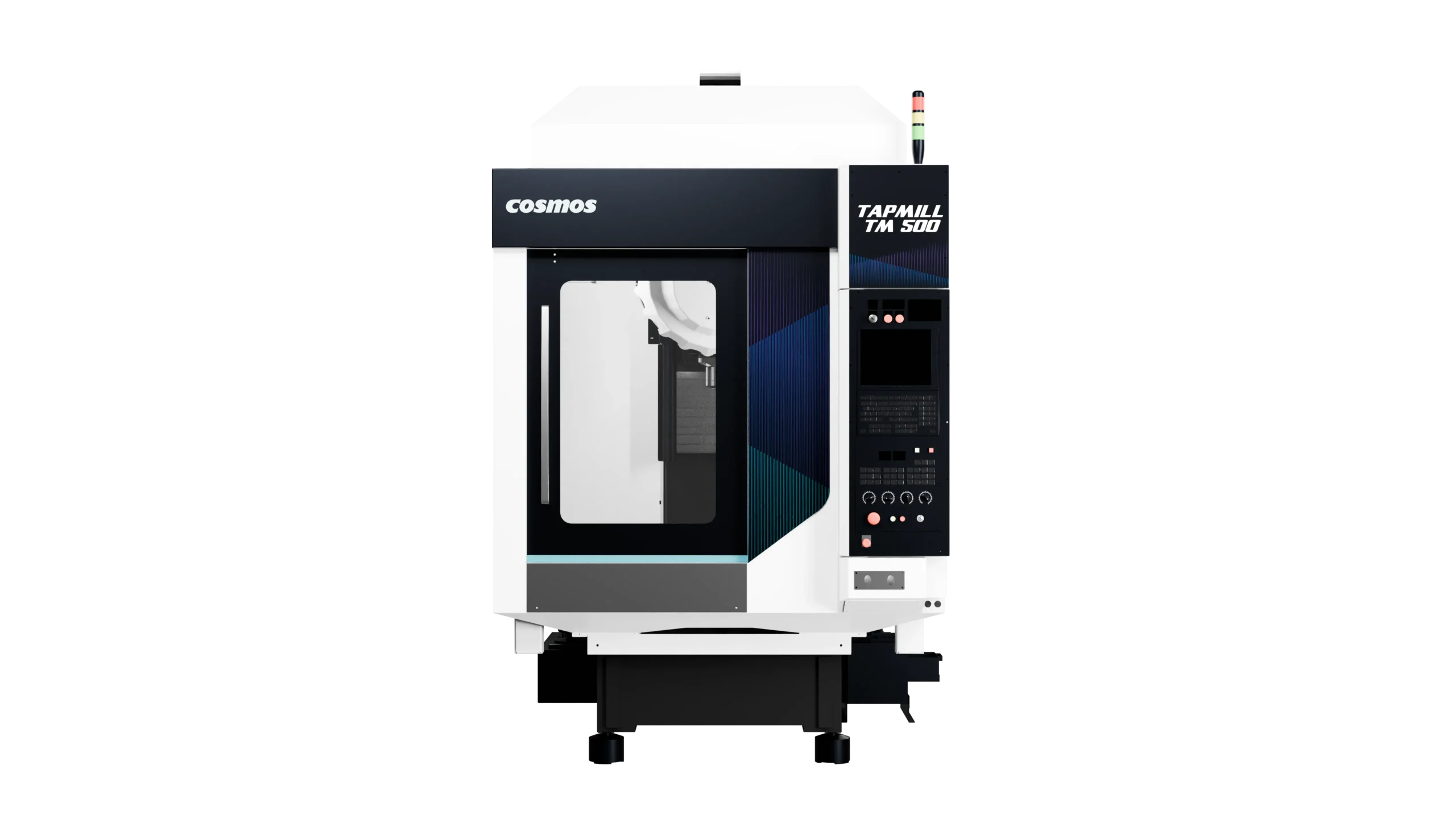

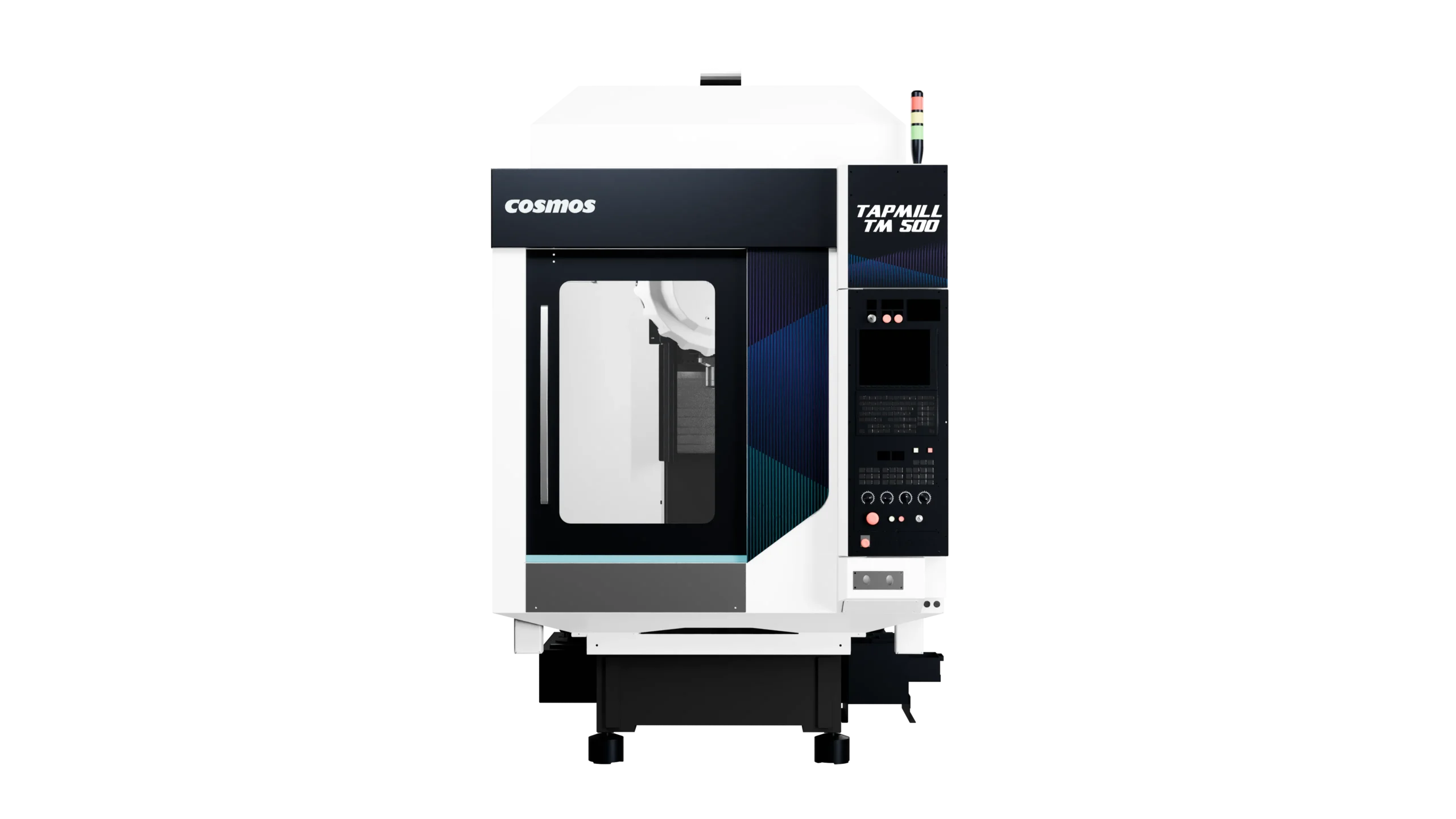

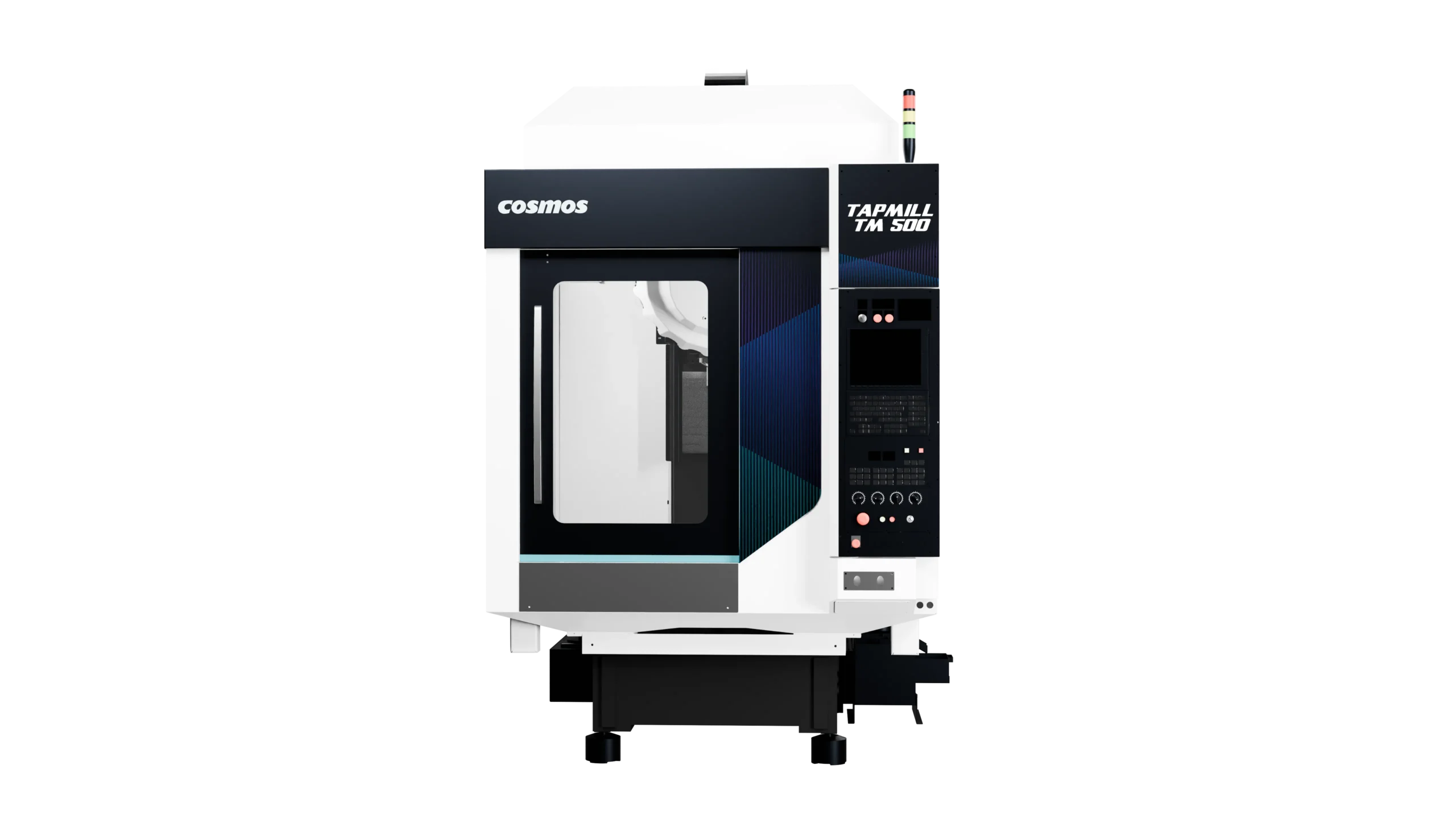

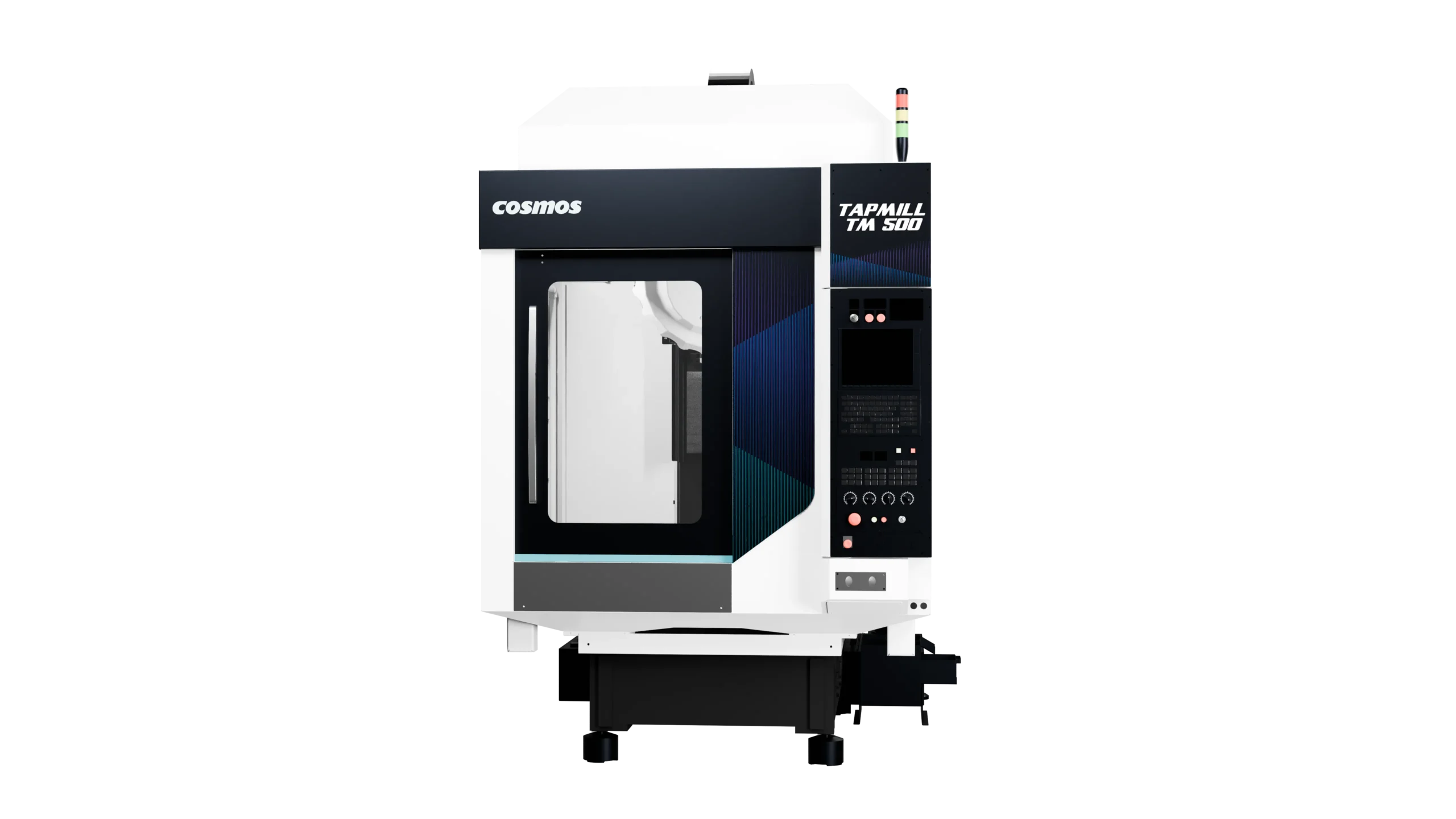

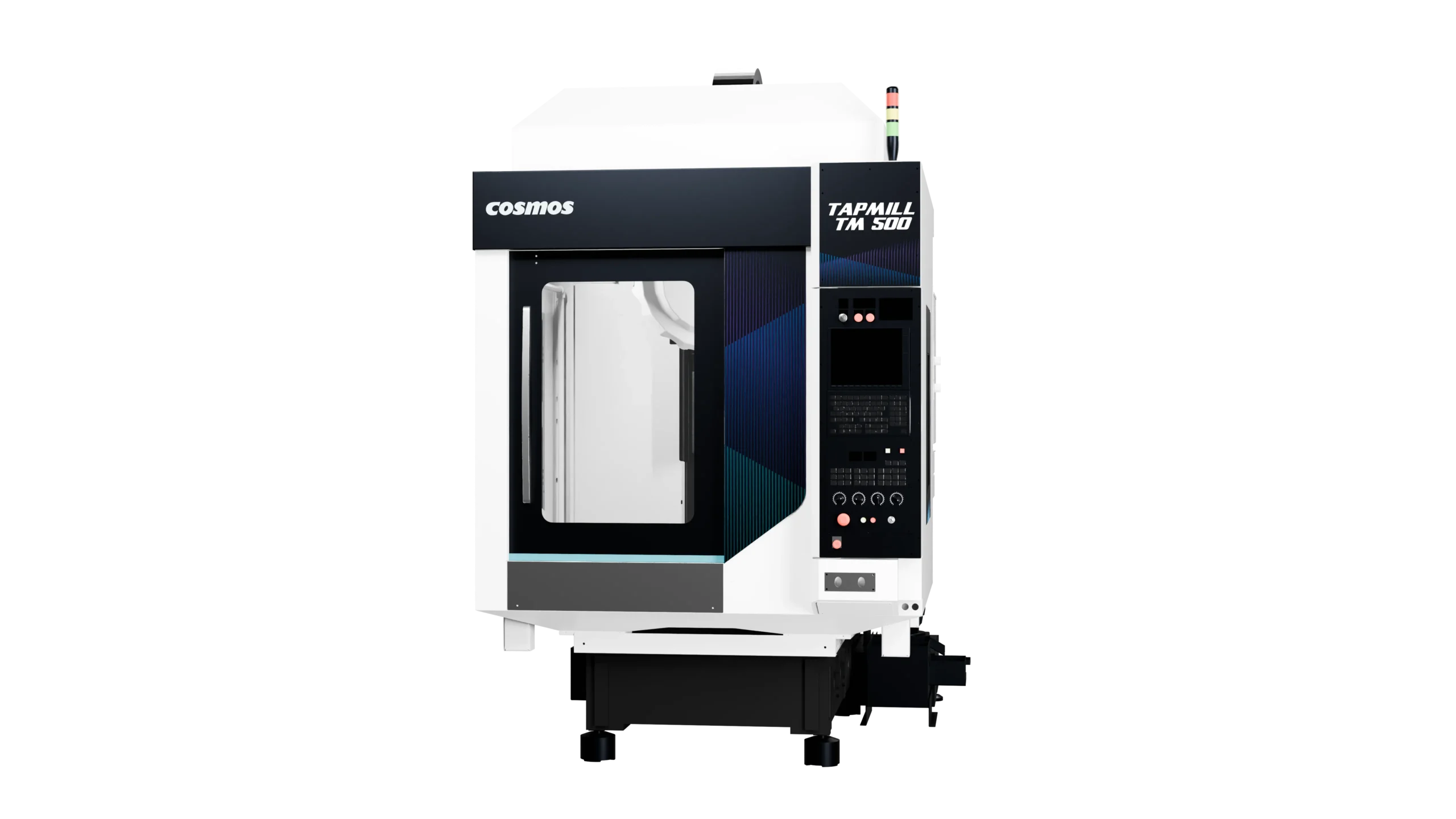

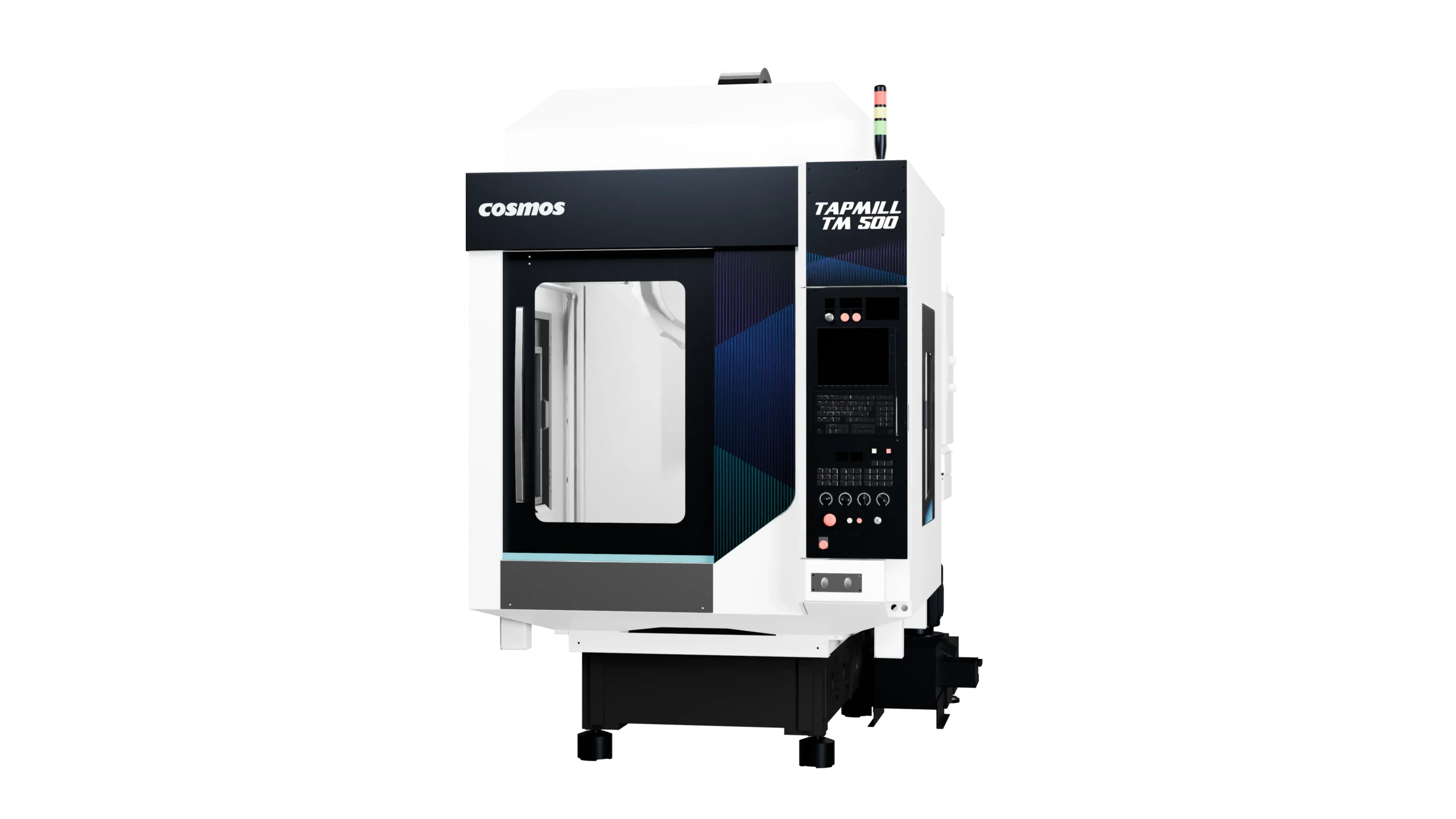

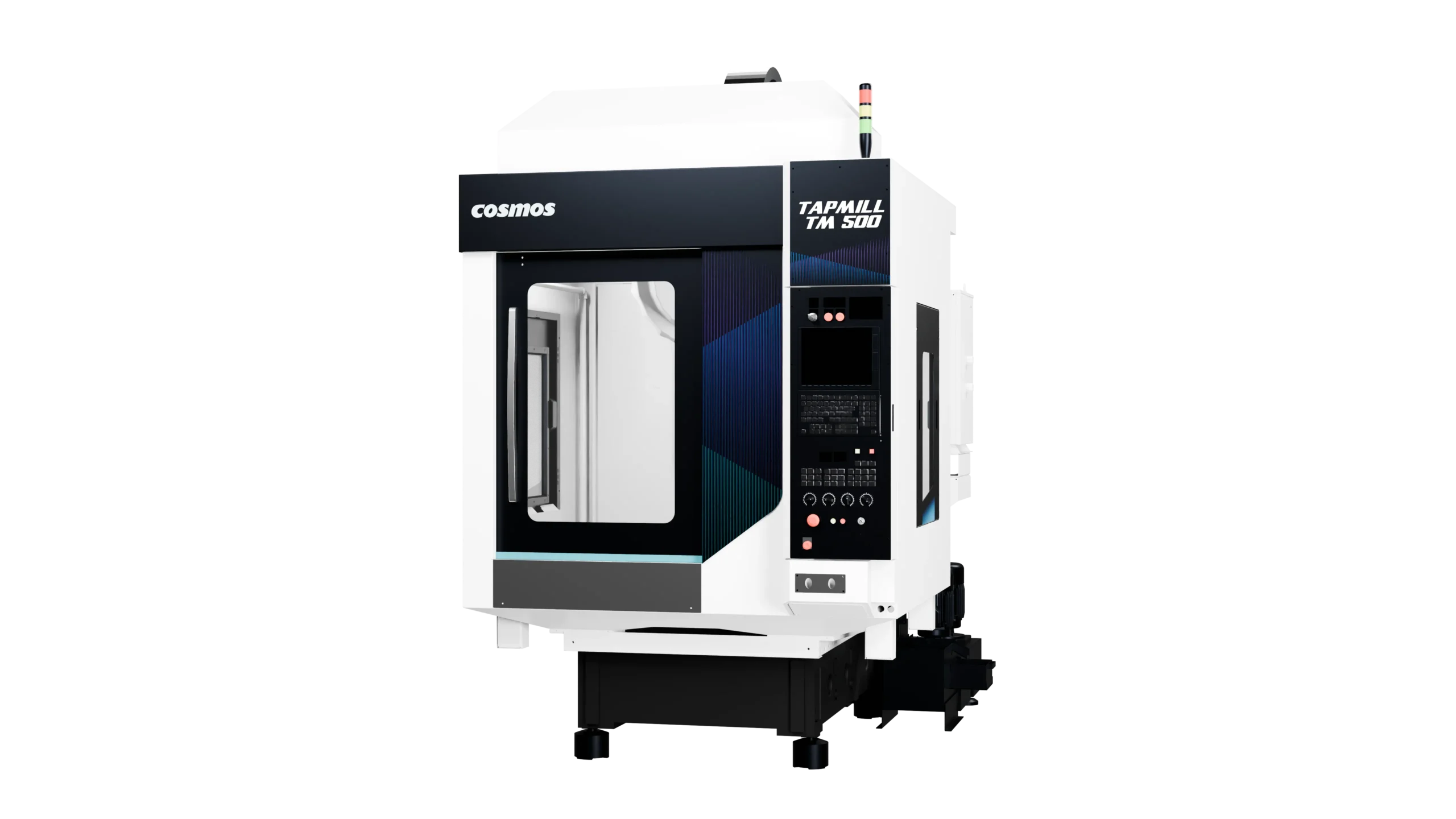

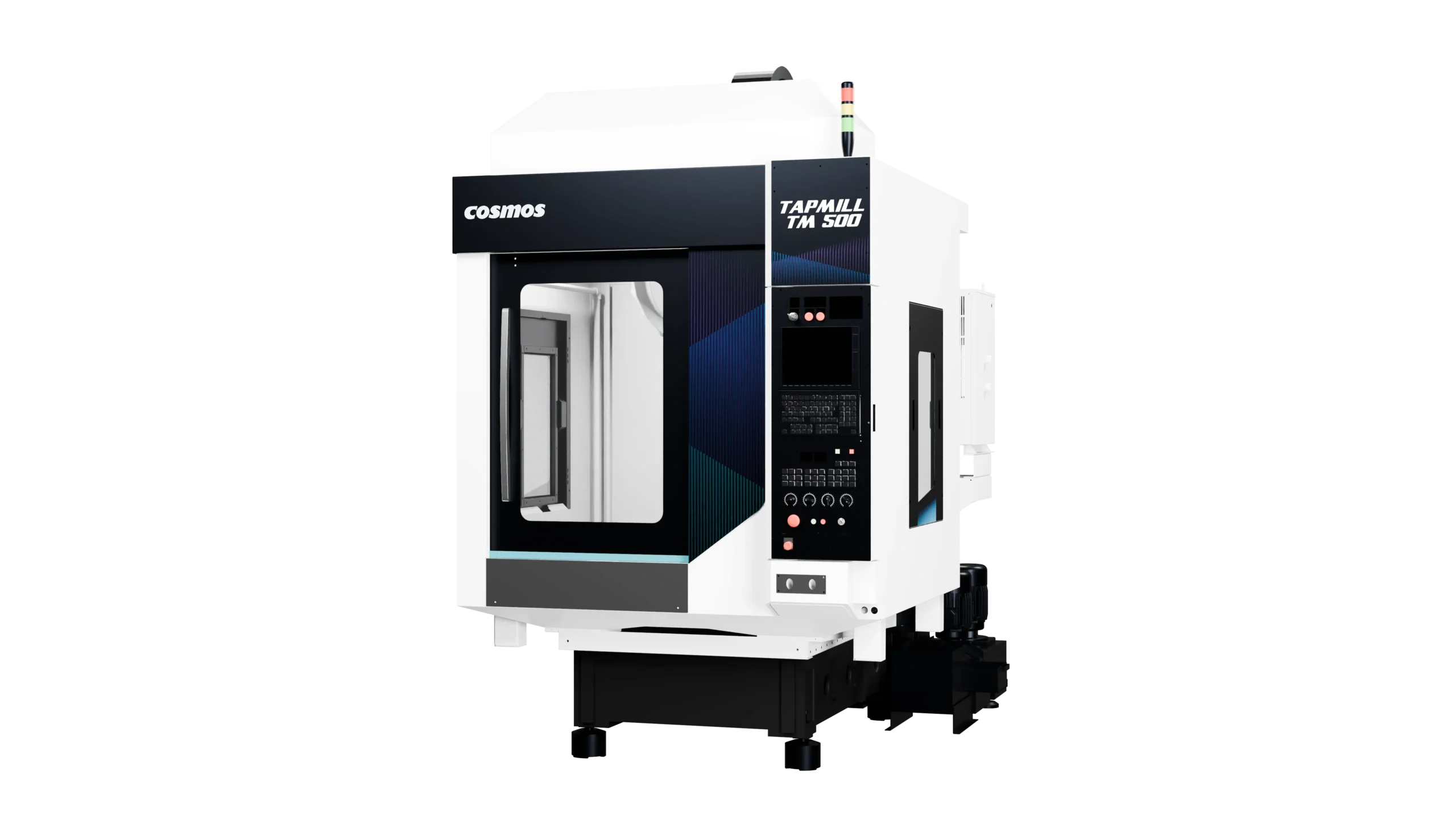

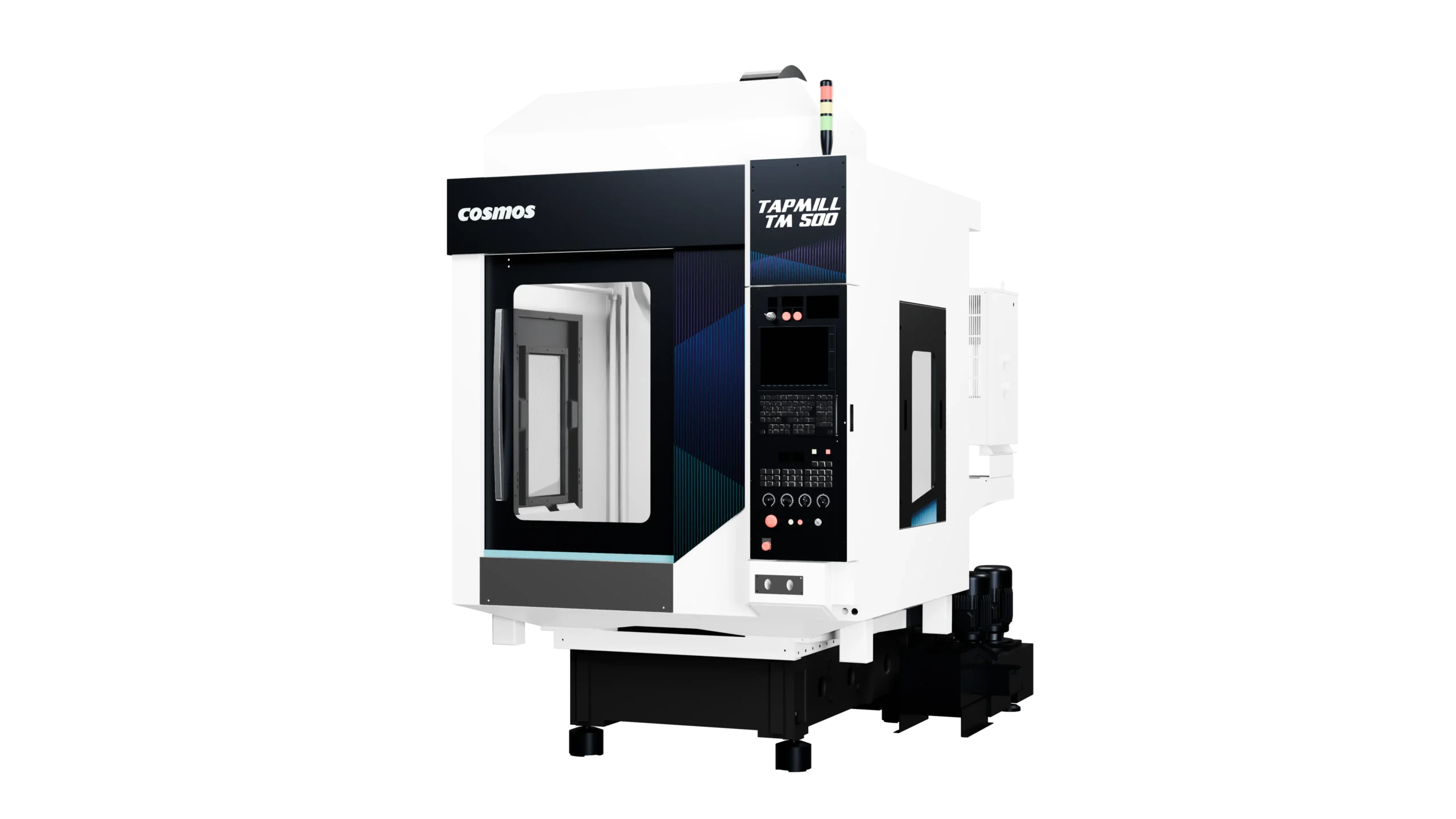

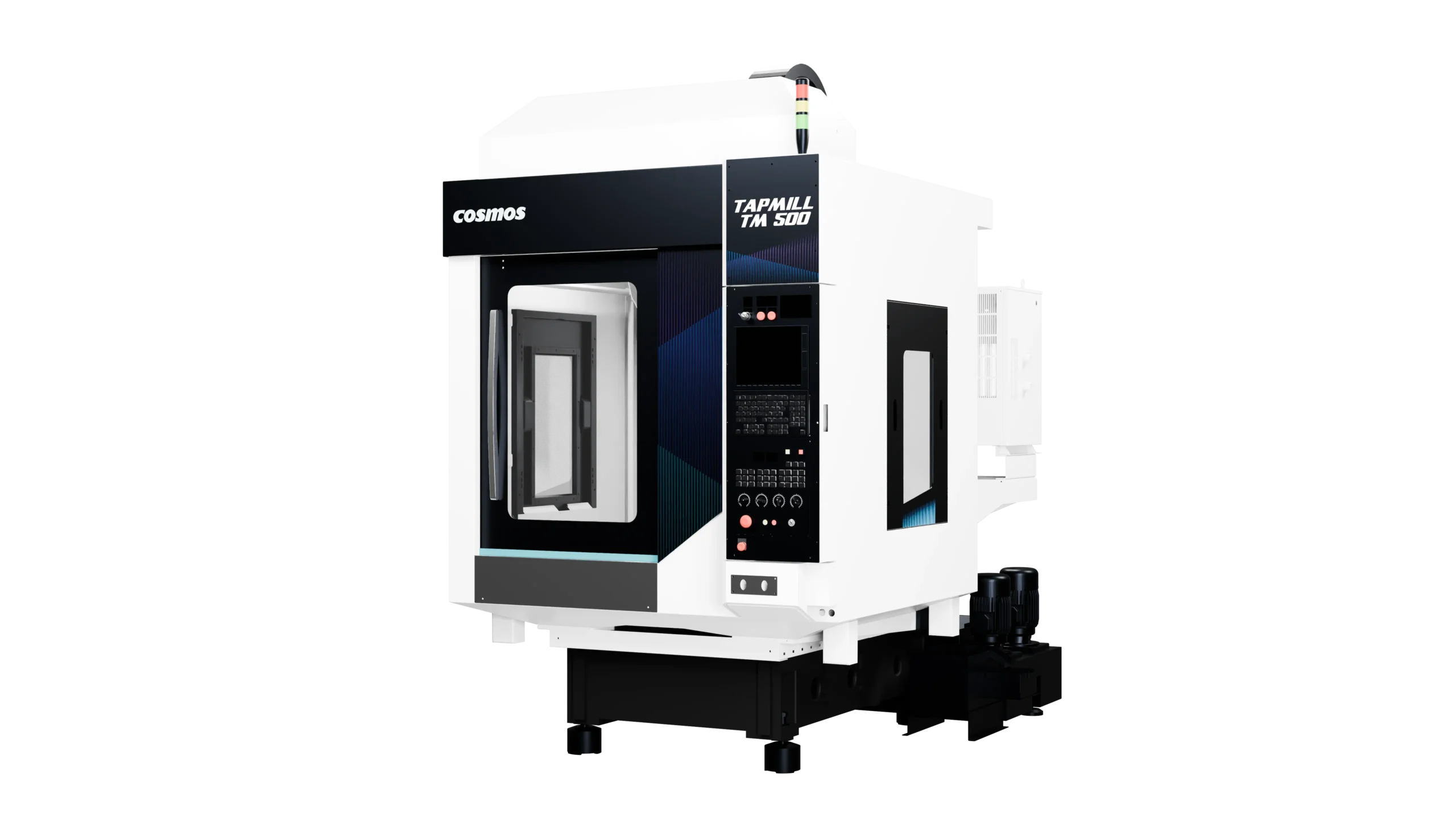

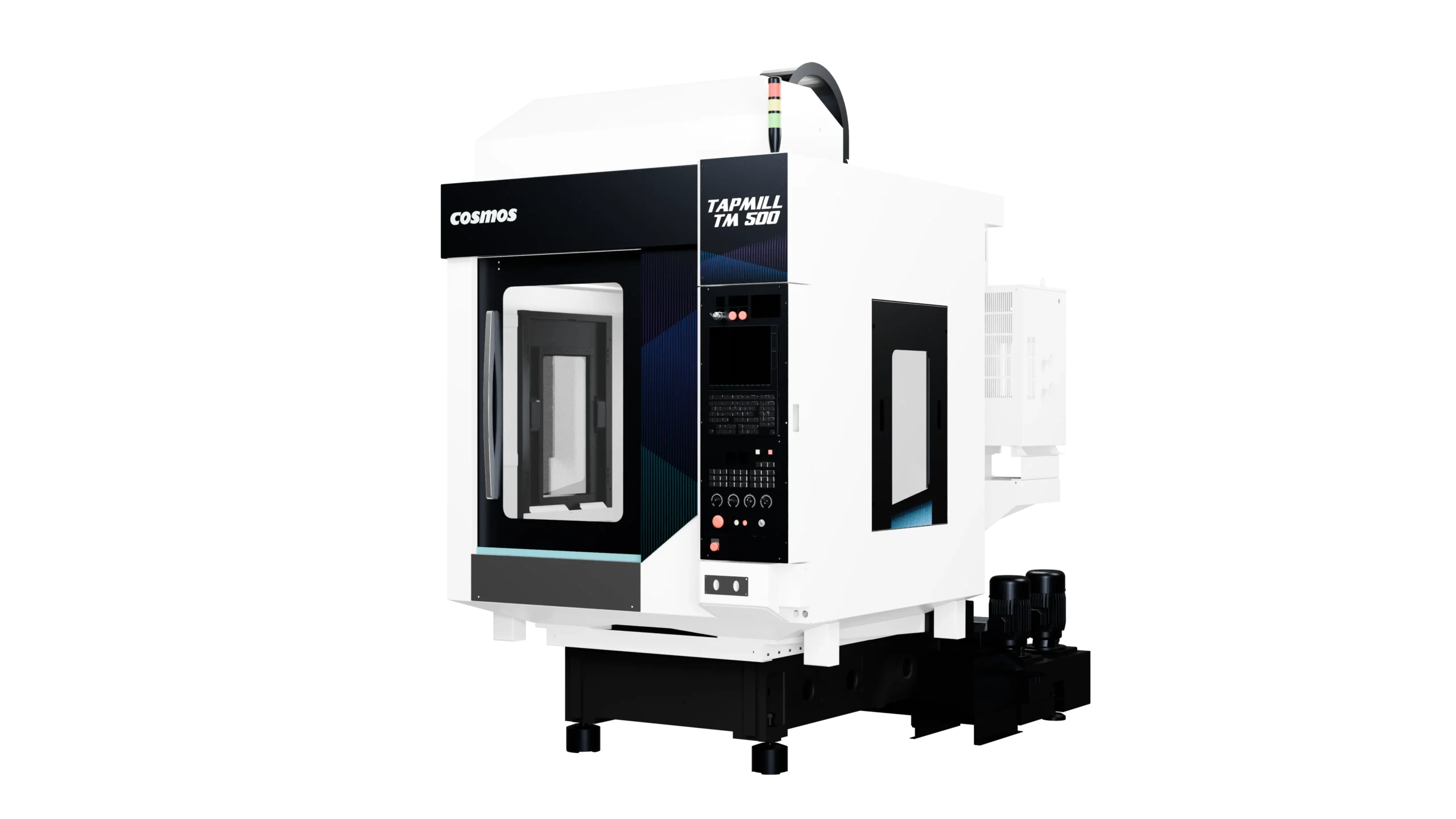

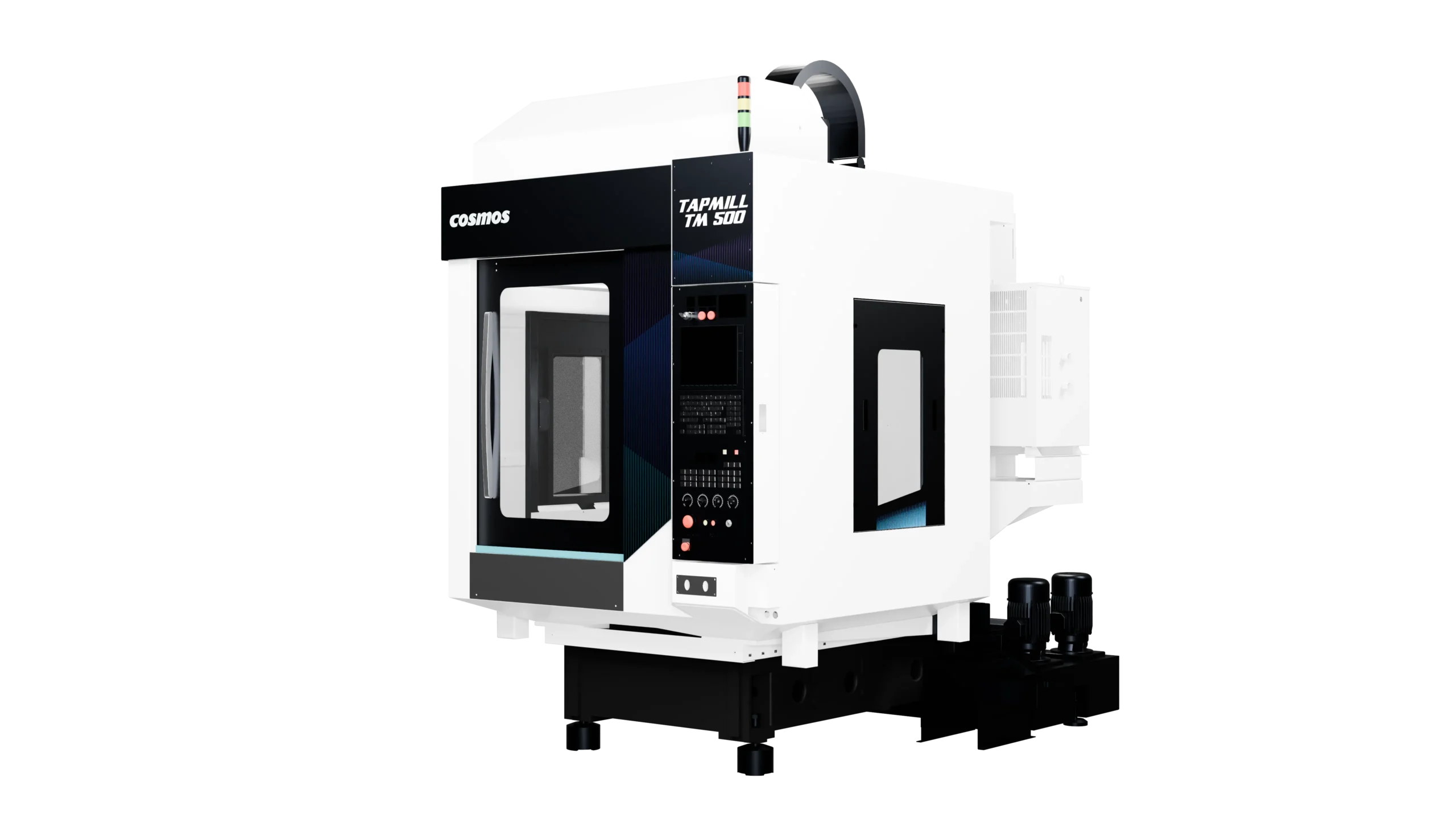

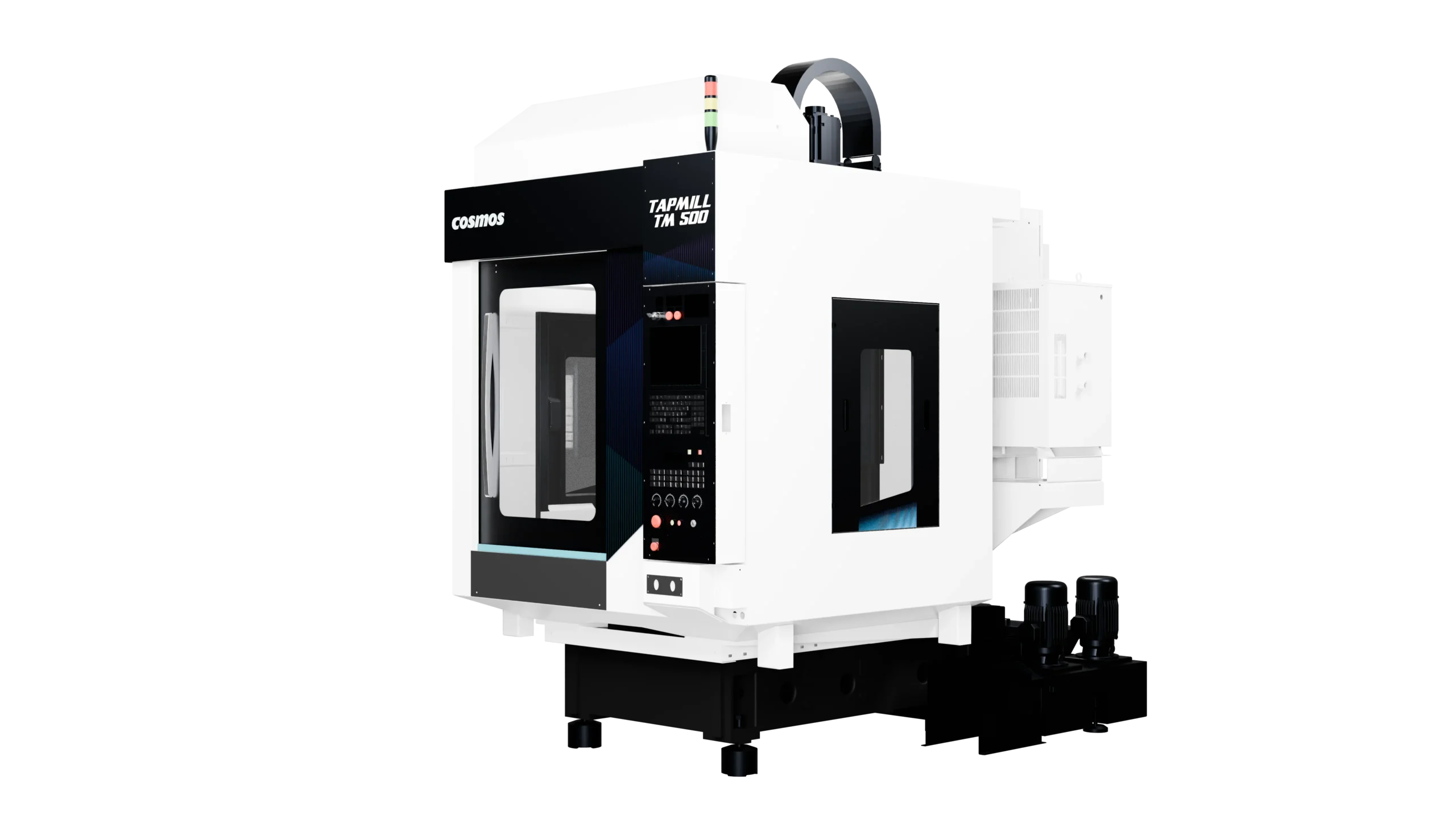

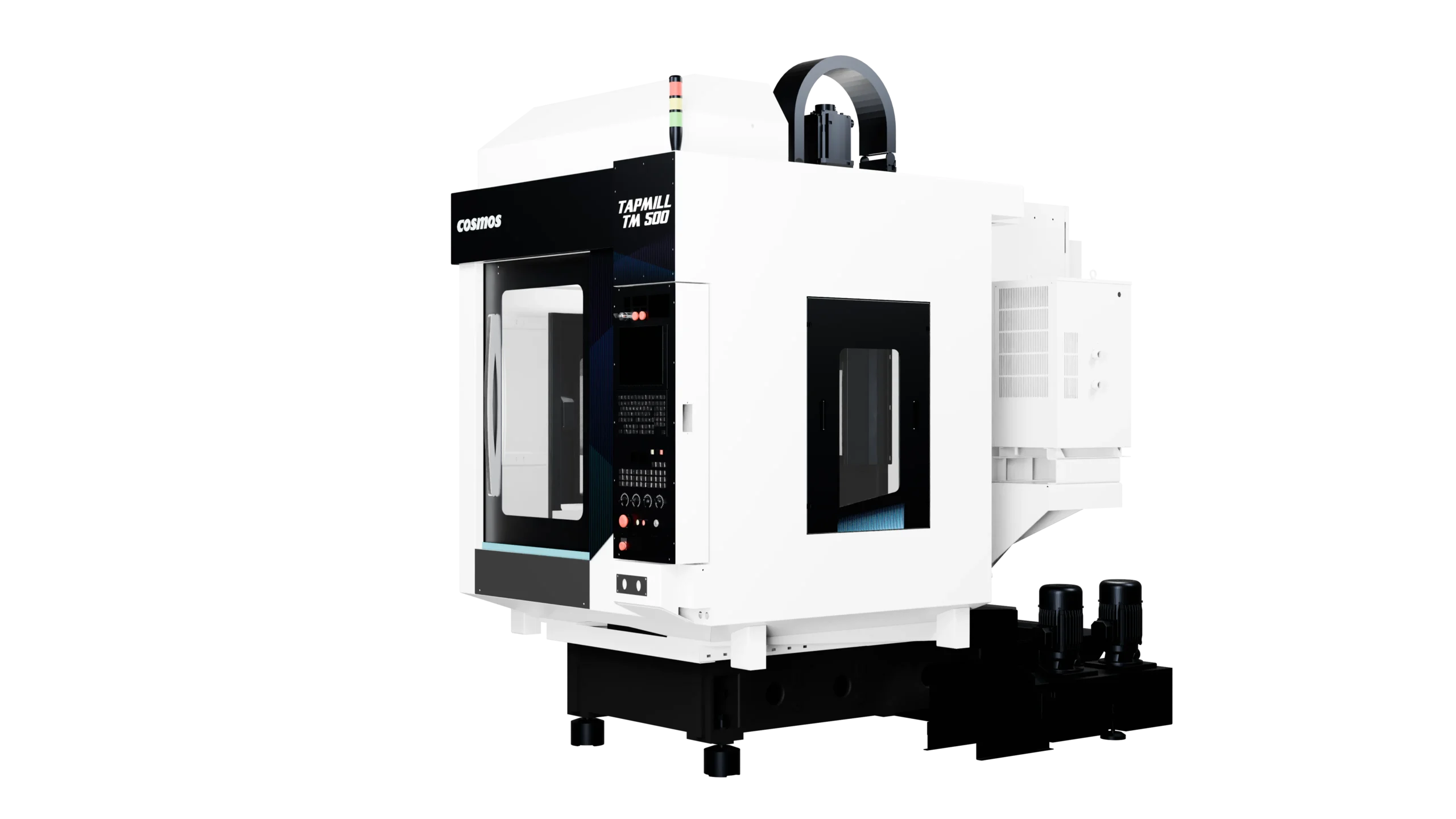

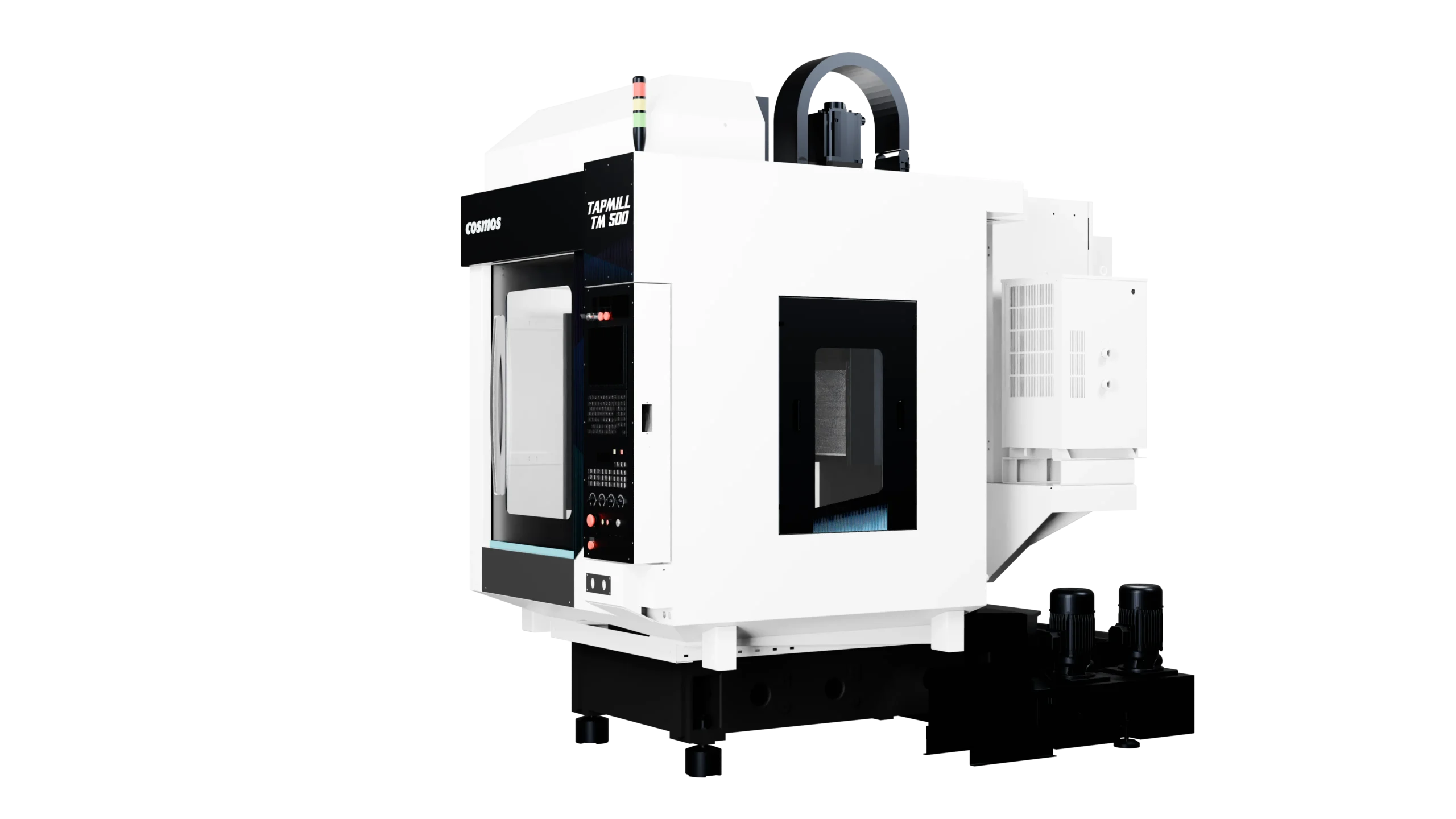

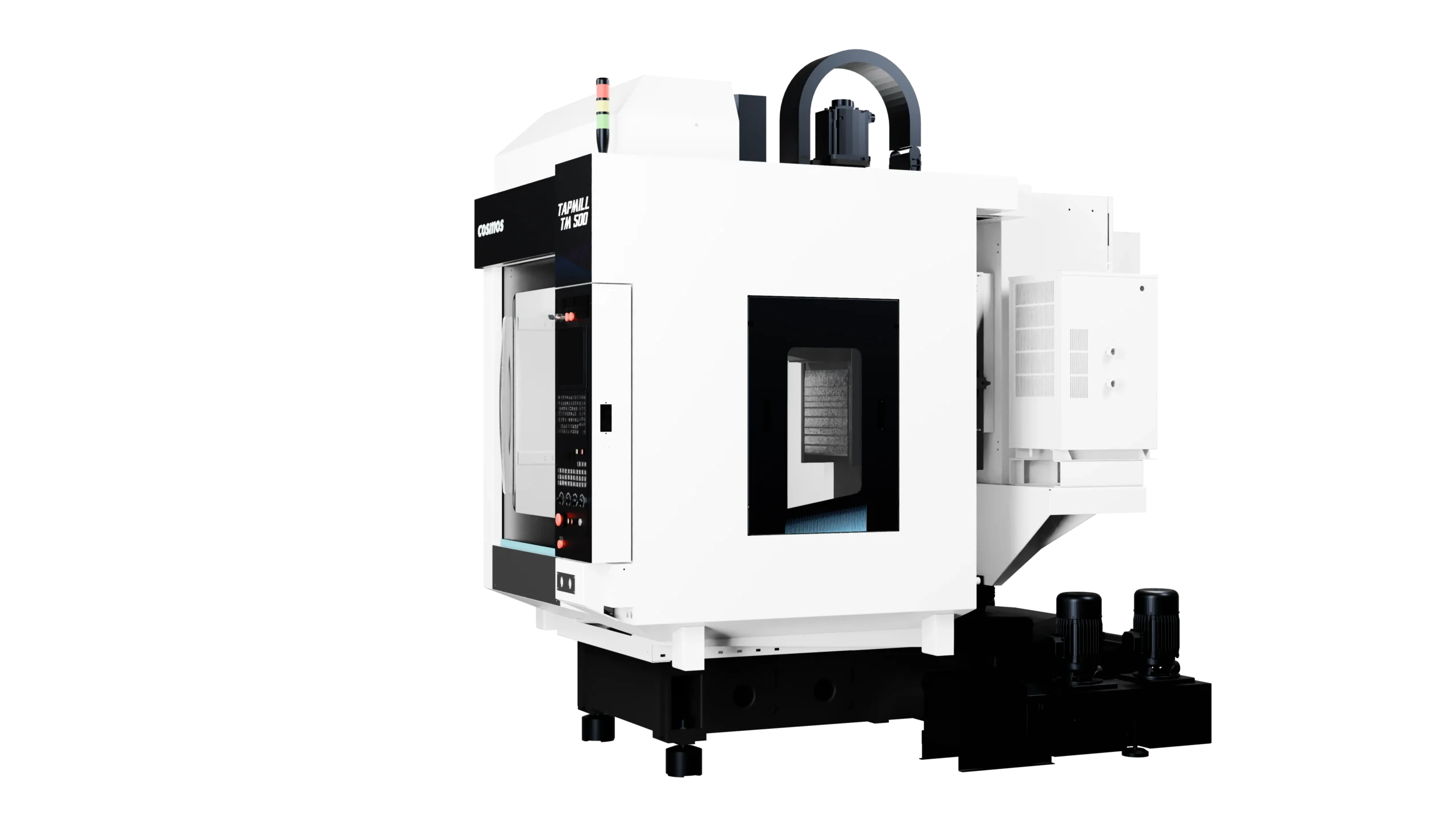

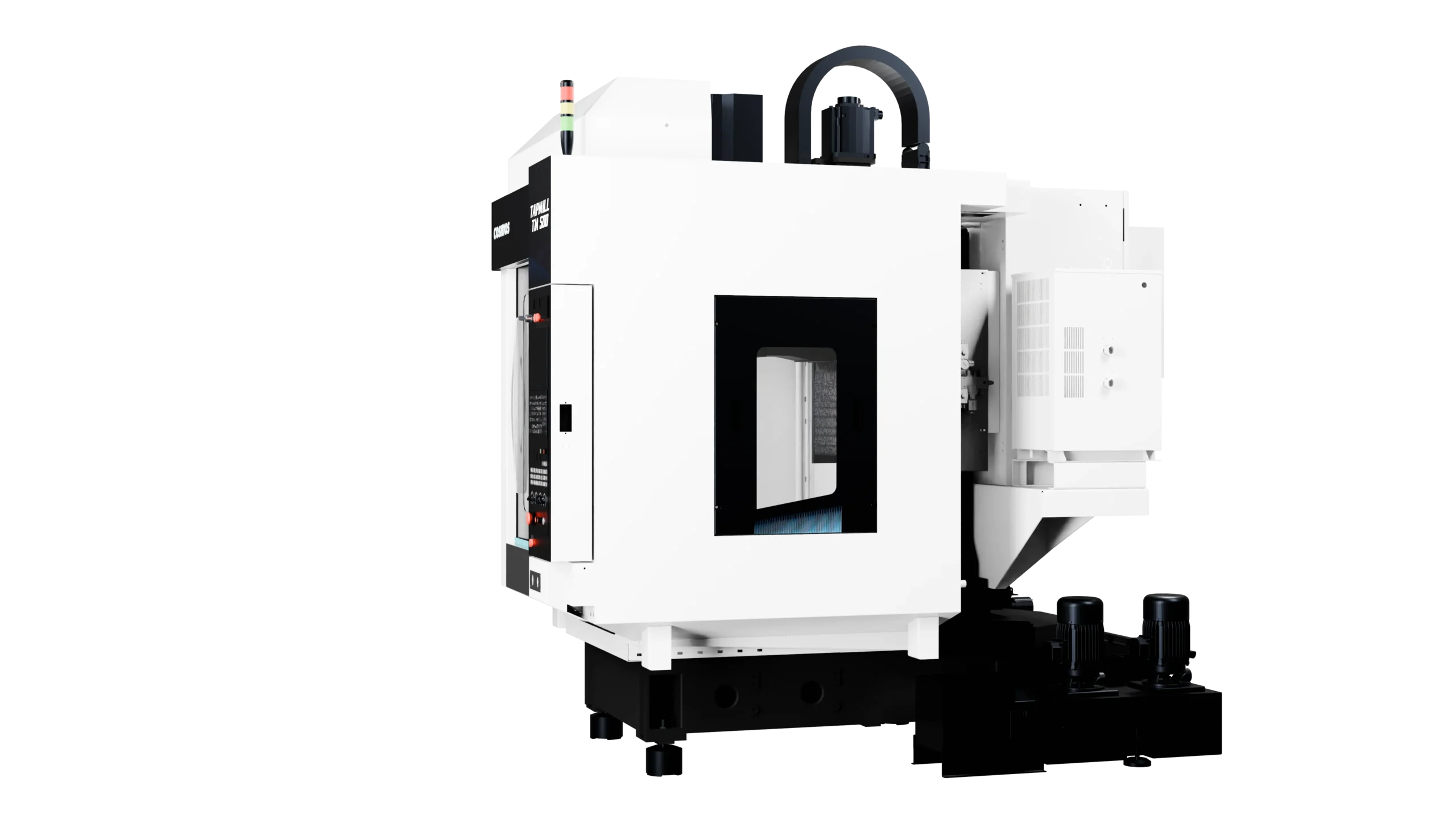

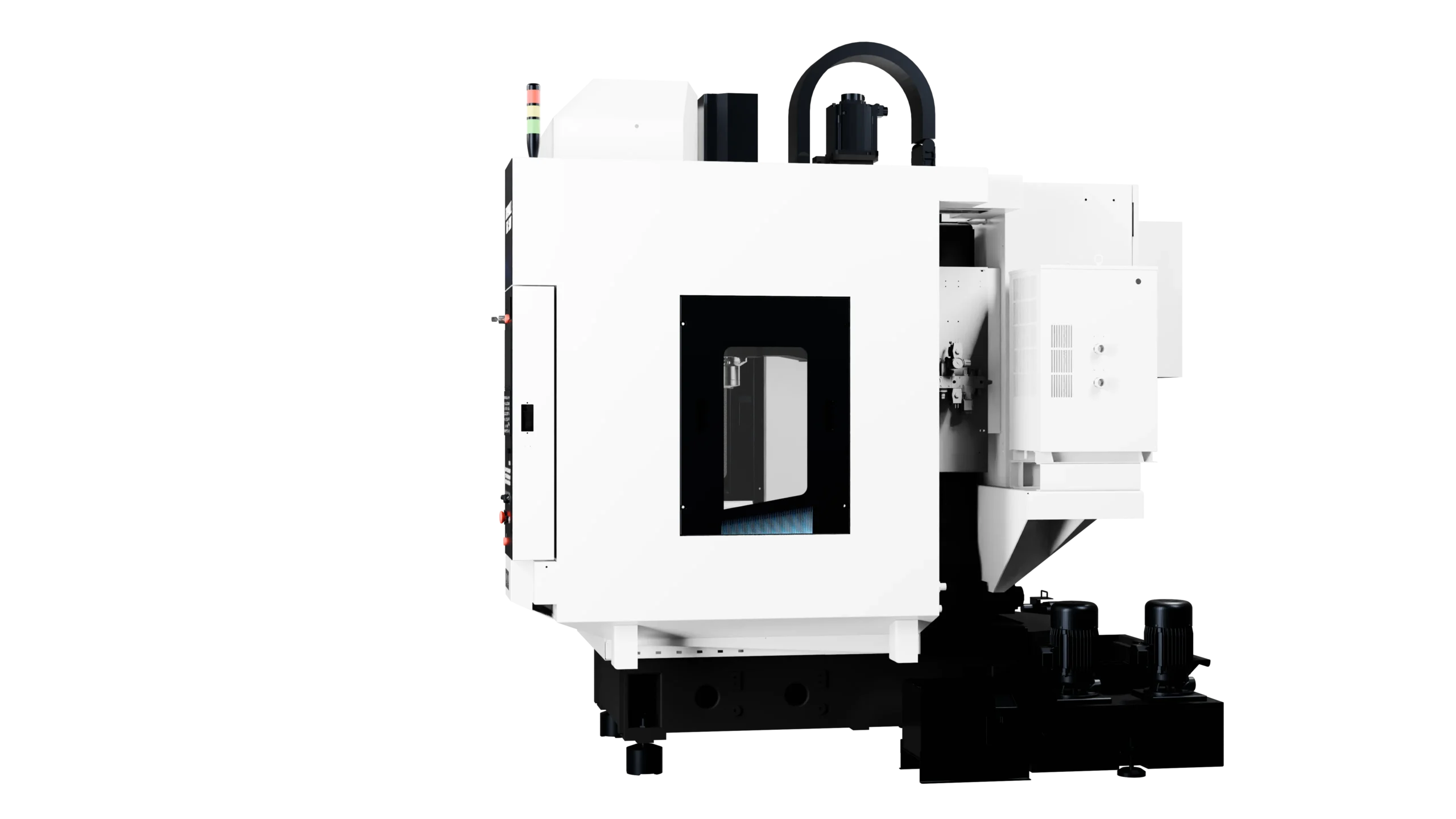

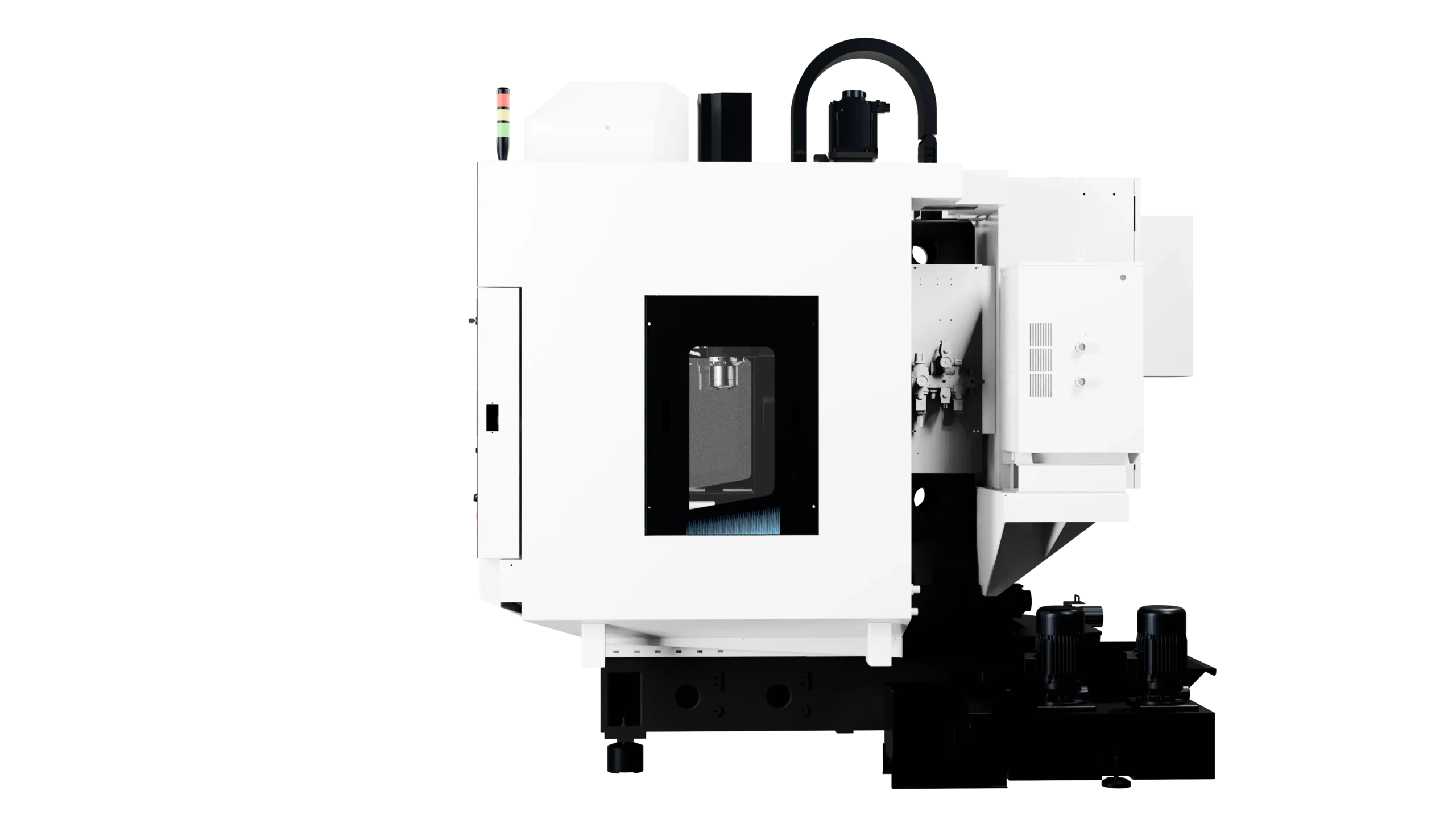

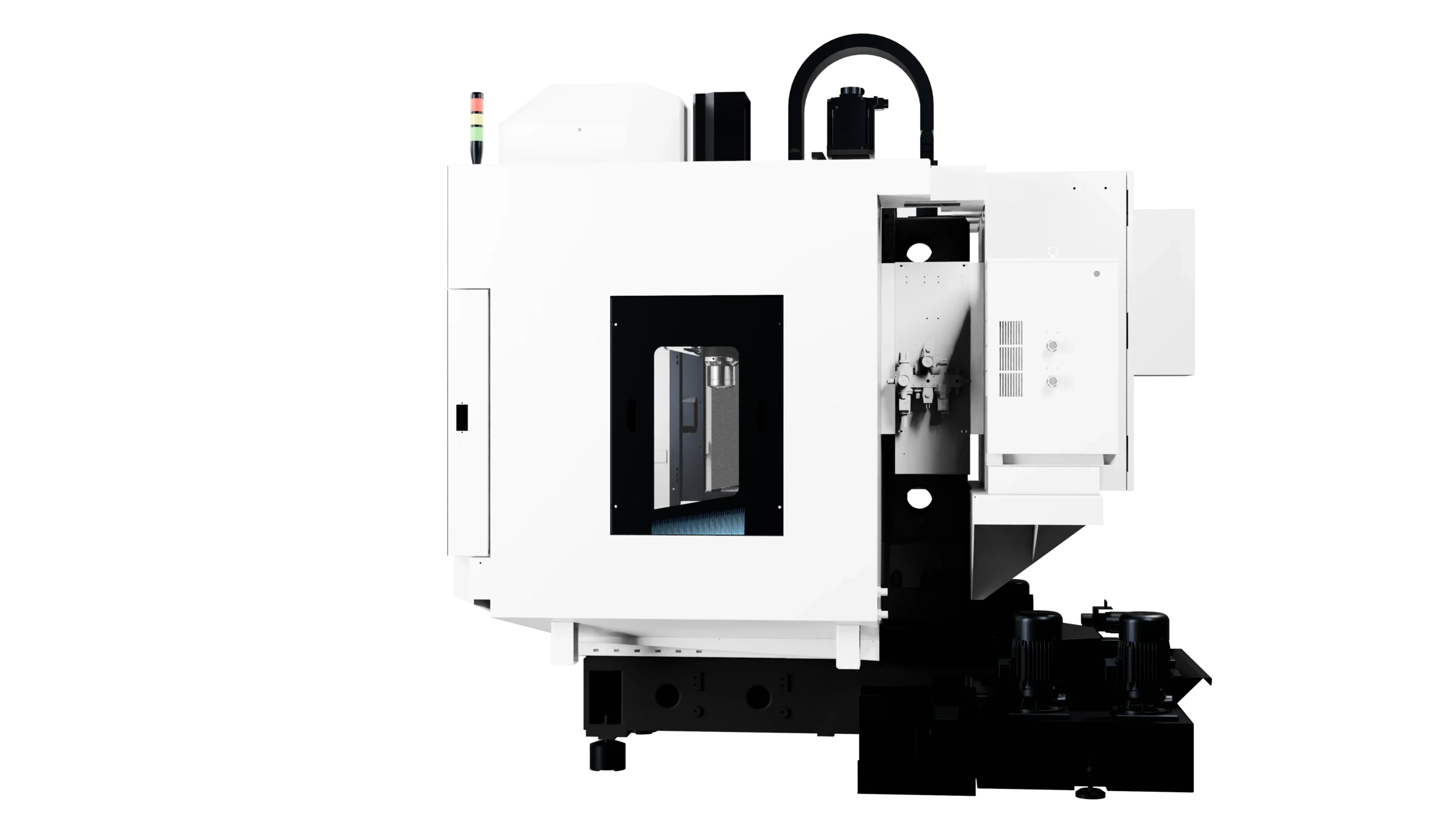

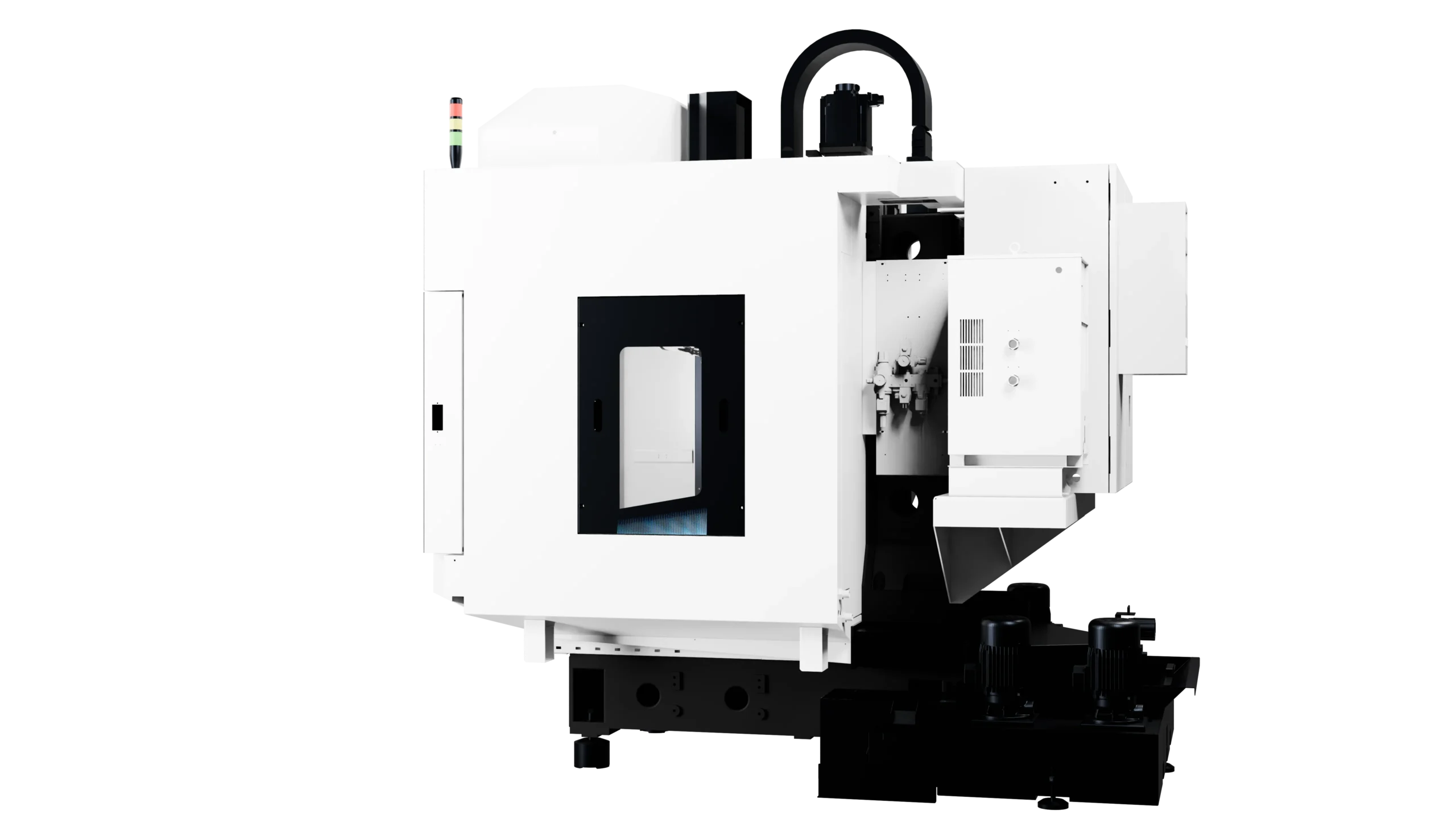

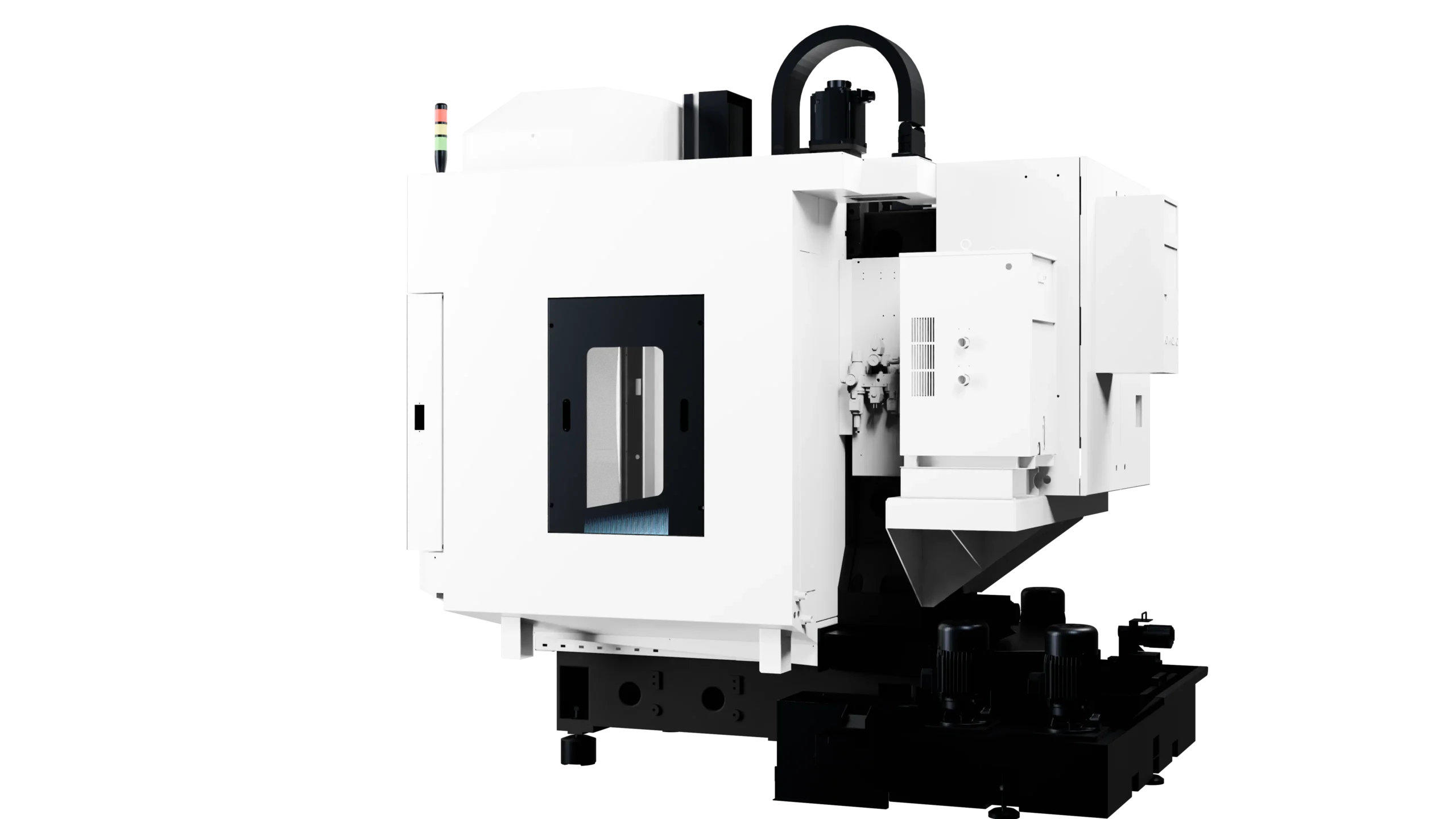

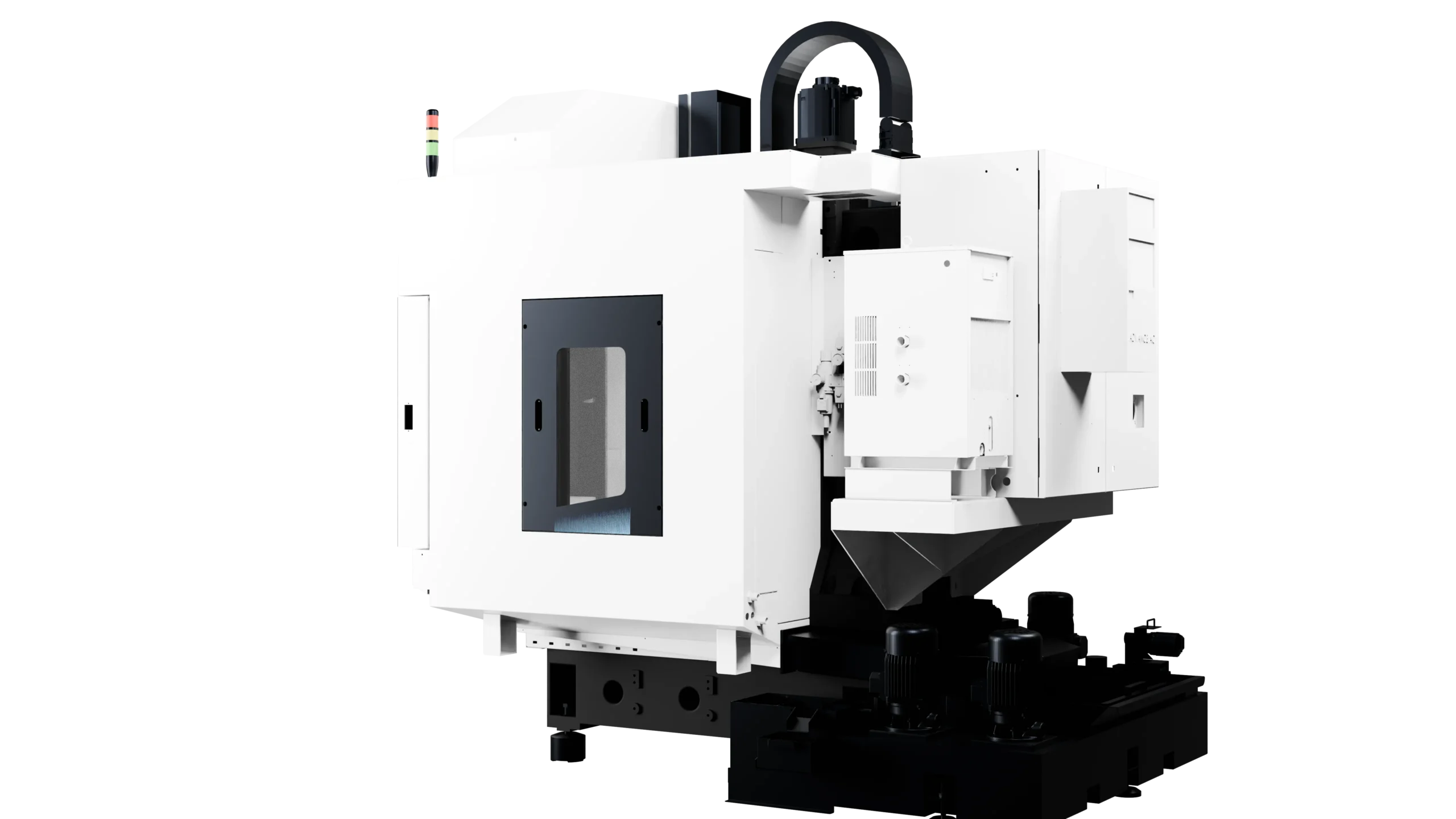

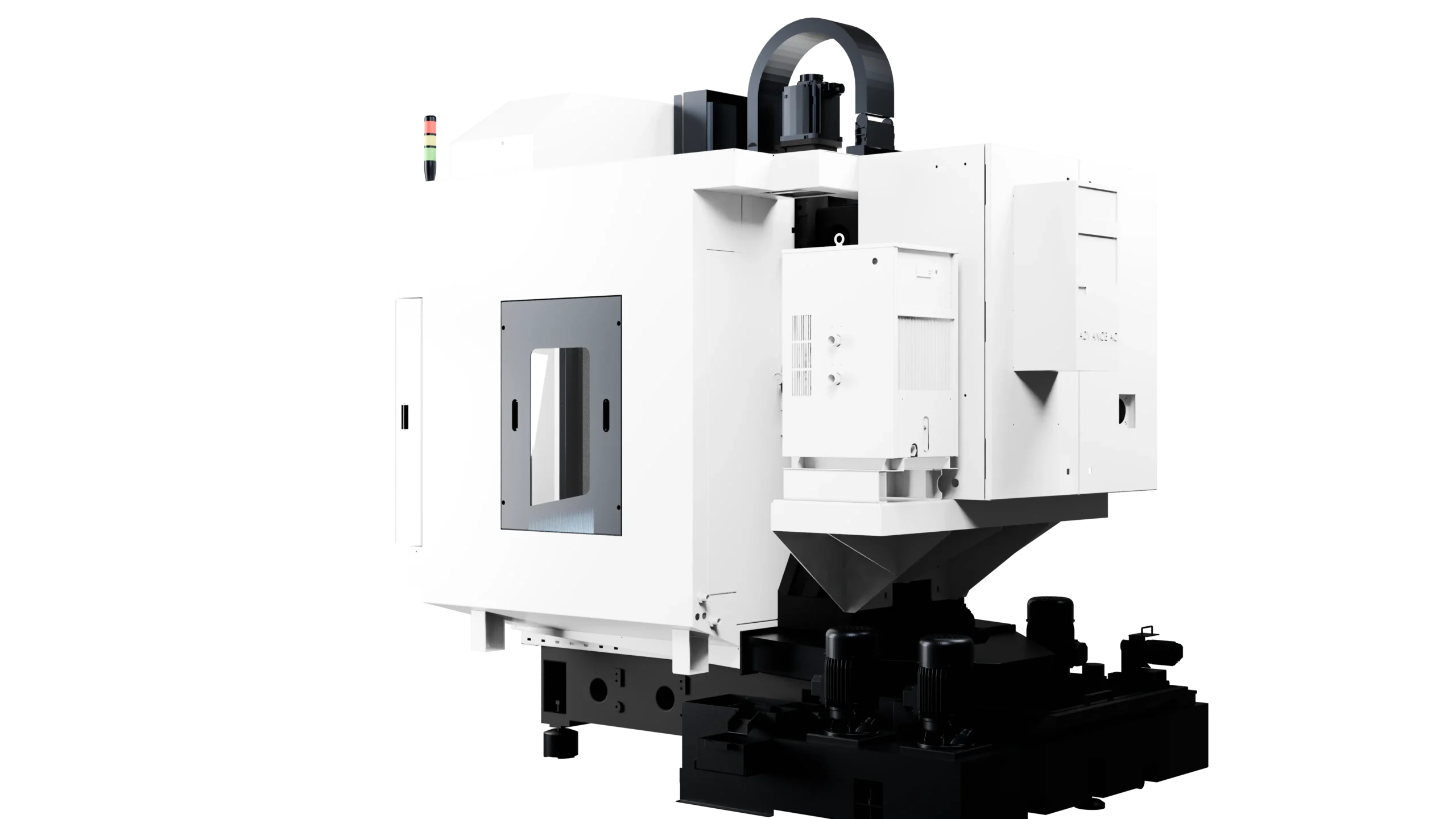

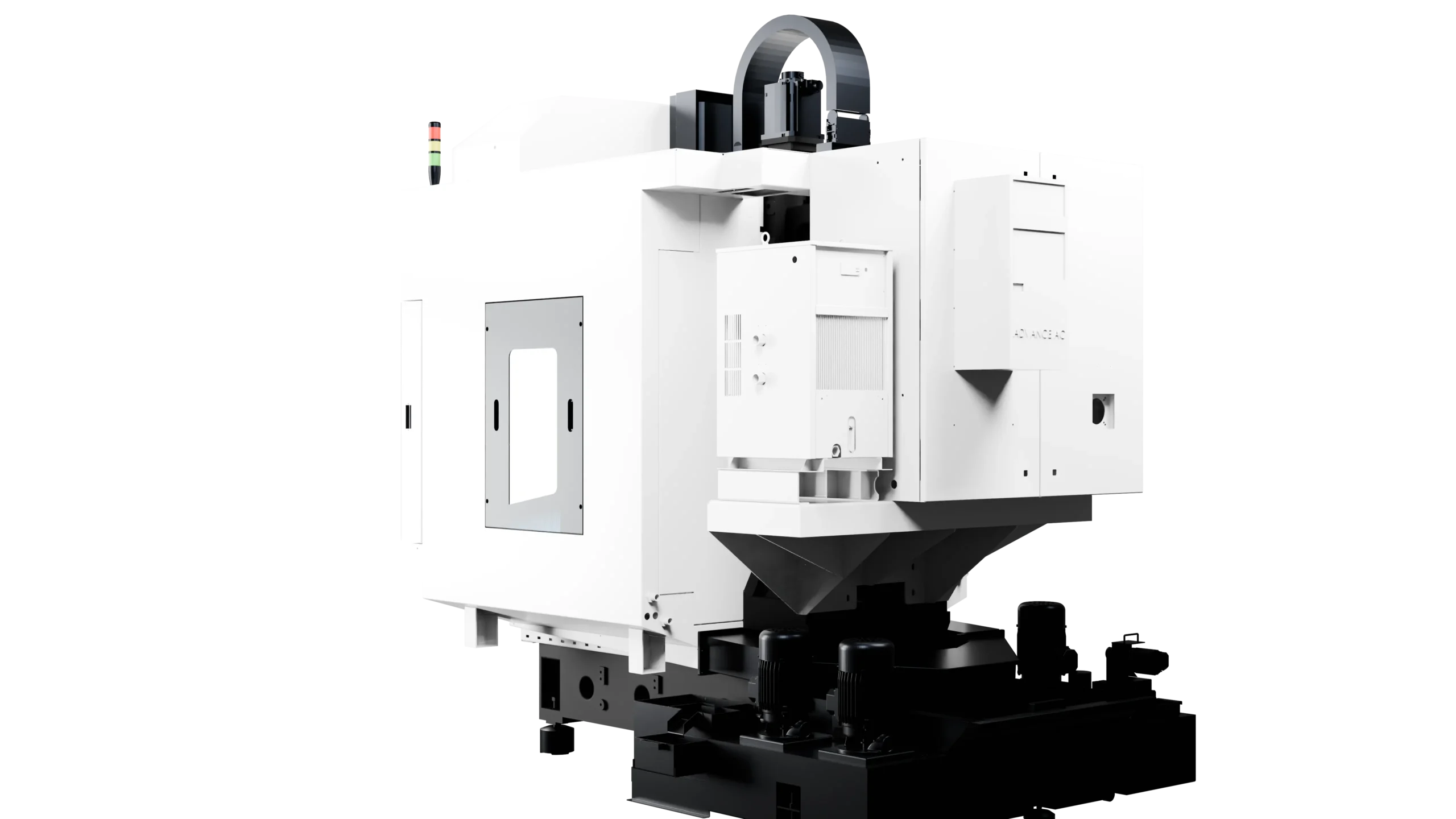

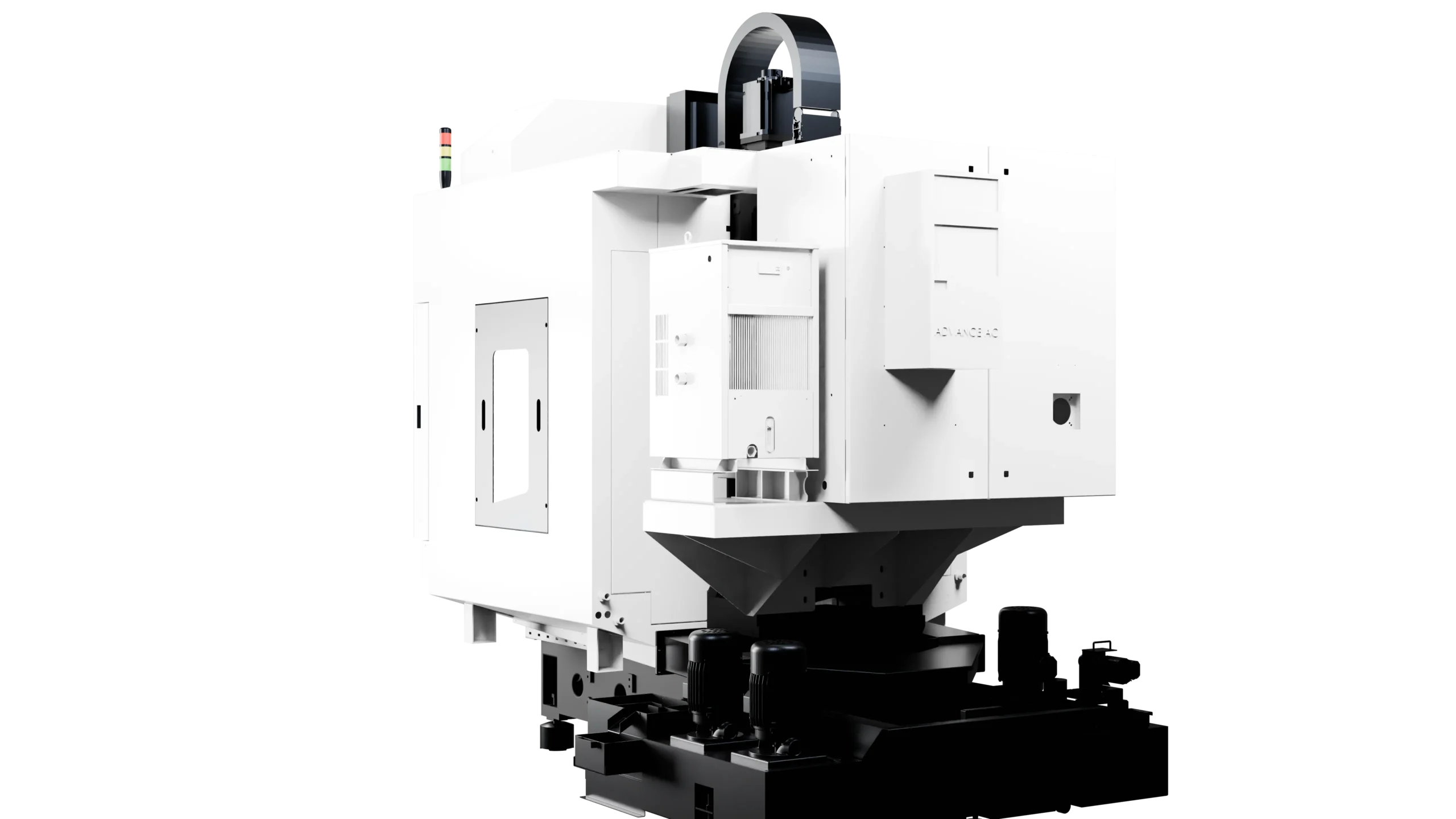

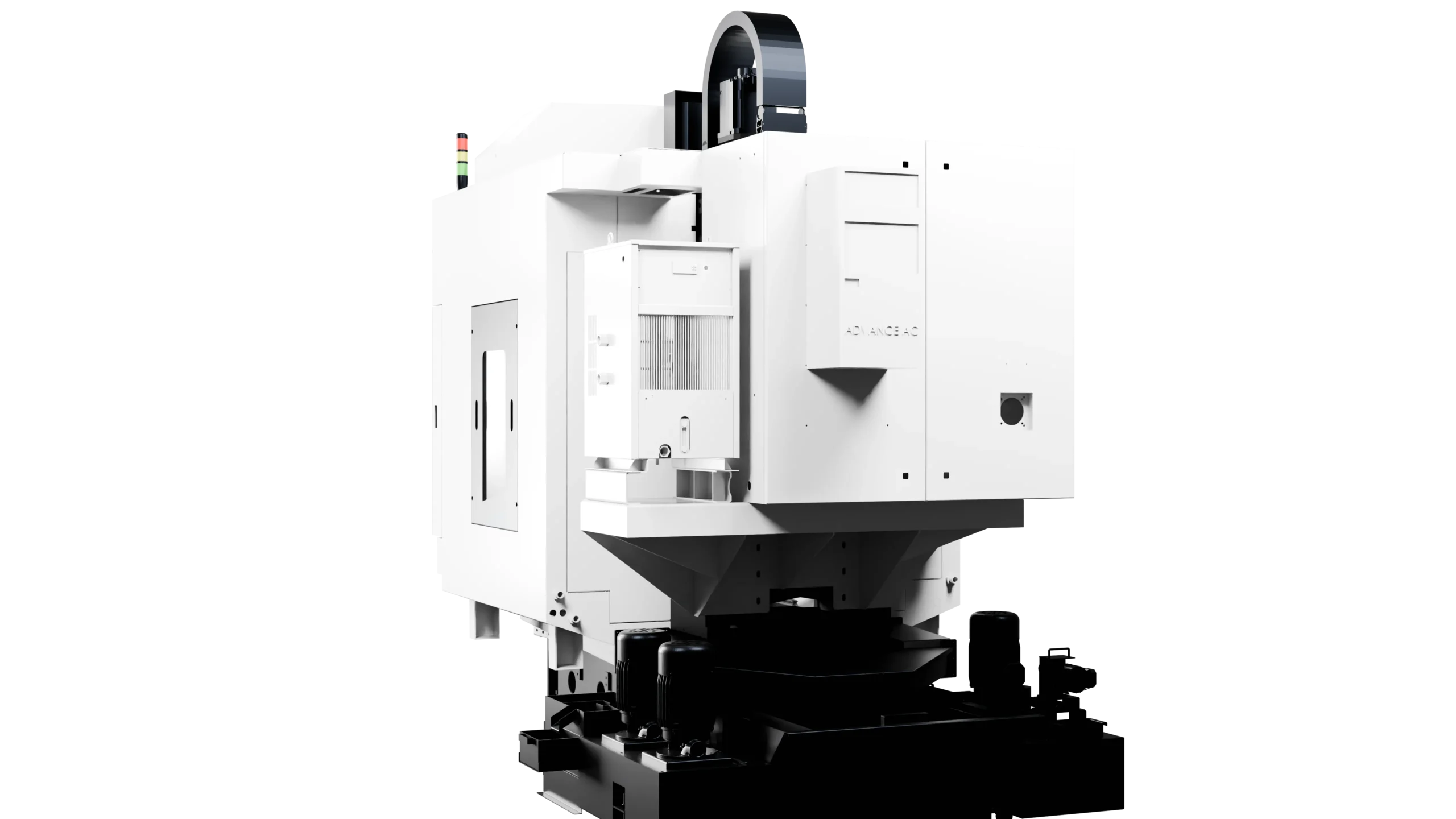

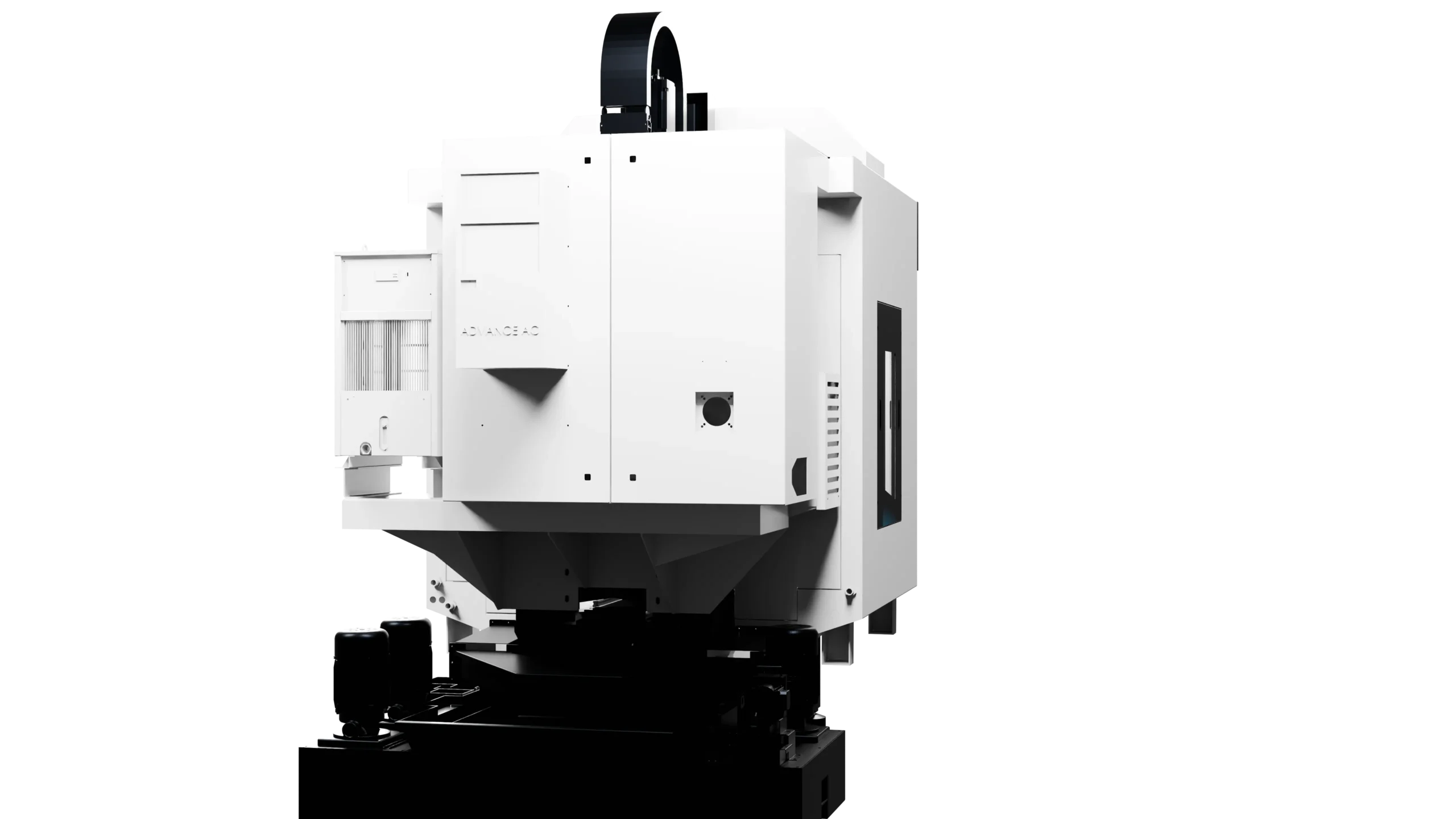

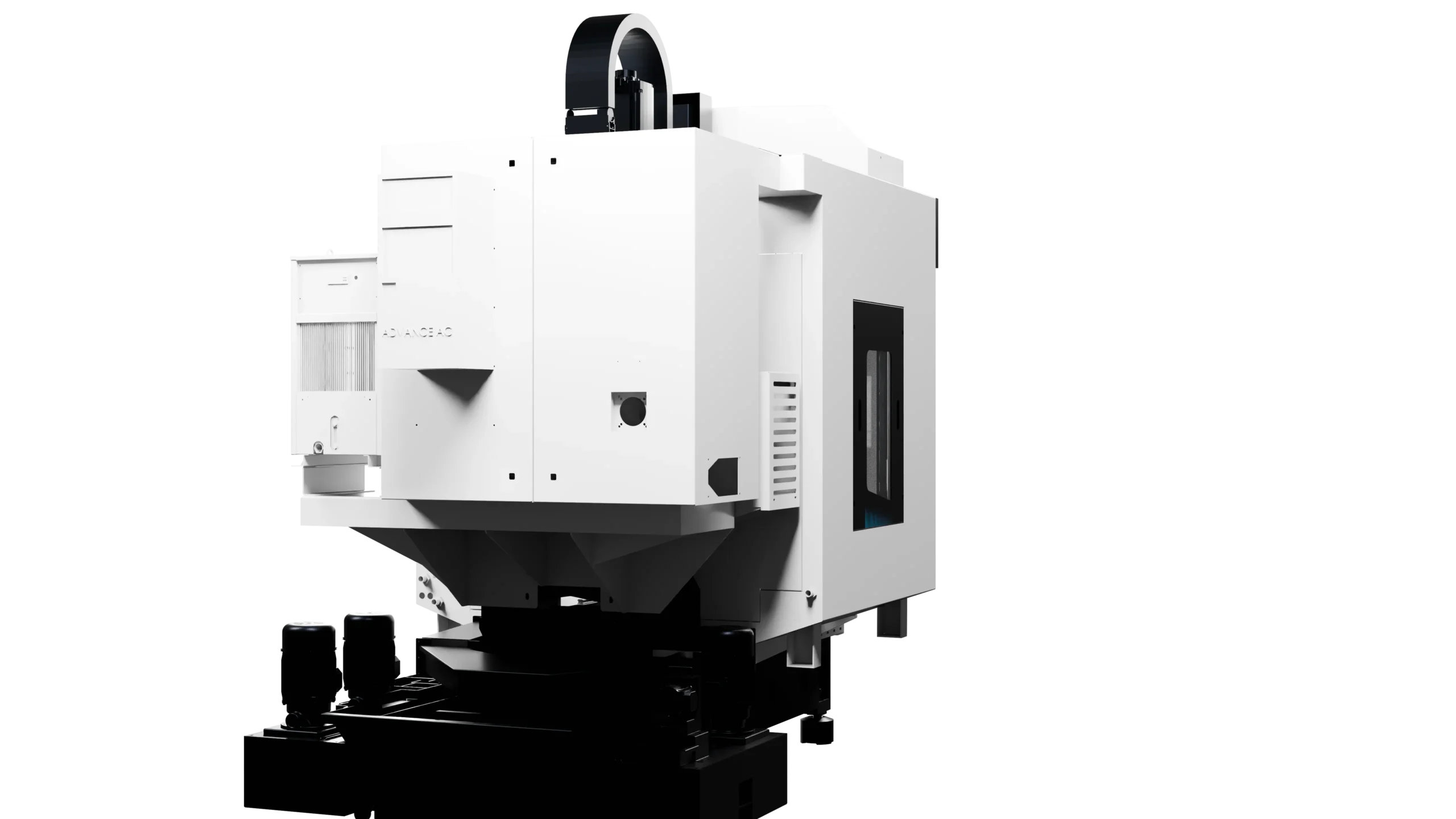

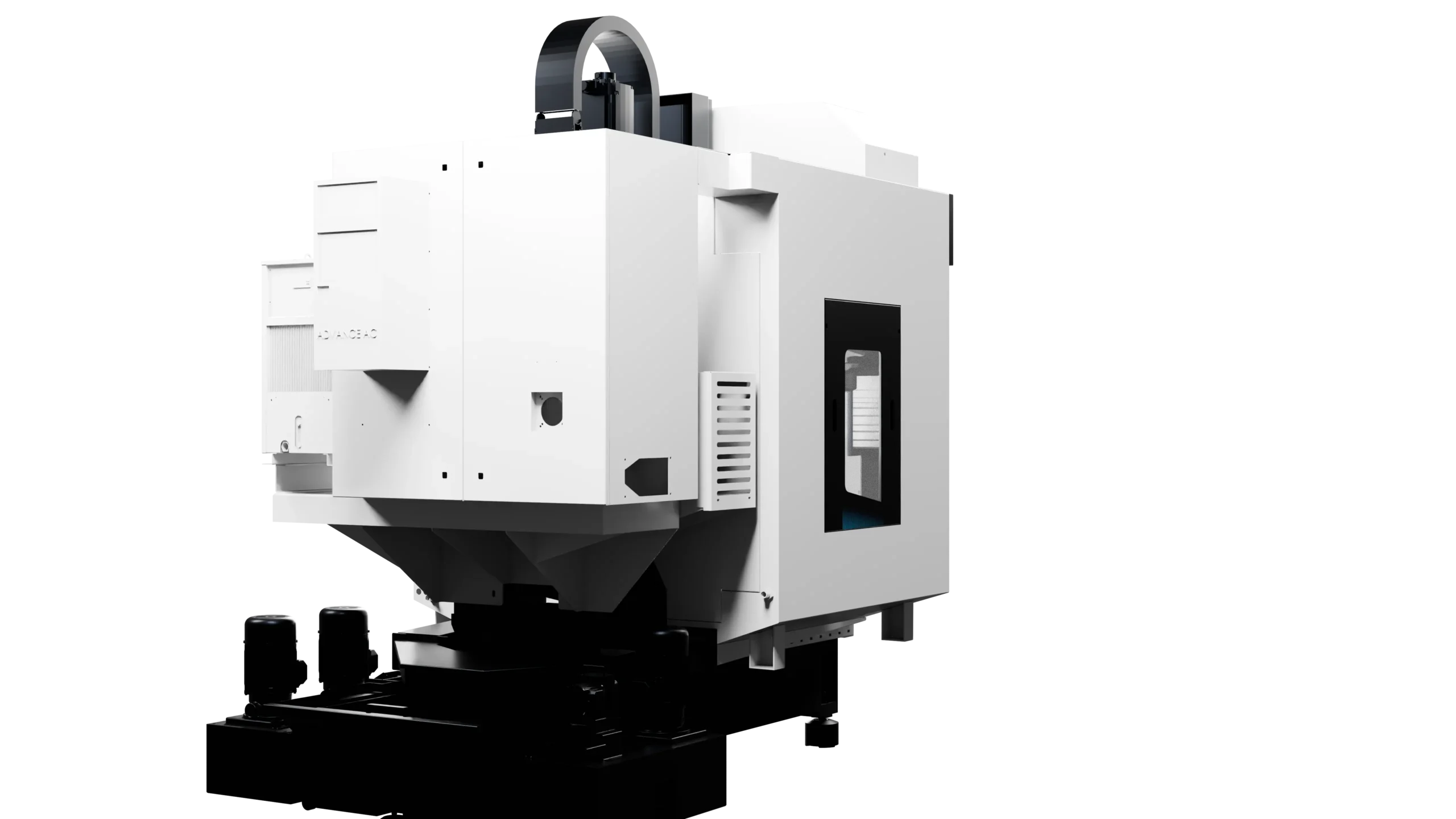

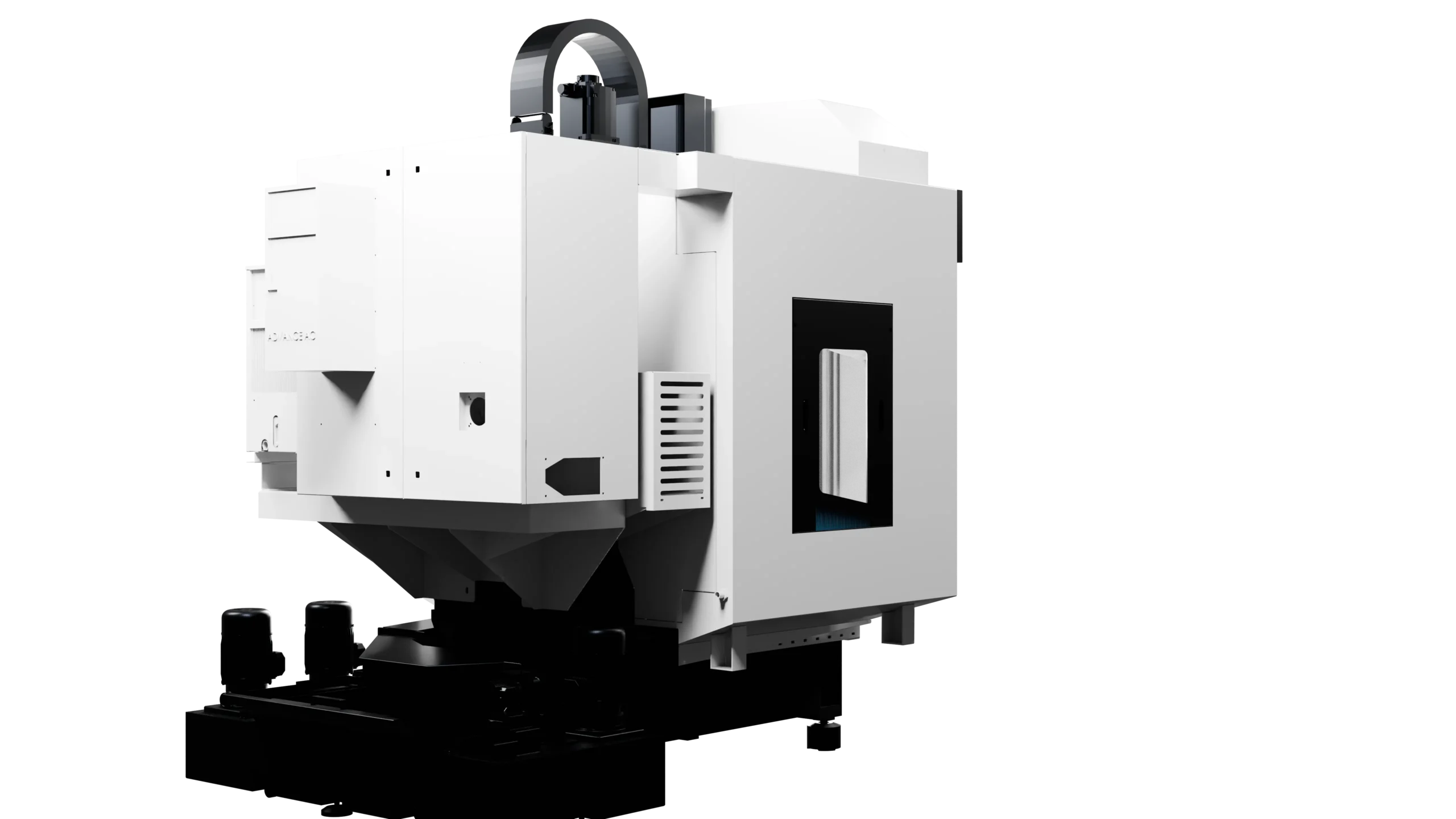

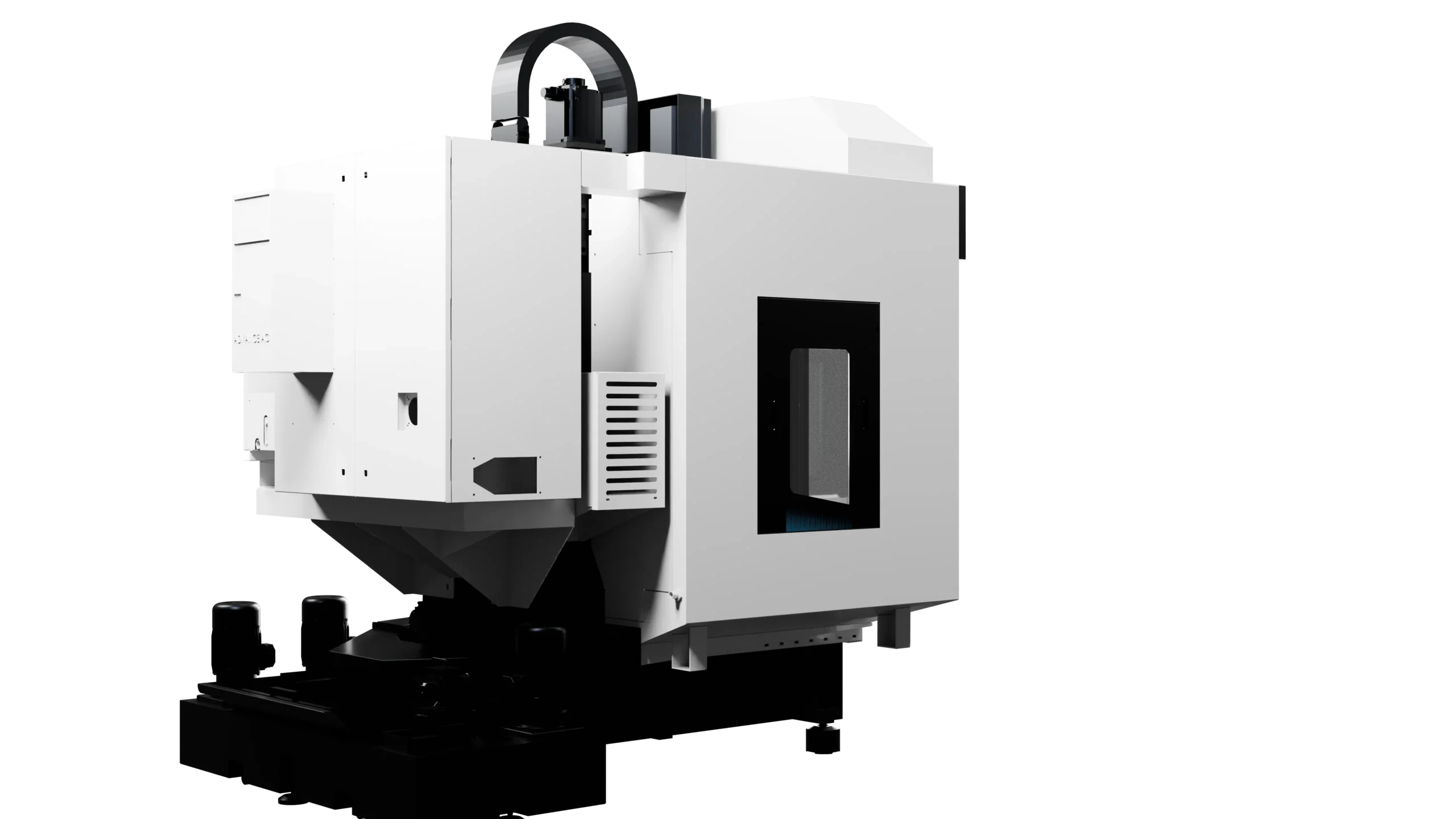

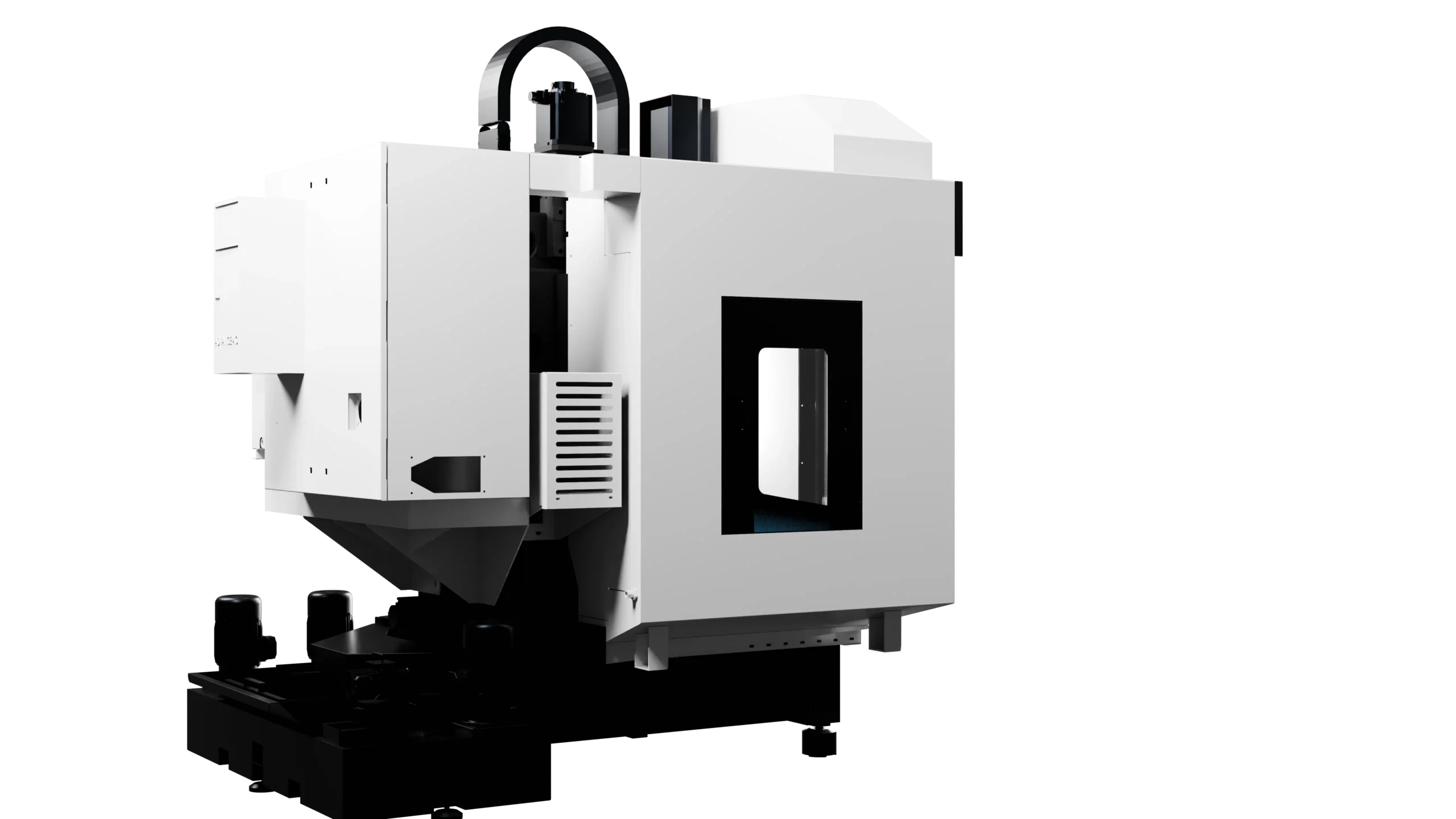

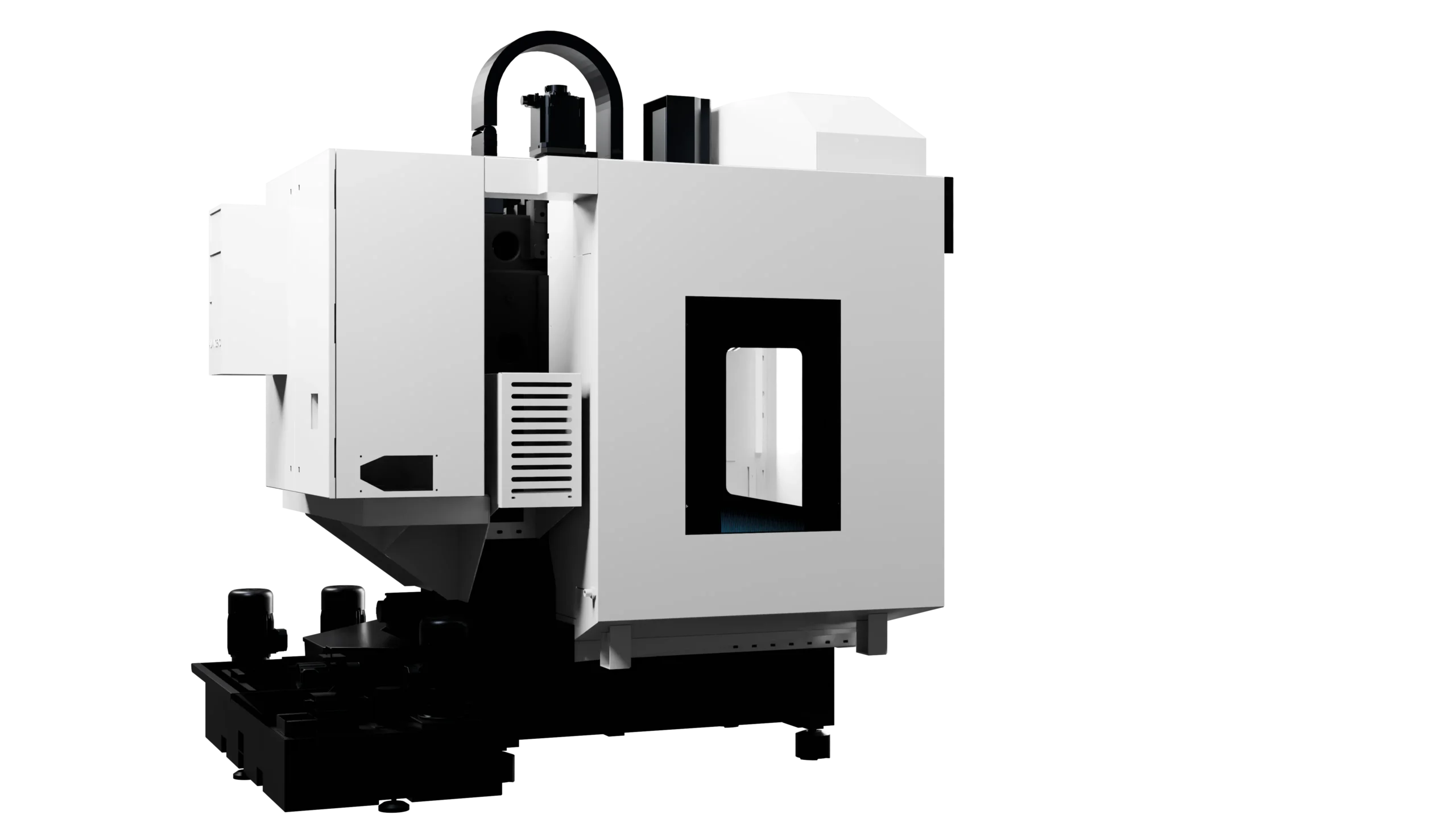

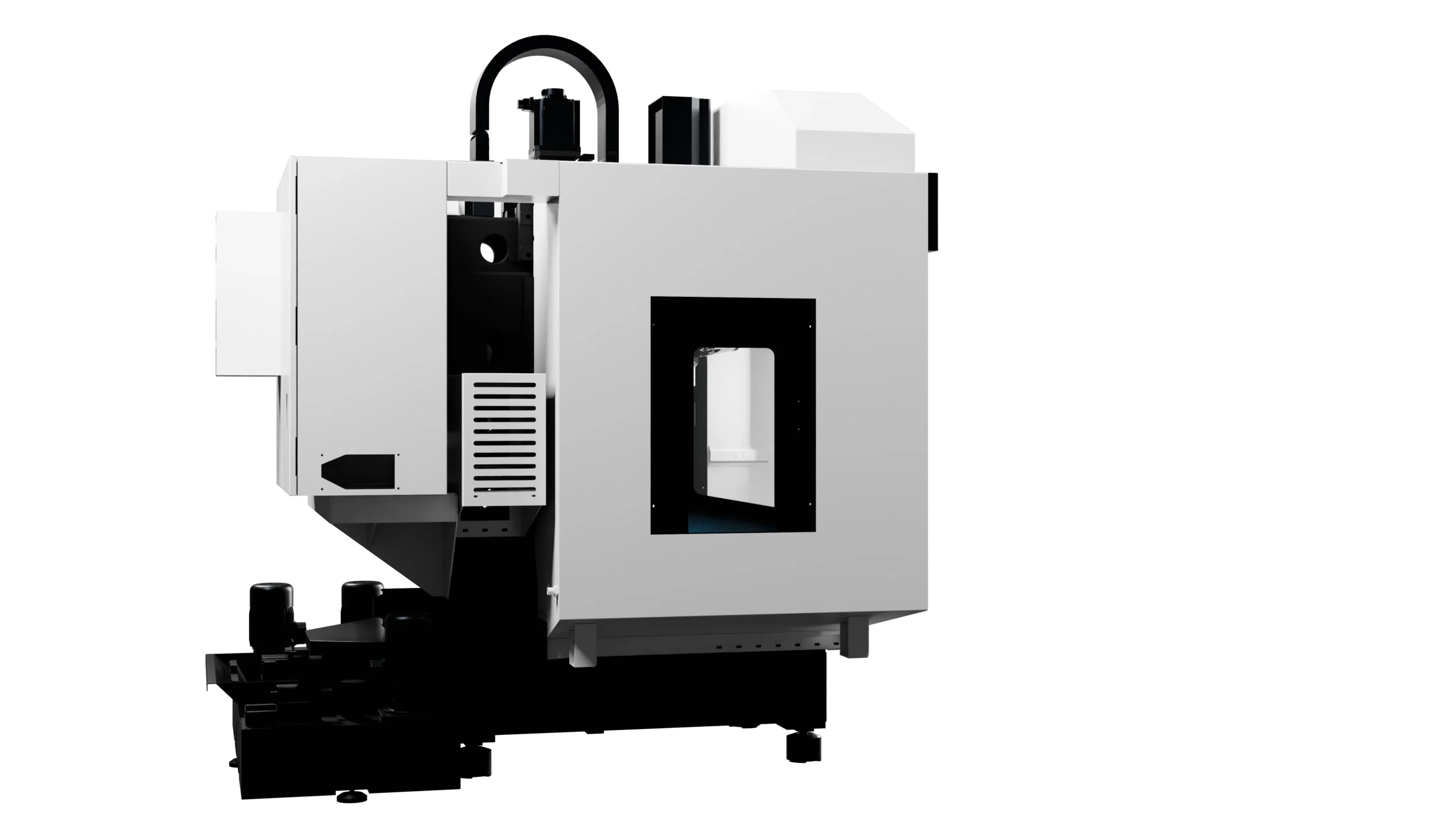

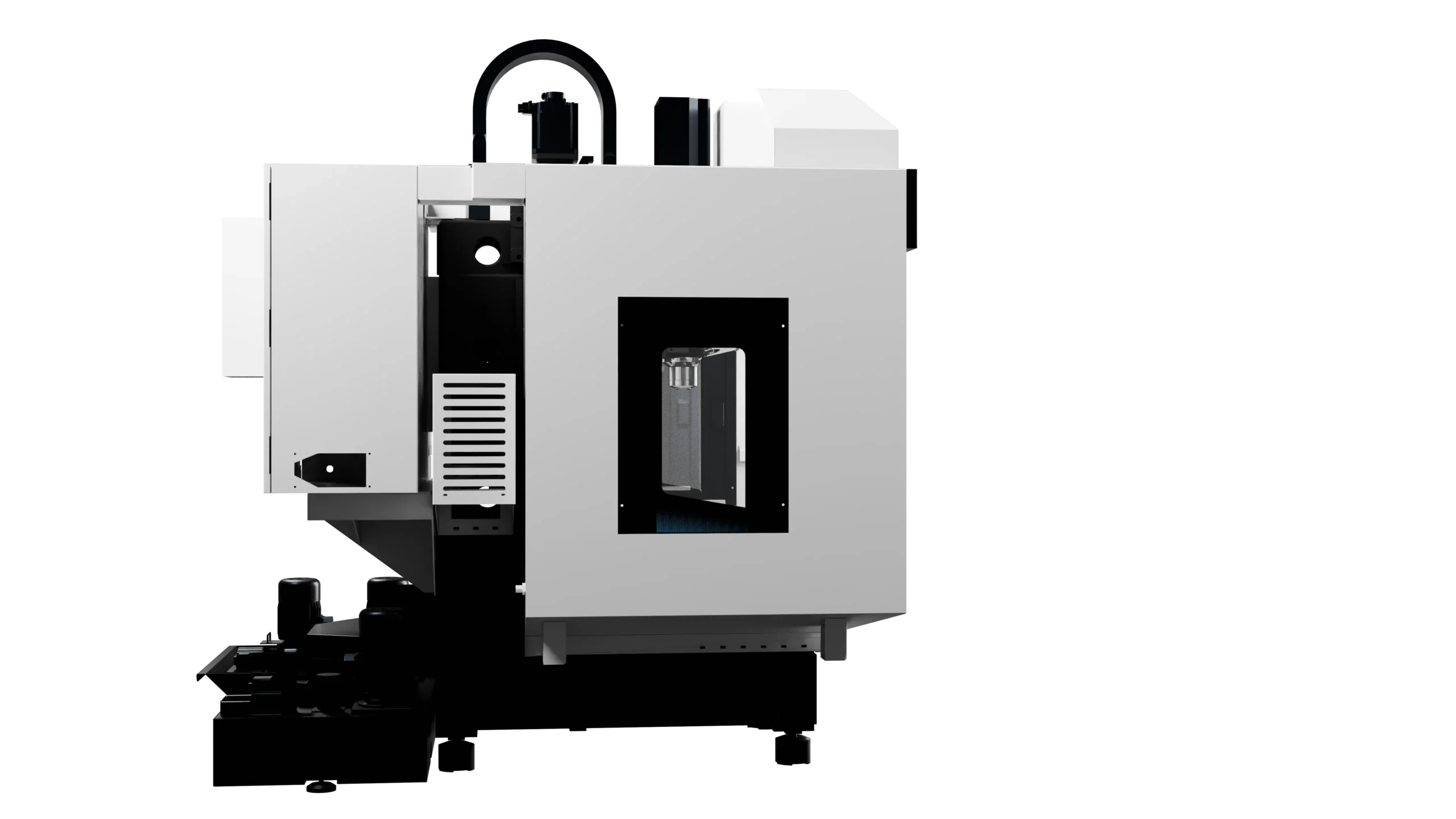

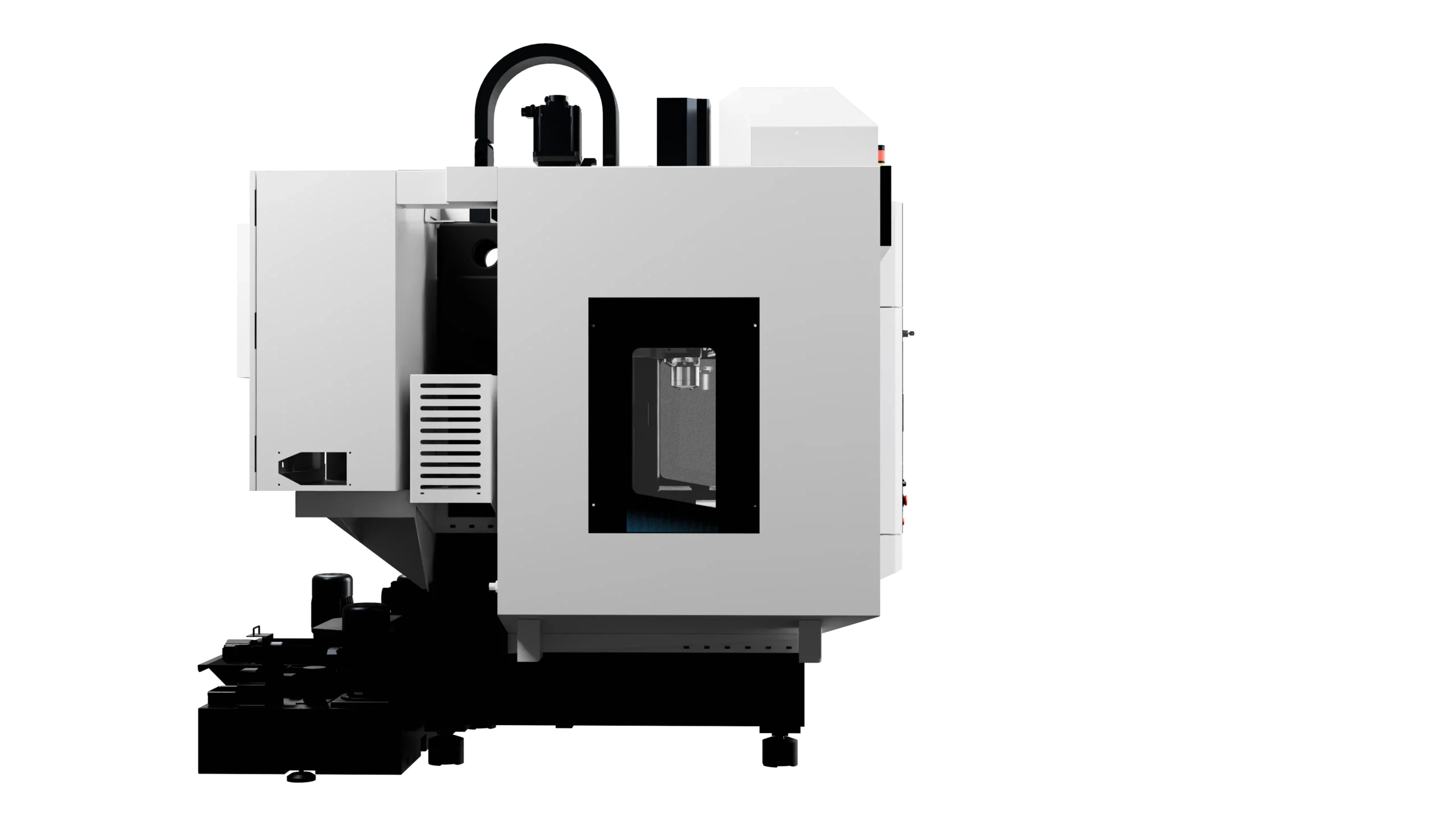

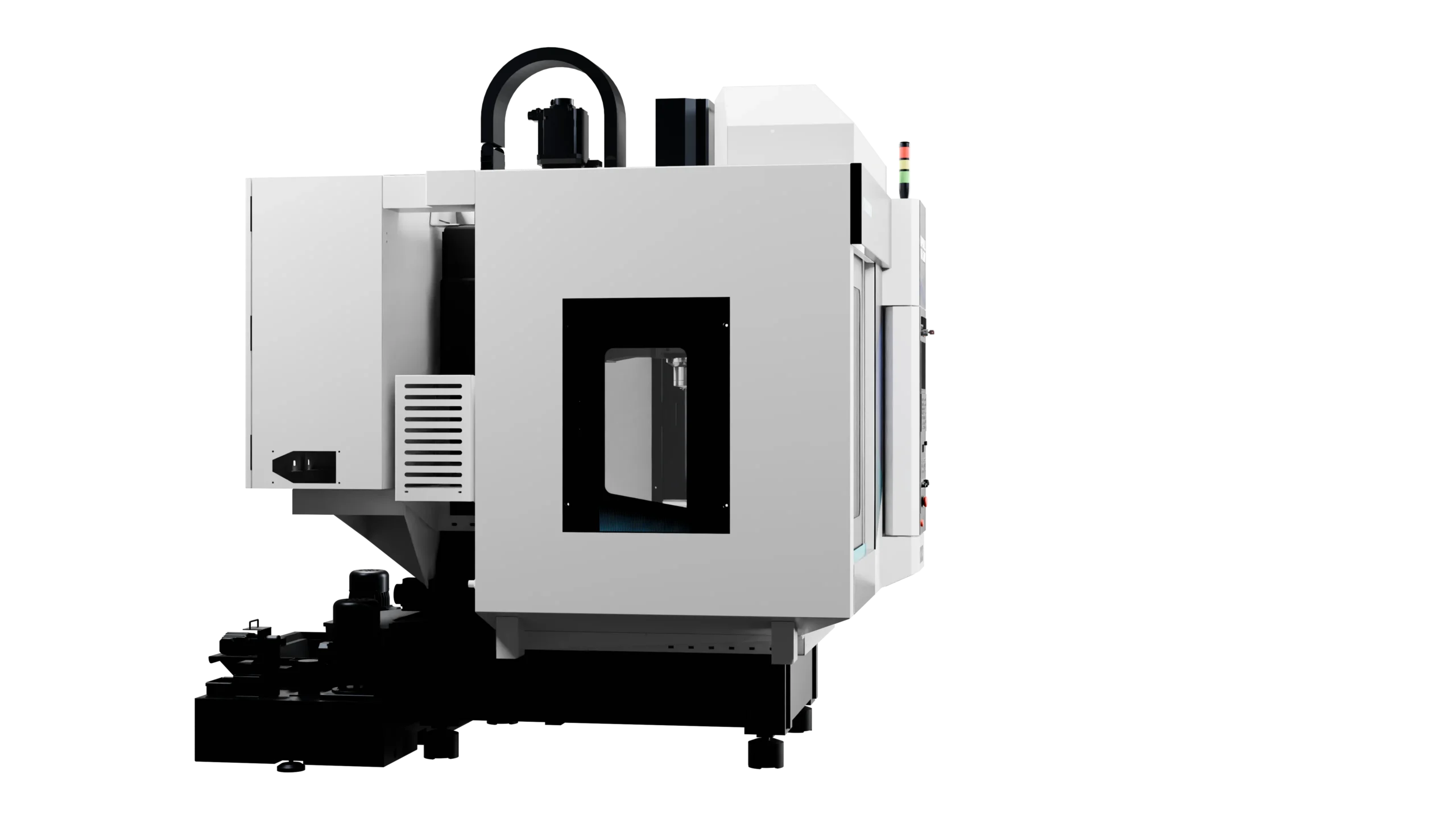

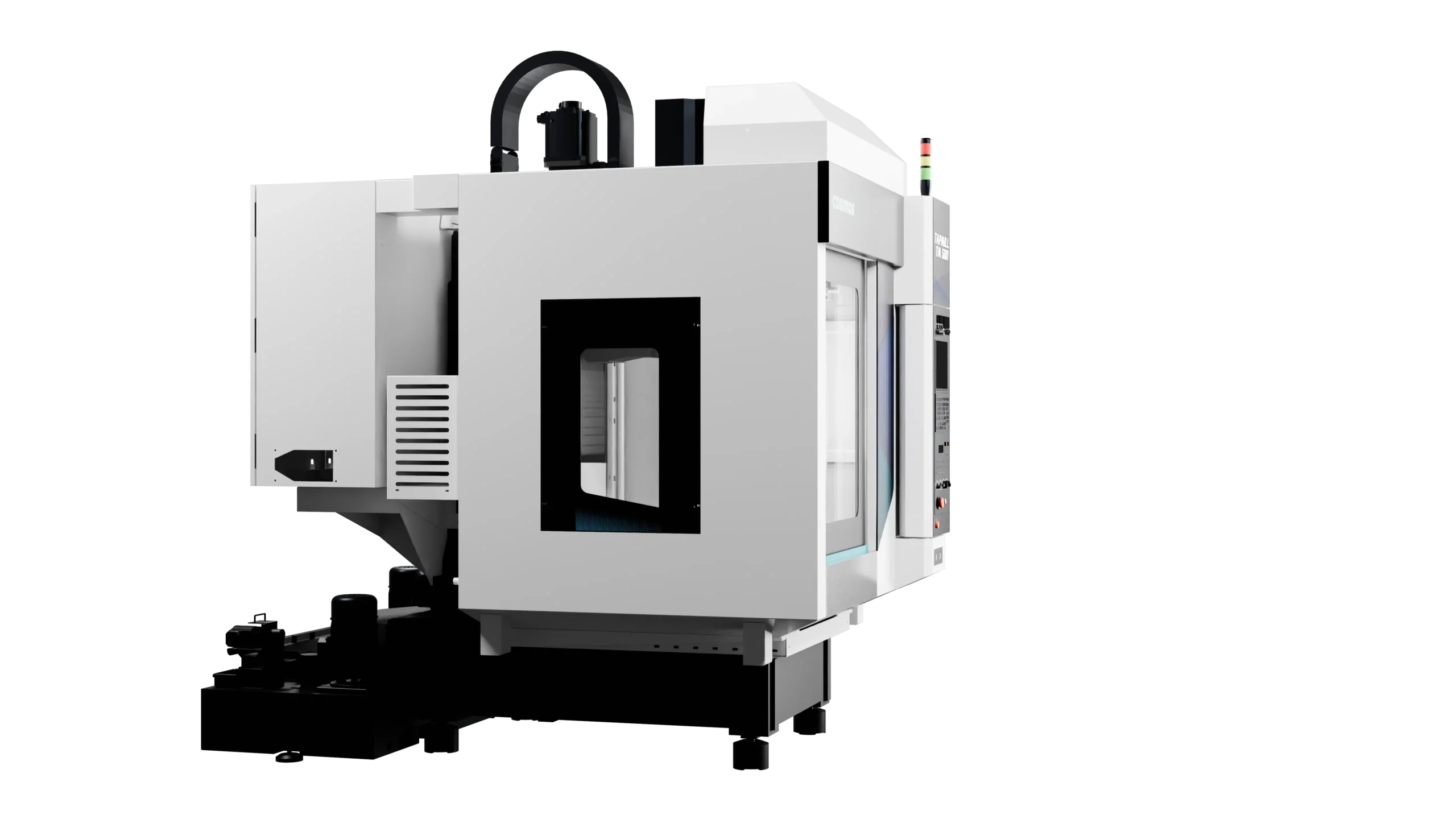

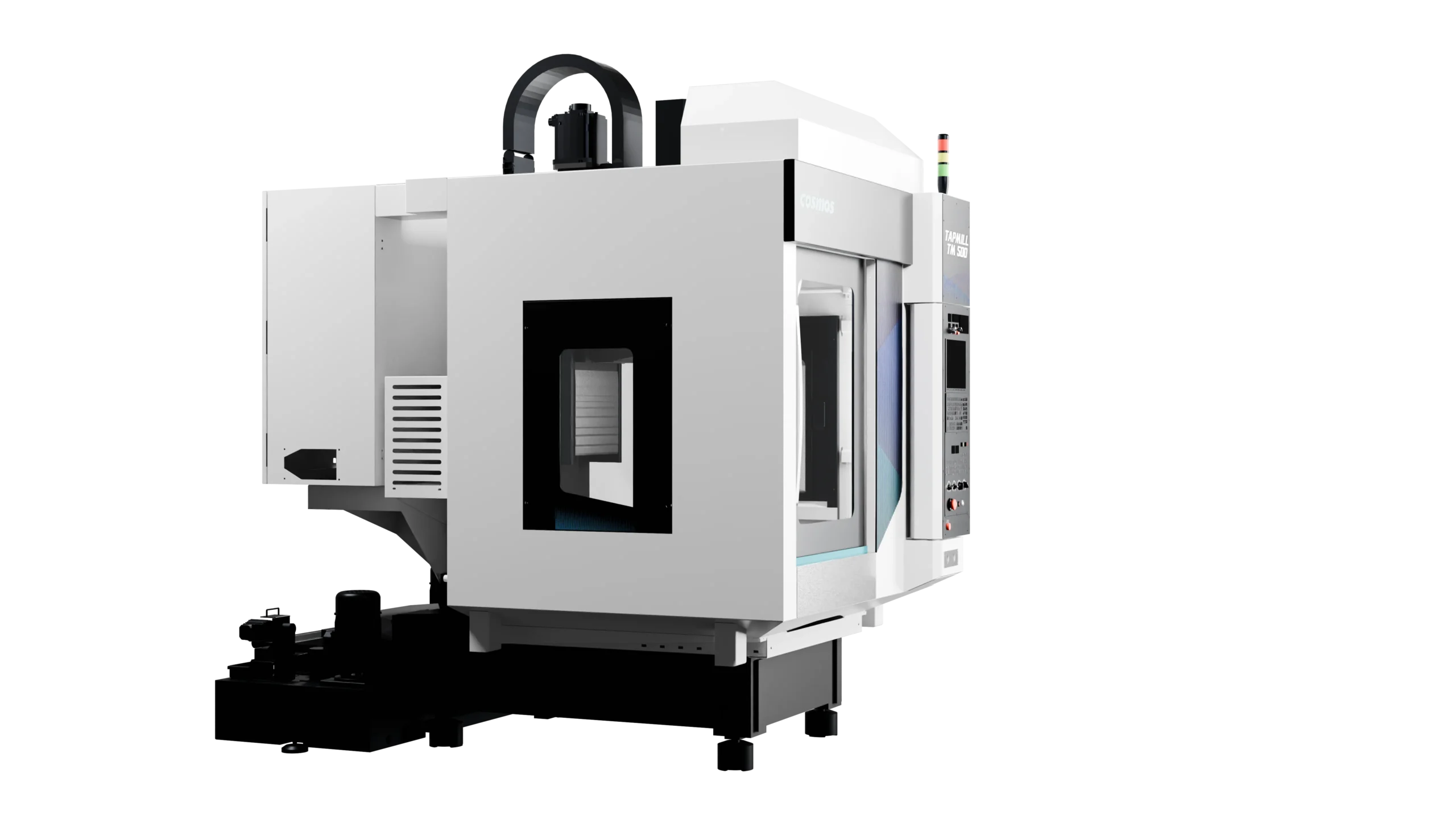

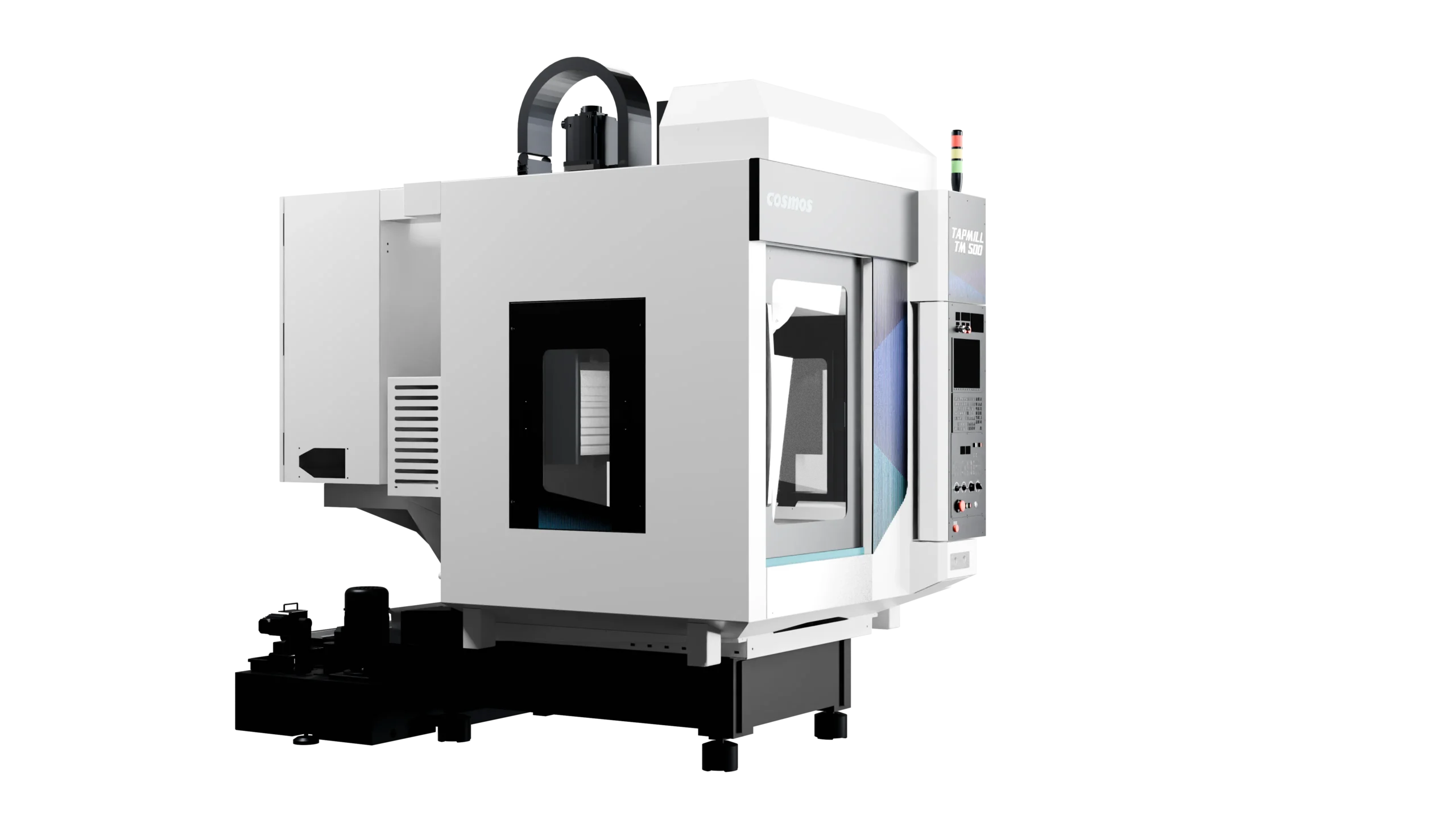

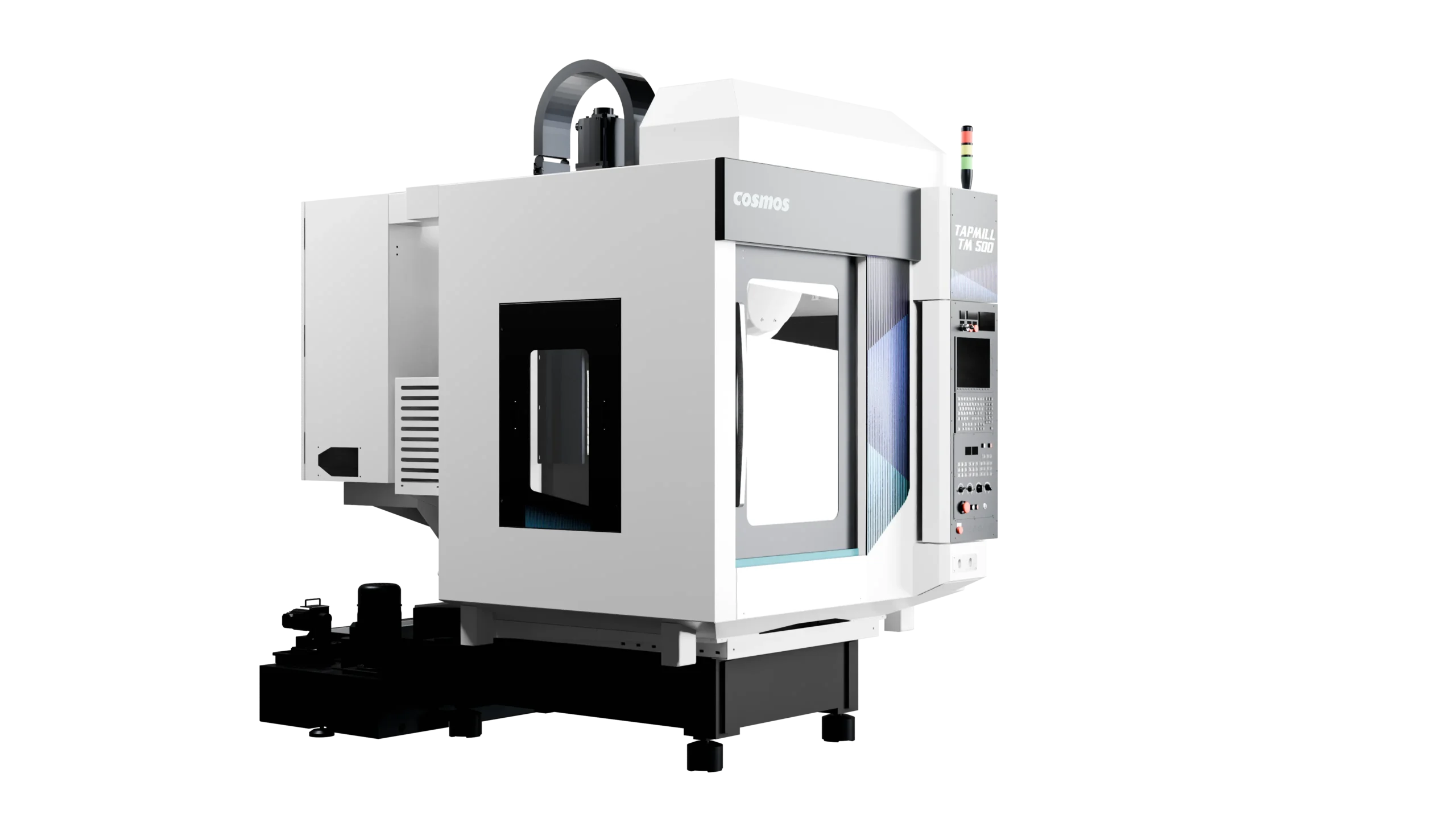

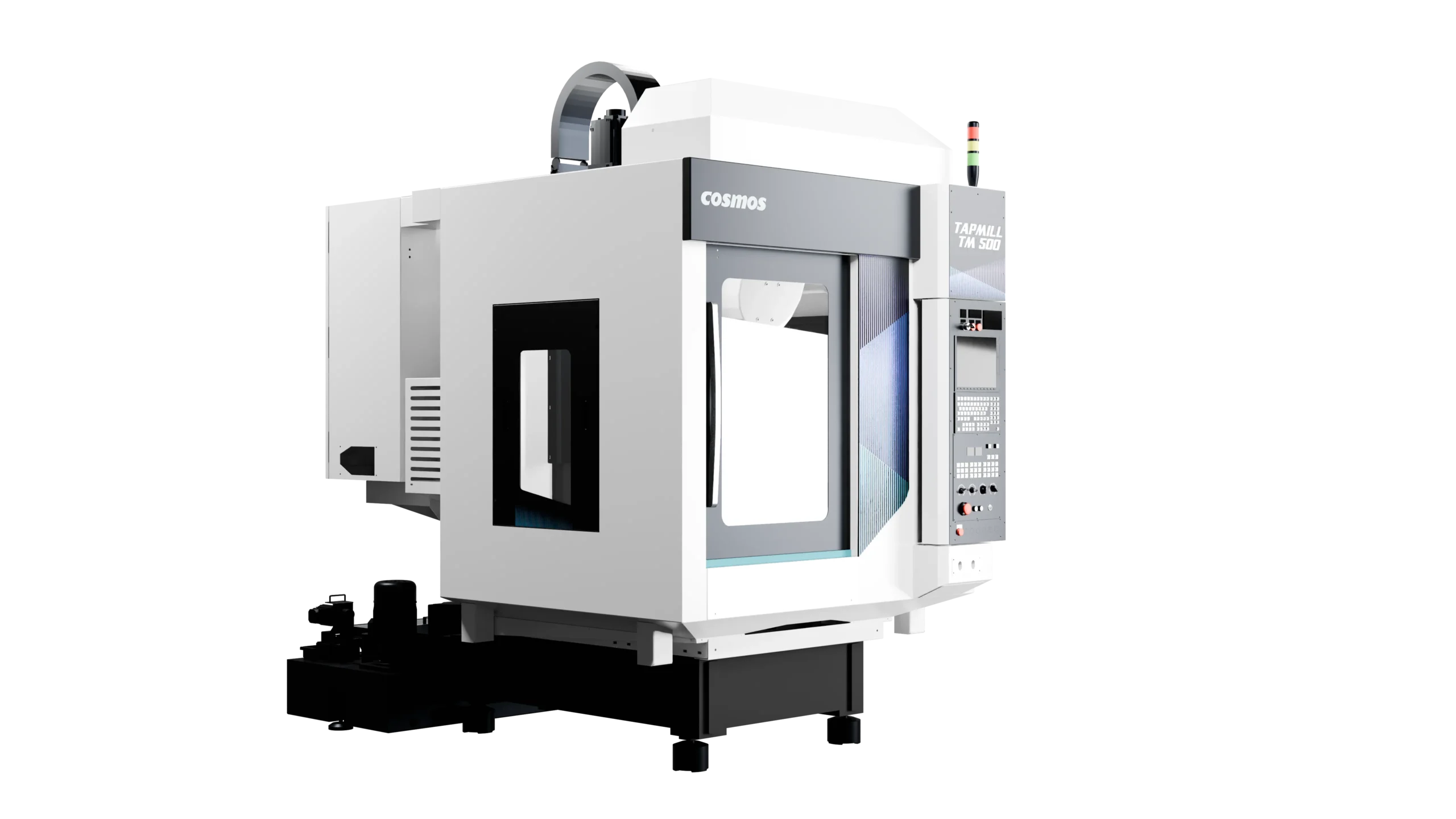

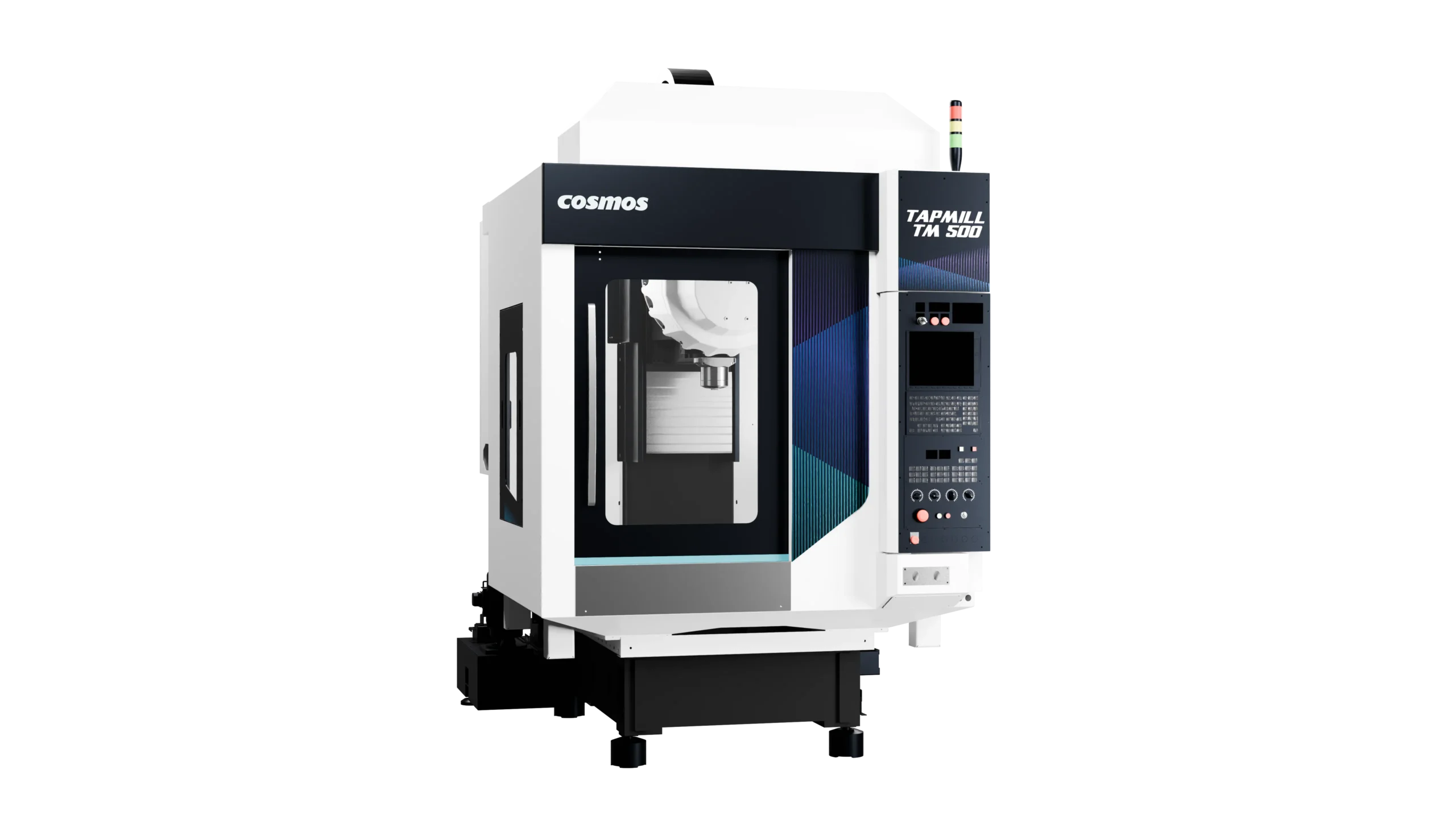

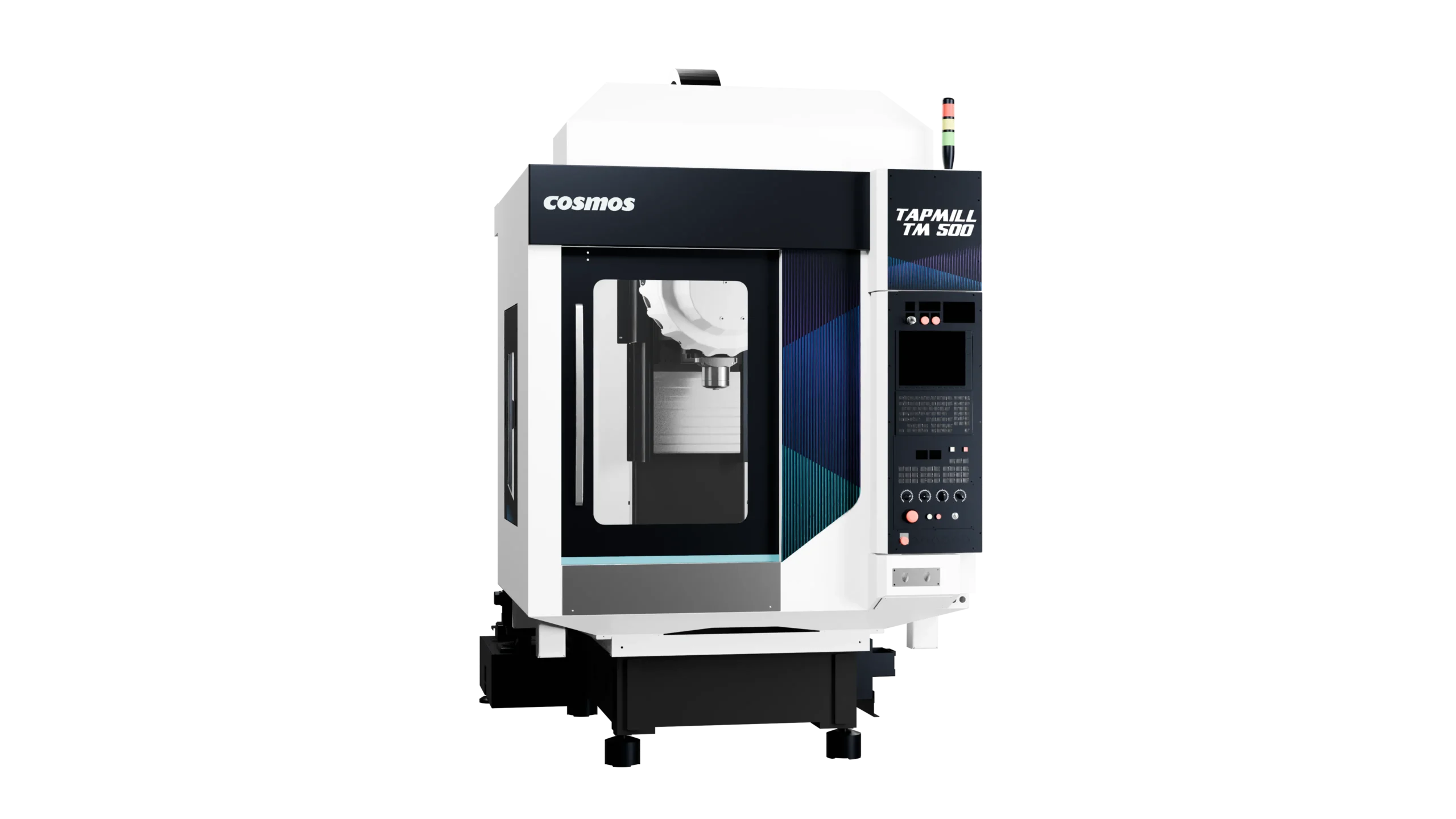

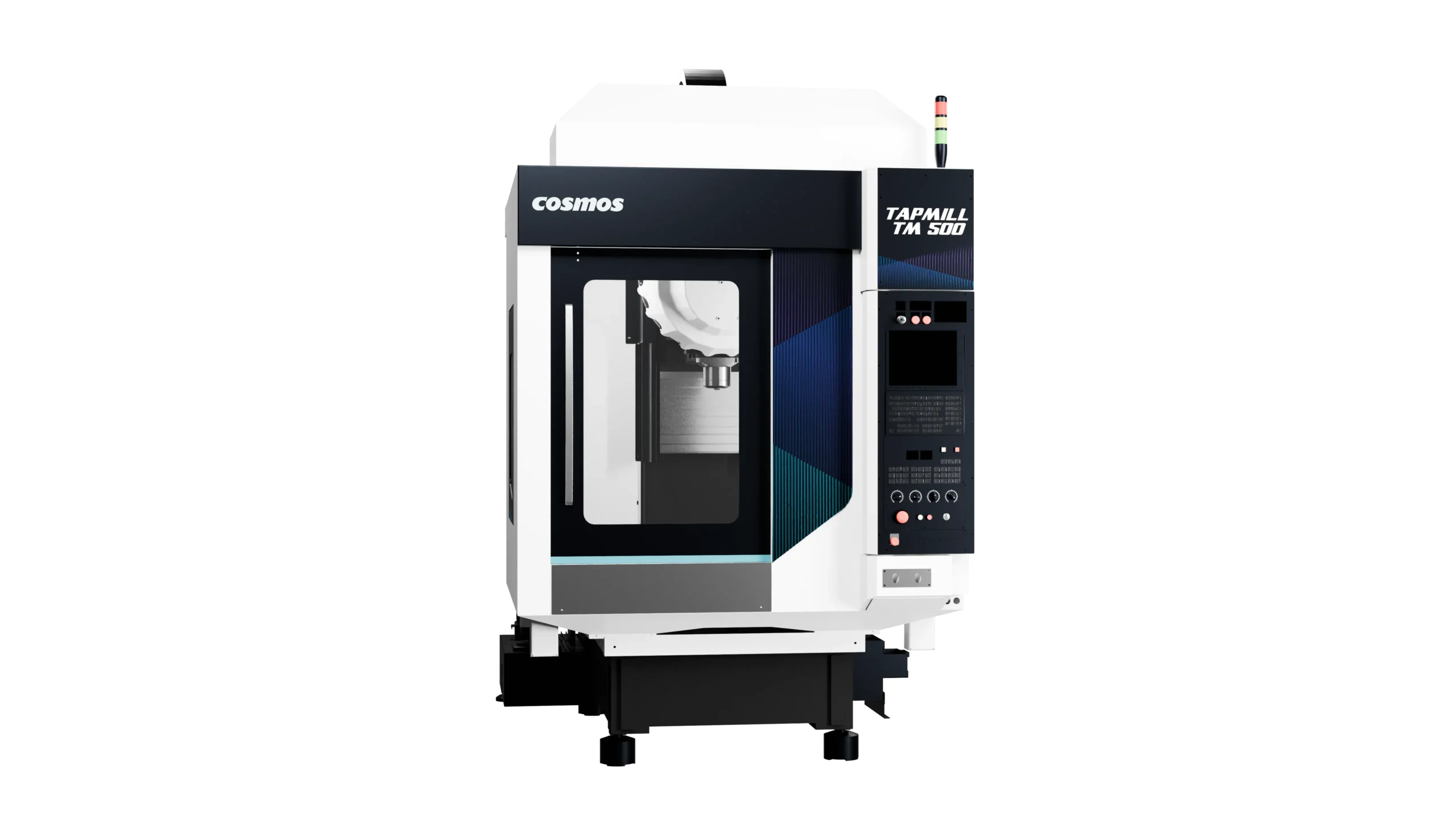

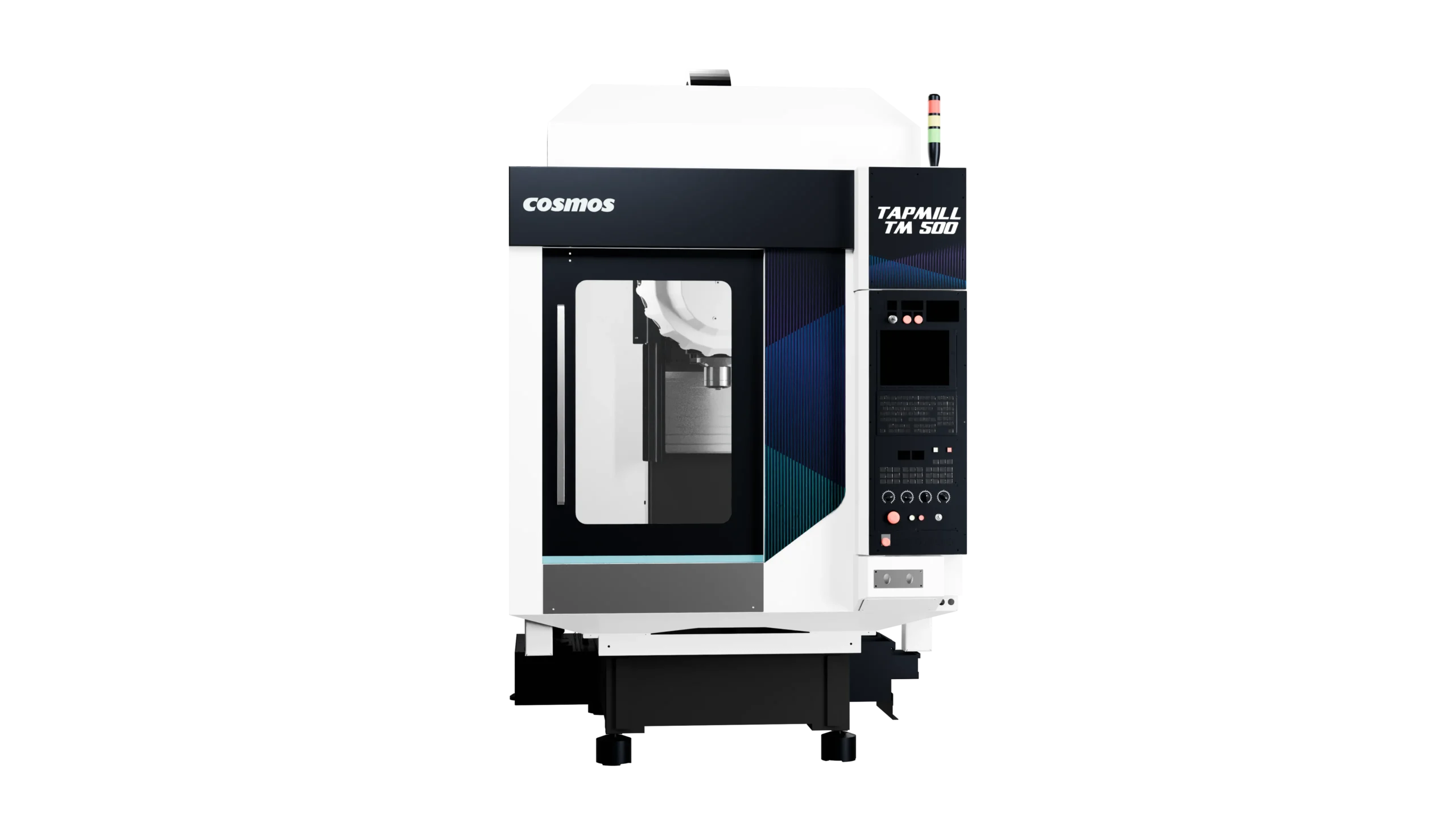

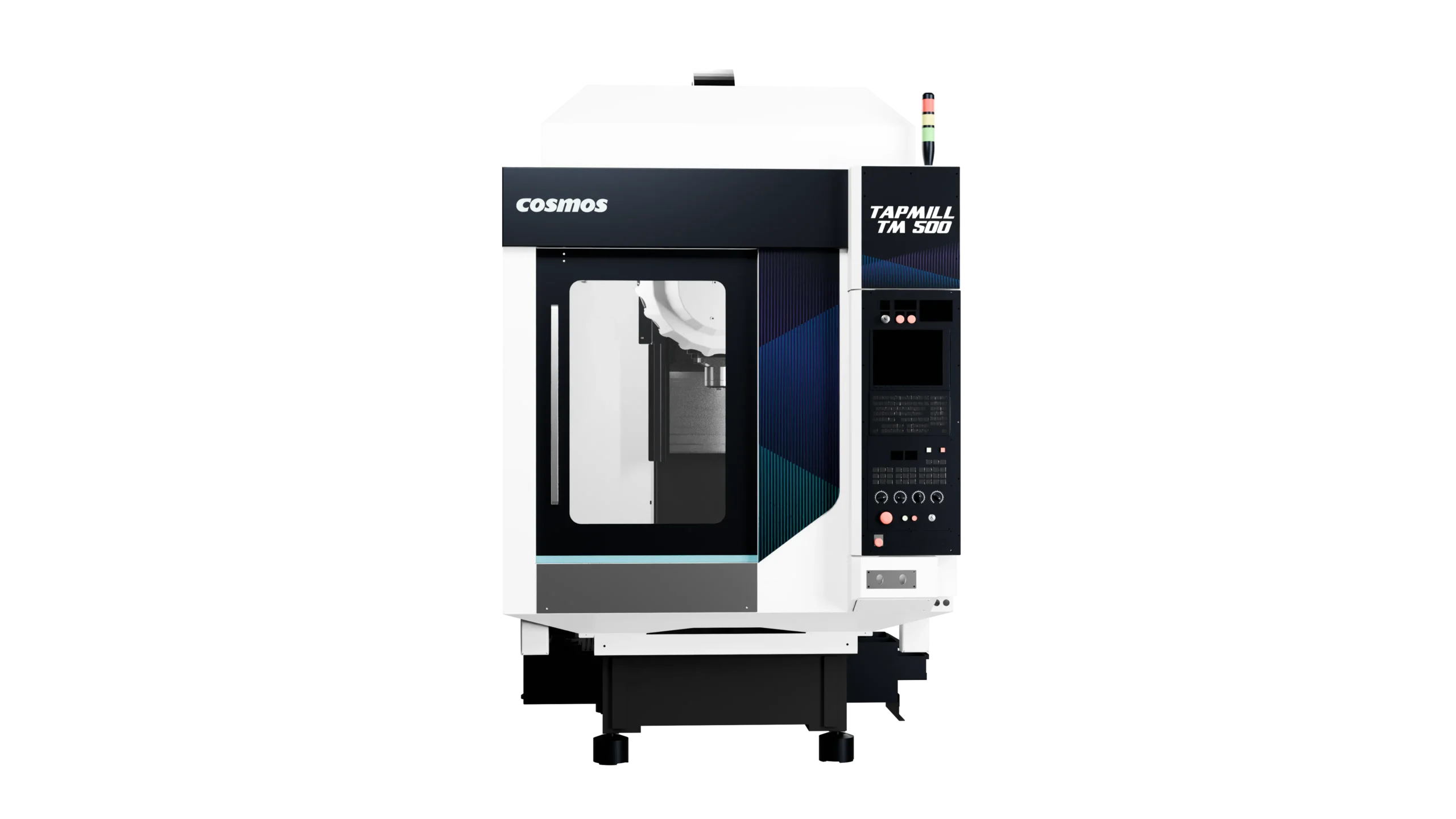

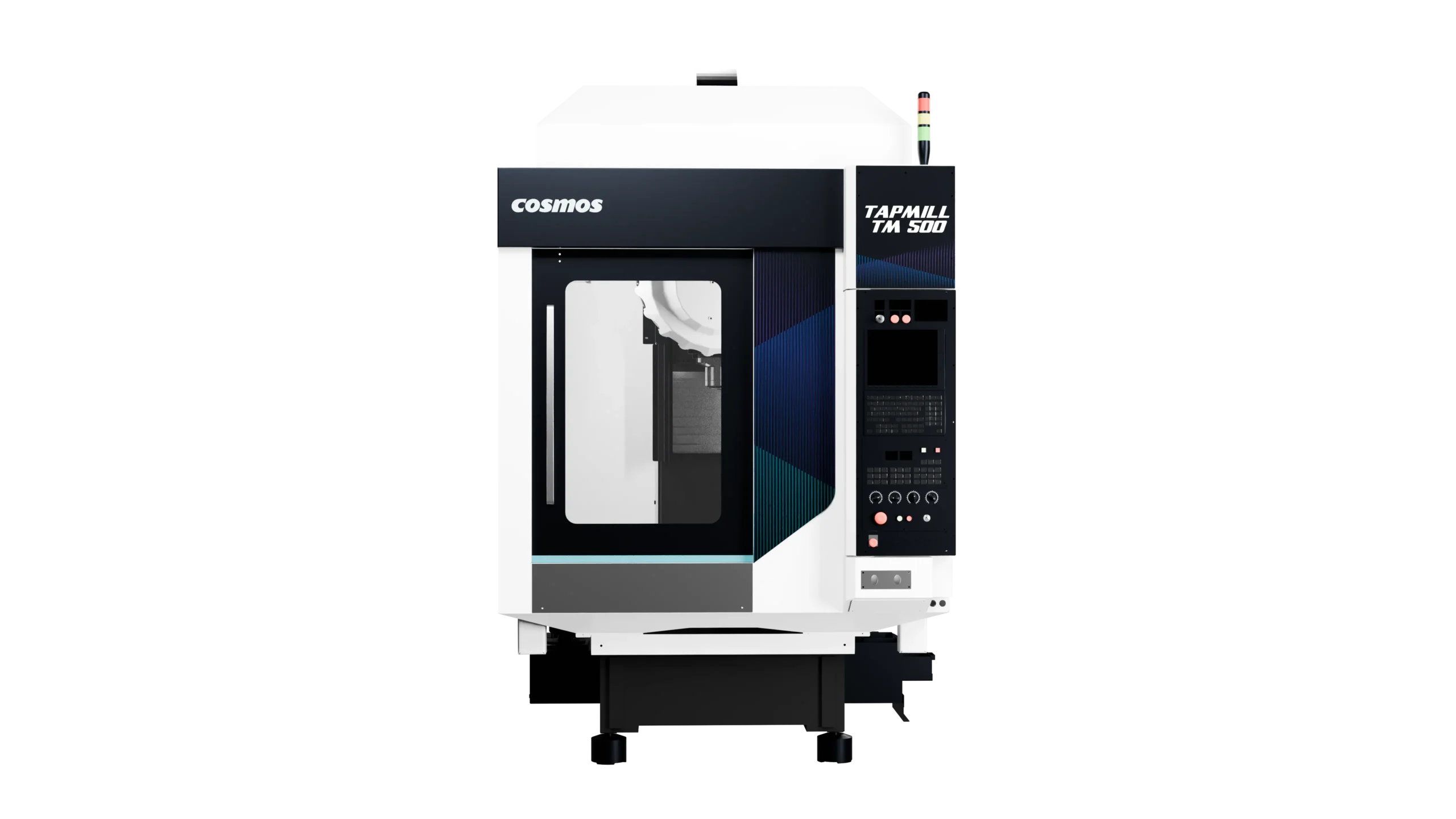

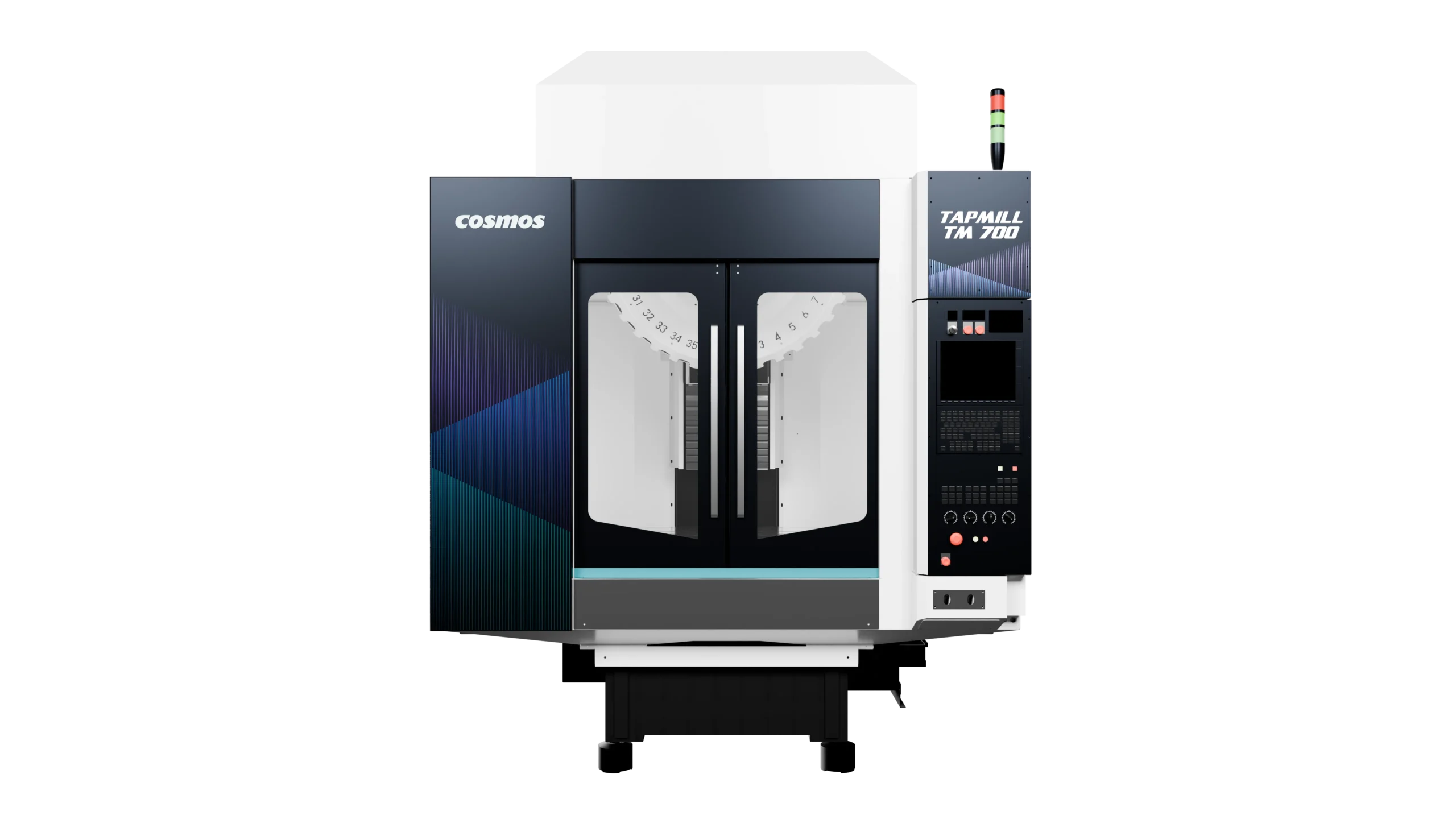

Machine Overview

Designed for efficiency and precision, the BBT 30 Spindle machine features a compact, energy-efficient build with a small footprint, delivering exceptional speed and reliable performance to boost productivity.

Additional Features

Spindle Characteristics

For TM 500 & TM 700

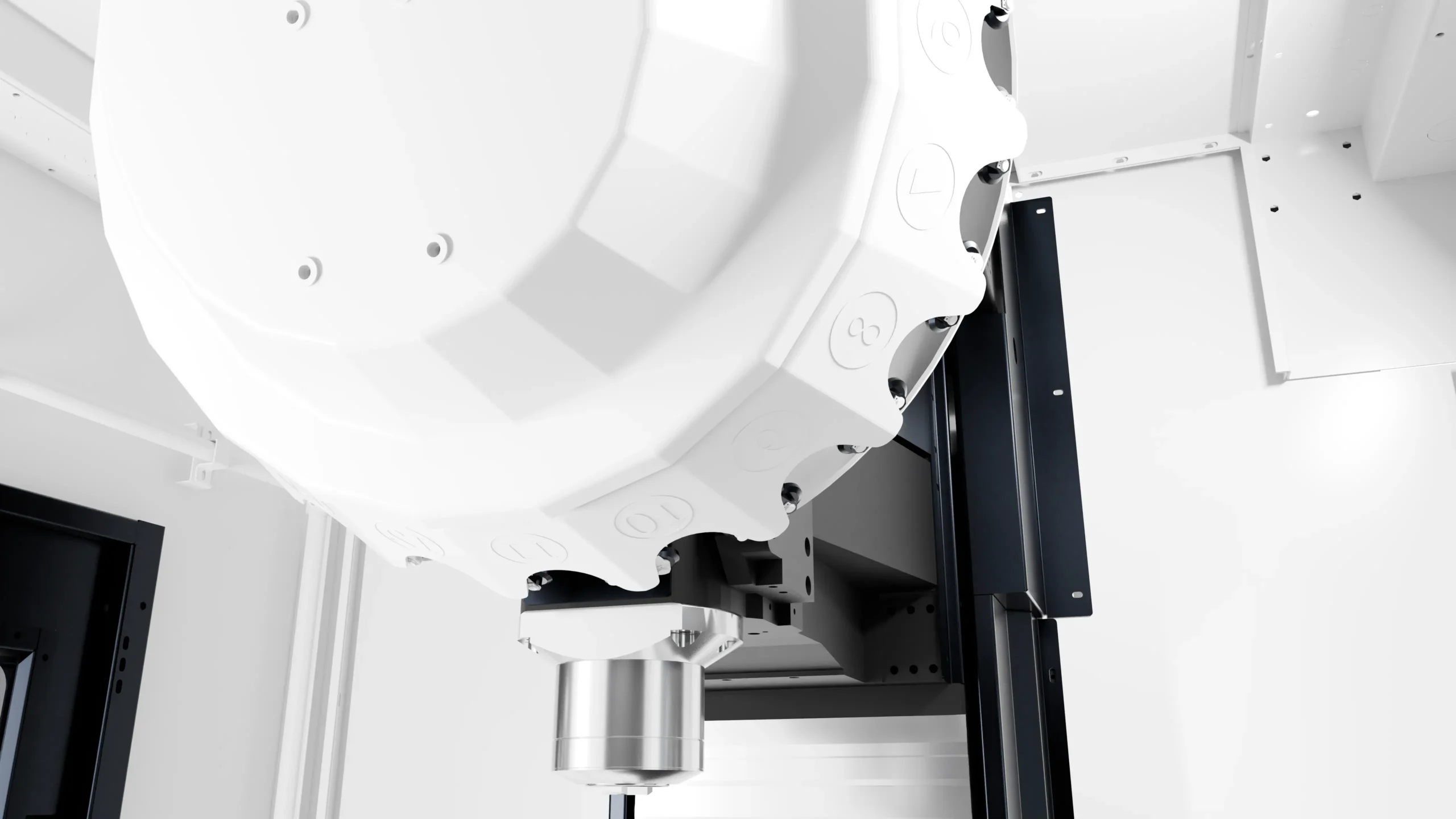

Direct Drive

Dual Contact - BBT 30 Taper

12,000 rpm - Standard

24,000 rpm - Optional

High Torque Spindle with 101 Nm Torque

For TM 500 HSC & TM 700 HSC

Direct Drive

Dual Contact - BBT 30 Taper

15,000 rpm - Standard

Acceleration 1.5G

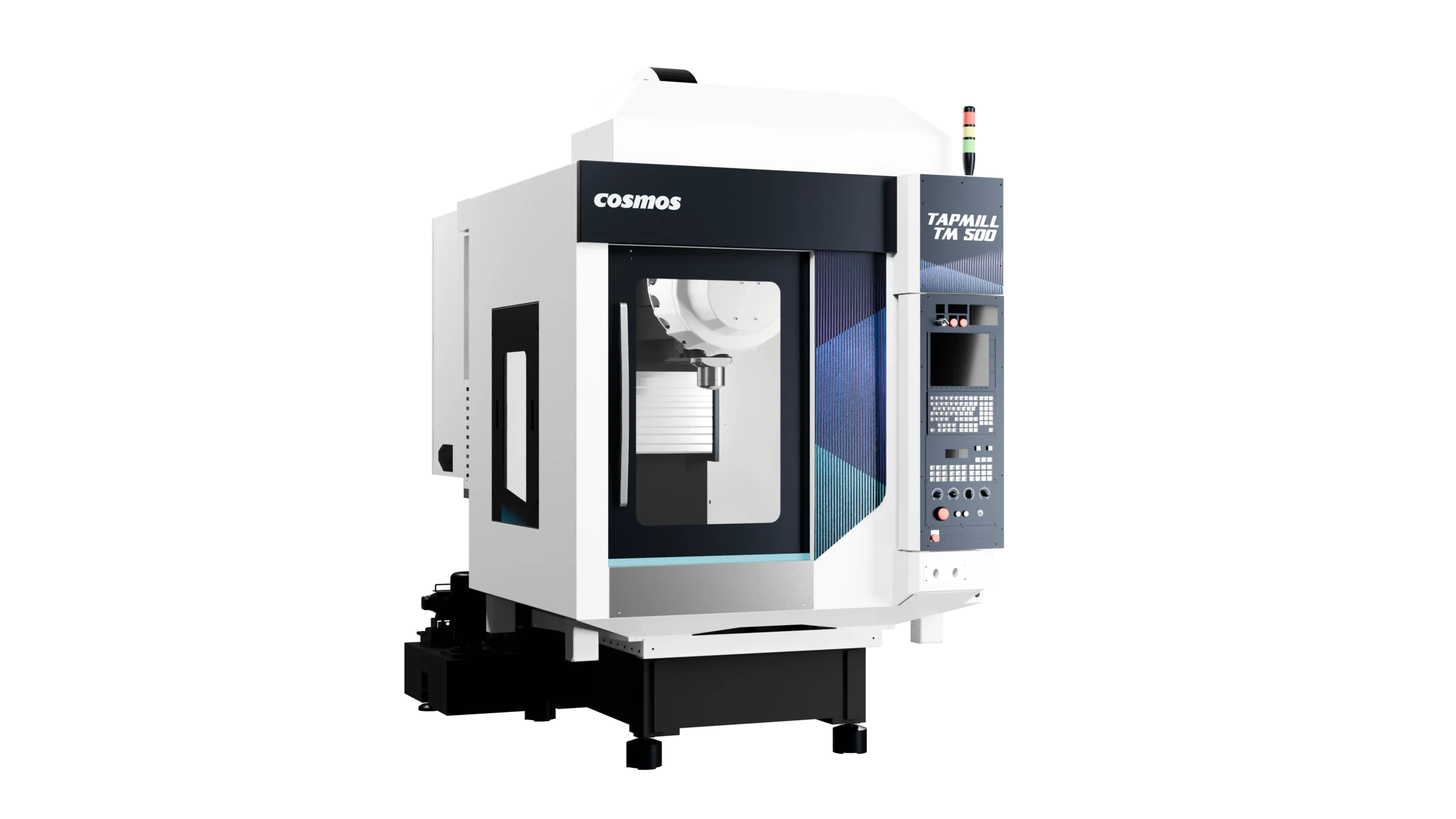

Automatic Tool Changer

Servo Type Tilting Pocket Design

1.5 Seconds (Tool to Tool)

21 Tools Storage (Standard)

36 Tools Storage (Optional - TM 700)

Machine Specs

X axis Travel: 500 mm

Y axis Travel: 400 mm

Z axis Travel: 330 mm

Table Size: 650×400 mm

Max Loading Capacity: 250 Kg

Spindle Motor Output: 3.7/5.5 kW

Spindle Max Speed: 12,000 rpm

Spindle Taper: BBT-30

Rapid Feed Of x/y/z: 60/60/60 m/min

X axis Travel: 700 mm

Y axis Travel: 400 mm

Z axis Travel: 330 mm

Table Size: 850×400 mm

Max Loading Capacity: 250 Kg

Spindle Motor Output: 3.7/5.5 kW

Spindle Max Speed: 12,000 rpm

Spindle Taper: BBT-30

Rapid Feed Of x/y/z: 60/60/60 m/min

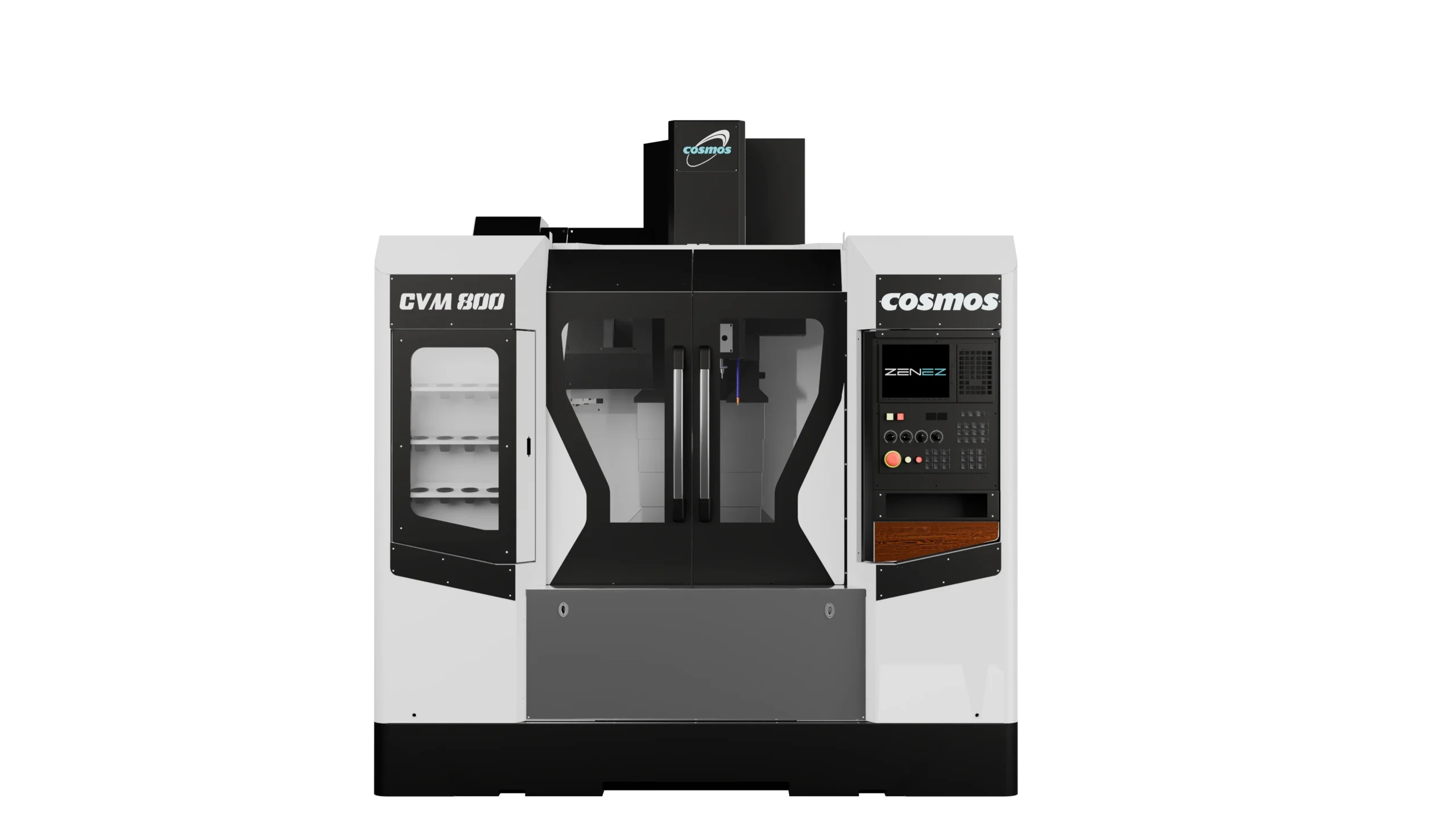

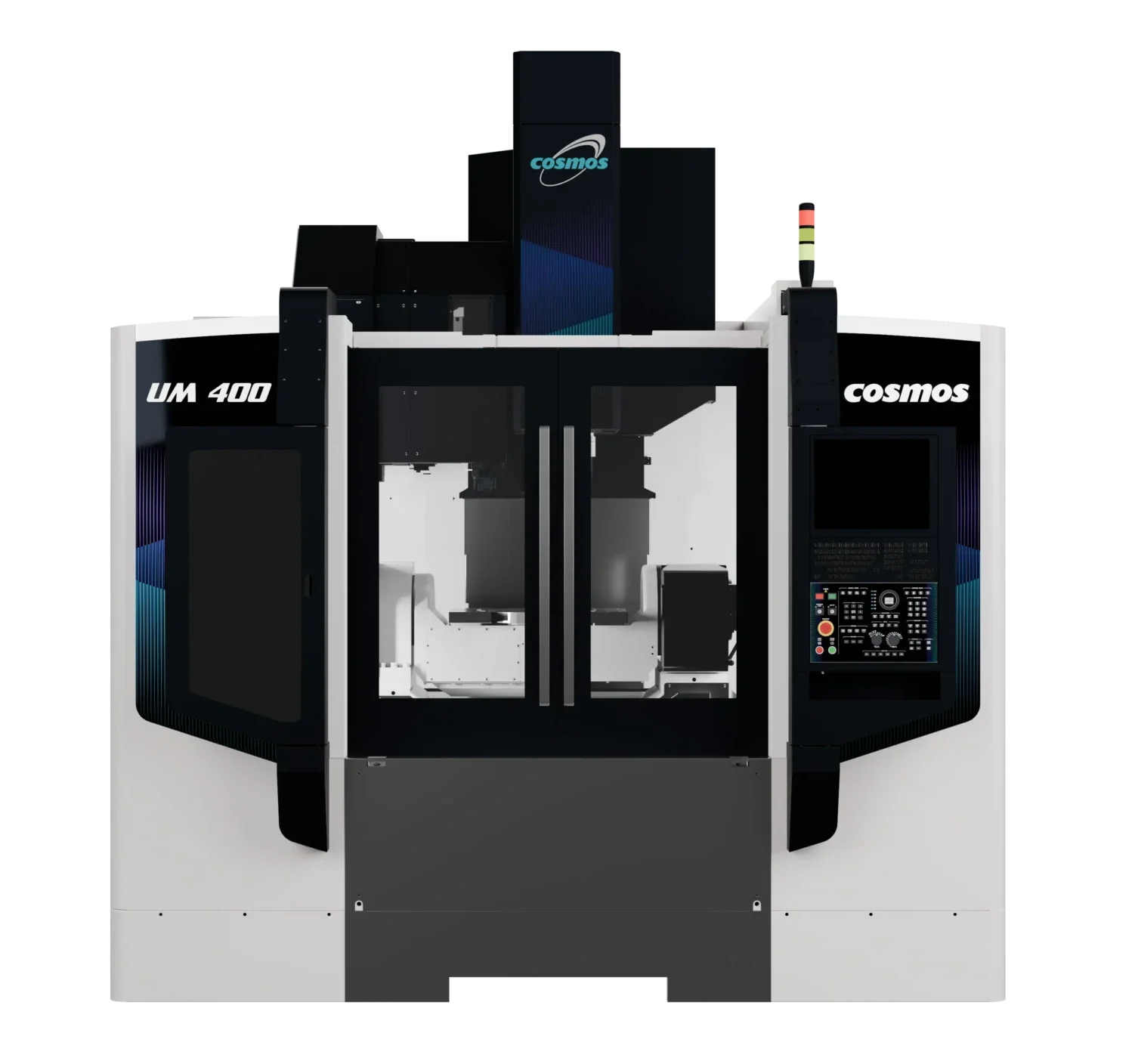

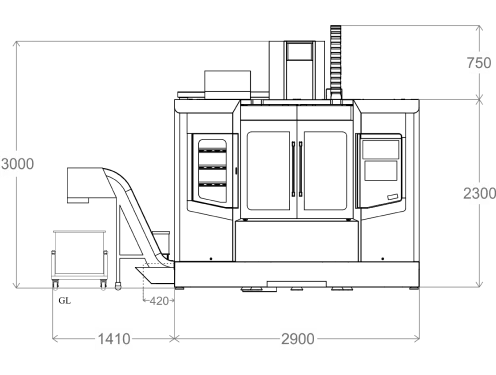

Dimensions

| X Axis Travel 1300 mm | Y Axis Travel 650 mm | Z Axis Travel 600 mm | Table Size 1450X650 mm |

| Spindle Nose to Table Surface 150-850 mm | Spindle Center to Sliding Cover Face 652 mm | Table T-Slot 18X5X125 mm |

| Machine Weight (with ATC) 7000 kg | Power Requirement (Controller) 30 KVA |

Capacity

| Spindle Taper BBT 40 | Guideway Type Ball LM Type | Auto Tool Changer Type 24 Tool Arm Type |

| Mitsubishi Motor power(OPT) 11/15/18.5 kw | Fanuc Motor power(OPT) 7.5/11/15 kw | Siemens Motor power(OPT) 9/17 kw |

| Rapid Traverse Rate (Opt) 30 m/min | Cutting Feed Rate 10 m/min | Tool Capacity 30 |

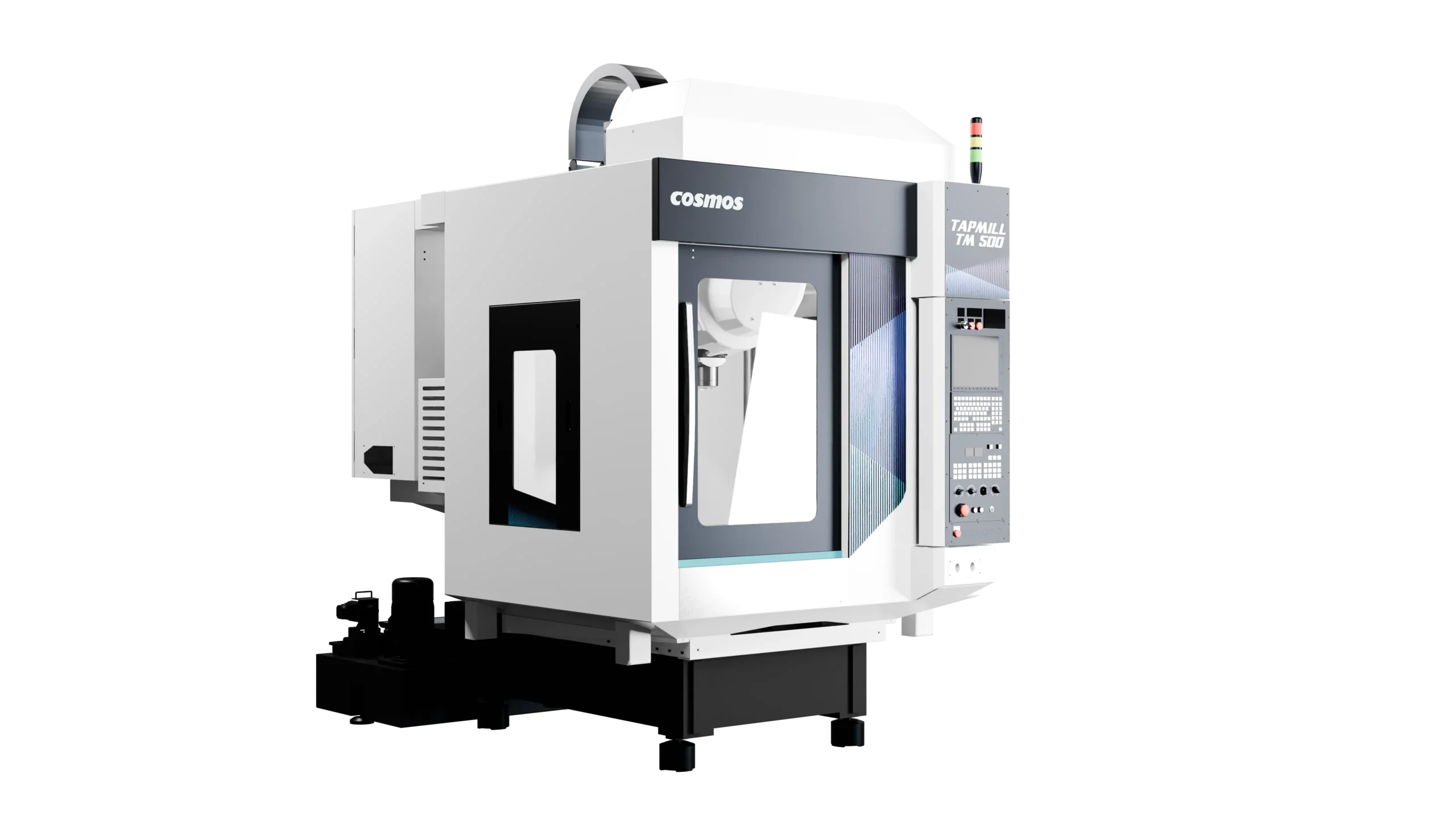

Flexible working Area

Capable of fitting 4th Axis rotary or fixture to satisfy different jobs requirement.

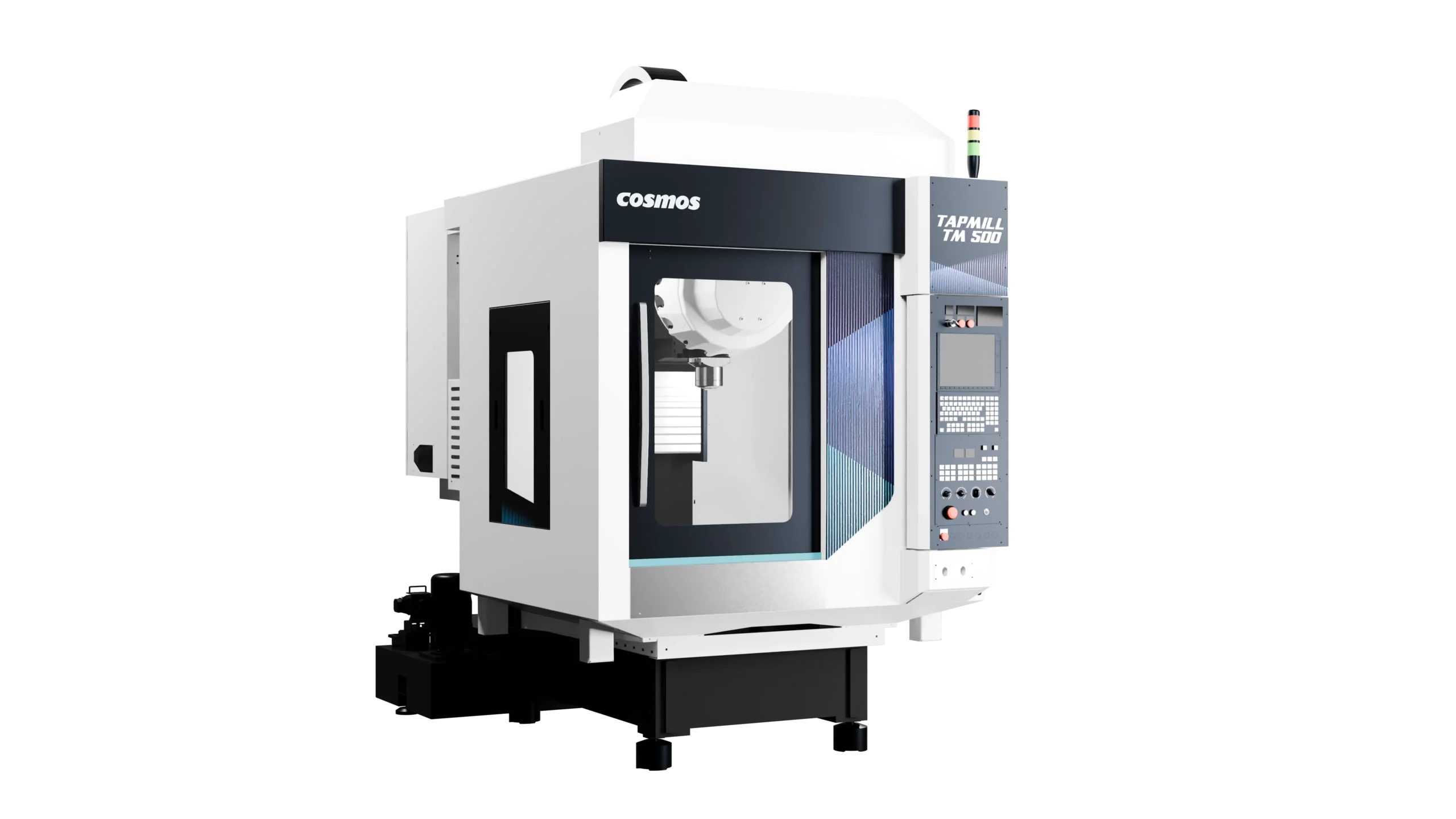

Excellent Chip Disposal

The machines feature steeply slanted telescopic sliding covers that excel in chip disposal performance, keeping your workspace clean and ensuring uninterrupted machining.

Torque Power Diagrams

Mitsubishi Controller

Fanuc Controller

Spindle Options Tailored to Specific Applications

Standard Spindle: Suitable for a wide range of machining needs.

High-Torque Spindle: Ideal for heavy- duty machining of steel components.

Quick-Acceleration Spindle: Designed for high-speed, high-efficiency machining of aluminium parts.

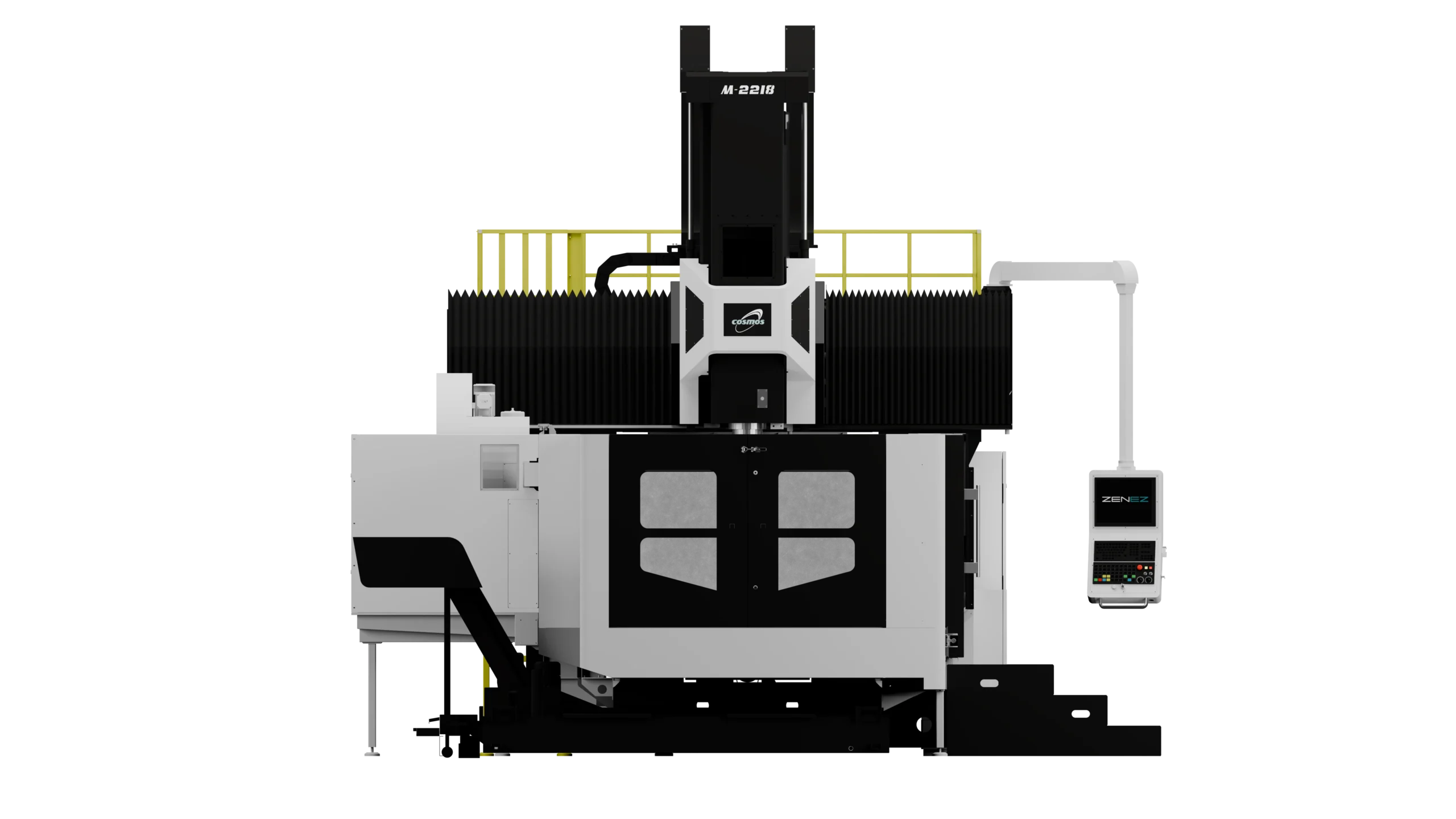

BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

It focuses on customised dashboards and tools that help the operator to simplify his daily activity. The overall feature and package can reduce the time lost due to the complexity of the controller GUI; as a result, Zenez can significantly increase the machine output and profitability. • 10.4-inch display or large 15-inch display.

- 10.4-inch display or large 15-inch display

- Multi-touch User Interface

- Fully functional vertical and horizontal soft-keys for non-touch usage

- Crystal Type

- Enhanced hardware to ensure reliability

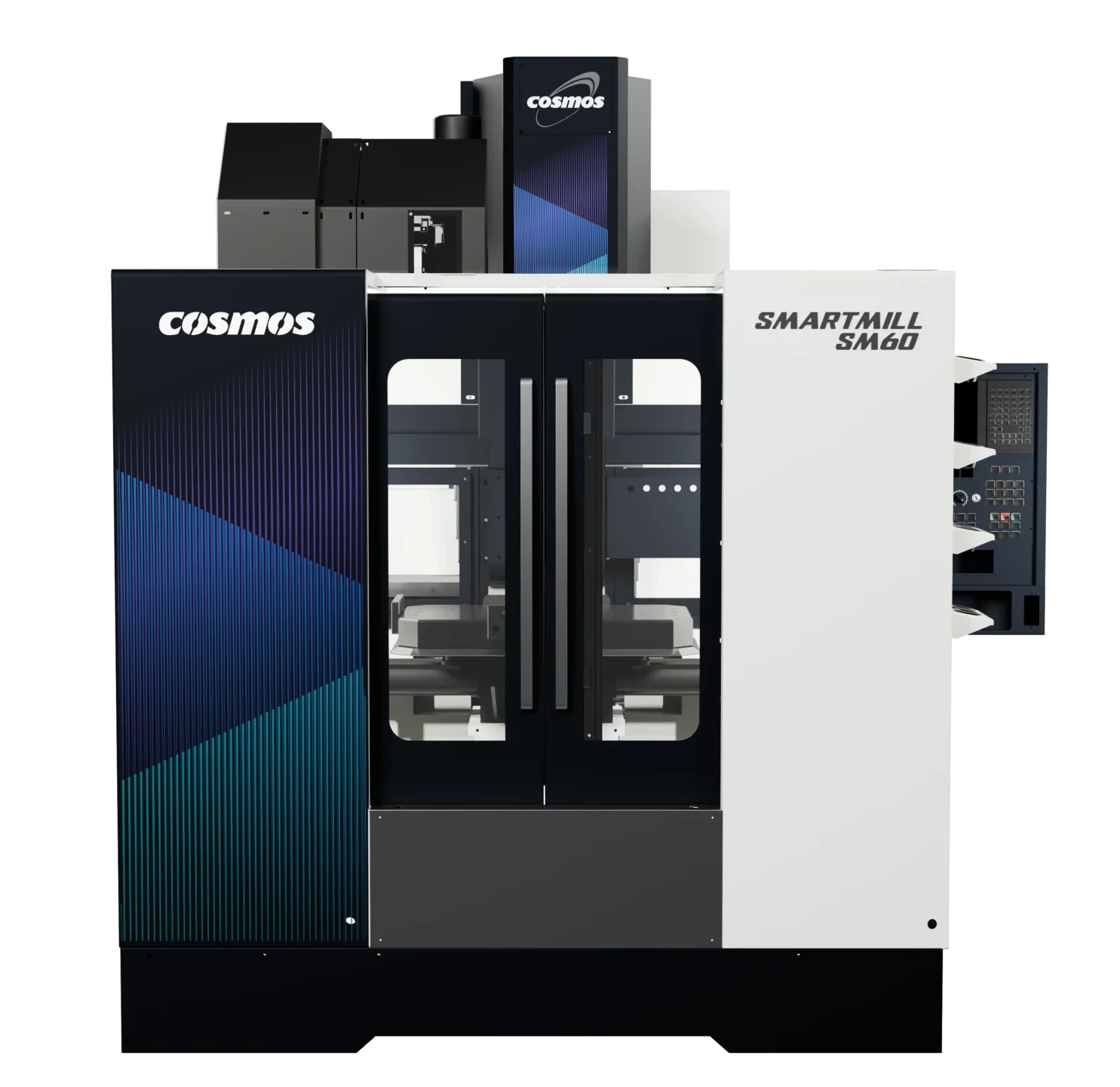

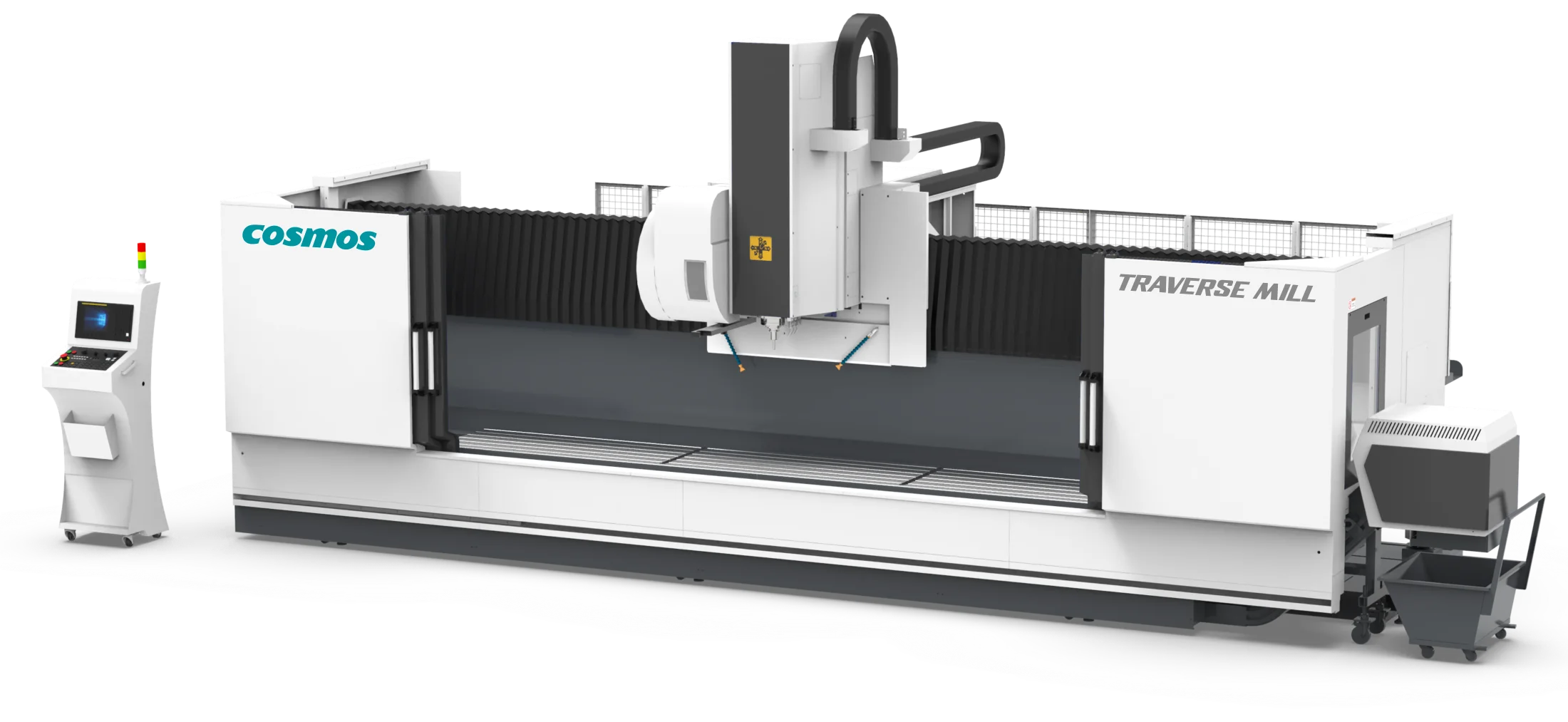

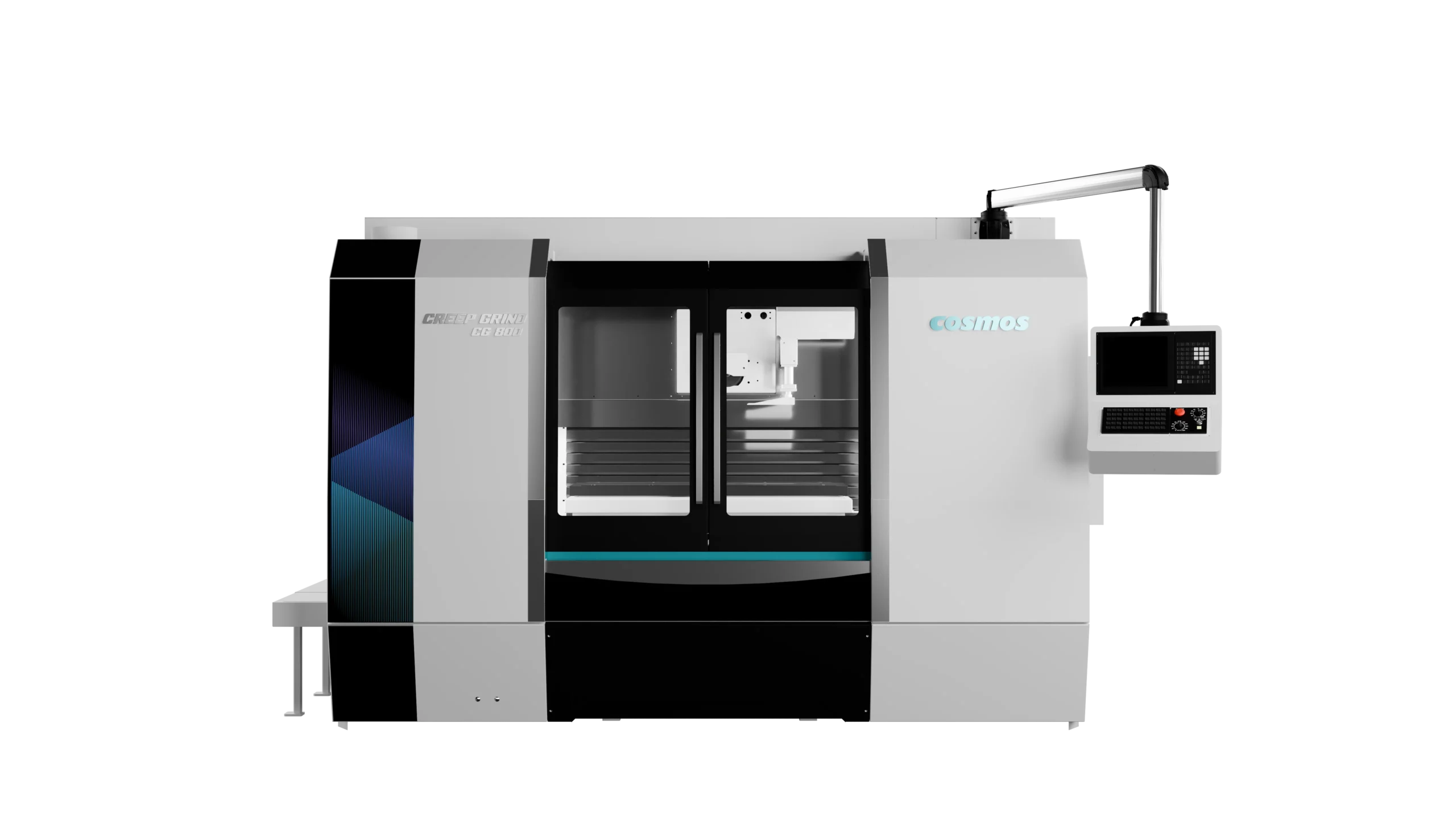

Our Other Range of Excellence

High-tech Products For Unmatched Performance