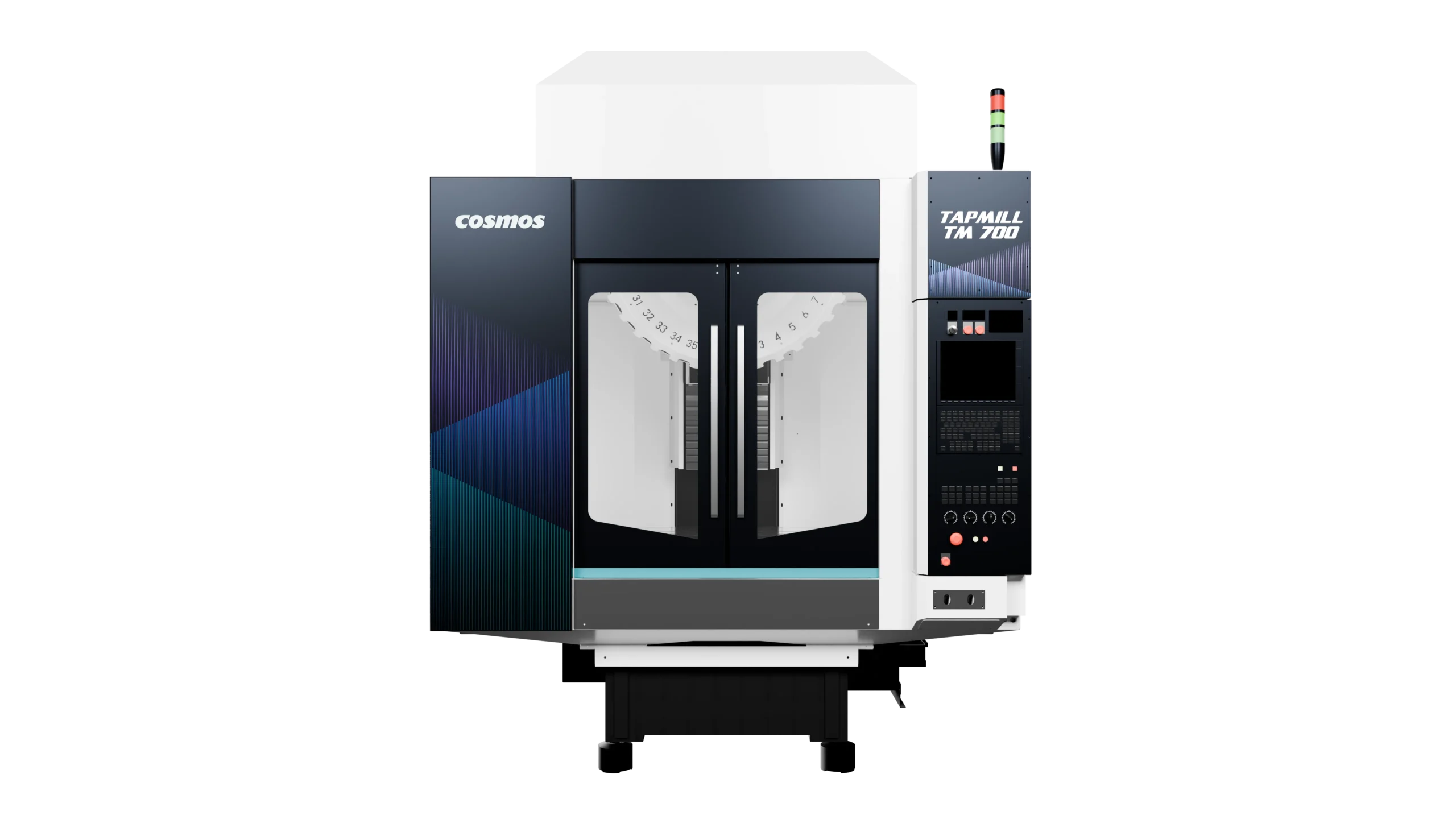

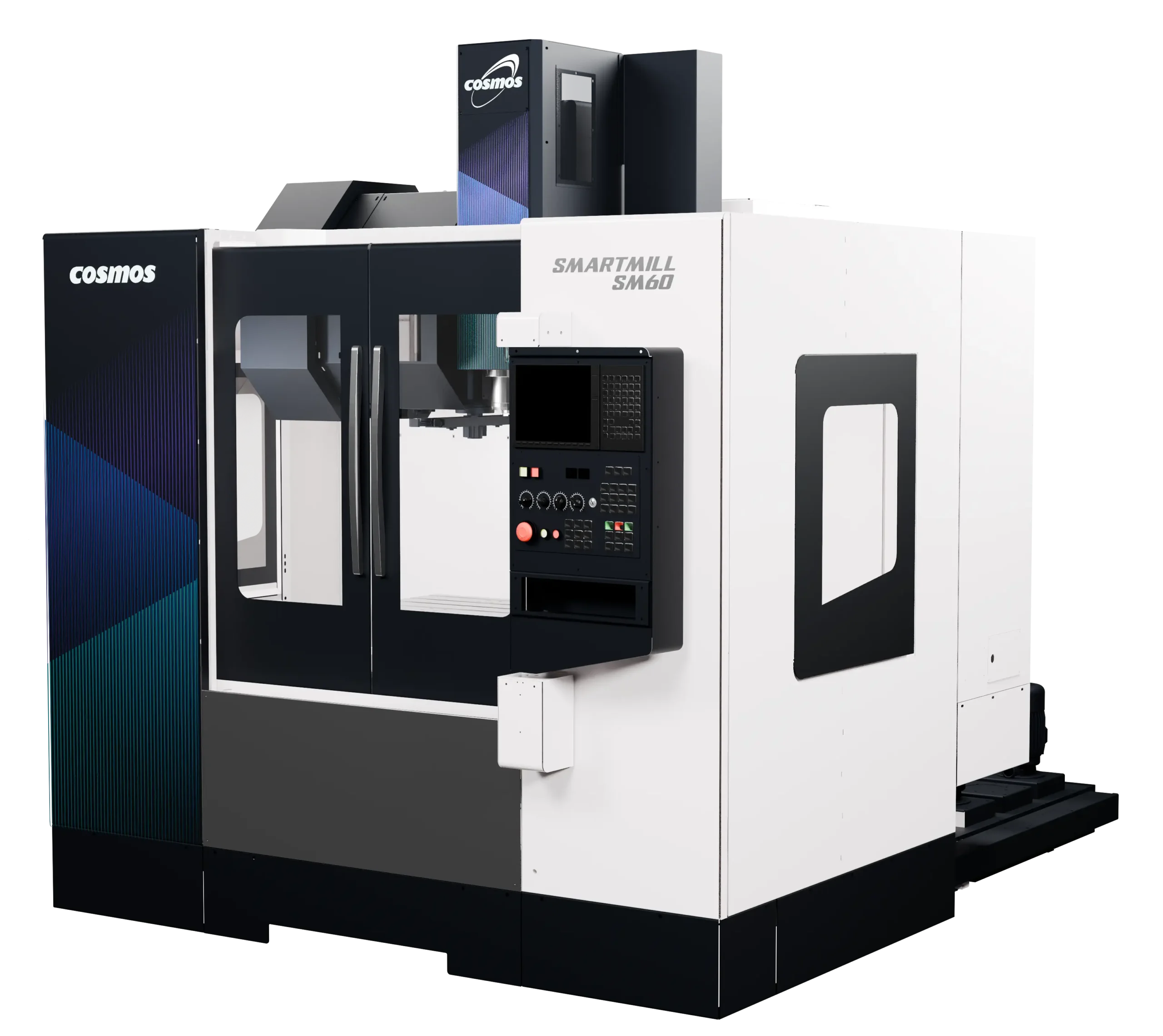

Product Information

Downtime Analysis

Email Alerts

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

FAQs

How are CNC machines utilised in the oil and gas industry?

CNC machines are critical for manufacturing high-precision components such as drill bits, valves, pumps, flanges, and pipelines, ensuring operational safety and efficiency.

Can Cosmos CNC machines support customised component manufacturing for oil and gas projects?

Yes, Cosmos CNC machines offer flexible configurations and advanced programming to create bespoke components tailored to specific oil and gas requirements.

What materials can be processed for oil and gas applications using Cosmos CNC machines?

Cosmos CNC machines can process durable materials like stainless steel, carbon steel, titanium, and superalloys, commonly used in oil and gas equipment.

Can Cosmos CNC machines handle the machining of large, heavy-duty oil and gas components?

Yes, Cosmos CNC machines are engineered with robust frames, extended worktables, and high-torque spindles to manage large and heavy components typical of the oil and gas sector.

What role do CNC machines play in improving operational safety in the oil and gas industry?

CNC machines produce high-precision components that reduce the risk of equipment failure, ensuring safer operations in high-risk environments like drilling and refining.

Have a question about our products or services?

Submit Your Enquiry

Our team of experts is here to assist you. Fill out our quick enquiry form and let

us know how we can help you achieve progress.

For more information, write us at hrd3@cosmos.in