BOOST YOUR PROFITABILITY BY

ACHIEVING THE MAXIMUM WITH EASE

- 10.4-inch Display or large 15-inch display

- Multi Touch User Interface

- Fully Functional Vertical and Horizontal Soft-keys for

- non-touch usage

- Crystal Type

- Enhanced hardware to ensure Reliability

ZENEZ, the Windows based GUI created by Cosmos Impex (I) Pvt Ltd. is an integrated system solution using an intuitive 15-inch touch screen.

The system provides a convenient operator interface, a high level of

customisation and useful technology apps.

New, Intuitive, User Friendly ZENEZ designed for your productivity.

- Designed for ease of operation with intelligent functions.

- Simple customiSation.

- Extend functionality with additional apps.

- Register for up to 3 levels of users.

- Supported by Windows 10 Embedded OS.

- 15-inch capacitive touch screen display.

Derived from the words “ZEN” and “Ease,” ZENEZ represents the idea of wisdom at ease

Key Functions

- ZAFC (Adaptive Feed Rate Control)

- ITA (Tapping Adjustment)

- CIMC (Intelligent Machine Configuration)

- OADC (Optimum Acceleration/Deceleration Control)

- Smart Machining Condition Selection

- Advanced Tool Management

- Advanced Tool Life Management

- Camera Interface with Black Box Media File Execution through M-Code Mini DigiFac

- Renishaw Reported and Inspect ZENCAM

- Module Works NGSP

- Smart Program Editor

- ZDT (Zero Down Time Check)

- Maintenance Manager

- Diagnosis Manager

- File Manager

Industrial IOT & Paperless Solutions for Industrial Manufacturers

High-Tech CNC Machine

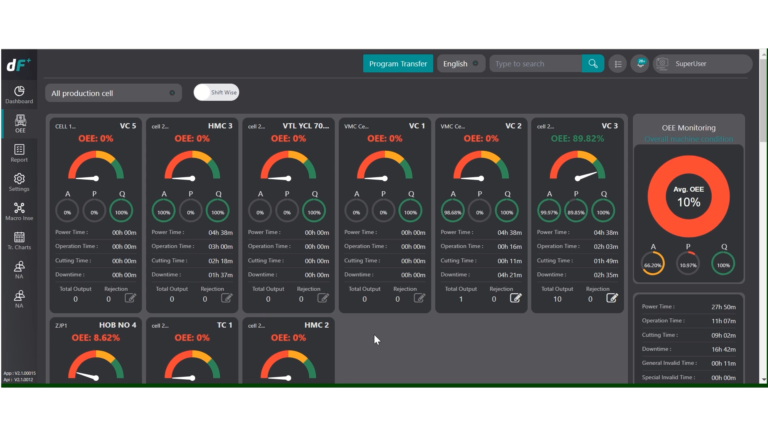

What is digiFAC?

The digiFAC is an IIoT (industrial IoT) platform that can integrate various signals from all kinds of controller-based machines, including CNCs, Injection Moulding Machines, and Press Machines, and analyze them automatically to generate accurate real-time reports. With the least human intervention, it collects the information directly from the machines and helps you get the maximum benefit from your assets and enhance productivity.

Why is digiFAC?

• Industry-Leading: Production efficiencies and agility.

• Highly expert team members.

•Phenomenal solutions to take your company to the next level.

• User-friendly Interface; use features as per dedicated roles/users.

• Transparent, quick, and real-time data availability that can help you make fast decisions

•To improve OEE.

• Increase your productivity by 20%.

• ROI within 3-4 months.

• To maintain your OTD.

• To reduce lead time, setting time, and deliver on time.

Credentials for Demo Panel

Username: userdigi

Password: Userdigi@123

How can digiFAC improve OEE?

Overall Equipment Effectiveness (OEE) is a measure of machine performance that provides visibility to options for progress. OEE is used by manufacturers to specify, monitor, and then reduce production failures. Knowing the OEE value is important for one particular reason: it allows you to find out about your losses and identify the bottlenecks in your value stream. If you know exactly where you are wasting time on your assets and why this is happening, you can take the necessary actions to improve your overall performance.

10~25%

Overall Equipment Effectiveness (OEE) is a measure of machine performance that provides visibility to options for progress. OEE is used by manufacturers to specify, monitor, and then reduce production failures. Knowing the OEE value is important for one particular reason: it allows you to find out about your losses and identify the bottlenecks in your value stream. If you know exactly where you are wasting time on your assets and why this is happening, you can take the necessary actions to improve your overall performance.

digiFAC Features

Dashboard Monitoring

- Live information of the entire factory.

- Categorise machines (Unit-wise).

- View regular utilisation of the machine.

Program Transfer

- Upload programs from computer to machine remotely.

- Download programs and edit them from anywhere around the globe.

Alarm Analysis

- Alarm history by code/machine.

- Time and duration of all alarms generated by a separate machine.

Tool Cutting Time Informationt

- No more unidentified dry-runs.

- Program path optimisation in-sight.

- Tool usage clarity.

- Shorter cycle-times (if modified).

- Eliminate NVA air time and improve your process.

All-in-One Dashboard

- Overview of all data of one machine on one screen.

- Find out the machine's status right away.

- One machine's information is displayed on a single screen.

Production Information (Utilisation)

- Detailed production information report: An automated daily production report.

- All reports are available in Excel format.

Downtime Analysis

- See total machine downtime.

- Monitor downtime and the reasons for it (Macro Downtime Feature).

- Focus and easily get the classified major losses/downtimes and work on optimisation .

Email Alerts

- Set a time for machines' idle condition and receive or get alarm notifications via email.

- Management Reporting: Receive daily production reports and downtime analysis reports by email on a daily basis.

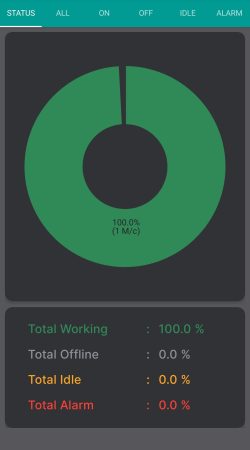

Mobile Application

This is the main screen of mobile application

Features of our package

• Monitoring

• Utilisation rate analysis

• Machine Downtime

• Work order Tracking*

• Downtime classification using Marco

Machine Monitoring

- Summary of machine status (Whole factory).

- Alarm notification including the duration of the current alarm & alarm code.

- Monitoring of machine work condition & parameter values.

Machine Monitoring

Utilisation Analysis / Machine Downtime Analysis

Daily Utilisation Report

Monthly Utilisation Report

Downtime Analysis

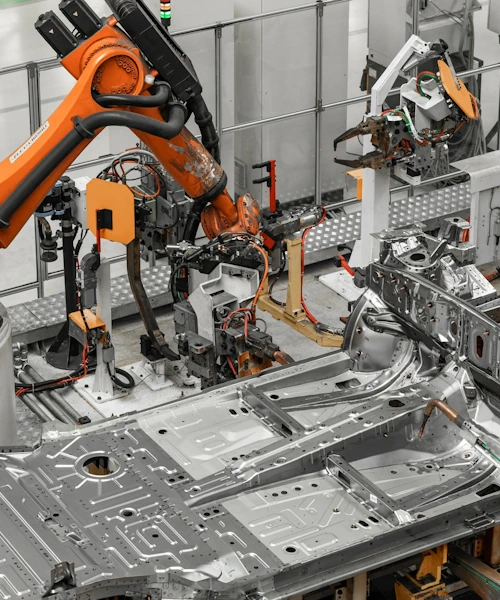

The Cosmos digiBOXY is designed for high-speed robotic loading and unloading of CNC machine tools, offering the most effective solution for your machine’s loading and unloading operations and standing out with its superior price-performance ratio.

The digiBOXY comes with 6-axis robot options of 7 kg, 10 kg, 12 kg, 25 kg, and 35 kg, capable of performing loading and unloading operations for small and medium-sized, heavy and large-sized workpieces, without any issues for single machines.

Each model features a robust drawer system designed to stock heavy items effortlessly. The drawers, available in various configurations, can support up to 50kg per drawer, ensuring reliable and efficient operation across all models.

Roborator V1:

Available with 7 kg and 10 kg robot options, it comes in 3-drawer and 5-drawer configurations.

Each drawer measures 600×400 mm, with a maximum part height of 85 mm for the 3-drawer configuration and 80 mm for the 5-drawer configuration.

Specifications

- FANUC 10kg Robot OR 7kg Robot

- 5 Drawers (600mm X 400mm X 80mm) OR 3 Drawers (600mm X 400mm X 85mm)

- EasySoft Software Package (SOFTBOXY)

- Interactive Auto Calibration Package by Touch Probe

- Interactive Quick Programming

- Touch Screen PC

- SPC Station

- CE Regulation

Roborator V2:

Features a 12 kg robot with drawers measuring 600×400 mm, supporting a maximum part height of 100 mm.

Specifications

- FANUC 12kg 6th Axis Robot

- 5 Drawers (800mm x 600mm X 100mm)

- EasySoft Software Package (SOFTBOXY)

- Interactive Auto Calibration Package by Touch Probe

- Interactive Quick Programming

- Touch Screen PC

- SPC Station

- CE Regulation

Roborator V5:

Equipped with a 6-axis, 10 kg robot and an additional 7th-axis drive system, it includes

15 drawers measuring 800×600 mm, with a maximum part height of 100 mm.

Specifications

- FANUC 12kg 6th Axis Robot

- 5 Drawers (800mm x 600mm X 100mm)

- EasySoft Software Package (SOFTBOXY)

- Interactive Auto Calibration Package by Touch Probe

- Interactive Quick Programming

- Touch Screen PC

- SPC Station

- CE Regulation

Zenµ

- Zenµ is “AI based” accuracy enhancement system which focuses on maintaining the tool centre point using ai algorithms.

- Using algorithms written in the module, the external zero point of X,Y and Z axis are shifted in multiple degrees of freedom to maintain the tool centre point at a constant position in the real time.

Where would you like to navigate next?

Click any option below to know more what Cosmos is all about!

About Cosmos Group

Read in detail about 'Your Partner in Progress' and its history

Cosmos in Media

All great innovations begin with a spark; ours is a million smiles.